In the realm of aquatic management, grasping the intricacies of your machinery is crucial for optimal performance and longevity. Knowing how each element contributes to the overall functionality allows for efficient maintenance and troubleshooting.

To enhance your knowledge, we will explore the visual representations that detail the various sections of this essential device. A comprehensive view can help in identifying specific mechanisms and understanding their roles in the system.

With a clear illustration of the intricate parts, users can effectively navigate the complexities of their equipment. This knowledge not only fosters confidence in handling issues but also aids in maximizing the device’s capabilities.

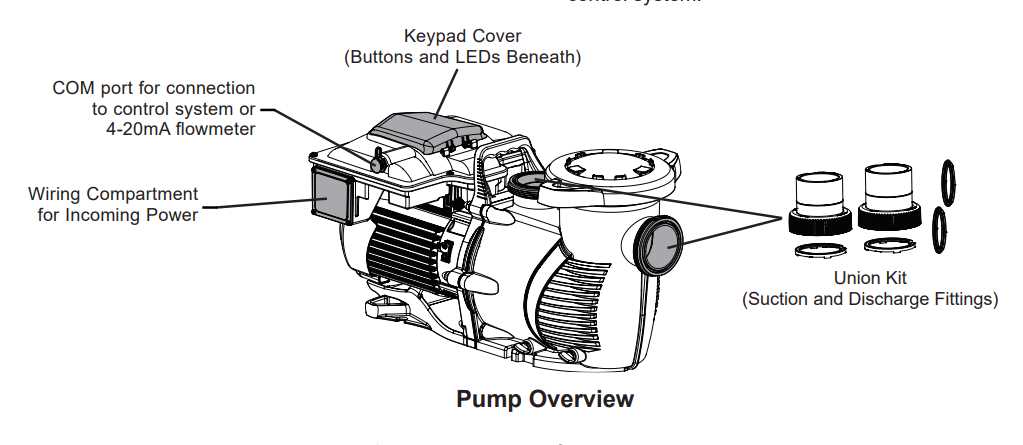

Pentair SuperFlo Pump Overview

This section provides a comprehensive insight into a popular water circulation solution widely utilized in residential and commercial settings. Its design emphasizes efficiency, durability, and ease of maintenance, making it an ideal choice for various applications.

Key features include:

- High performance and energy efficiency

- Robust construction materials

- Quiet operation

- User-friendly interface for easy control

When selecting a water circulation solution, consider the following advantages:

- Improved water flow

- Enhanced filtration capabilities

- Long lifespan with minimal upkeep

Overall, this solution stands out for its ability to meet the ultimate needs of users seeking reliability and efficiency in their water management systems.

Key Features of SuperFlo Pump

This section explores the essential attributes of a leading water circulation system, designed for optimal performance and efficiency. With innovative engineering, it ensures smooth operation, reliability, and user satisfaction.

Energy Efficiency: One of the standout qualities is its ability to conserve energy. The system operates quietly while minimizing electricity consumption, making it an eco-friendly choice.

Durability: Constructed from high-quality materials, this equipment is built to withstand harsh environmental conditions. Its robust design ensures longevity, reducing the need for frequent replacements.

Ease of Maintenance: With user-friendly features, maintenance is straightforward. Accessible components allow for quick inspections and repairs, ensuring minimal downtime.

Advanced Technology: Incorporating the latest advancements, this system offers enhanced functionality. Features like variable speed control adapt to specific needs, optimizing water flow and pressure.

Quiet Operation: The system is engineered for minimal noise, allowing it to operate unobtrusively. This is particularly beneficial for residential areas where noise reduction is a priority.

Versatility: Suitable for various applications, this equipment can efficiently serve both small and large installations, making it a versatile solution for diverse water management needs.

Importance of Proper Pump Maintenance

Regular upkeep of water circulation devices is crucial for ensuring their efficiency and longevity. Neglecting maintenance can lead to a range of issues, including reduced performance and premature failure. By prioritizing care, users can avoid costly repairs and enhance the overall functionality of their systems.

Routine inspections play a vital role in identifying potential problems before they escalate. Checking for leaks, unusual noises, or vibrations can help detect wear and tear early on. Additionally, cleaning components regularly prevents the buildup of debris that can hinder operation.

Furthermore, lubrication and replacement of worn-out elements are essential practices. These actions not only optimize performance but also extend the life of the equipment. Ultimately, maintaining these devices ensures reliable service and peace of mind for users.

