In any fluid transfer system, comprehending the individual elements and their interactions is crucial for effective operation and maintenance. Each component plays a specific role, contributing to the overall efficiency and reliability of the entire mechanism. By familiarizing oneself with these segments, one can enhance performance and address potential issues proactively.

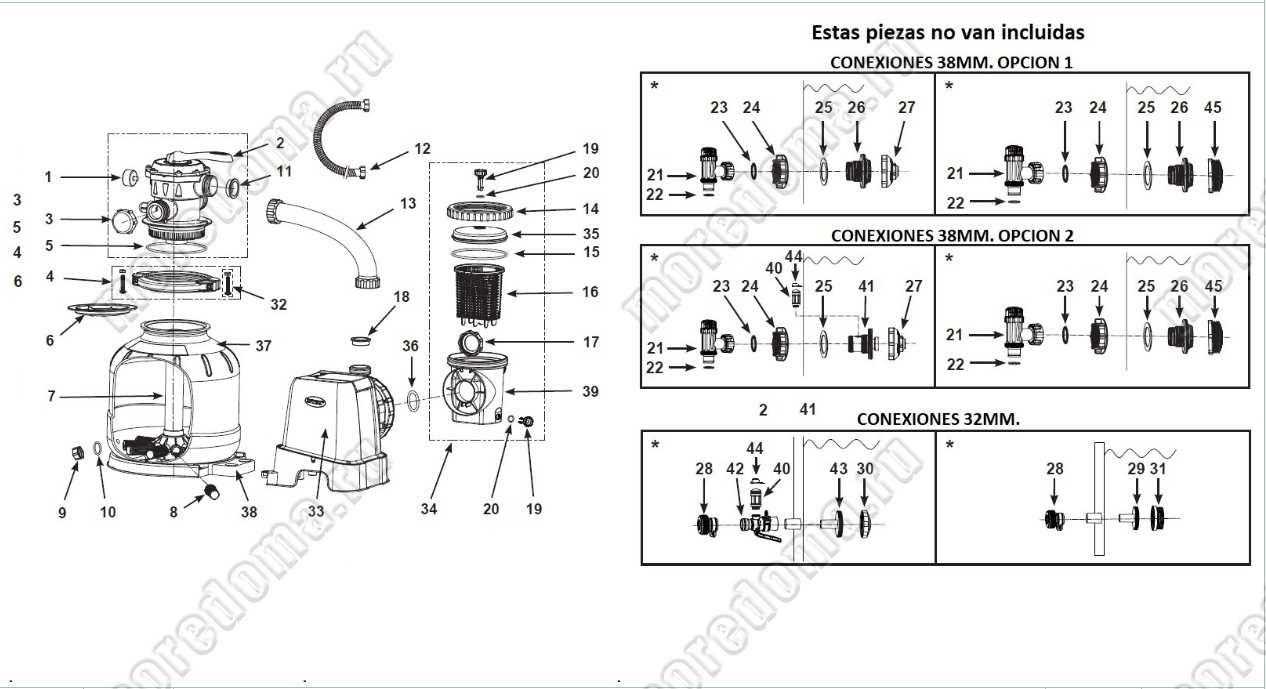

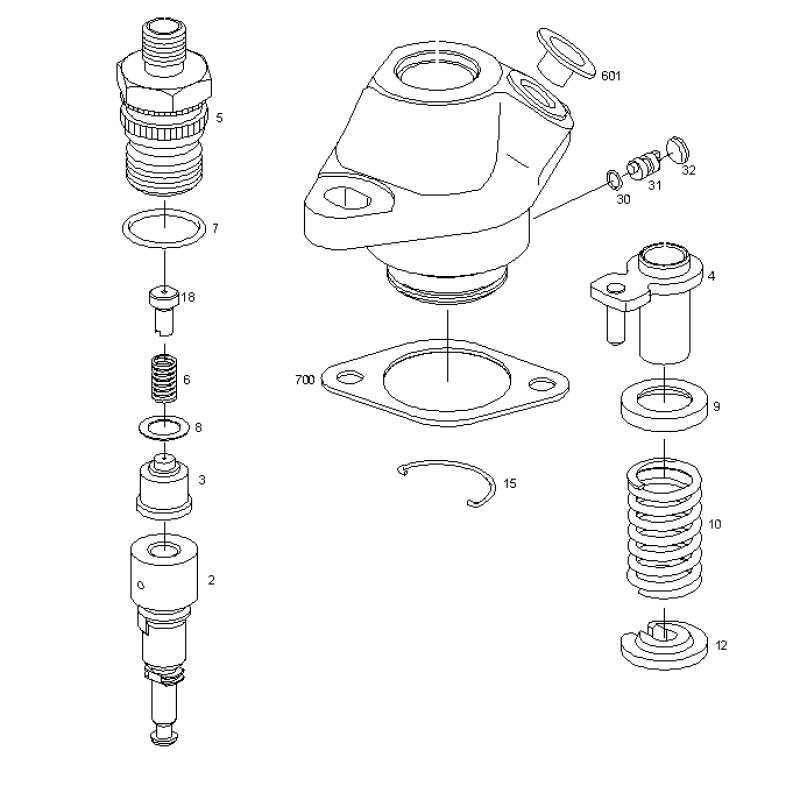

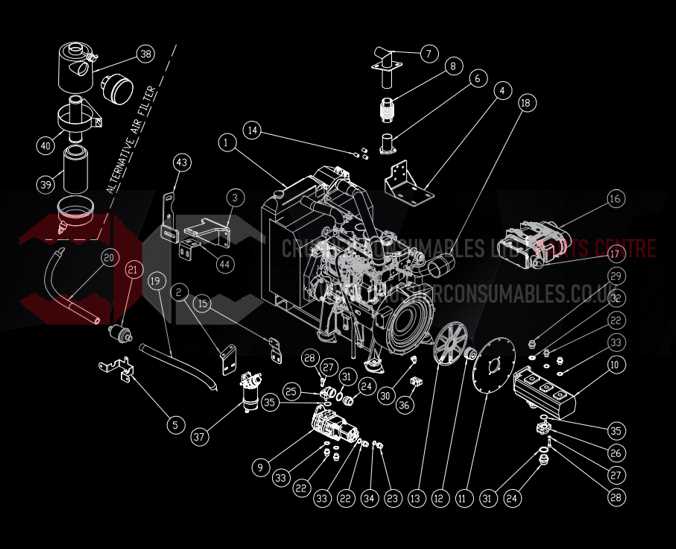

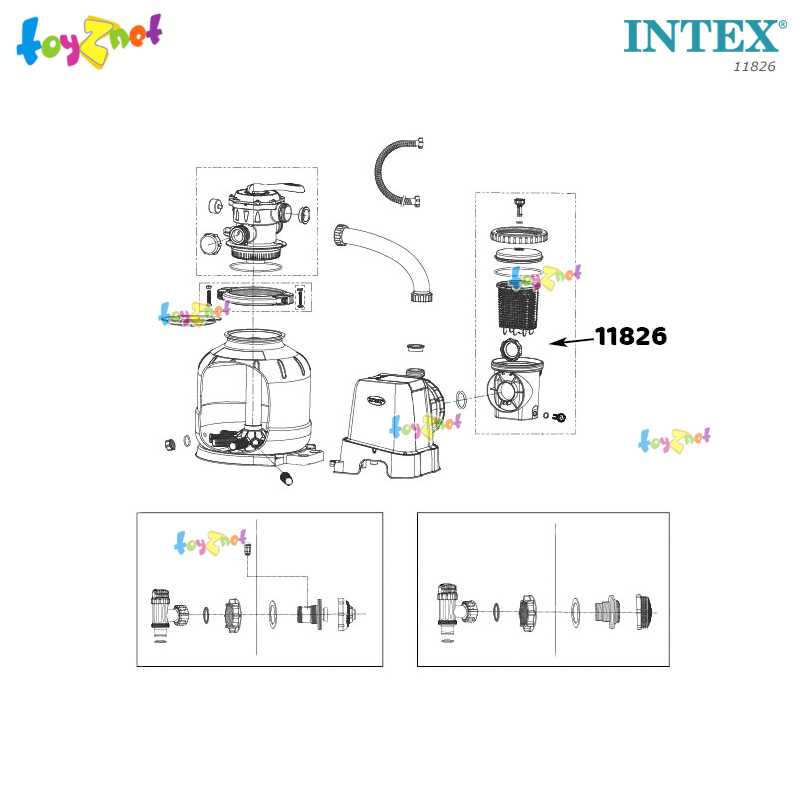

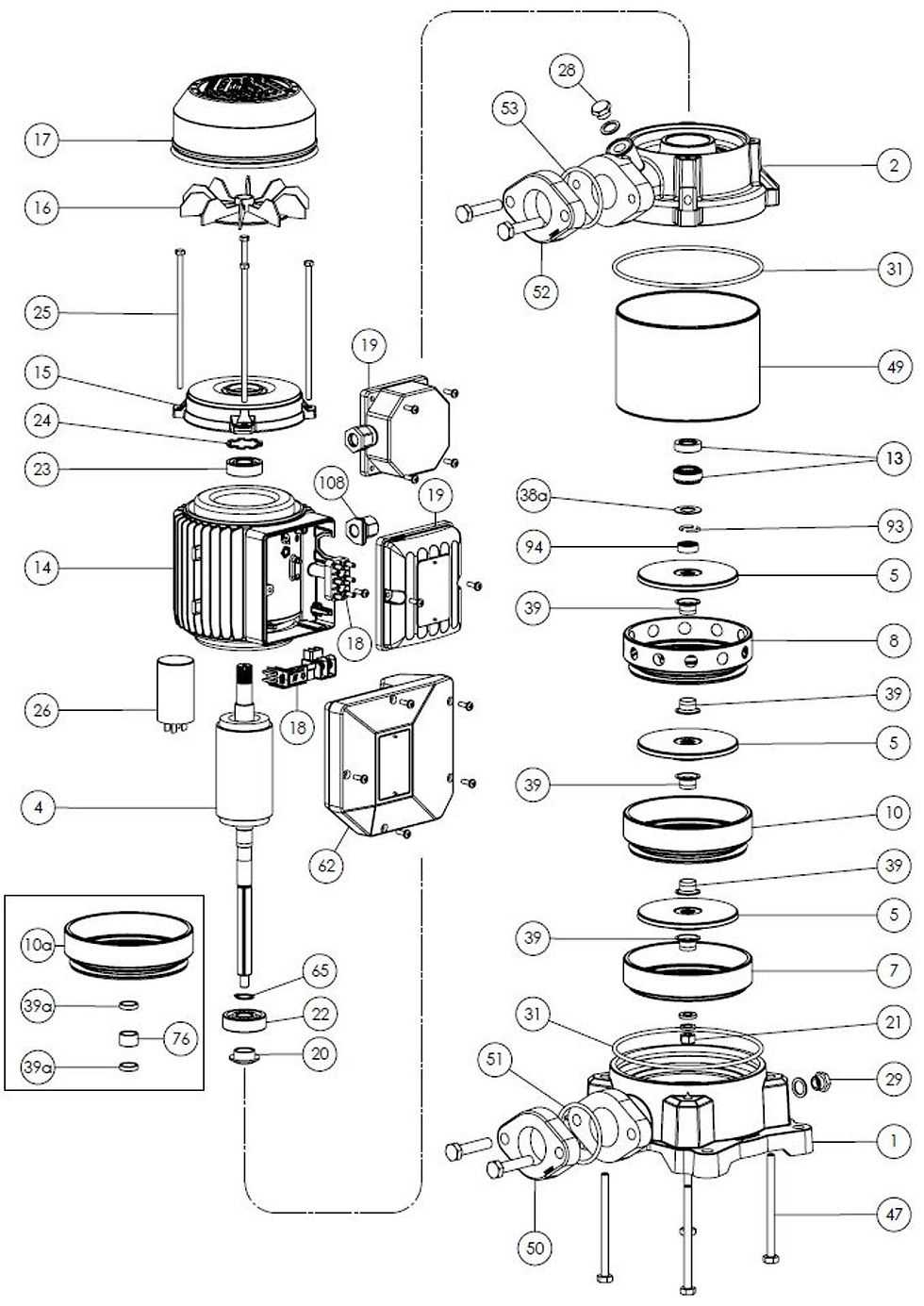

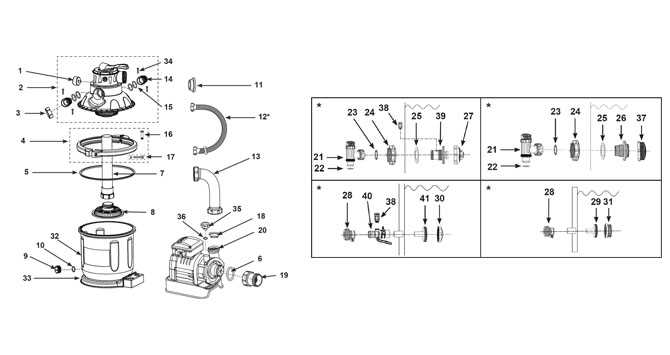

Visual representations of these elements can greatly aid in grasping their functions and relationships. Such illustrations serve as valuable tools for both novice users and experienced technicians, enabling them to pinpoint