Maintaining a vibrant and well-manicured yard requires a reliable and efficient tool. Understanding the inner workings of such a device can significantly enhance its longevity and performance. This section delves into the essential elements that contribute to the functionality of this valuable equipment, providing insight into their roles and interconnections.

By familiarizing oneself with these crucial components, operators can effectively troubleshoot issues and carry out necessary repairs. Recognizing how each element functions within the overall system allows for more informed decisions regarding maintenance and upgrades, ultimately leading to improved results in yard care.

Moreover, a detailed examination of these components aids in comprehending the intricate design that supports efficient operation. This knowledge empowers users to maximize the potential of their equipment, ensuring it remains an indispensable ally in achieving a lush and healthy landscape.

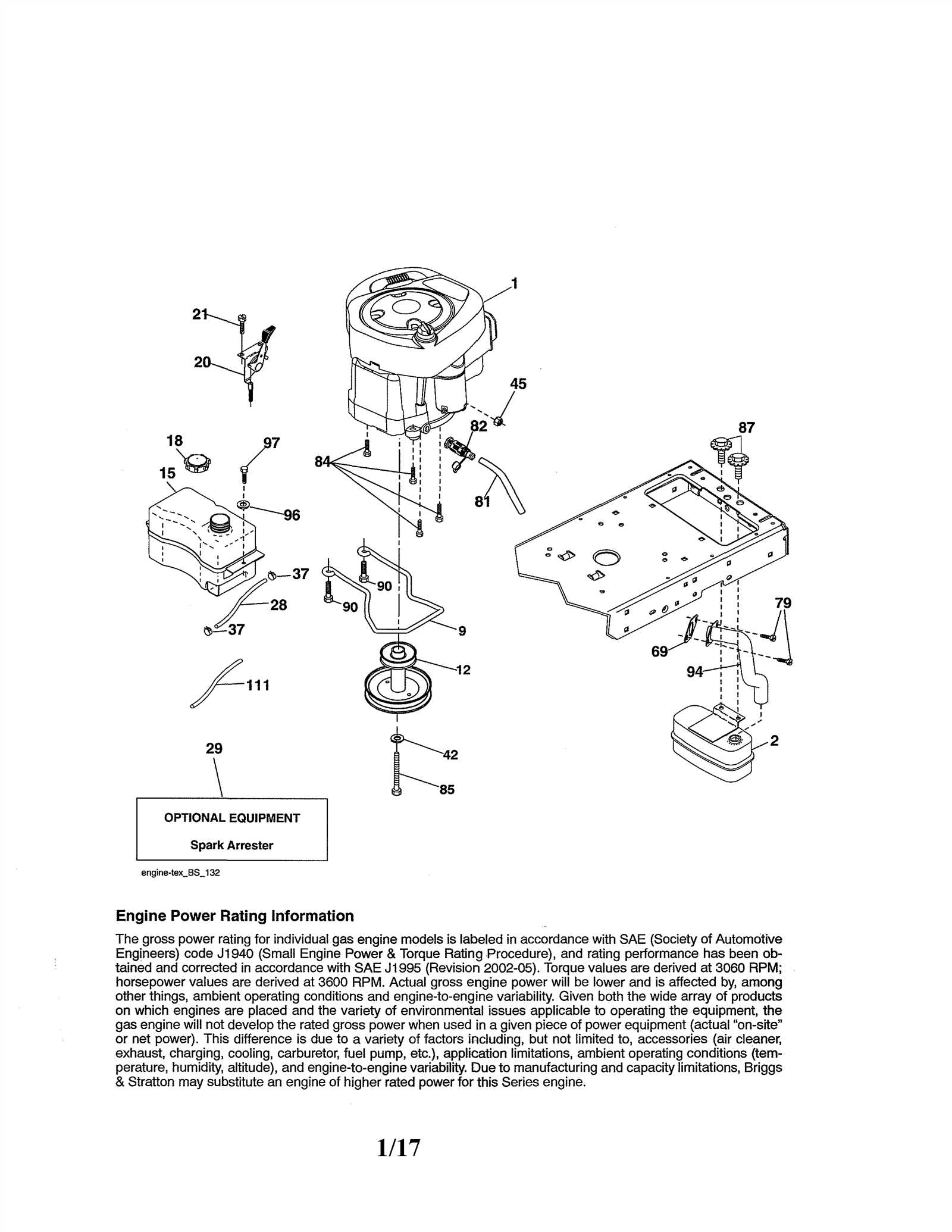

This section aims to explore the essential elements that contribute to the overall functionality of a specific type of machinery designed for outdoor maintenance. By delving into the various components and their roles, readers will gain a comprehensive understanding of how these elements interact to ensure efficient operation.

