In the realm of household appliances, it is crucial to grasp the intricate workings of essential systems. This knowledge enables users to maintain optimal functionality and address any issues that may arise over time. By familiarizing oneself with these internal mechanisms, individuals can enhance their experience and extend the lifespan of their equipment.

Every appliance contains various elements that contribute to its overall performance. Recognizing how these components interact allows for better troubleshooting and maintenance practices. With a comprehensive overview of these systems, users can confidently navigate challenges and ensure their devices operate efficiently.

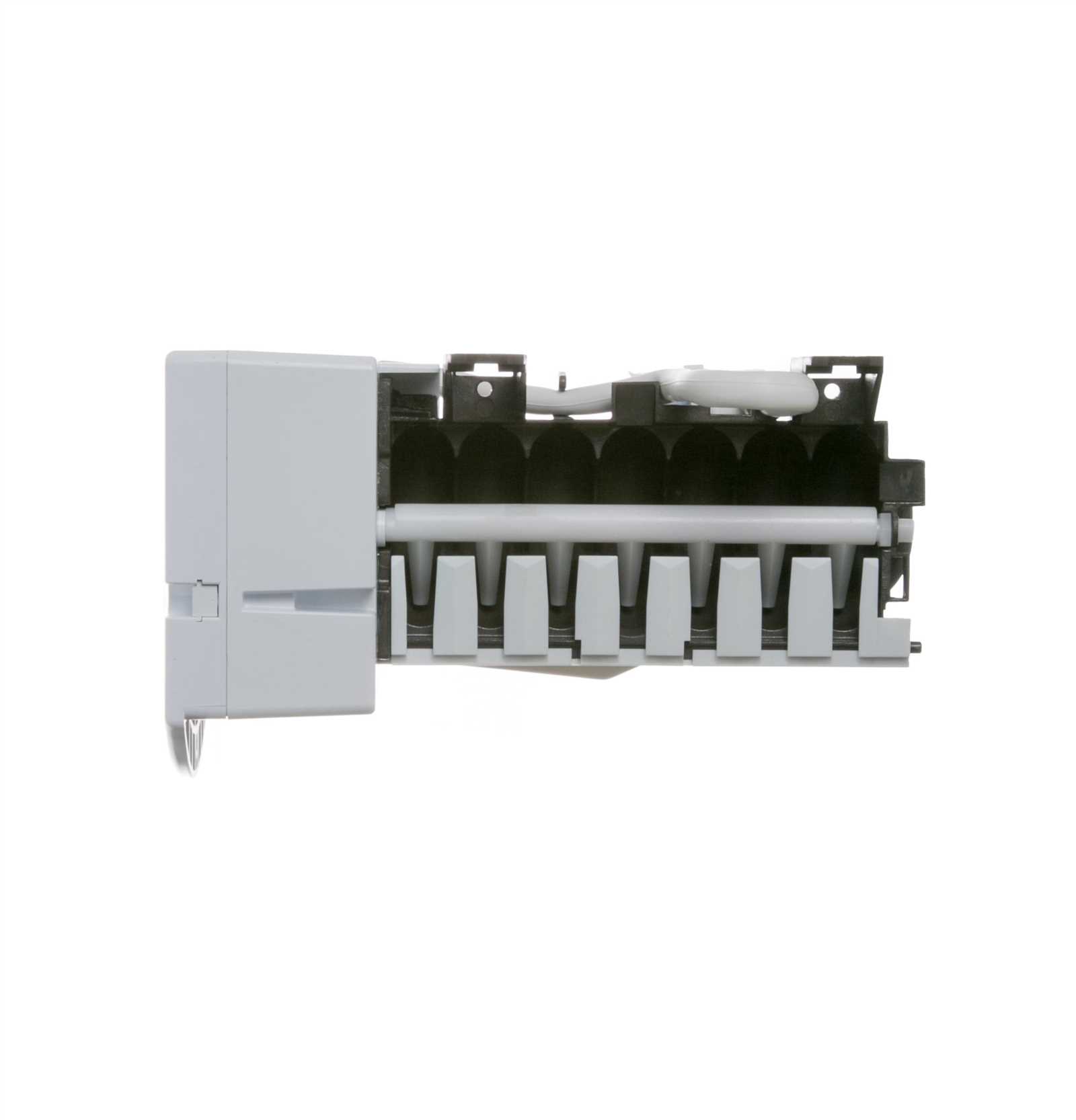

Focusing on the mechanisms responsible for producing chilled substances, understanding the assembly and arrangement of these essential components becomes vital. Each part plays a specific role in the overall functionality, and a clear grasp of their positions aids in efficient repairs and replacements. This insight can empower users to take proactive measures in their maintenance routines.

