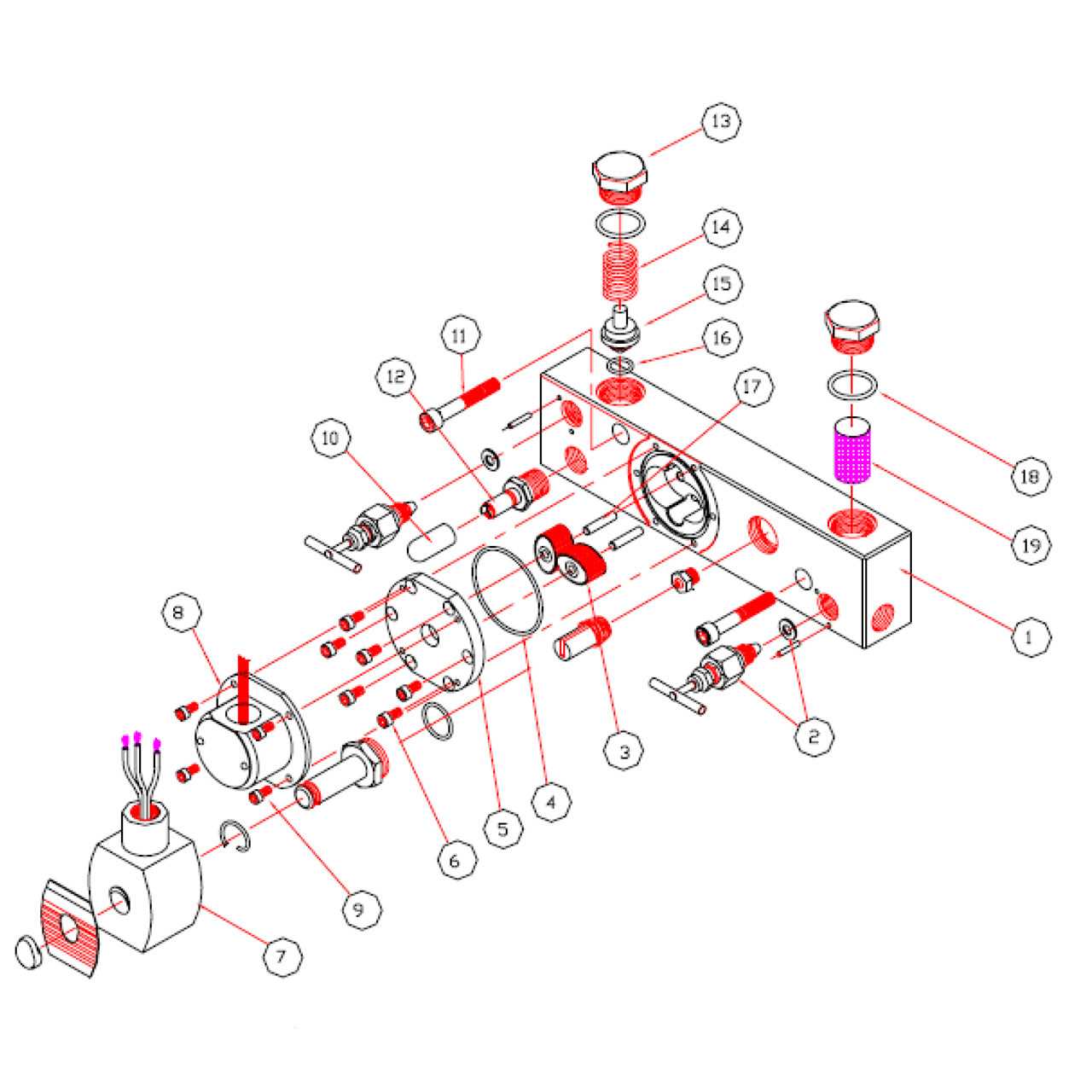

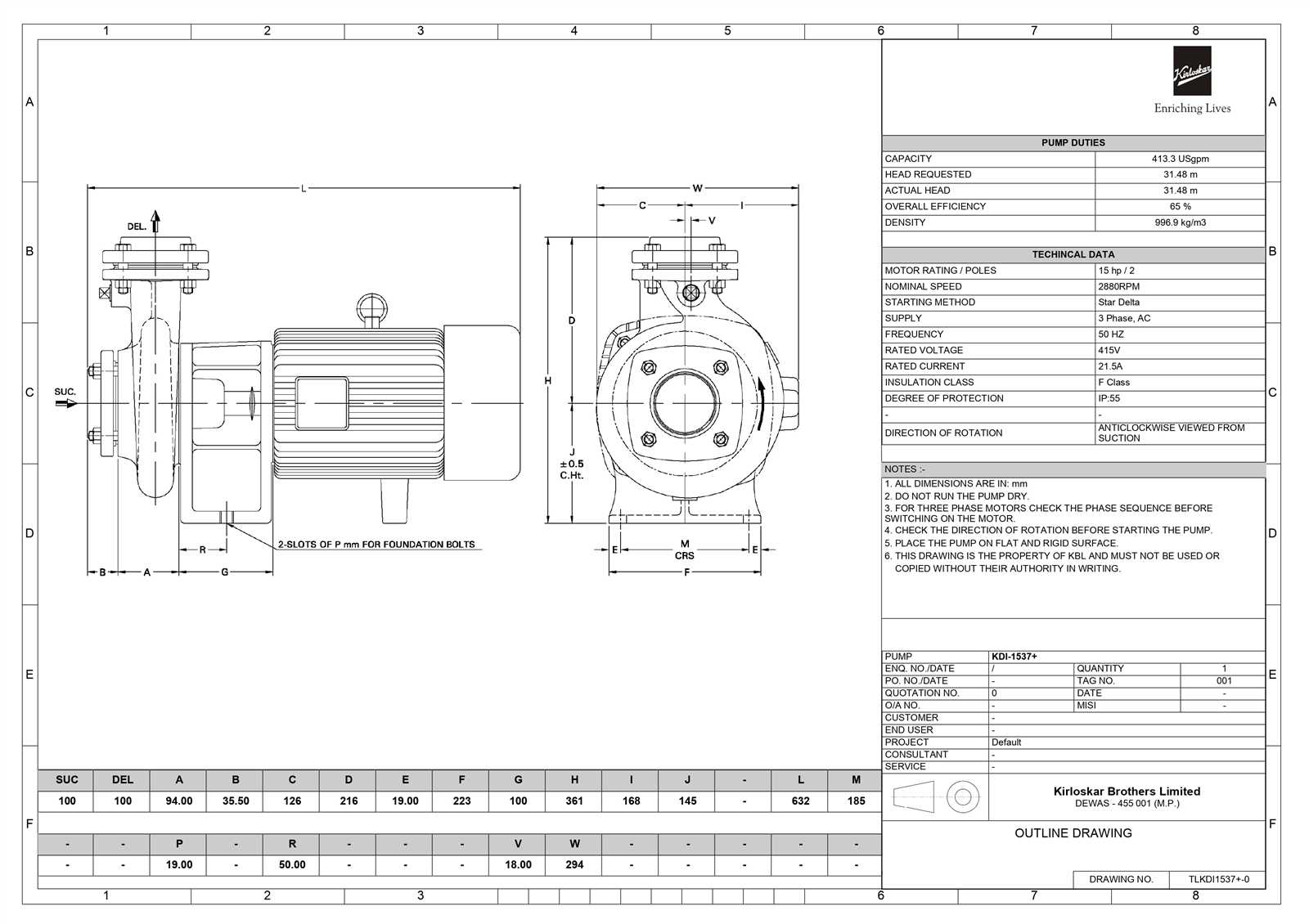

In the realm of fluid transfer systems, comprehending the intricate elements that contribute to effective operation is essential. A well-designed mechanism consists of various components that work in harmony to ensure optimal performance and reliability. This section aims to shed light on these fundamental elements, providing a visual representation that enhances the understanding of their interactions and functions.