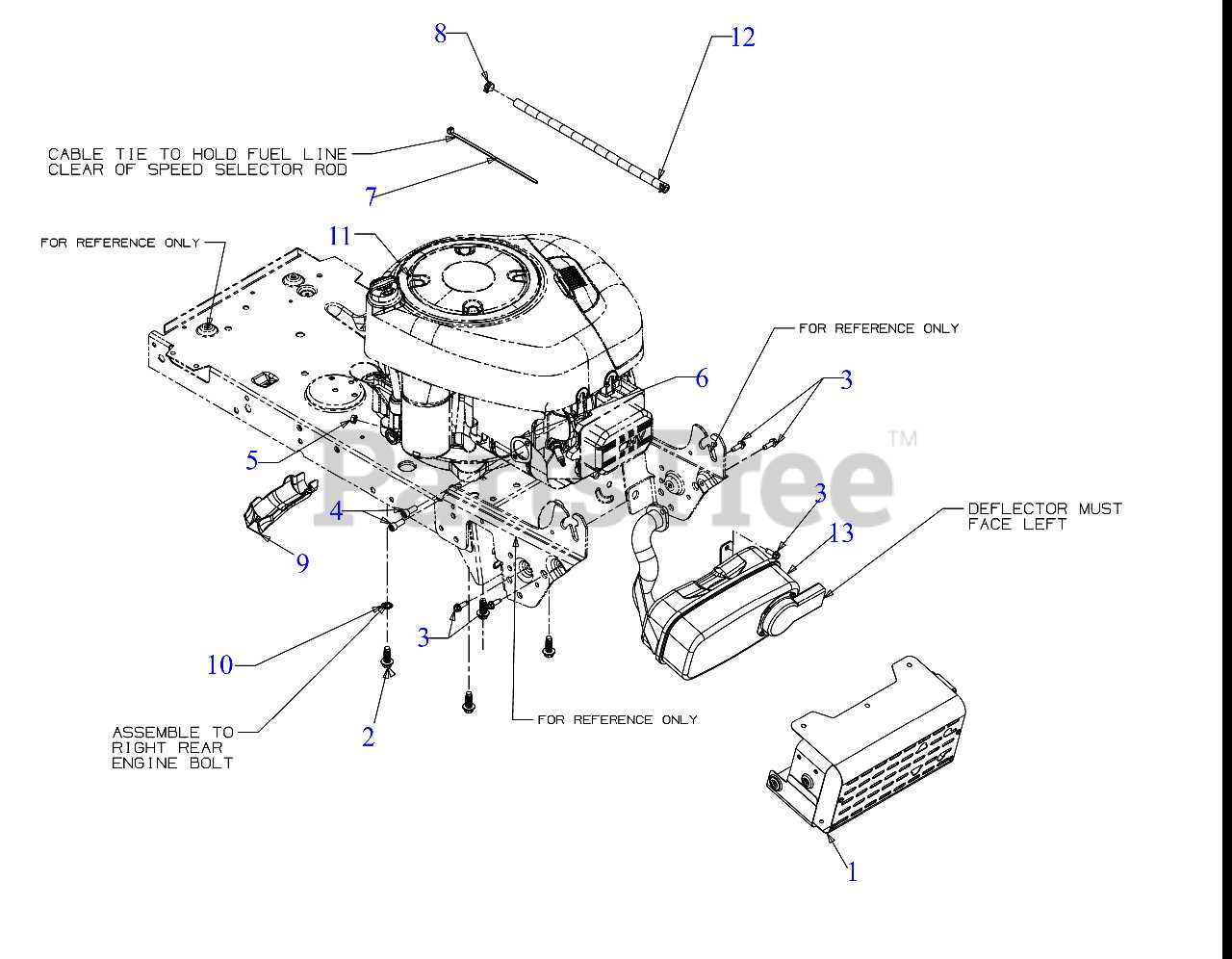

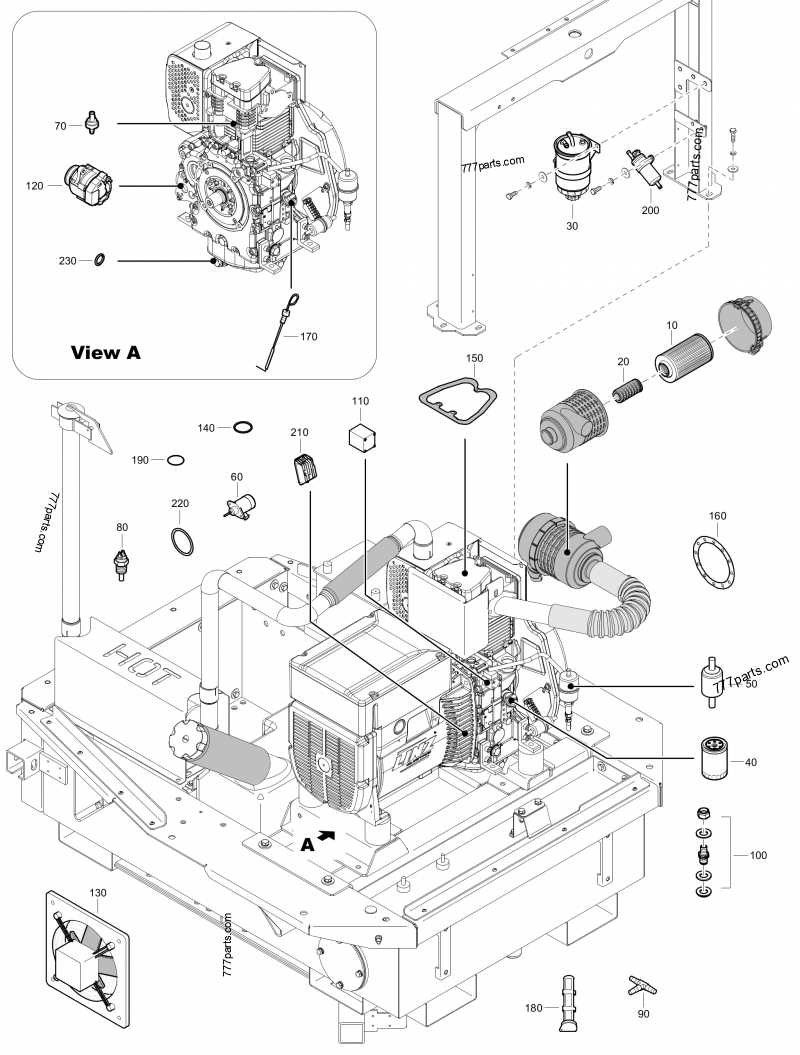

- Power Source: Investigating the primary mechanism that drives the system.

- Fuel Delivery System: An overview of how energy is supplied to the machine.

- Cooling Mechanism: Understanding the methods used to prevent overheating.

- Ignition Assembly: Examining the components responsible for starting the system.

- Lubrication System: Discussing how friction is minimized among moving parts.

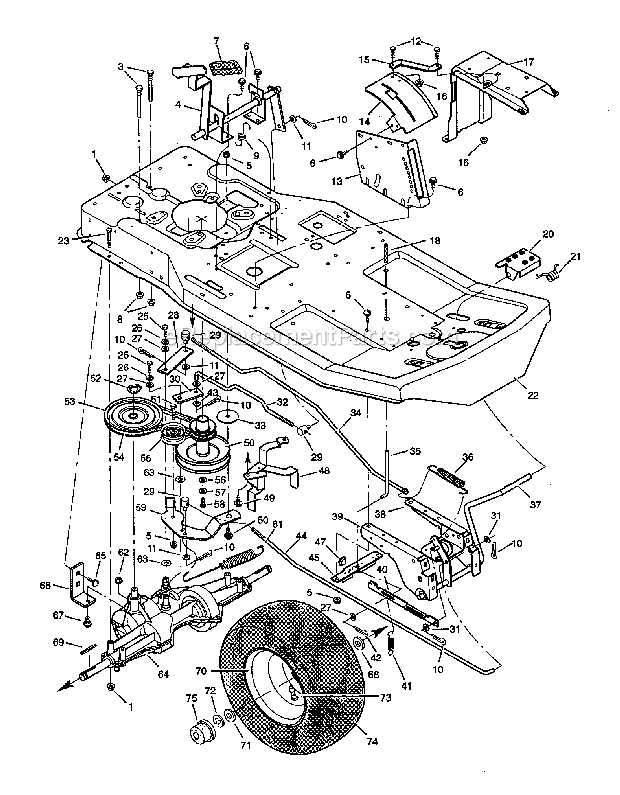

- Transmission Components: A look at how power is transferred throughout the device.

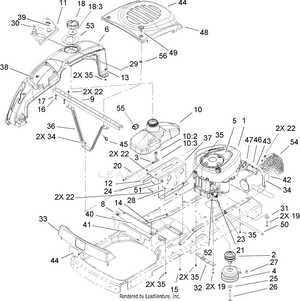

- Chassis Structure: Evaluating the framework that supports all functional elements.

- Control Systems: Analyzing the user interface and operational controls.

- Exhaust System: Understanding how emissions are managed and expelled.

- Safety Features: Reviewing mechanisms designed to protect users during operation.

- Maintenance Recommendations: Providing guidance on upkeep and care for longevity.