Common Issues with SuperFlo Pumps

Many users encounter various challenges when operating their water circulation devices. Understanding these common problems can enhance performance and longevity.

- Noise Issues: Unusual sounds may indicate wear or misalignment.

- Inadequate Flow: Reduced water movement can stem from clogs or impeller damage.

- Leaks: Water escaping from seals often suggests the need for replacement.

- Overheating: Excessive heat can result from debris buildup or motor issues.

- Electrical Failures: Malfunctions in wiring can disrupt functionality.

Addressing these issues promptly can prevent further damage and ensure optimal operation.

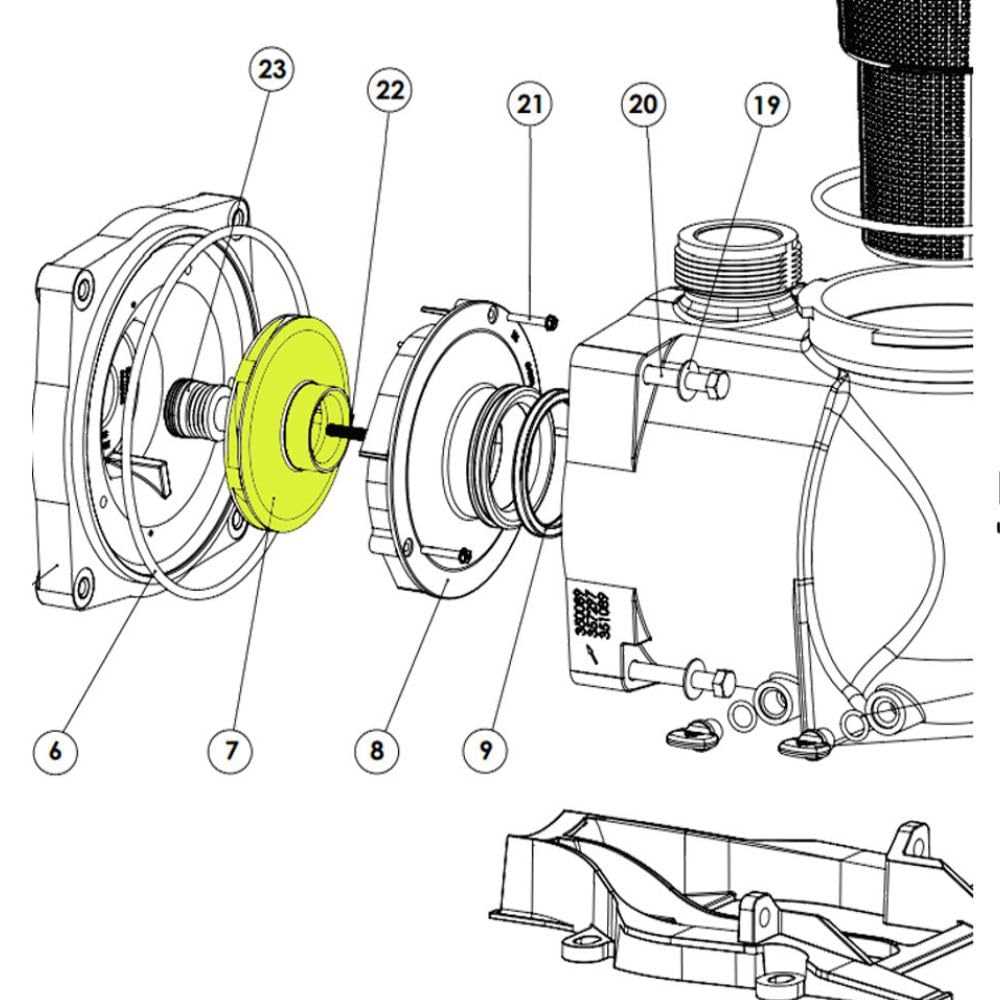

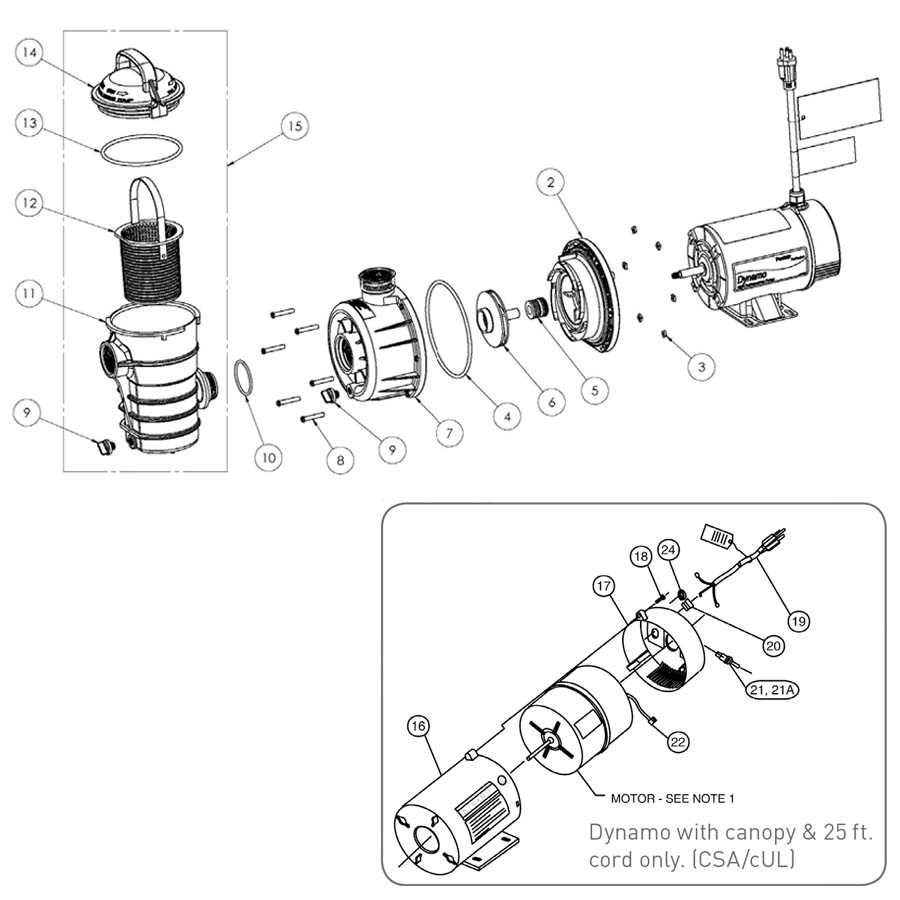

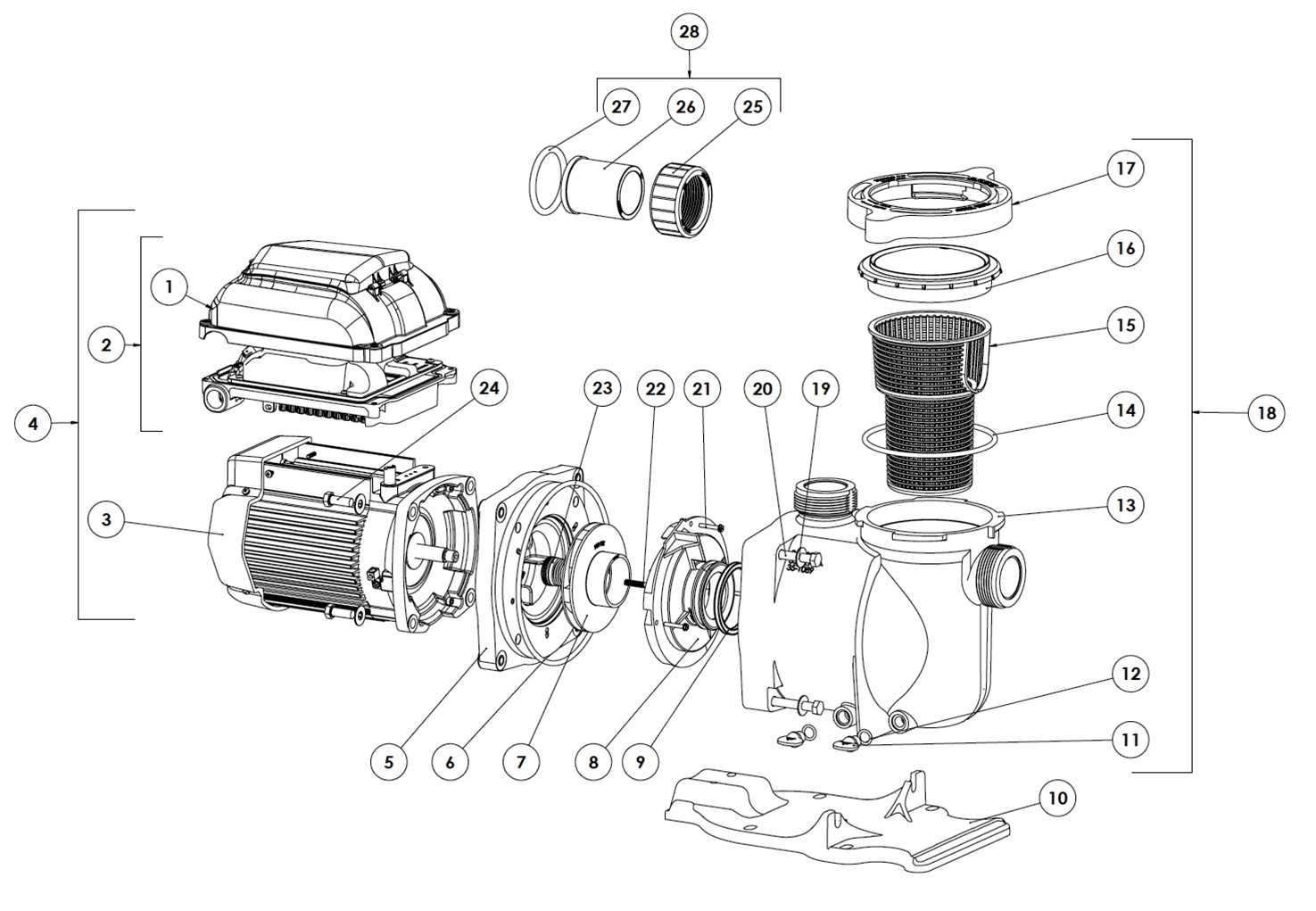

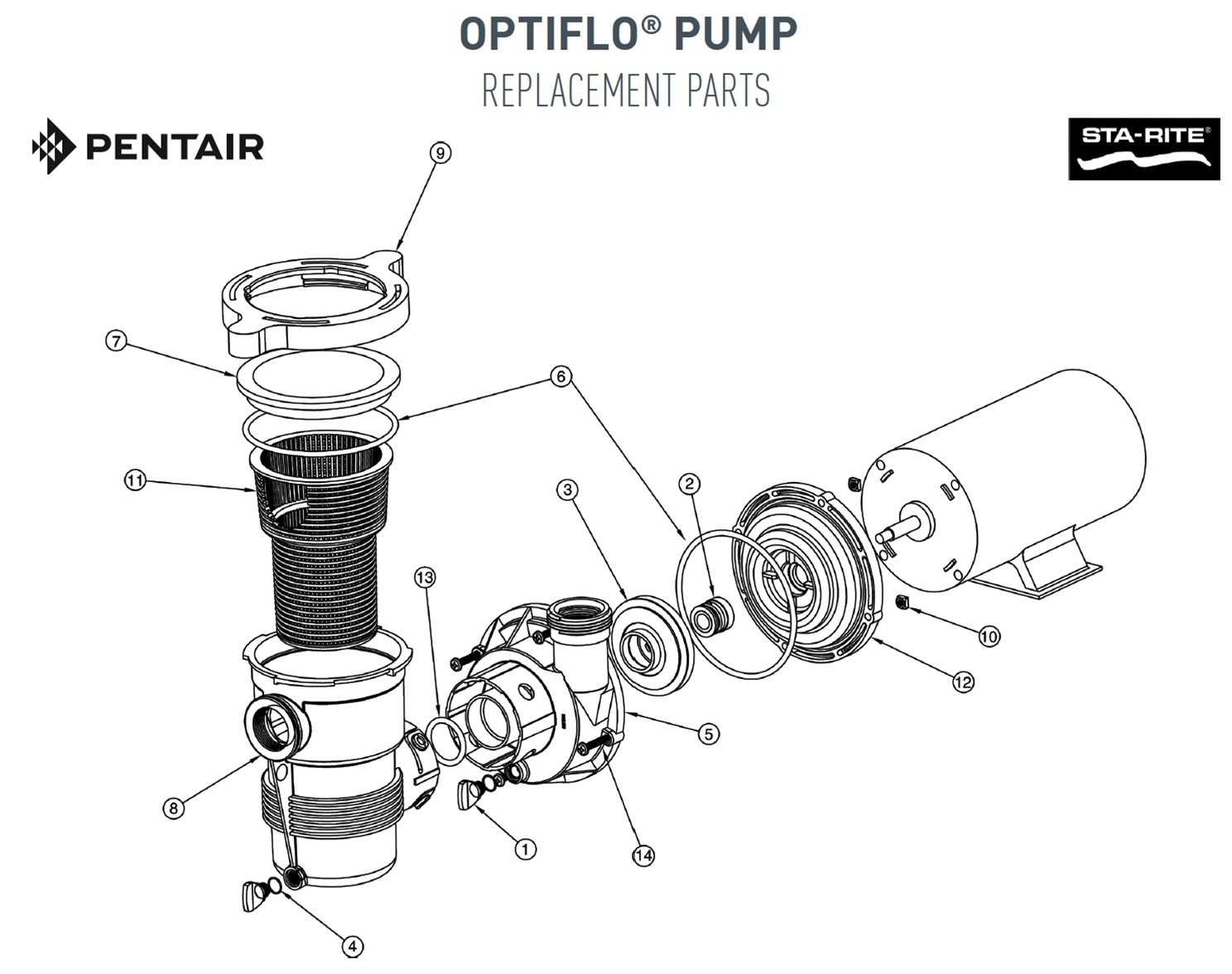

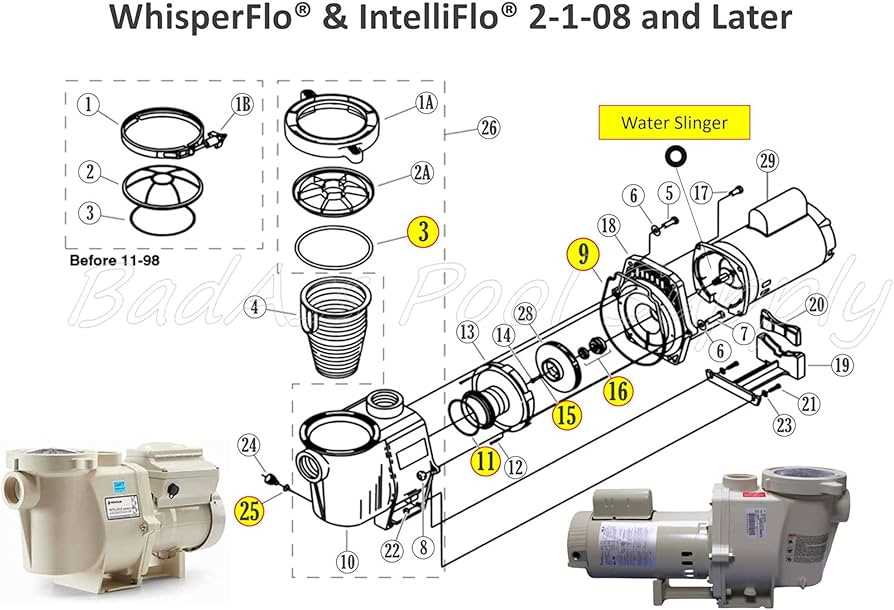

Understanding Pump Components and Functions

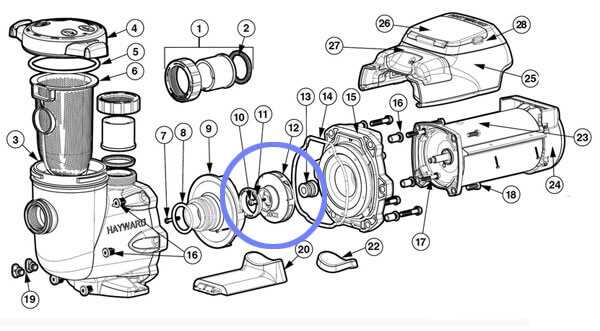

In any fluid circulation system, a variety of elements work together to ensure efficient operation. Each component plays a specific role, contributing to the overall functionality and reliability of the mechanism. Understanding these individual roles can enhance maintenance practices and improve system performance.

Main Components

The essential elements of a fluid circulation system typically include an intake, an impeller, and a discharge outlet. The intake is responsible for drawing in the fluid, while the impeller increases the fluid’s velocity, propelling it through the system. Finally, the discharge outlet releases the fluid into the intended area, completing the circulation process.

Each element’s functionality is critical. For instance, a well-designed impeller can significantly enhance flow rates, while a properly configured intake minimizes turbulence and energy loss. Understanding the interplay between these components allows for more effective troubleshooting and optimization, ensuring that the system operates smoothly and efficiently over time.