Common Issues with Ice Makers

Many individuals encounter challenges with their freezing apparatus, which can hinder their ability to produce frozen cubes effectively. Understanding the typical complications can assist in identifying and resolving issues promptly.

Insufficient Freezing

One prevalent problem is inadequate freezing, where the equipment fails to produce enough frozen cubes. This situation may arise due to various factors, such as improper temperature settings, obstructed airflow, or a malfunctioning cooling mechanism. Regular maintenance can help mitigate these issues.

Clogged Water Supply

Another frequent concern is a blockage in the water supply. Mineral buildup or ice formations within the lines can impede the flow, leading to reduced production. Checking the water lines and ensuring they are free of obstructions is essential for optimal functionality.

Essential Components of Ice Makers

The functionality of an ice-producing device relies on several key elements that work together to ensure efficient operation. Understanding these fundamental components can help users maintain and troubleshoot the appliance more effectively.

Water Supply Mechanism

A reliable water supply system is crucial for producing frozen cubes. This includes a valve that controls the flow of water into the system and ensures that the correct amount is available when needed.

Freezing Unit

The freezing mechanism is where the actual formation of frozen shapes occurs. This unit often consists of a chilled surface that lowers the temperature of the water, allowing it to solidify. Proper maintenance of this component is essential for optimal performance.

