In the realm of gardening and land cultivation, a thorough comprehension of machinery is essential for achieving optimal results. These devices, designed to enhance soil aeration and preparation, consist of various elements that work in harmony. Recognizing each component’s function is crucial for effective maintenance and operation.

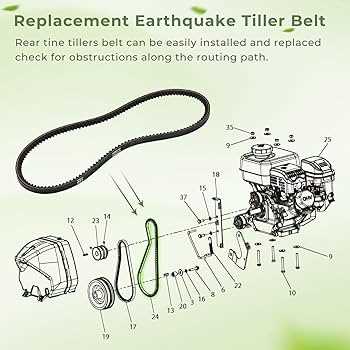

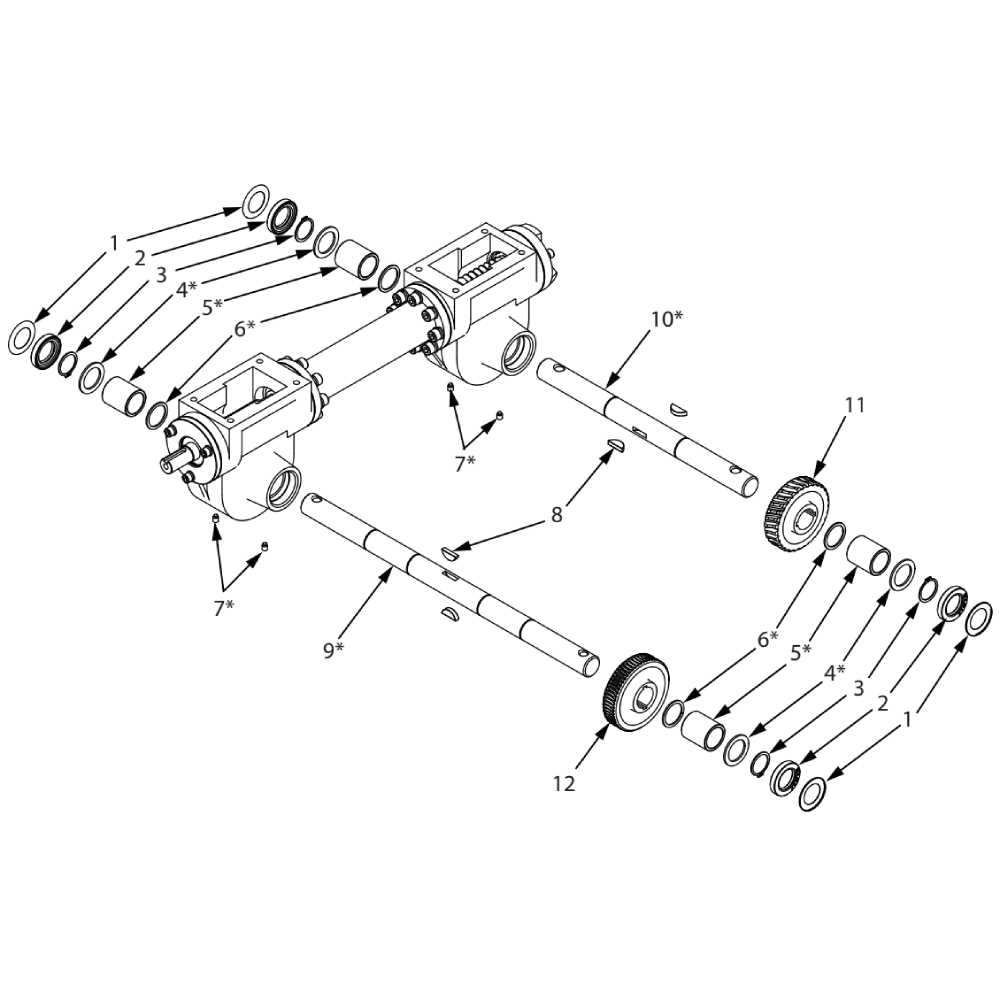

Delving into the intricate layout of these implements provides valuable insights into their assembly and utility. A well-organized schematic can serve as a reliable reference, aiding users in troubleshooting and repairs. Mastering the arrangement of each section ensures that operators can maximize efficiency and longevity.

Ultimately, possessing knowledge about the structure and interconnections of these tools empowers users to enhance their gardening experience. Understanding how each piece contributes to the overall performance transforms the cultivation process into a seamless endeavor.