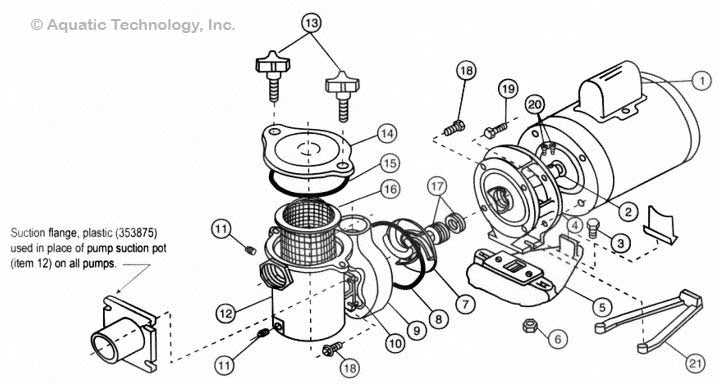

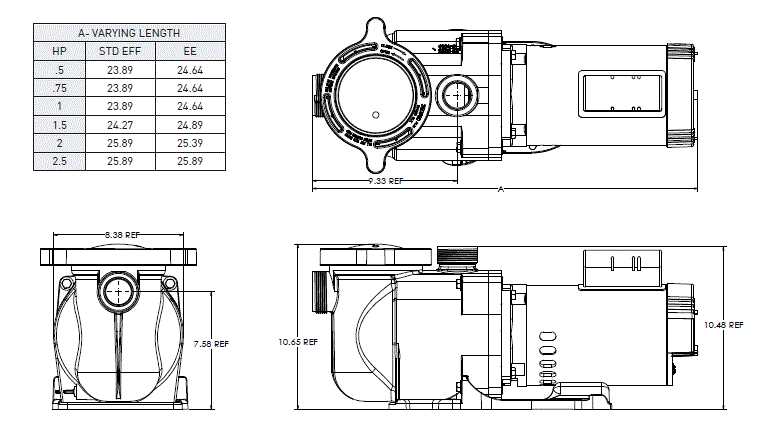

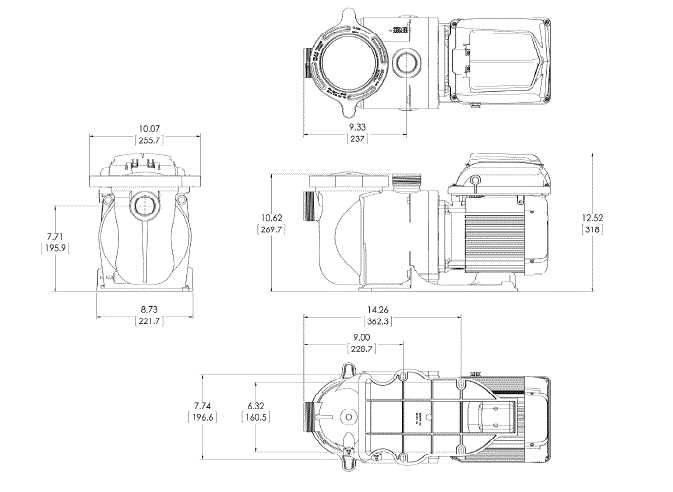

How to Read a Parts Diagram

Understanding a schematic representation of components can greatly enhance your ability to identify and locate essential elements within a system. Mastering this skill is crucial for effective maintenance and troubleshooting.

Key Elements to Consider

- Labels: Pay attention to names and codes that indicate specific components.

- Lines and Connections: Observe how items are linked to understand the flow and relationships.

- Symbols: Familiarize yourself with standard icons that represent different parts.

Steps to Follow

- Start by locating the legend or key that defines symbols.

- Identify the main assembly to grasp the overall layout.

- Trace connections systematically to see how components interact.

- Refer back to the legend as needed for clarification.