Each segment within the assembly plays a crucial role, influencing the efficiency and longevity of the entire system. By examining the layout and arrangement of these components, users can better appreciate how they collectively contribute to the seamless movement of liquids. This exploration not only aids in troubleshooting but also in routine maintenance and upgrades, fostering a deeper knowledge of the technology at hand.

Through detailed illustrations and explanations, this guide invites readers to delve into the specificities of these essential units. From the driving mechanisms to the sealing solutions, each feature is pivotal in maintaining the desired flow and pressure. A thorough understanding of these components empowers operators and technicians alike, equipping them with the insights necessary to optimize their systems for superior functionality.

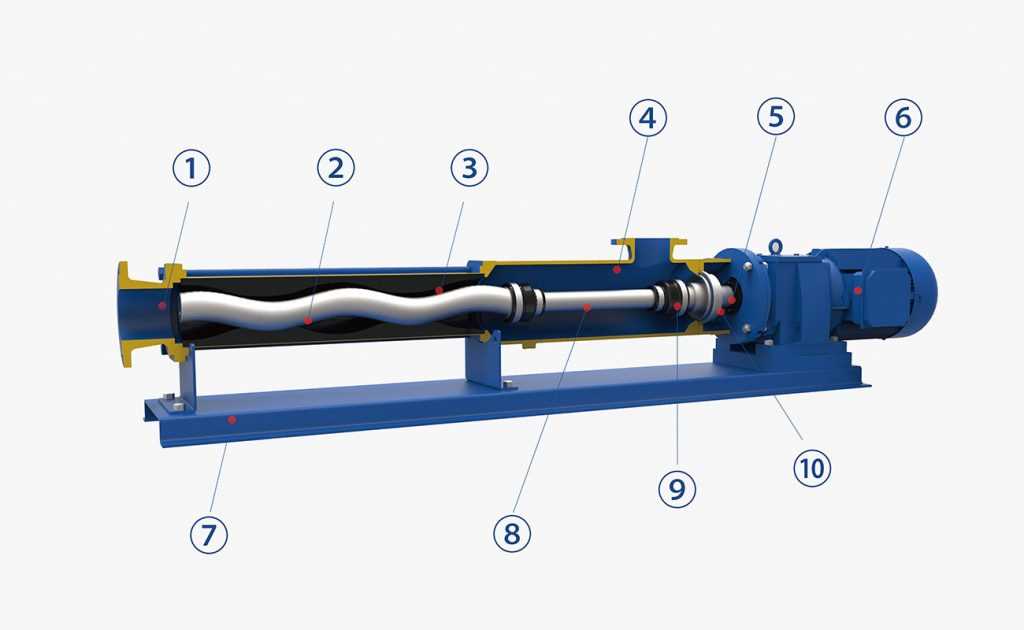

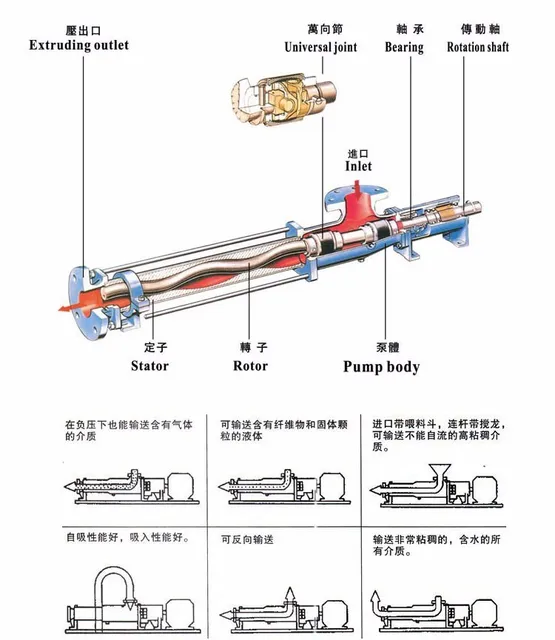

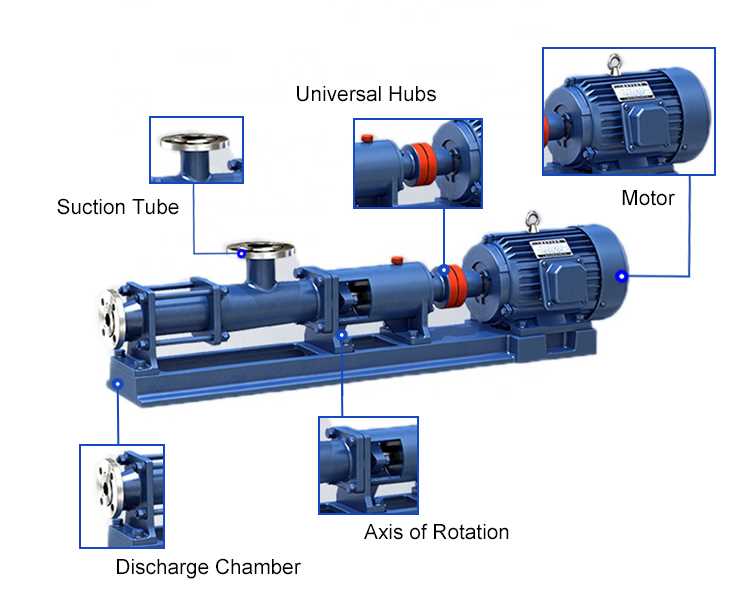

Components of Mono Pump Systems

The functionality and efficiency of fluid transfer systems depend on a variety of interconnected elements. Each component plays a crucial role in ensuring optimal performance and reliability, contributing to the overall effectiveness of the operation. Understanding these individual parts allows for better maintenance, troubleshooting, and enhancements in various applications.

Key Elements

- Rotor: The central element that drives fluid movement, providing the necessary action to transfer substances.

- Stator: This stationary part surrounds the rotor, creating a sealed environment that aids in effective fluid flow.

- Seal: Essential for preventing leakage, the seal maintains pressure within the system and enhances longevity.

- Drive Mechanism: This component powers the rotor, ensuring smooth and consistent operation throughout the process.

- Inlet and Outlet: These ports facilitate the entry and exit of fluids, allowing for seamless transfer and discharge.

Additional Considerations

- Bearings: They support the rotor’s rotation, reducing friction and wear over time.