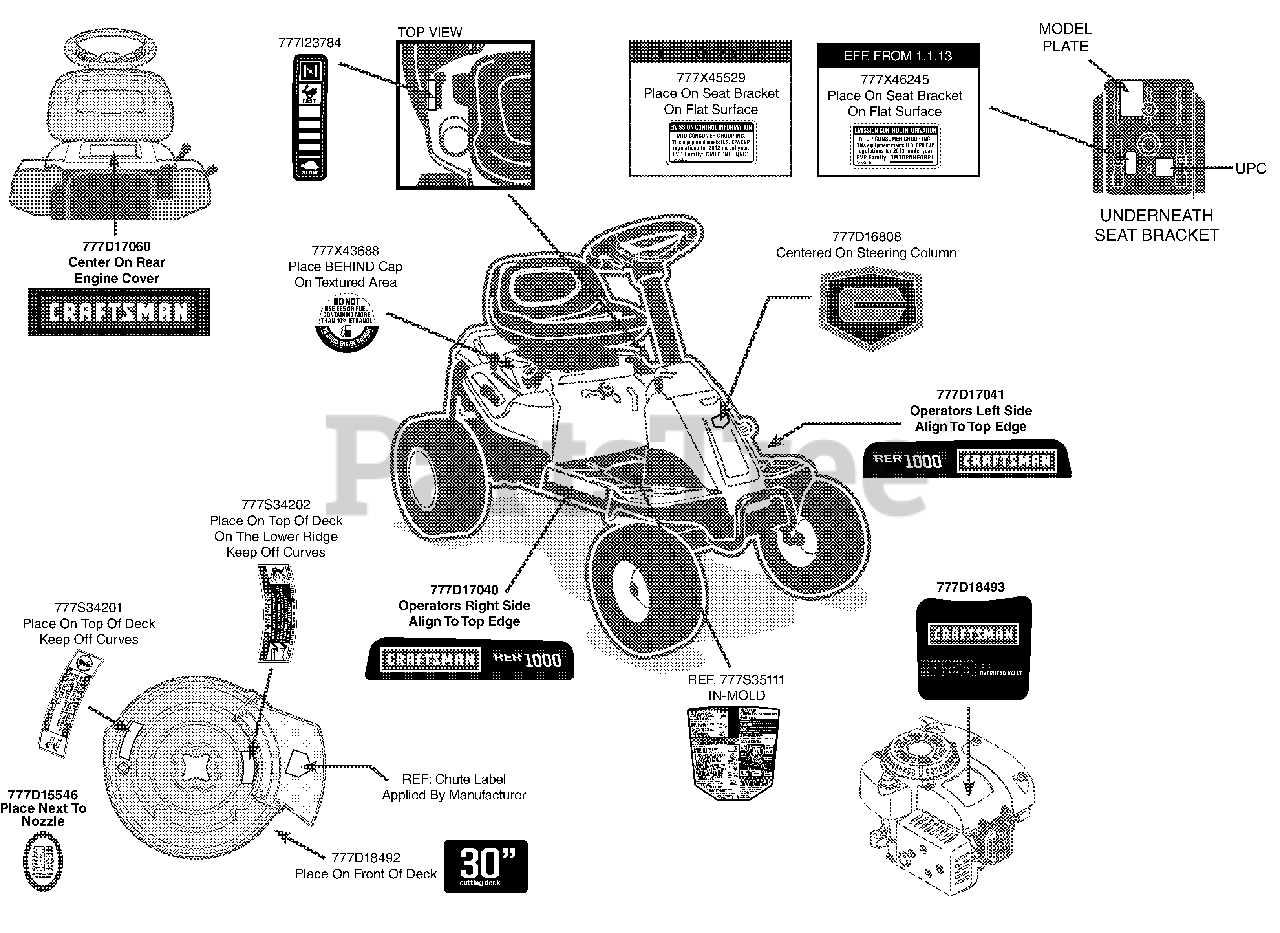

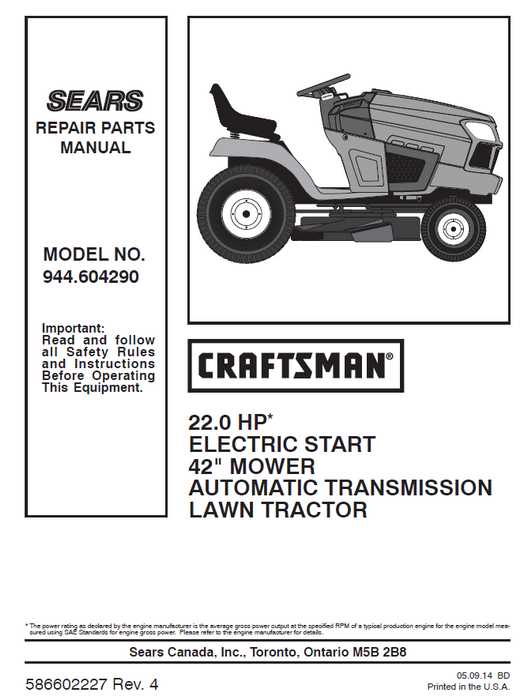

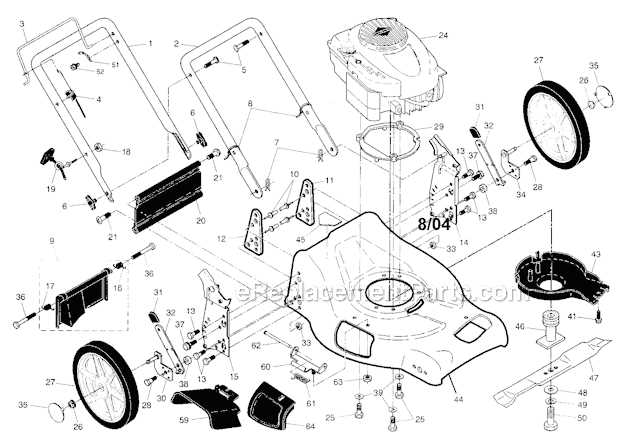

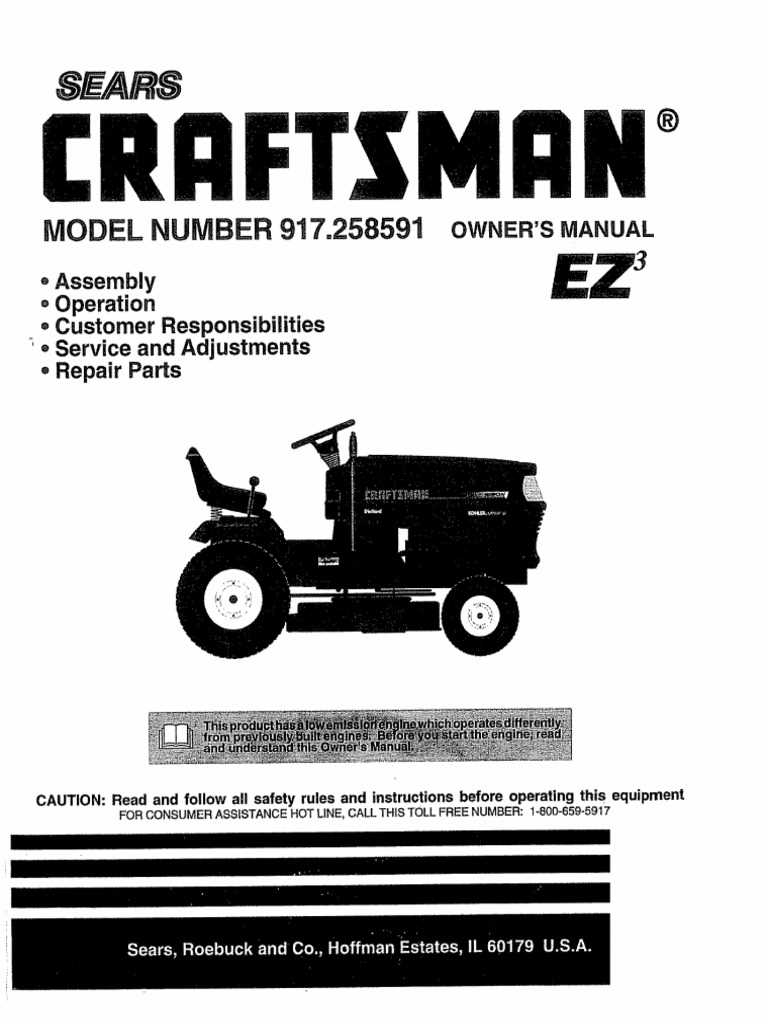