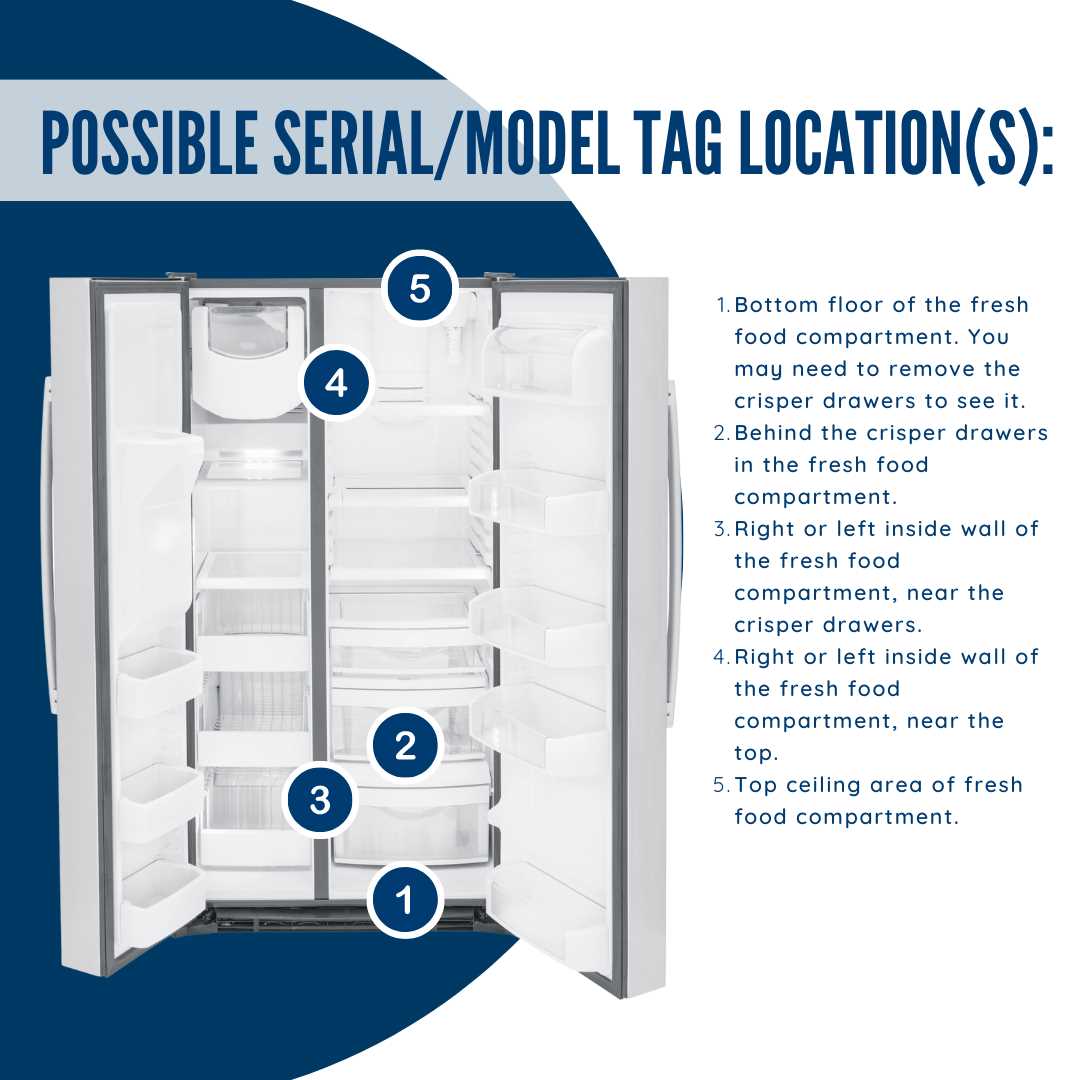

How to Identify Parts

Understanding the components of your appliance can greatly enhance your ability to maintain and troubleshoot it effectively. Recognizing different elements is essential for ensuring optimal performance and addressing any issues that may arise. This guide will provide insights into the key features to look for.

Visual Inspection

Start with a careful visual examination. Here are some tips to help you identify specific components:

- Look for unique shapes and sizes that distinguish each element.

- Check for any labeling or markings that may indicate the function.

- Observe the connections and how each item interacts with others.

Utilizing Reference Materials

Having access to reliable reference materials can simplify the identification process:

- Consult user manuals for detailed descriptions and illustrations.

- Use online resources or repair guides specific to your model.

- Seek out videos that demonstrate the functions and locations of each component.

Maintenance Tips for Ice Makers

Proper upkeep of your frozen water production unit is essential for optimal performance and longevity. Regular care can prevent malfunctions and ensure a steady supply of frozen water for your needs. Here are some key strategies to maintain your unit effectively.

Regular Cleaning

It is crucial to keep the components of your frozen water production unit clean to prevent the buildup of minerals and bacteria. Regularly check and clean the following parts:

| Component | Cleaning Frequency | Recommended Method |

|---|---|---|

| Water reservoir | Monthly | Warm, soapy water |

| Dispensing chute | Every two months | Soft cloth and mild cleaner |

| Filter | Every six months | Replace as needed |

Monitoring Temperature and Water Quality

Ensure that the water entering the unit is clean and at the correct temperature. This not only improves the quality of the frozen water but also enhances the efficiency of the machine. Use a water filtration system if necessary and check the water temperature regularly.

Replacement Procedures for Broken Parts

Addressing the need for replacements in malfunctioning appliances is crucial for maintaining optimal functionality. Understanding the steps involved in replacing components can simplify the process and ensure efficient operation once again.

Identification of Damaged Components

The first step involves accurately identifying which components are non-functional. This may require a thorough inspection to determine visible signs of wear or damage. Pay attention to any irregularities in performance, as these can guide you to the source of the issue.

Replacement Steps

Once the faulty components have been identified, follow these steps for successful replacement:

| Step | Description |

|---|---|

| 1 | Turn off the appliance and disconnect it from the power source to ensure safety. |

| 2 | Remove any coverings or panels that obstruct access to the damaged components. |

| 3 | Carefully detach the broken parts from their respective connections. |

| 4 | Install the new components by connecting them securely in place. |

| 5 | Replace any coverings or panels removed during the process. |

| 6 | Reconnect the appliance to the power source and test its functionality. |

Differences Between Models

When it comes to home appliances, variations in functionality and design can significantly impact user experience. Different units may offer distinct features tailored to specific needs, making it essential to understand these variations for optimal selection.

Design Variations

One of the primary differences among various units lies in their structural designs. Some models may incorporate a more compact layout, ideal for limited spaces, while others provide a more spacious configuration, accommodating larger capacities. The choice of materials also varies, affecting durability and maintenance requirements.