- Mounting Base: This sturdy platform secures the entire assembly, ensuring stability during operation.

- Control System: Regulates the operation, enabling adjustments based on flow requirements and system demands.

- Safety Features: Incorporates mechanisms to prevent overheating, excessive pressure, and other potential hazards.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the effective understanding and operation of complex machinery. They serve as visual aids that clarify the intricate components and mechanisms involved. High-quality representations ensure that users can effectively assemble, maintain, and troubleshoot devices.

Clear visual representations offer several benefits, including:

- Enhanced Communication: Accurate visuals convey essential information quickly and efficiently, reducing the risk of misunderstandings.

- Increased Efficiency: With well-designed illustrations, users can easily identify components, facilitating faster assembly and repairs.

- Improved Safety: Detailed representations highlight critical areas, enabling users to operate equipment safely and reduce the likelihood of accidents.

To achieve these advantages, it is vital to ensure that illustrations are:

- Detailed: Every element should be clearly labeled to provide comprehensive understanding.

- Accurate: Representations must reflect the actual configurations of components to prevent errors.

- Consistent: Use of uniform symbols and notations aids in maintaining clarity across different documents.

In conclusion, investing time in creating and utilizing accurate visuals significantly enhances operational proficiency and safety, ultimately contributing to the longevity and reliability of the machinery involved.

Common Applications of Mono Pumps

These advanced fluid transfer devices find extensive use across various industries due to their unique design and operational efficiency. Their ability to handle a wide range of fluids, including those with high viscosity and abrasive properties, makes them suitable for numerous applications. Below are some common sectors where these devices play a crucial role in optimizing processes and ensuring reliable fluid management.

