Efficient water removal is critical in maintaining dry conditions in areas prone to excess moisture. Various systems are designed to help keep these spaces free from water damage, ensuring the safety and structural integrity of a building. In this section, we will explore the key elements involved in one such water management solution, outlining their roles and functionality.

Each component plays a unique role in the overall operation, contributing to the effectiveness of water drainage. By understanding how these individual parts work together, homeowners and professionals alike can ensure proper maintenance and troubleshooting. This knowledge is crucial for preventing malfunctions and extending the lifespan of the system.

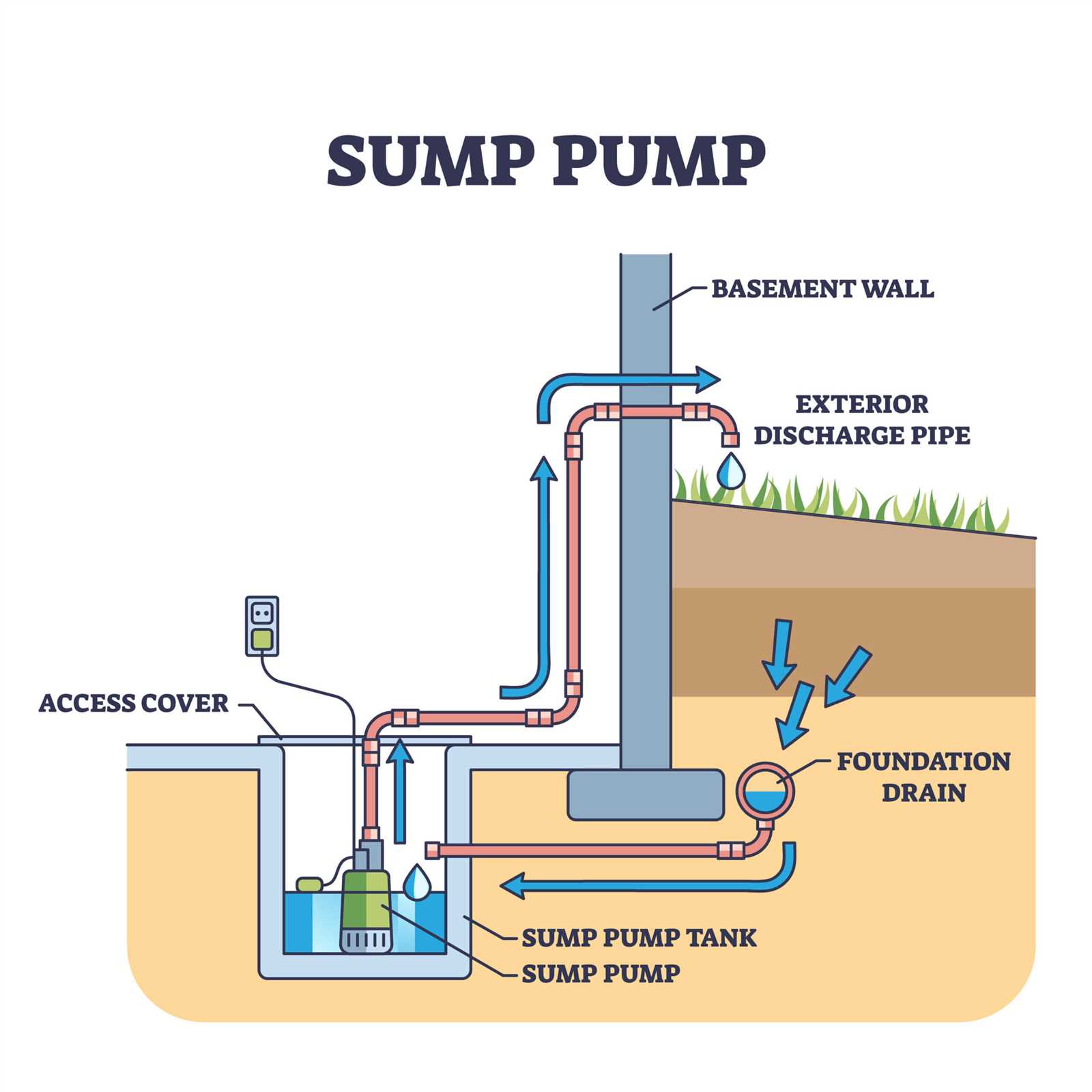

Sump Pump Parts Diagram

Understanding the key elements that make up this essential device is crucial for ensuring its proper function. Each component works in harmony to efficiently manage excess water, preventing potential damage to your home. By knowing the role of each individual part, it becomes easier to identify and resolve issues before they escalate into major problems.