Functional Features

Another aspect that differentiates these units is their operational capabilities. Certain models might include advanced technology for efficiency, while others may focus on simplicity and ease of use. Additionally, variations in temperature control settings and energy consumption can greatly influence performance and utility costs.

Safety Precautions During Repair

When engaging in maintenance tasks on appliances, it is essential to prioritize safety. Proper precautions help to prevent accidents and ensure a smooth repair process. Understanding and following these guidelines can significantly reduce risks associated with handling electrical equipment.

General Safety Guidelines

- Always disconnect the appliance from the power source before starting any repair work.

- Use insulated tools to minimize the risk of electrical shock.

- Wear safety glasses and gloves to protect yourself from potential hazards.

- Work in a well-ventilated area to avoid inhaling harmful fumes or gases.

Handling Components Safely

- Carefully inspect all components for damage before handling.

- Avoid touching any exposed wires or connections unless necessary.

- Keep small parts organized to prevent loss and ensure easy reassembly.

- Follow manufacturer guidelines when replacing or repairing any elements.

Tools Needed for Ice Maker Repair

Repairing a cooling unit that produces frozen cubes requires specific tools to ensure the process is efficient and effective. Having the right equipment on hand can make a significant difference in the speed and quality of the repair work.

Here are some essential tools to consider for the repair task:

- Screwdrivers: Various sizes, including flathead and Phillips, are crucial for removing screws and accessing components.

- Pliers: Needle-nose and standard pliers assist in gripping, twisting, and manipulating small parts.

- Socket Set: A range of sockets is necessary for loosening and tightening nuts and bolts securely.

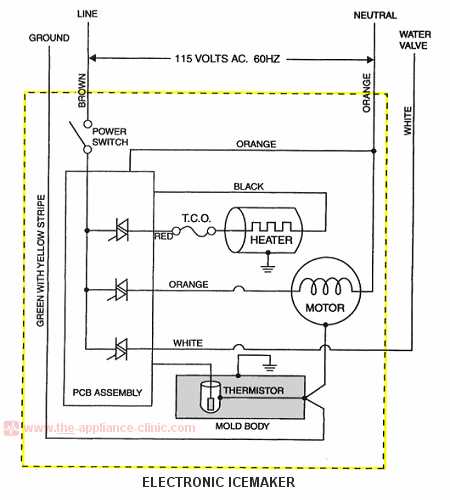

- Multimeter: This device is essential for testing electrical components and diagnosing issues within the system.

- Wrench Set: Both adjustable and fixed wrenches help in loosening or tightening various fittings.

- Tape Measure: Accurate measurements can assist in ensuring parts fit correctly during replacement.

- Utility Knife: Useful for cutting through any insulation or packaging materials that may be in the way.

Gathering these tools before starting the repair can streamline the process and minimize interruptions, allowing for a more effective restoration of functionality.

Troubleshooting Guide for Your Freezing Unit

When your chilling appliance isn’t producing the expected frozen cubes, it can be frustrating. This section provides a systematic approach to identifying and resolving common issues that may arise within the freezing mechanism. By following the steps outlined below, you can efficiently diagnose problems and ensure optimal performance.

- Check the Power Supply:

- Ensure the unit is plugged in securely.

- Inspect the power cord for any visible damage.

- Confirm that the outlet is functional by testing it with another device.

- Examine the Water Supply:

- Verify that the water line is connected properly and not kinked.

- Check for any blockages in the water supply line.

- Ensure that the water valve is open and functioning correctly.

- Inspect the Internal Components:

- Look for any obstructions within the compartment.

- Examine the filling mechanism for signs of wear or damage.

- Clean any debris that may be hindering operation.

- Test the Temperature Settings:

- Ensure the temperature is set to the recommended level for optimal freezing.

- Monitor the temperature inside the unit to confirm it remains within the appropriate range.

- Check for Defrost Issues:

- Examine for signs of frost buildup, which could impede functionality.

- Ensure that the defrost cycle is operating as intended.

If problems persist after performing these checks, it may be beneficial to consult a professional technician for further assistance.