Understanding Earthquake Tiller Mechanisms

The inner workings of soil cultivation machines reveal a fascinating interplay of components designed to optimize efficiency and effectiveness. Each element plays a crucial role in achieving the ultimate goal of preparing the earth for planting and growth.

Mechanisms such as the engine provide power, while various attachments work in harmony to break up soil and manage debris. Understanding these interactions can greatly enhance one’s ability to maintain and troubleshoot these essential gardening tools.

Moreover, knowledge of how these components fit together not only facilitates better performance but also extends the lifespan of the equipment. Delving into the mechanics fosters a deeper appreciation for the engineering behind these devices and their impact on agricultural practices.

Importance of Tiller Maintenance

Regular upkeep of gardening equipment is crucial for ensuring optimal performance and longevity. Proper maintenance not only enhances efficiency but also prevents unexpected failures during crucial times. Understanding the components and their care can lead to better results in cultivation tasks.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspecting blades | Monthly | Ensures effective soil breaking |

| Changing oil | Every season | Improves engine performance |

| Cleaning air filter | Every month | Enhances airflow and efficiency |

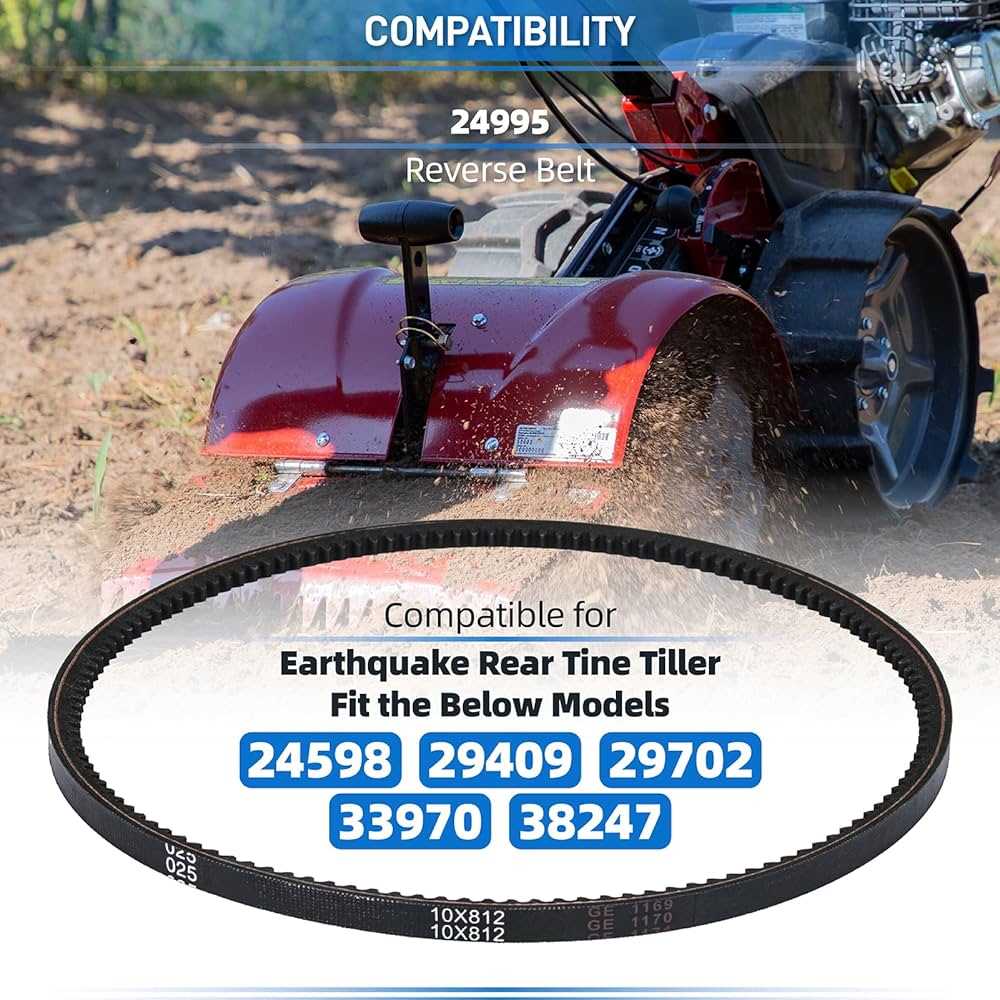

| Checking belts | Before each use | Prevents unexpected breakdowns |

Consistent attention to these tasks ensures that the equipment operates at its best, maximizing productivity and minimizing repair costs.