These mechanisms include several interconnected elements, all designed to work together in directing water flow and maintaining the system’s efficiency. From the main unit responsible for water movement to the auxiliary pieces that ensure stability and control, the system’s performance relies on the seamless operation of all its elements.

Overview of a Sump Pump System

An efficient water removal system is critical in preventing flooding and protecting the structural integrity of a building. These systems are designed to handle excess moisture accumulation, particularly in areas prone to water buildup. By guiding unwanted water away from the foundation, they ensure that the environment remains dry and safe. Understanding the components that make up this system is essential for proper maintenance and troubleshooting.

Key Components

The system consists of several vital elements that work together to manage water levels. Each component has a specific role, contributing to the overall functionality of the setup. Below is a breakdown of the primary elements involved in this water management process:

| Component | Function |

|---|---|

| Drainage Pipes | These are responsible for directing water into the designated basin. |

| Float Switch | This device activates the system when water reaches a certain level. |

| Check Valve | Prevents water from flowing back into the basin, ensuring smooth operation.

Key Components of a Sump PumpThe operation of a water removal system relies on a few essential elements that work together to prevent flooding in basements and low-lying areas. These crucial mechanisms ensure the effective movement of water away from vulnerable spaces. Understanding the main elements of this system is vital for both maintenance and troubleshooting. Primary UnitAt the heart of the system is the central device responsible for transferring water out of the designated area. This component activates when water levels reach a certain threshold, automatically beginning the removal process to prevent overflow. Float SwitchThe float switch is a critical control element that regulates the system’s activity. It detects rising water levels and triggers the main unit to engage, ensuring the system only operates when necessary. This prevents unnecessary energy use and prolongs the life of the equipment. Understanding the Pump Motor FunctionThe motor plays a critical role in driving the mechanism responsible for removing excess water from specific areas. Its function is centered around converting electrical energy into mechanical power, allowing the entire system to operate efficiently. By understanding the motor’s operation, one can better appreciate how the entire device performs its primary task. Motor Components