areas for improvement or necessary replacements. An accurate layout reveals how each piece fits into the larger assembly, offering insights into optimal operation practices.

Furthermore, understanding the assembly not only facilitates troubleshooting but also promotes informed decision-making regarding upgrades and modifications. As technology advances, being aware of the latest designs and innovations ensures that the system remains competitive and efficient in a rapidly evolving landscape. This comprehensive awareness ultimately leads to enhanced performance and longevity of the equipment.

Understanding SF60110-1 Pump Components

This section aims to provide insights into the various elements that make up a specific fluid transfer mechanism. Each component plays a crucial role in ensuring efficiency and reliability, contributing to the overall functionality of the system.

Key Components and Their Functions

Familiarizing oneself with the individual elements helps in understanding how they interact to facilitate fluid movement. Below are some essential components:

- Drive Mechanism: Converts energy into mechanical motion, initiating the movement of fluids.

- Housing: Encloses and protects the internal elements, maintaining structural integrity under pressure.

- Seals: Prevent leakage and ensure that the fluid remains contained within the system.

- Impellers: Generate flow by transferring energy to the fluid, crucial for effective circulation.

- Discharge Outlet: Directs the flow of the fluid out of the assembly to the desired location.

Maintenance and Care

To prolong the lifespan and efficiency of the mechanism, regular maintenance is essential. Here are some best practices:

- Inspect seals and gaskets periodically to prevent leaks.

- Clean the housing and internal components to avoid buildup of debris.

- Monitor the performance regularly to detect any irregularities in fluid movement.

- Replace worn-out components promptly to maintain optimal performance.

Diagram Overview and Key Features

This section provides a comprehensive look at the visual representation and significant characteristics of the assembly in question. Understanding these elements is crucial for effective maintenance and operation, ensuring optimal performance and longevity.

Key Elements of the Assembly

The illustration highlights various components, each serving a specific function. Critical features include the structural integrity, fluid dynamics, and accessibility for servicing, all essential for enhancing overall efficiency.