Key Components of Earthquake Tillers

The efficiency of gardening machinery hinges on its essential elements, which work together to enhance performance and reliability. Understanding these crucial components can help users maintain and optimize their equipment for the best results in soil cultivation and preparation.

Power Source

The heart of any gardening machine is its power source. Whether powered by gas or electricity, this component provides the necessary energy for operation. Gas engines are typically favored for their portability and strength, while electric motors are valued for their quiet operation and ease of use.

Cutting Mechanism

Another vital aspect is the cutting mechanism, which includes blades or tines designed to break up and aerate the soil. The design and arrangement of these implements play a significant role in the efficiency of soil penetration and the overall effectiveness of the machine. Users should regularly inspect and maintain these elements to ensure optimal performance.

By familiarizing oneself with these key components, users can make informed decisions regarding maintenance and upgrades, ultimately leading to improved gardening outcomes.

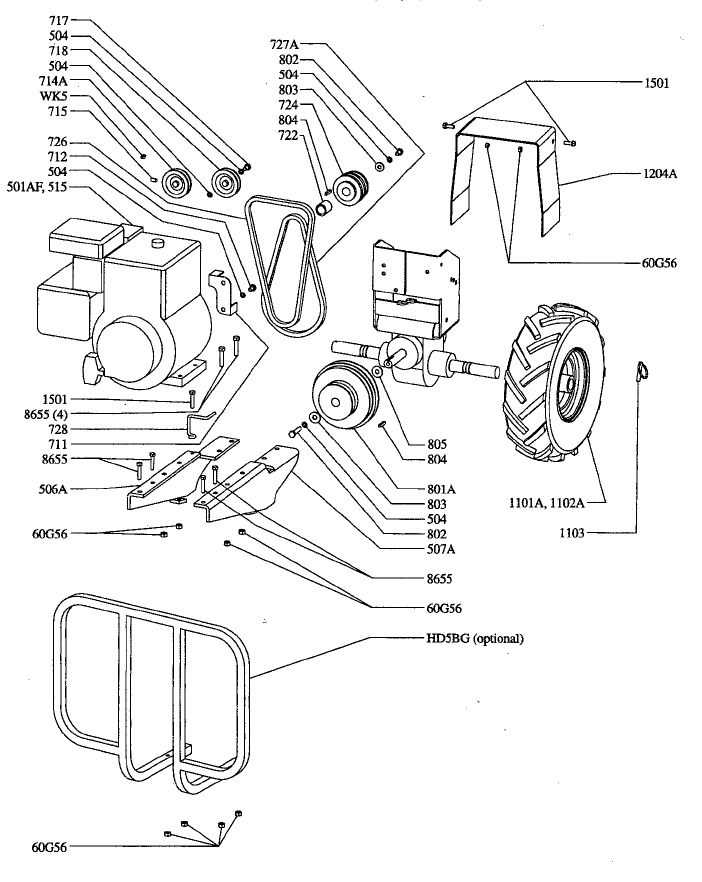

How to Identify Tiller Parts

Recognizing the components of gardening equipment is essential for effective maintenance and troubleshooting. Understanding the various elements and their functions can significantly enhance performance and longevity. This guide aims to simplify the process of identifying these crucial sections.

Common Components and Their Functions

Each piece of machinery consists of specific elements, each serving a distinct role. Familiarizing yourself with these can aid in repairs and upgrades.

| Component | Description |

|---|---|

| Engine | Powers the entire unit, providing the necessary force for operation. |

| Handle | Used for steering and maneuvering the device effectively. |

| Blades | Dig into the soil, breaking it up for better aeration and planting. |

| Chassis | The main frame that supports all other components. |

| Transmission | Transfers power from the engine to the blades, controlling speed and torque. |

Visual Inspection Tips

Performing a visual check is an effective way to identify components. Look for labels, part numbers, or unique shapes that distinguish different sections. Document any discrepancies or signs of wear, which can guide replacement or repair decisions.

Common Issues with Tiller Parts

Understanding the frequent problems that can arise with cultivation equipment is essential for maintaining optimal performance. These complications can lead to inefficiencies and increased wear, necessitating timely intervention to ensure smooth operation.

Frequent Problems

- Worn Blades: Over time, blades can become dull or damaged, reducing effectiveness.

- Fuel System Issues: Contaminated or stale fuel can lead to engine malfunctions.

- Electrical Failures: Wiring problems can prevent proper starting or functioning.

- Clogged Air Filters: Dust and debris can hinder airflow, impacting performance.