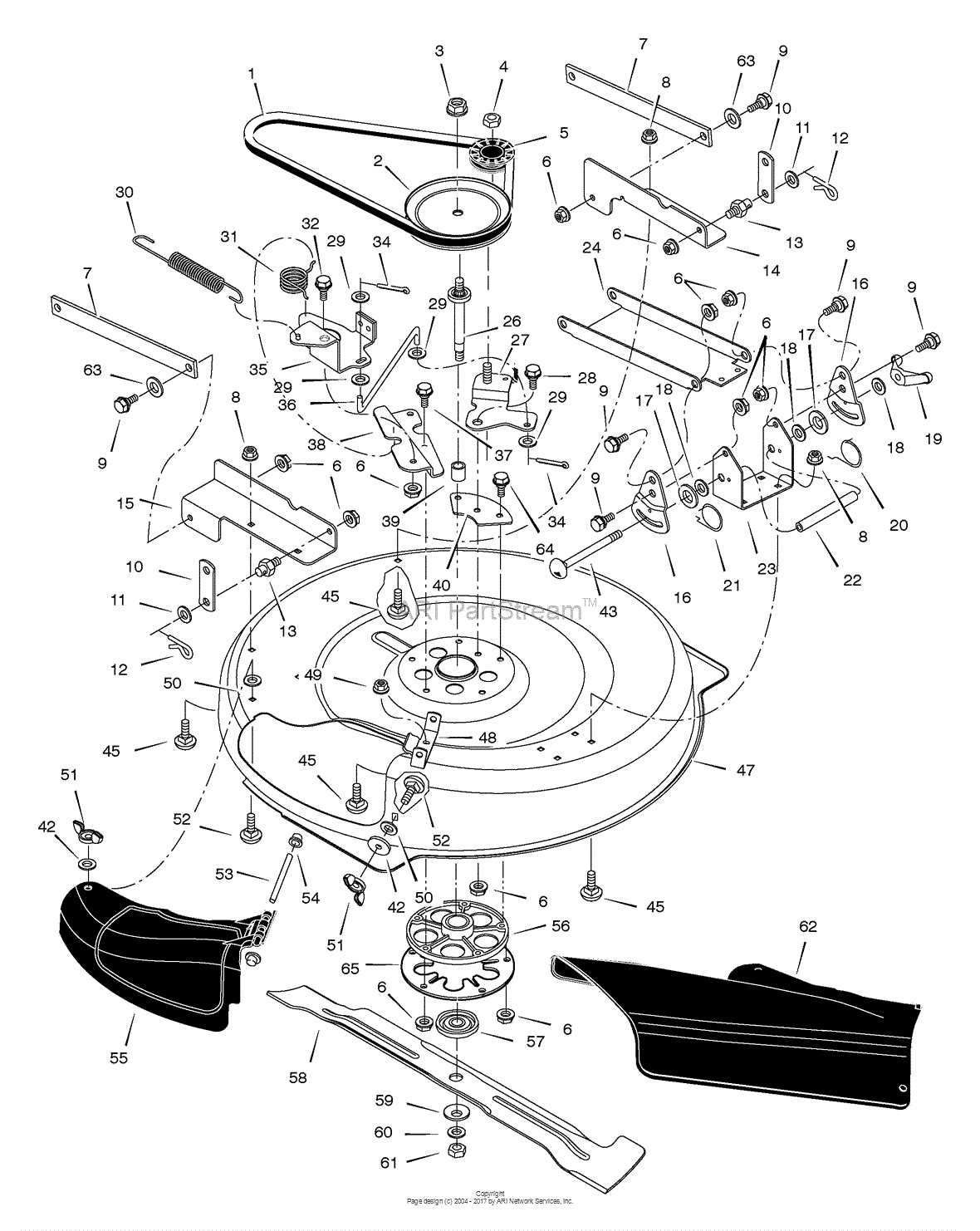

Key Parts of a Riding Mower

Understanding the essential components of a grass-cutting vehicle is crucial for effective maintenance and operation. Each element plays a significant role in the overall functionality, contributing to a smooth and efficient experience. Below, we explore the vital elements that make up these machines.