How the Motor WorksWhen activated, the motor receives an electric charge that energizes the stator. This magnetic force causes the rotor to spin, which in turn powers the mechanical elements connected to it. The speed and strength of this rotation directly affect the overall efficiency of the system, making the motor’s performance crucial to the successful operation of the entire unit. Role of the Impeller in Water MovementThe impeller plays a crucial role in facilitating the movement of water by converting rotational energy into fluid motion. This component is specifically designed to propel liquid, allowing it to move efficiently within various systems. Its function is integral to maintaining a continuous flow, ensuring that water reaches the desired location without interruptions or delays. How the Impeller WorksBy rotating at high speeds, the impeller generates centrifugal force, pushing water outward from the center. This outward movement is what drives the liquid through the system, allowing for a steady and controlled flow. The efficiency of this mechanism depends heavily on the design and material of the impeller, as well as the speed at which it operates. Importance of Impeller MaintenanceOver time, wear and tear can reduce the effectiveness of the impeller. Regular inspections and timely replacements are essential for ensuring the component continues to perform optimally. Proper care helps maintain the overall fluid movement efficiency, preventing potential disruptions in water flow. Importance of the Float Switch MechanismThe float switch mechanism plays a crucial role in managing fluid levels in various applications. This component ensures that the system operates effectively by automatically regulating the flow based on the liquid’s height. By responding to changes in level, it maintains a balance that prevents overflow or depletion. Functionality and ReliabilityThis mechanism operates through a simple yet effective design, using buoyancy to trigger electrical circuits. When the fluid reaches a specific height, the float rises, activating the switch. This action can either start or stop the system, depending on its configuration. The reliability of this mechanism is vital, as it directly impacts the overall performance and safety of the installation. Impact on EfficiencyIncorporating a float switch enhances operational efficiency by ensuring optimal fluid levels. This regulation minimizes unnecessary energy consumption and reduces wear on other components, prolonging their lifespan. Consequently, a well-functioning float switch mechanism not only safeguards the equipment but also contributes to cost savings over time. Check Valve Purpose and BenefitsCheck valves are crucial components in various fluid management systems, serving to regulate the flow of liquids and prevent backflow. Their design allows for unidirectional flow, ensuring that fluids move in the desired direction while effectively blocking any reverse movement. This functionality is essential for maintaining system integrity and efficiency. Prevention of BackflowOne of the primary benefits of check valves is their ability to prevent backflow. This feature safeguards systems from potential damage caused by reverse fluid movement, which can lead to contamination and operational failures. By ensuring that the flow remains unidirectional, these valves contribute to the overall reliability of the installation. Enhanced System EfficiencyIn addition to preventing backflow, check valves enhance the efficiency of fluid systems. By minimizing turbulence and pressure fluctuations, they help maintain optimal flow rates. This leads to improved performance and can reduce energy consumption, ultimately benefiting both the system and its operators. How the Discharge Pipe WorksThe discharge pipe plays a crucial role in the management of excess water, ensuring that it is efficiently directed away from the designated area. This component is essential for maintaining a dry environment by channeling water to a suitable drainage location. Understanding its functionality can help homeowners appreciate the importance of proper water management systems. Functionality of the Discharge PipeThis pipe is responsible for transporting the collected water away from the reservoir. When the water level rises to a certain point, a mechanism activates, allowing the liquid to flow through the discharge pipe. Gravity or mechanical force aids in moving the water to its final destination, preventing accumulation and potential flooding. Maintenance ConsiderationsRegular maintenance of the discharge pipe is vital for optimal performance. Homeowners should inspect the pipe for any obstructions or leaks that may impede water flow. Ensuring that the pipe remains clear and functional helps to avoid issues related to water buildup and enhances the overall effectiveness of the drainage system. Explaining the Sump Pit StructureThe structure designed for water collection plays a vital role in managing excess moisture. Understanding its components and layout is essential for effective operation and maintenance. This section delves into the various elements that make up this crucial system. At its core, the water collection area consists of several key elements:

Each component works together to create an efficient system that minimizes water accumulation. Regular inspections and maintenance of these parts are crucial to ensure optimal performance and longevity. Backup Systems for Sump PumpsIn situations where water management is crucial, having a reliable backup system ensures continuous operation, even during power failures or mechanical malfunctions. These systems serve as a safeguard against flooding, helping to protect homes and properties from water damage. Types of Backup SystemsThere are several types of backup systems available, including battery-operated and water-powered options. Battery-operated models are particularly popular due to their ability to function independently during outages. Water-powered alternatives utilize municipal water pressure to operate, providing an eco-friendly solution that does not rely on electricity. Maintenance ConsiderationsRegular maintenance is essential to ensure the reliability of backup systems. Routine checks on battery levels, connections, and operational efficiency can prevent unexpected failures. Additionally, keeping components clean and free of debris enhances performance and prolongs the lifespan of the equipment. Common Materials Used in Sump PumpsIn the construction of drainage systems, various materials play a crucial role in ensuring durability and efficiency. The selection of these components is vital for optimal performance and longevity, as they must withstand harsh environments and resist corrosion. Understanding the common materials utilized in these systems can help in making informed decisions when selecting or replacing elements. One of the primary materials is thermoplastic, known for its resistance to chemicals and lightweight nature. It is often used in the housing and casing, providing a robust structure that can endure external pressures. Additionally, metal alloys, such as stainless steel, are frequently employed due to their strength and ability to resist rust and wear, especially in components that require added durability. Another significant material is rubber, commonly found in seals and gaskets. Its flexibility and water-resistant properties make it ideal for preventing leaks. Moreover, composite materials are gaining popularity, as they combine the benefits of various substances, offering both strength and reduced weight. The thoughtful integration of these materials contributes to the overall effectiveness and reliability of the system. Maintenance Tips for Sump Pump PartsRegular upkeep is essential for ensuring the longevity and efficiency of your water removal system. Proper care not only enhances performance but also prevents costly repairs and replacements. Below are some helpful suggestions for maintaining various components. Routine InspectionConducting frequent checks can help identify potential issues before they escalate. Consider the following:

Cleaning and CareKeeping your equipment clean is vital for optimal functionality. Follow these cleaning tips:

|