Preventive Measures

- Regular Maintenance: Schedule consistent checks to catch issues early.

- Quality Fuel: Use fresh fuel to prevent engine complications.

- Blade Inspection: Regularly assess and replace worn blades as needed.

- Clean Filters: Keep air filters free from debris to ensure optimal airflow.

Steps for Replacing Worn Components

Maintaining the efficiency of your garden equipment is crucial for optimal performance. Over time, certain elements may become worn, necessitating replacement to ensure smooth operation. This guide outlines essential steps to effectively swap out these components and restore your machinery to its best condition.

Begin by disconnecting the power source to prevent any accidents during the process. Carefully inspect the unit to identify which components require replacement. Once determined, gather the necessary tools and new parts. Remove the old components, taking note of their positioning for easier reassembly.

Install the new elements by following the reverse order of removal, ensuring everything is securely fastened. Finally, reconnect the power source and perform a test run to confirm that the equipment is functioning correctly. Regularly checking and replacing worn parts can significantly enhance the longevity and effectiveness of your tools.

Benefits of Using Original Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. These original items are designed specifically for your model, providing a perfect fit and reliable functionality.

Here are some key advantages of choosing original components:

- Quality Assurance: Original parts undergo rigorous testing and quality control, ensuring they meet high standards.

- Enhanced Performance: They are engineered to work seamlessly with your equipment, maximizing efficiency and productivity.

- Longevity: Authentic components typically last longer, reducing the frequency of replacements and repairs.

- Warranty Protection: Many manufacturers offer warranties on their original parts, providing peace of mind in case of defects.

- Safety: Using genuine items minimizes the risk of malfunction, promoting safe operation during use.

In summary, investing in original components not only improves the functionality of your equipment but also enhances its overall reliability and safety, ultimately saving you time and money in the long run.

DIY Repairs for Earthquake Tillers

Maintaining your garden cultivator can significantly extend its lifespan and enhance performance. By understanding common issues and their solutions, you can effectively troubleshoot and fix problems without the need for professional assistance. This not only saves money but also boosts your confidence in handling gardening equipment.

Identifying Issues: Begin by observing any unusual sounds or vibrations during operation. Issues like difficulty starting or inconsistent performance may indicate a need for maintenance.

Essential Tools: Equip yourself with basic tools such as wrenches, screwdrivers, and replacement parts to facilitate repairs. Having these on hand will make the process smoother and more efficient.

Routine Maintenance: Regularly check the machine’s components, including the engine, belts, and blades. Keeping these parts clean and well-lubricated will prevent future problems and ensure optimal functionality.

Step-by-Step Repairs: When facing specific issues, refer to the user manual for guidance on disassembly and reassembly. Take your time to delve into each step, ensuring everything is correctly aligned and securely fastened.

By taking a proactive approach to repairs, you can enjoy a well-functioning cultivator that supports your gardening endeavors.

Resources for Tiller Parts Diagrams

Understanding the components of your gardening equipment is essential for effective maintenance and repair. Various sources offer valuable insights and visual references to help users identify and procure the necessary elements for their machines. These resources can enhance your knowledge and ensure optimal performance.

Online Resources

- Manufacturer Websites: Most producers provide detailed manuals and schematics on their official sites. These documents often include part numbers and descriptions.

- Forums and Communities: Gardening enthusiasts frequently share their experiences and resources in online forums. These platforms can be great for troubleshooting and finding unofficial diagrams.

- Parts Retailers: Many retailers that specialize in gardening equipment offer online catalogs featuring component illustrations and specifications.

Print Resources

- Instruction Manuals: Original user manuals typically include breakdowns of the equipment, highlighting individual elements and their functions.

- Repair Guides: Numerous publications are available that provide step-by-step instructions and visuals for repairing and maintaining gardening tools.

- Local Libraries: Many libraries offer access to reference materials and repair manuals that can be beneficial for users looking to understand their tools better.

Where to Buy Replacement Parts

Finding suitable components for your garden machinery is essential to ensure optimal performance and longevity. Numerous avenues exist for acquiring these essential items, whether through local retailers or online platforms. Understanding the best options can save both time and money.

Local Stores

Visiting a nearby hardware store or specialized garden center often provides immediate access to required components. Staff at these locations can offer valuable insights and recommendations, making it easier to locate the right fit for your equipment.

Online Retailers

Shopping online expands your choices significantly. Websites dedicated to gardening tools often have comprehensive catalogs, allowing you to delve into various brands and models. Reading customer reviews can guide you toward the ultimate selection for your needs.