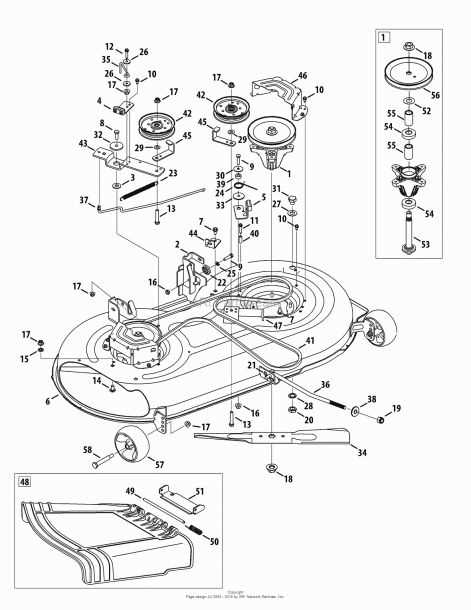

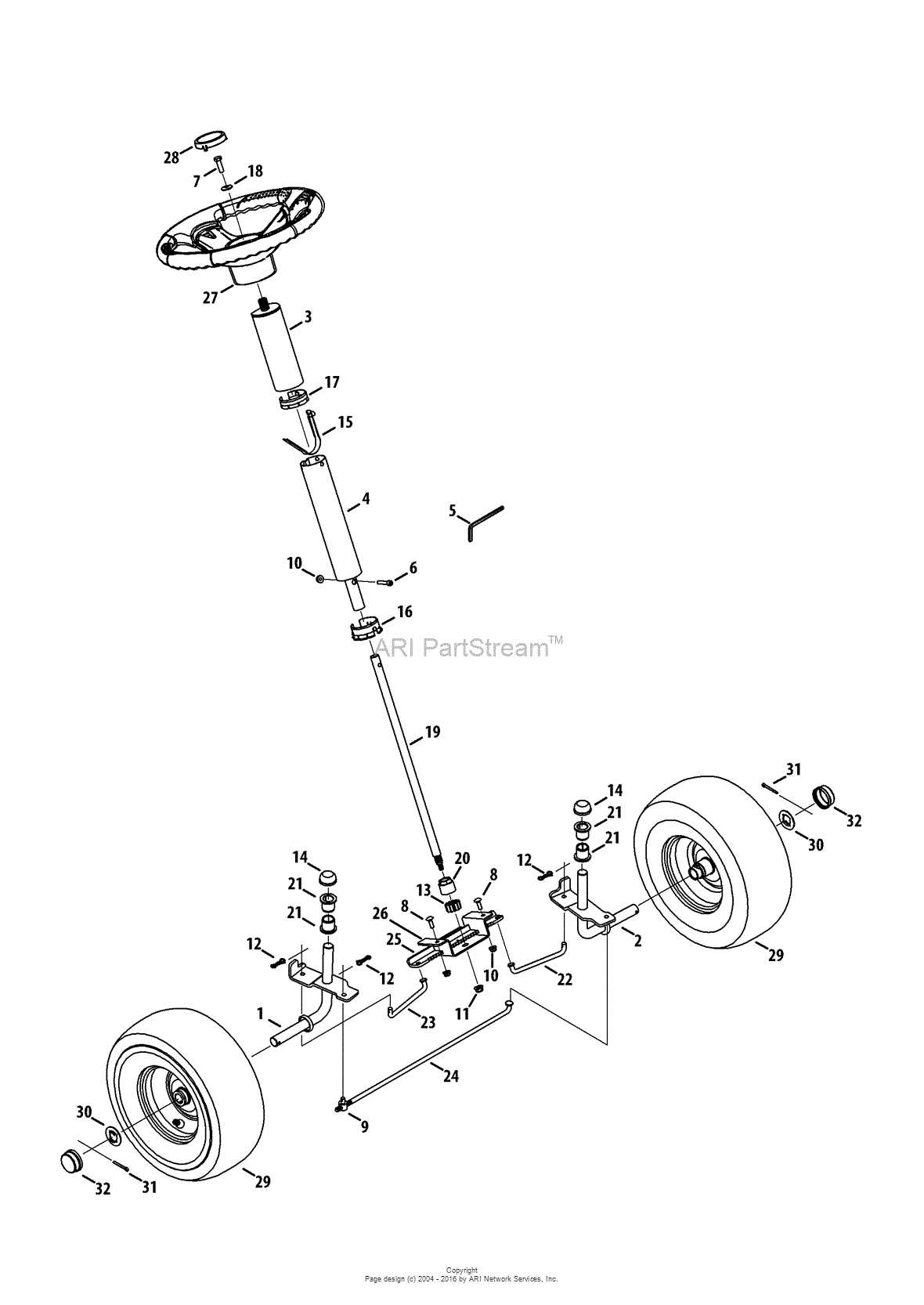

One of the primary features is the cutting mechanism, which ensures precise trimming of the grass. Additionally, the propulsion system allows for smooth movement across various terrains. The power source serves as the heart of the vehicle, providing the necessary energy for operation. Other important components include the steering assembly, which enhances maneuverability, and the chassis that supports all parts, ensuring stability during use.

Functionality of Each Component

This section delves into the roles played by various elements within a mechanical system, highlighting how each part contributes to the overall operation. Understanding these functions is crucial for effective maintenance and troubleshooting.

Core Elements and Their Roles

- Fuel System: Responsible for delivering the necessary fuel to the combustion area, ensuring efficient energy production.

- Ignition Assembly: Generates the spark required to initiate combustion, playing a pivotal role in starting the system.

- Cooling Mechanism: Maintains optimal operating temperatures, preventing overheating and potential damage.

Supporting Components

- Transmission Unit: Facilitates the transfer of power to the driving wheels, ensuring smooth movement.

- Exhaust System: Expels combustion byproducts, helping to maintain air quality and performance.

- Frame Structure: Provides stability and support, housing all components securely during operation.

Maintenance Tips for Longevity

Ensuring the extended life of your outdoor machinery requires consistent care and attention. Implementing a routine maintenance schedule can significantly enhance performance and prevent costly repairs. Here are some essential practices to consider.

Regular Inspections

- Check fuel levels and quality regularly to avoid starting issues.

- Inspect belts and cables for signs of wear or damage.

- Examine wheels and tires for proper inflation and tread wear.

Cleaning and Storage

- Keep the exterior clean to prevent rust and corrosion.

- Store in a dry location to protect from moisture and extreme temperatures.

- Remove debris from undercarriage to enhance airflow and performance.

Following these simple guidelines can lead to improved efficiency and a longer lifespan for your machinery.

Troubleshooting Common Issues

Maintaining optimal performance in outdoor machinery requires addressing various challenges that may arise during operation. Understanding typical malfunctions and their solutions is essential for ensuring longevity and efficiency.

Identifying Performance Problems

When equipment fails to operate as expected, identifying the root cause is crucial. Common signs include unusual noises, difficulty starting, or inconsistent power delivery. Troubleshooting these issues often involves checking essential components and connections.

Common Issues and Solutions

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Engine Won’t Start | Fuel supply problem | Check fuel levels and lines for blockages |

| Overheating | Clogged cooling system | Clean air filters and cooling fins |

| Uneven Cutting | Worn blades | Sharpen or replace cutting blades |

| Excessive Vibration | Loose components | Tighten all fasteners and inspect for damage |

Tools Needed for Repairs

When it comes to maintaining and fixing machinery, having the right tools is essential for a successful outcome. Various implements and devices are required to ensure that repairs are carried out efficiently and effectively, minimizing downtime and enhancing performance.

Here is a list of essential tools that will aid in the repair process:

- Socket Set: Ideal for loosening and tightening bolts.