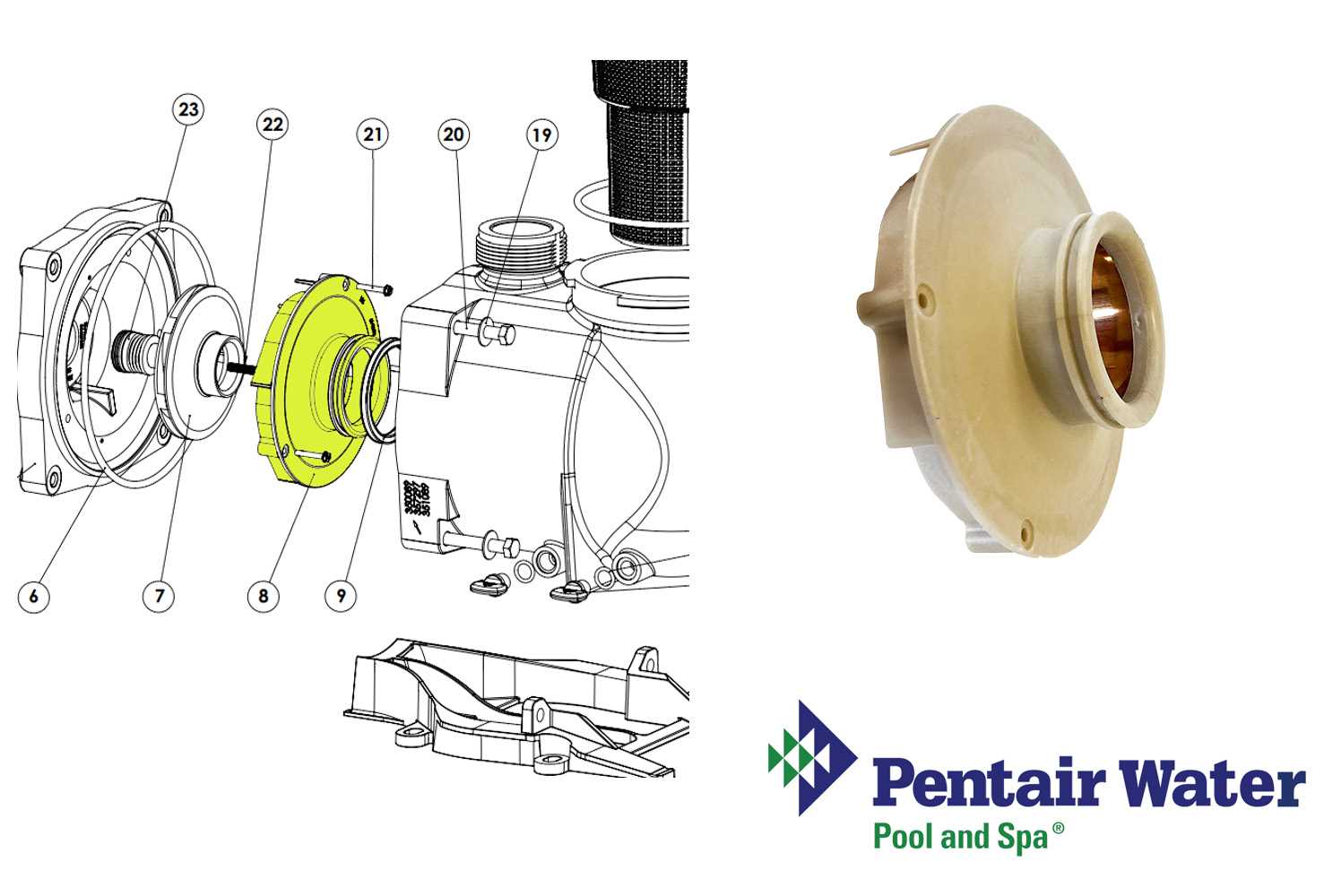

Identifying Replacement Parts Easily

Finding the right components for your equipment can often seem daunting. However, with a systematic approach, you can simplify the process. Understanding how to recognize and locate necessary elements can save both time and effort, ensuring your system operates efficiently once again.

Start by familiarizing yourself with the key elements of your equipment. Many manufacturers provide detailed guides that outline each component’s function and location. Utilizing these resources can help you pinpoint what you need without confusion.

| Component Name | Description | Common Issues |

|---|---|---|

| Seal | Prevents leakage from the unit. | Worn out due to age or pressure. |

| Motor | Powers the system for optimal performance. | Overheating or failure to start. |

| Impeller | Moves water through the system. | Blockages or damage affecting flow. |

| Filter | Cleans the water before circulation. | Clogging leading to reduced efficiency. |

Once you identify the components you need, cross-reference them with the manufacturer’s catalog to ensure compatibility. Many resources are available online, allowing you to view specifications and find alternative options if necessary.

By following this approach, you’ll not only streamline the process of finding replacements but also gain a deeper understanding of your system’s inner workings, leading to more informed maintenance decisions in the future.

Step-by-Step Assembly Instructions

Assembling a water circulation device can be straightforward if you follow a systematic approach. This guide outlines the essential steps to ensure a smooth and efficient assembly process, enabling optimal performance of your equipment.

Required Tools and Materials

Before starting the assembly, gather all necessary tools and components. This will streamline the process and minimize delays.

| Tool/Material | Quantity |

|---|---|

| Screwdriver | 1 |

| Wrench | 1 |

| Sealing tape | 1 roll |

| O-rings | 2 |

| Mounting screws | 4 |

Assembly Steps

Begin by laying out all components on a clean surface. Follow these steps to complete the assembly:

- Secure the base to a stable platform using mounting screws.