Importance of Accurate Representation

An accurate depiction facilitates better comprehension of the system’s architecture. Detailed views allow technicians to pinpoint issues swiftly, making it easier to implement solutions and reduce downtime.

Common Issues with Pump Parts

Understanding the frequent challenges associated with components in hydraulic systems is essential for maintaining optimal performance. These issues can lead to inefficiencies, costly repairs, and system failures if not addressed promptly.

Worn Seals and Gaskets

Degradation of seals and gaskets is a prevalent problem, often caused by prolonged exposure to heat and pressure. Leaks can occur, resulting in loss of fluid and reduced effectiveness of the system.

Clogged Filters

Filters play a crucial role in ensuring cleanliness within the system. Over time, they can become blocked by contaminants, leading to decreased flow rates and increased strain on other components. Regular maintenance is key to preventing these issues.

Maintenance Tips for SF60110-1

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a structured maintenance routine can help prevent unexpected breakdowns and extend the lifespan of components. Here are some key practices to keep in mind.

Routine Checks

- Inspect all connections and seals for wear and tear.

- Monitor fluid levels and top up as necessary to avoid dry running.

- Examine hoses for cracks or leaks; replace them if any damage is detected.

Cleaning and Lubrication

- Regularly clean external surfaces to prevent dirt buildup.

- Lubricate moving parts according to the manufacturer’s specifications.

- Use appropriate cleaning solutions that won’t damage components.

By adhering to these maintenance tips, you can ensure reliable operation and reduce the likelihood of costly repairs in the future.

Replacement Parts: What You Need

Ensuring optimal performance requires understanding the essential components that may need substitution over time. Identifying these critical elements can significantly enhance efficiency and prolong the lifespan of your equipment.

Common Components to Consider

Key elements often require replacement include seals, bearings, and gaskets. Regularly checking these can prevent malfunctions and maintain functionality.

Choosing Quality Substitutes

Opting for high-quality alternatives is crucial. Reliable suppliers provide products that meet or exceed original specifications, ensuring compatibility and durability.

How to Read Pump Diagrams

Understanding technical illustrations is essential for effective maintenance and troubleshooting. These visuals convey critical information about the components and their relationships, helping you grasp the inner workings of a system. Familiarity with key elements enhances your ability to interpret the layout and perform necessary tasks efficiently.

Key Elements to Identify

- Symbols: Each symbol represents a specific component. Learning these will provide insights into the overall design.

- Labels: Pay attention to labels that indicate part names, sizes, and other relevant details.

- Flow Directions: Arrows usually indicate the direction of movement, which is crucial for understanding operational processes.

Steps to Interpret the Visual

- Start with a general overview to understand the layout.

- Identify the symbols and match them with the provided legend or key.

- Trace the flow paths to see how the elements interact.

- Note any additional notes or instructions that may clarify assembly or function.

By mastering these techniques, you can confidently navigate technical illustrations, leading to improved comprehension and effective problem-solving.

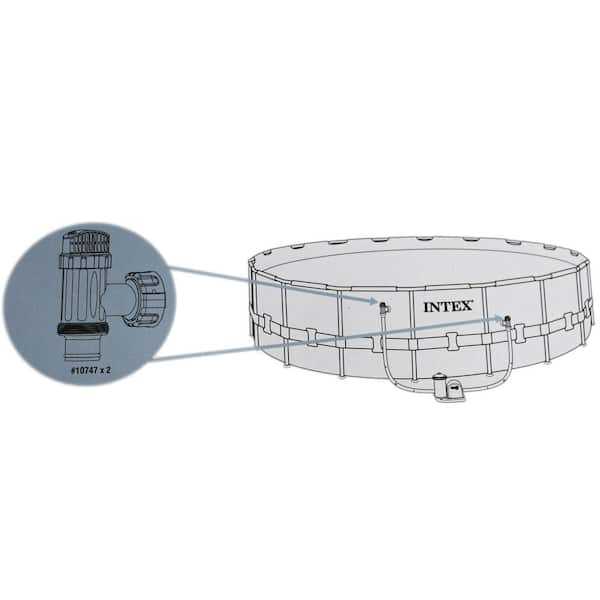

Installation Guide for SF60110-1

Proper setup is essential for optimal performance and longevity of your equipment. This guide provides a comprehensive overview of the necessary steps to ensure everything is installed correctly, reducing the risk of future complications.