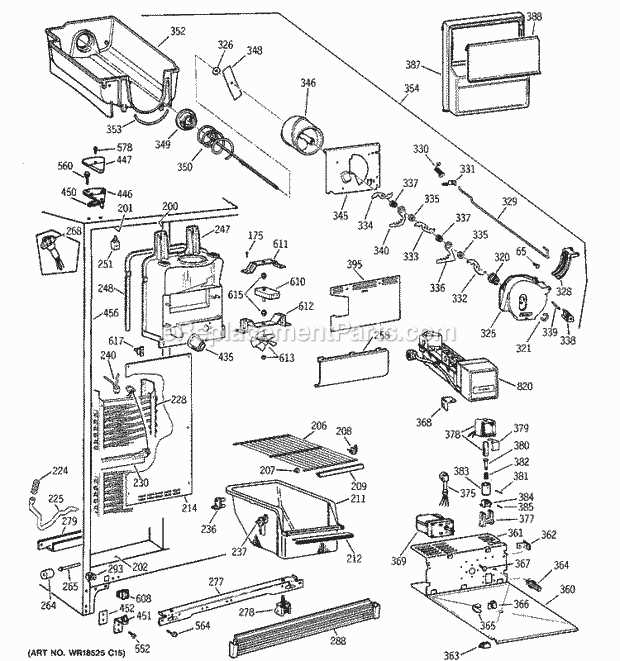

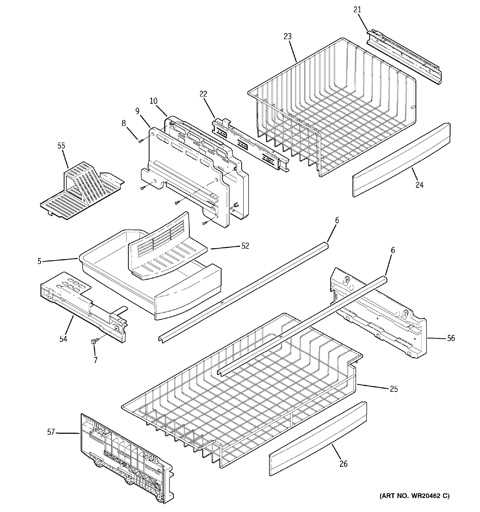

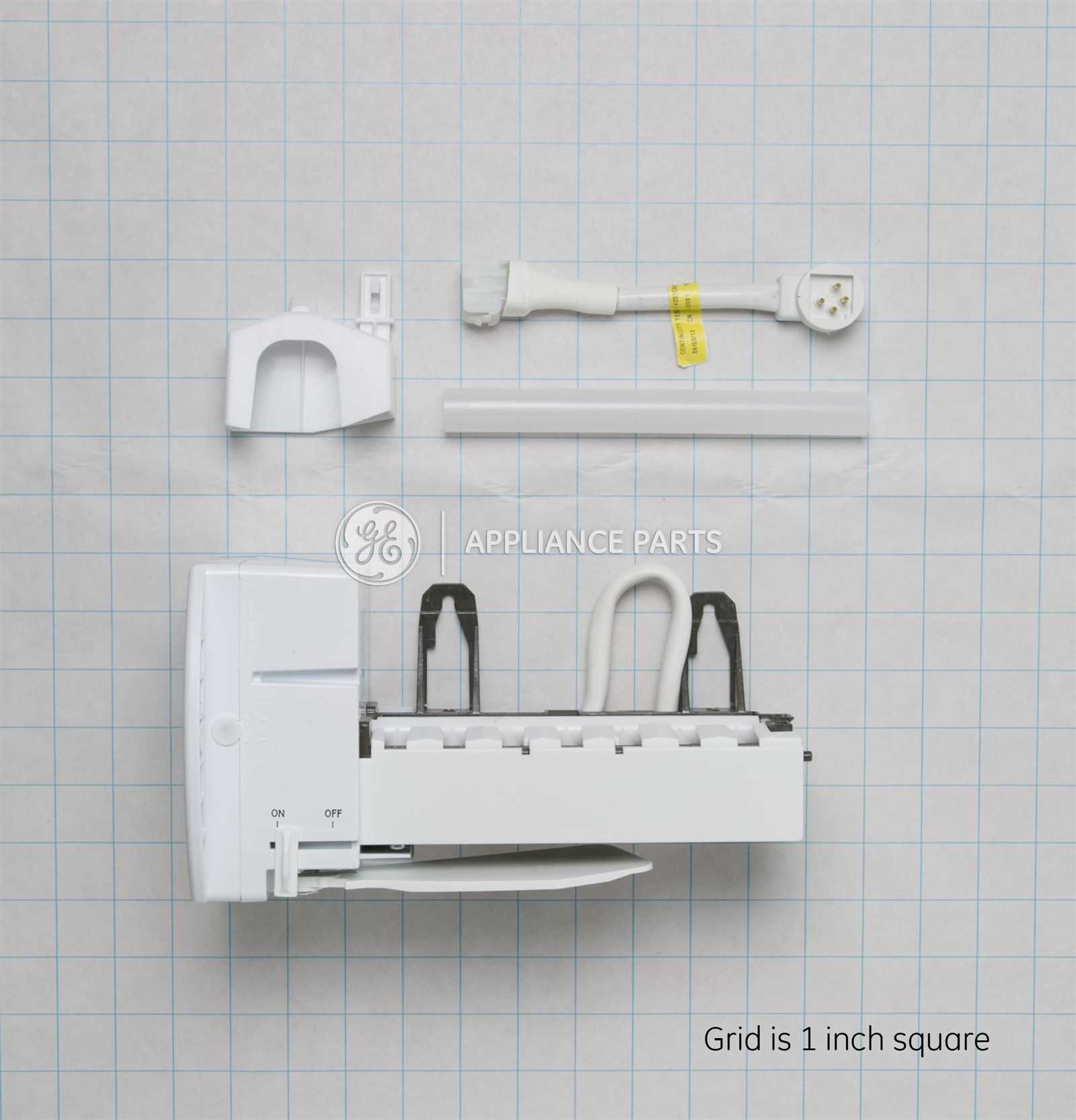

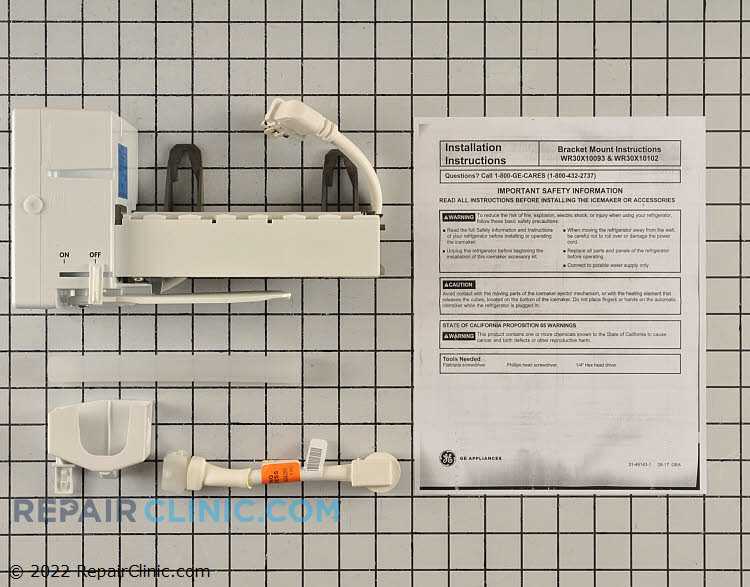

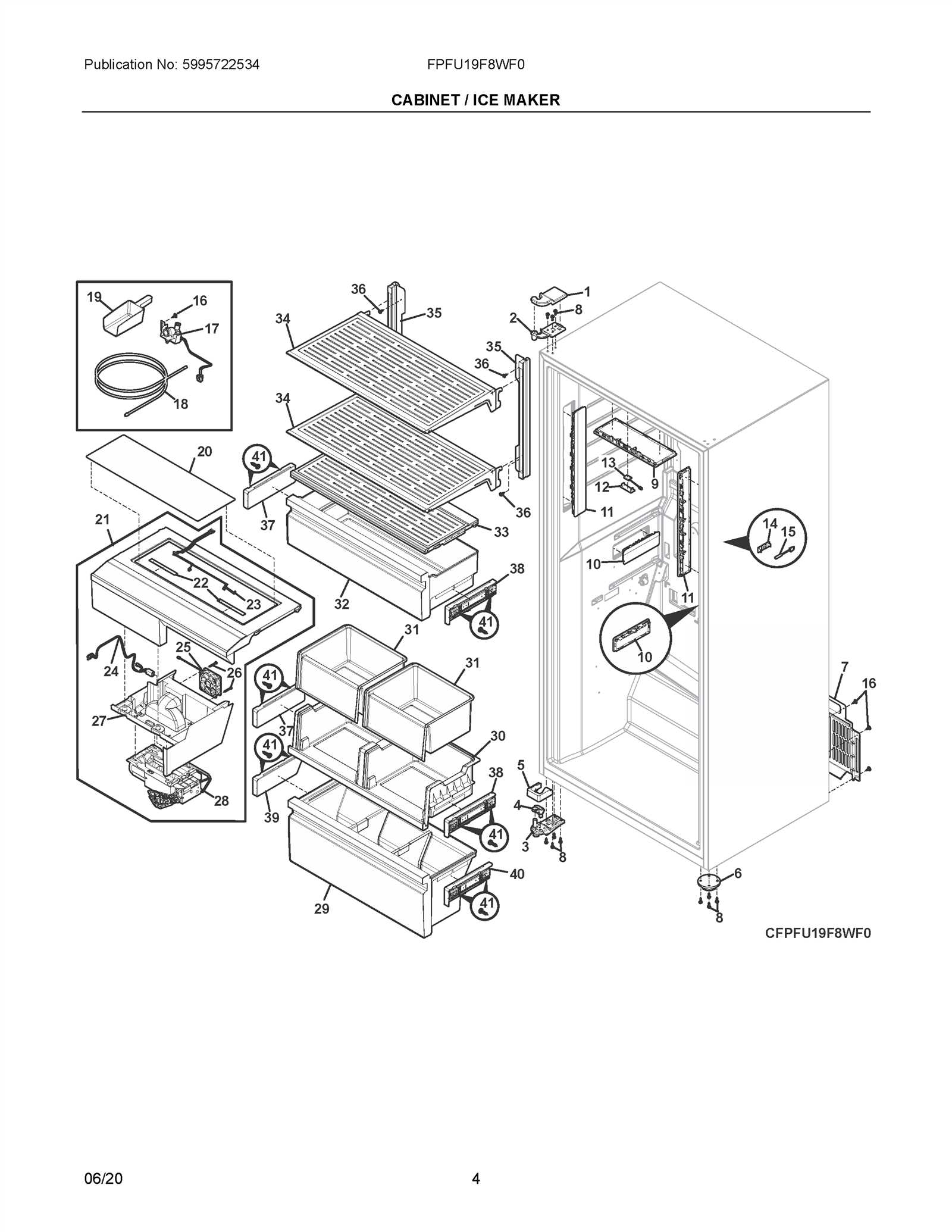

Visual Representation of Parts

This section offers a detailed illustration of various components found within a cooling unit, highlighting their arrangement and functionality. Understanding the layout and interactions of these elements can greatly assist in troubleshooting and maintenance tasks.

The visual guide serves as a valuable resource, providing clarity on how each element contributes to the overall operation of the appliance. It emphasizes the importance of recognizing each component’s role, enabling users to identify potential issues more effectively.

By familiarizing oneself with the configuration depicted in this section, individuals can gain insights into the operational dynamics and ensure proper care and handling of the unit. This knowledge ultimately enhances the longevity and efficiency of the equipment.

Where to Purchase Replacement Parts

When it comes to finding suitable components for your cooling appliance, there are several reliable options available. Understanding where to look can save time and ensure that you get high-quality items necessary for maintaining optimal performance.

Online Retailers

Many consumers prefer shopping online due to convenience and variety. Here are some trusted platforms:

- Amazon: A vast selection of various components with user reviews to guide your purchase.

- eBay: Offers both new and refurbished items at competitive prices.

- Specialty Websites: Websites dedicated to cooling systems often carry specific items tailored to your needs.

Local Appliance Stores

For those who prefer in-person shopping, local appliance stores can be a great resource. Consider visiting:

- Authorized Dealers: They often have direct access to manufacturer components.

- Repair Shops: Local repair businesses may offer a selection of necessary items and can provide expert advice.

- Home Improvement Stores: These larger stores typically carry a variety of components for household appliances.