Industrial Sector

In the industrial landscape, these systems are frequently employed for the movement of slurries, chemicals, and waste materials. Their robust construction allows them to manage challenging environments, providing consistent performance even under strenuous conditions.

Agricultural Usage

In agriculture, these machines are utilized for transferring liquids such as fertilizers, pesticides, and water for irrigation purposes. Their efficiency contributes to sustainable practices, helping farmers maximize yield while minimizing waste.

| Application | Description |

|---|---|

| Food Processing | Transporting viscous products like sauces and pastes without damaging the integrity of the materials. |

| Mining | Handling slurries containing solids efficiently, which is critical for mineral extraction processes. |

| Pharmaceuticals | Ensuring precise transfer of liquids while adhering to strict hygiene and quality standards. |

Maintenance Tips for Mono Pump Parts

Regular upkeep of essential components is crucial for ensuring optimal performance and longevity. By adhering to specific practices, one can enhance the efficiency and reliability of the system, minimizing the risk of unexpected failures and costly repairs.

Routine Inspections

Conduct frequent examinations to identify signs of wear and tear. Look for leaks, cracks, or unusual noises during operation. Addressing minor issues promptly can prevent them from escalating into major problems.

Lubrication and Cleaning

Ensure that all moving elements are adequately lubricated to reduce friction and wear. Additionally, maintain cleanliness by removing any debris or buildup that could hinder performance. Regular cleaning promotes smooth operation and extends the lifespan of the mechanism.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining the efficiency and longevity of machinery. Over time, components can experience various forms of damage due to friction, corrosion, or other environmental factors. Understanding these signs enables timely interventions, ensuring optimal performance and preventing costly failures.

Common indicators of wear include visible scratches, discoloration, or unusual noises during operation. Regular inspections can help in detecting changes early on, allowing for proactive measures. Additionally, monitoring fluid leakage and fluctuations in performance can provide insights into the condition of the components involved.

Employing a systematic approach to evaluate the condition of machinery will not only enhance reliability but also reduce downtime. Maintaining detailed records of inspections and repairs can assist in tracking the history of each component, providing valuable data for future maintenance decisions.

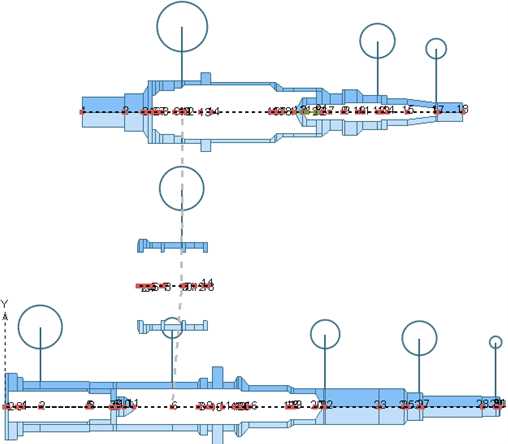

How to Read a Parts Diagram

Understanding the intricate visuals that represent various components of a mechanical system is essential for efficient maintenance and troubleshooting. This knowledge enables users to identify individual elements and comprehend their relationships within the assembly. By familiarizing oneself with these representations, one can streamline repair processes and enhance overall functionality.

Key Elements to Consider

- Labels: Each element typically features a label that provides a unique identifier, aiding in easy reference.

- Legends: A legend often accompanies the visual, explaining symbols and color codes used to signify different features or materials.

- Scale: Understanding the scale is crucial, as it helps gauge the size and proportion of components relative to each other.

Steps to Decipher the Visual Representation

- Begin by reviewing the legend to familiarize yourself with the symbols used.

- Identify the main assembly and its major segments, noting how they connect to one another.

- Look for directional arrows that indicate the flow of operation or assembly sequence.

- Cross-reference identified components with a list or manual to ensure proper understanding.

Replacing Components Effectively

Maintaining and upgrading equipment is crucial for ensuring optimal performance and longevity. This process often involves substituting outdated or worn-out elements with new, high-quality alternatives. By approaching this task with careful consideration and systematic techniques, users can enhance the functionality of their systems and minimize downtime.