- Attach the motor unit to the base, ensuring proper alignment.

- Install the impeller by placing it in the designated slot.

- Connect the outlet and inlet fittings using sealing tape to prevent leaks.

- Finally, double-check all connections and ensure that everything is tightly secured.

Tools Needed for Pump Repairs

When it comes to maintaining and fixing your water circulation equipment, having the right tools is essential for efficient and effective repairs. A well-stocked toolkit can save time, reduce frustration, and ensure that the job is done correctly. Understanding which instruments are necessary can make the process smoother and enhance your overall repair experience.

Essential Tools

First and foremost, a reliable set of wrenches and screwdrivers is crucial. These tools help in loosening and tightening various components. Additionally, a multi-tool can be invaluable for tackling different types of fasteners without needing to switch between multiple devices. Always ensure that your tools are of good quality, as this can greatly affect the outcome of your repairs.

Safety Equipment

Safety should never be overlooked during any repair work. Protective gloves and eyewear are important to prevent injuries. A sturdy pair of work gloves will protect your hands from sharp edges and debris, while safety glasses shield your eyes from any potential hazards. Investing in safety gear is just as important as having the right tools, ensuring a safe and efficient repair process.

Safety Precautions When Repairing Pumps

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. By adhering to specific guidelines, individuals can create a secure work environment that promotes efficiency and minimizes risks.

Preparation and Personal Safety

Before beginning any maintenance task, it is essential to equip oneself with appropriate personal protective equipment (PPE). This includes gloves, goggles, and steel-toed boots to shield against potential hazards. Additionally, familiarize yourself with the equipment’s manual to understand its specific safety protocols.

Working Environment

Maintain a clean and organized workspace to reduce the likelihood of slips and falls. Ensure that the area is well-ventilated, especially if working with chemicals or lubricants. Properly disconnect power sources and use lockout/tagout procedures to prevent accidental activation during repairs.

Comparing SuperFlo to Other Models

When evaluating different hydraulic systems, it’s essential to consider their efficiency, durability, and features. This comparison highlights the strengths and weaknesses of various alternatives, allowing users to make informed choices based on their specific needs.

- Efficiency: Some models are designed for higher energy savings, while others prioritize power output.

- Durability: Material quality and design impact longevity; certain systems withstand harsher conditions better than others.

- Noise Levels: Variability in sound production can affect the overall user experience, with some options being notably quieter.

Ultimately, understanding these differences helps in selecting the right system for both residential and commercial applications.

Where to Buy Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its efficiency and longevity. Fortunately, there are various sources where you can procure high-quality replacements to ensure optimal performance. Here, we outline some of the most reliable avenues to explore when searching for these necessary items.

Online Retailers

The internet offers a plethora of options for sourcing replacements. Many dedicated websites specialize in providing a wide range of items suitable for various models. Shopping online often allows for competitive pricing and convenient delivery to your doorstep.

Local Suppliers

If you prefer to shop in person, local suppliers and hardware stores can be excellent resources. These establishments often carry a selection of essential items and can provide valuable advice on compatibility and installation.

| Source Type | Advantages | Considerations |

|---|---|---|

| Online Retailers | Convenience, wide selection, competitive prices | Shipping times, potential compatibility issues |

| Local Suppliers | Immediate access, personalized service | Limited selection, possibly higher prices |

Frequently Asked Questions About SuperFlo

This section addresses common inquiries related to a popular model known for its efficiency and reliability in the swimming pool industry. Understanding the most frequently asked questions can help users maximize performance and troubleshoot potential issues.

What are the main features of this model?

The unit is designed with energy efficiency in mind, offering quiet operation and ease of installation. It also includes a user-friendly control interface that simplifies adjustments.

How can I identify issues with the system?

Common indicators of trouble include unusual noises, decreased water flow, or erratic functioning. Regular maintenance checks can help in early detection and resolution of these problems.

What maintenance is required for optimal performance?

Routine cleaning of the strainer basket and inspecting the seals and gaskets are essential. Additionally, ensuring proper alignment and tight connections can prevent leaks and enhance efficiency.

Is there a warranty on this unit?

Yes, the manufacturer typically offers a warranty covering specific components, ensuring peace of mind for users regarding their investment.

Where can I find replacement components?

Replacement items can often be sourced from authorized retailers or online marketplaces specializing in pool equipment. Always ensure compatibility with your specific model.

Can I install this model myself?

While many users opt for professional installation, handy individuals may successfully install the unit by following the provided guidelines and safety precautions.