Step 1: Begin by reviewing all components and confirming they are in good condition. Any damaged items should be replaced before proceeding.

Step 2: Ensure you have all required tools at hand. This preparation minimizes interruptions during the installation process.

Step 3: Follow the manufacturer’s instructions closely. Align each element according to the specified configuration to guarantee proper function.

Step 4: After assembly, conduct a thorough inspection to verify that all connections are secure. This step is crucial for preventing leaks and ensuring efficiency.

Step 5: Once everything is checked, power up the system and observe its operation. Pay attention to any unusual sounds or behaviors that may indicate issues.

Regular maintenance and adherence to the installation guidelines will lead to the ultimate performance of your system.

Differences Between Similar Pump Models

When examining various models in a specific category, it’s essential to identify the nuances that set them apart. These distinctions can significantly influence performance, efficiency, and application suitability. Understanding these differences aids in making informed decisions for specific needs.

Design Variations

One of the primary factors to consider is the design variations. Different models may feature unique configurations, which affect their operation. For instance, variations in casing shapes or materials can lead to differences in durability and resistance to wear.

Performance Metrics

Another critical aspect is the performance metrics. Models may differ in flow rates, pressure capabilities, and energy consumption. Assessing these parameters ensures that the selected unit aligns with operational requirements, maximizing efficiency and effectiveness.

Best Practices for Pump Operation

Ensuring optimal functionality and longevity of fluid transfer systems requires careful consideration and adherence to established guidelines. These practices not only enhance efficiency but also minimize the risk of breakdowns and maintenance issues.

Regular Maintenance and Inspection

Consistent upkeep is crucial for sustaining the operational integrity of any fluid-moving equipment. Scheduling routine checks allows for the early identification of wear and tear, which can prevent more significant problems. Inspect seals, bearings, and connections regularly to ensure they are in good condition.

Monitoring Operating Conditions

Keeping an eye on operational parameters is essential for optimal performance. Monitoring temperature, pressure, and flow rates helps detect irregularities that could indicate potential failures. Properly calibrating sensors and gauges contributes to a reliable and efficient system.

FAQs About SF60110-1 Parts

This section aims to address common inquiries regarding components associated with the SF60110-1 model. Understanding these elements can help ensure optimal performance and longevity.

Common Questions

- What are the main components included in the assembly?

- How do I identify the correct specifications for each part?

- Are there any recommended maintenance tips for these elements?

Replacement and Compatibility

- Where can I find high-quality replacements?

- Are all components interchangeable with similar models?

- What should I consider when purchasing new elements?

By addressing these questions, users can make informed decisions and enhance their experience with this equipment.

Resources for Further Learning

Expanding your knowledge in the field of mechanical systems can greatly enhance your understanding and proficiency. This section provides valuable resources to deepen your insights, whether you’re a novice or an experienced professional. Explore books, online courses, and community forums that cater to various aspects of mechanical design and maintenance.

Books and Publications

Numerous texts delve into the intricacies of machinery and their components. Look for titles that cover both theoretical principles and practical applications. Technical manuals often provide in-depth explanations and illustrations that can clarify complex concepts. Additionally, consider subscribing to relevant journals to stay updated on the latest advancements in technology.

Online Learning Platforms

Digital courses offer flexibility and accessibility for learning. Platforms like Coursera, edX, and Udemy feature a wide range of subjects related to engineering and mechanical systems. Many of these courses include interactive elements and assessments, making the learning experience both engaging and effective.