Identifying the Right Components

To achieve successful replacements, it is essential to select the correct elements that match the specifications and requirements of the system. This includes considering factors such as size, material, and compatibility. Consulting technical manuals or manufacturer guidelines can provide valuable insights into the necessary characteristics for each component.

Step-by-Step Replacement Process

Following a structured approach during the substitution process can prevent errors and ensure efficient execution. Begin by powering down the equipment and disconnecting any relevant connections. Carefully remove the old element, taking note of its placement and configuration for reference. Install the new part in the same position, ensuring a secure fit before re-establishing connections and powering the equipment back on. Testing the system after installation is critical to verify proper function and performance.

Safety Considerations in Pump Maintenance

Regular upkeep of mechanical systems is essential for their longevity and efficient operation. However, it is crucial to prioritize safety during these maintenance activities. Proper precautions help prevent accidents, injuries, and equipment damage, ensuring a safe working environment for all personnel involved.

Personal Protective Equipment (PPE)

Before beginning any maintenance work, it is vital to equip oneself with the necessary protective gear. The following items should be considered:

- Safety goggles to protect the eyes from debris and harmful substances.

- Gloves to safeguard hands from sharp edges and hazardous materials.

- Hard hats for head protection in areas with overhead hazards.

- Steel-toed boots to prevent foot injuries from heavy objects.

- Hearing protection when working near loud machinery.

Procedural Guidelines

Adhering to established procedures can significantly enhance safety during maintenance tasks. Key guidelines include:

- Always follow the manufacturer’s maintenance instructions.

- Ensure the equipment is de-energized and isolated from power sources before starting work.

- Conduct a thorough inspection for leaks, wear, or damage prior to maintenance.

- Utilize proper lifting techniques or equipment when handling heavy components.

- Maintain a clean and organized workspace to reduce the risk of slips and falls.

Choosing Quality Replacement Parts

Selecting high-quality components for machinery is crucial for ensuring optimal performance and longevity. When it comes to repairs or upgrades, the integrity of the elements you choose can significantly impact overall functionality. This section will provide insights on how to identify and procure reliable substitutes that meet your operational needs.

When evaluating options, consider the following factors:

- Material Quality: Opt for durable materials that can withstand wear and tear, especially in demanding environments.

- Compatibility: Ensure that the selected components are suitable for your specific equipment model to prevent issues during installation and use.

- Manufacturer Reputation: Choose suppliers known for their reliability and adherence to industry standards.

- Performance Ratings: Look for components with favorable reviews or performance certifications to gauge their effectiveness.

Additionally, always request documentation that verifies the authenticity and specifications of the components you intend to purchase. This practice can help avoid potential pitfalls associated with counterfeit or substandard items.

In summary, prioritizing quality in your selection process not only enhances the efficiency of your equipment but also contributes to a longer lifespan and reduced maintenance costs.

Resources for Further Learning

Expanding your knowledge in this field can greatly enhance your understanding and proficiency. Numerous resources are available to help deepen your insights and improve your skills. Whether you are a beginner or an experienced individual, exploring a variety of materials can provide valuable information and practical applications.

- Books:

- “Fluid Mechanics: Fundamentals and Applications” by Yunus Çengel

- “Engineering Fluid Mechanics” by Clayton T. Crowe

- “Pump Handbook” by Igor J. Karassik

- Online Courses:

- Coursera – Engineering Courses on Fluid Dynamics

- edX – Mechanical Engineering Fundamentals

- Udemy – Hands-on Training in Fluid Transfer Systems

- Websites:

- Engineering Toolbox

- Pump Zone

- Hydraulic Institute

- Forums and Communities:

- Eng-Tips Engineering Forums

- Reddit – r/engineering

- LinkedIn Groups for Fluid Mechanics Professionals

Utilizing these resources can provide practical insights and foster a deeper understanding of the concepts at play. Engaging with communities and educational materials can significantly contribute to your growth in this specialized area.