- Wrench Set: Necessary for gripping and turning fasteners.

- Screwdriver Set: Useful for various types of screws encountered during repairs.

- Pliers: Essential for gripping and bending components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Multimeter: Important for testing electrical connections and diagnosing issues.

- Fuel Line Pliers: Specifically designed to manage fuel lines safely.

- Oil Drain Pan: Necessary for collecting fluids during maintenance tasks.

By utilizing the appropriate tools, you can significantly improve the quality of your repairs and prolong the lifespan of your equipment.

Identifying Wear and Tear

Recognizing signs of degradation in mechanical components is essential for maintaining optimal performance. Regular inspection can help pinpoint issues before they escalate, ensuring the longevity of the equipment.

Visual Inspection: Begin by examining surfaces for cracks, rust, or unusual discoloration. Such signs often indicate underlying problems that require immediate attention.

Functional Testing: Evaluate the operational aspects of the machinery. Listen for unusual noises during operation, which may signal worn bearings or misaligned parts.

Performance Metrics: Monitor performance metrics like power output and efficiency. A noticeable drop can suggest that certain elements are not functioning as intended, warranting further investigation.

Regular Maintenance: Implementing a routine maintenance schedule can significantly reduce the risk of wear. Regularly lubricate moving components and replace any degraded materials to maintain peak functionality.

Safety Precautions During Work

Ensuring a secure working environment is crucial when handling mechanical equipment. Adopting the right safety measures not only protects individuals but also enhances the efficiency of the task at hand.

Before beginning any maintenance or repair activities, consider the following essential precautions:

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Keep the workspace clean and free of clutter to prevent accidents.

- Ensure that the equipment is turned off and disconnected from the power source before starting any work.

- Use tools and equipment that are in good condition and suitable for the task.

- Familiarize yourself with the manufacturer’s guidelines and safety instructions.

- Never work alone; have someone nearby in case of emergencies.

By following these guidelines, you can minimize risks and ensure a safe and productive experience while maintaining your machinery.

Replacement Parts and Compatibility

When it comes to maintaining outdoor machinery, understanding the components and their interchangeability is crucial for optimal performance. Selecting the right substitutes can enhance efficiency and prolong the lifespan of the equipment.

Identifying Suitable Alternatives

To ensure smooth operation, it is essential to verify that any chosen replacements match the specifications of the original elements. This includes examining dimensions, materials, and functionality to avoid compatibility issues.

Quality Considerations

Investing in high-quality alternatives can significantly impact the overall performance and reliability of the equipment. Always consider reputable suppliers that offer reliable components to ensure lasting durability and efficiency.

Assembly and Disassembly Guidelines

Understanding the processes of assembling and disassembling machinery components is essential for effective maintenance and repairs. This section provides comprehensive instructions to ensure a smooth workflow and prevent potential issues.

Before beginning, it is crucial to gather the necessary tools and materials. Ensure you have:

- Wrenches and sockets

- Screwdrivers

- Pliers

- Safety goggles and gloves

Follow these steps for disassembly:

- Ensure the machine is powered off and disconnected from any electrical source.

- Carefully remove any protective covers to access internal components.

- Document the arrangement of parts as you remove them for easier reassembly.

- Store small components in labeled containers to avoid loss.

For assembly:

- Refer to your documentation to ensure each part is returned to its original position.

- Tighten screws and bolts to the manufacturer’s specified torque.

- Replace protective covers securely.

- Test the assembly for proper function before full operation.

Upgrading Your Engine System

Enhancing your power unit can significantly improve performance and efficiency. By considering various upgrades, you can achieve better output and longevity, ensuring that your equipment runs optimally for years to come.

Benefits of Upgrading

Investing in upgrades can yield numerous advantages, such as increased horsepower, improved fuel efficiency, and reduced emissions. These enhancements not only elevate the performance of your machine but also contribute to a more environmentally friendly operation.

Key Components for Consideration

When planning your upgrade, focus on critical components that can make a difference:

| Component | Description | Benefits |

|---|---|---|

| Intake System | Enhances airflow to the combustion chamber. | Boosts power and efficiency. |

| Exhaust System | Improves gas flow out of the system. | Reduces back pressure and enhances performance. |

| Ignition System | Upgrades spark delivery for better combustion. | Increases reliability and power output. |

Resources for Further Learning

For those eager to deepen their understanding of small machinery and its components, a wealth of resources is available. These materials cater to various learning preferences, from hands-on experiences to theoretical knowledge, enabling enthusiasts and professionals alike to enhance their skills.

Online Tutorials and Courses

Numerous websites offer comprehensive tutorials and courses focused on machinery maintenance and repair. These platforms often feature videos, step-by-step guides, and interactive forums, allowing learners to engage with experts and fellow enthusiasts.

Books and Manuals

Books dedicated to mechanical systems provide in-depth insights into design and function. Look for manuals that specifically cover maintenance procedures and troubleshooting techniques to gain a thorough grasp of the subject.