Understanding the structure and function of various mechanical elements within a lawn maintenance machine is crucial for proper operation and upkeep. These elements work together to ensure smooth and efficient performance, making it important to have a clear guide on their placement and connections.

For those involved in the repair or enhancement of such a machine, having a well-organized visual layout of its inner workings can simplify the process. This detailed visualization helps to pinpoint specific mechanisms, ensuring that adjustments or replacements can be done with precision.

The following sections will provide an insightful look into how different components are arranged, aiding in both routine maintenance and complex repairs. By following these guidelines, users can enhance the longevity and performance of their lawn equipment.

Understanding the Components of a Craftsman Riding Mower

Each mechanical tool designed for maintaining lawns is a complex assembly of various systems working together to deliver smooth operation. The key to maximizing the efficiency and longevity of such a machine lies in having a clear understanding of the fundamental components that allow it to function effectively.

The power source, typically an internal combustion engine, drives the mechanism, ensuring that the device has sufficient force to perform its intended tasks. Connected to this is the transmission, which is responsible for translating engine power into motion, allowing the machine to navigate terrain with ease.

Next, the cutting system forms the heart of the tool, equipped with blades that are engineered to handle a range of grass types and densities. This system often features adjustable height settings, enabling users to customize their experience depending on the landscape.

The steering and control mechanisms allow for easy maneuver

Engine Assembly and Key Functions

The heart of any mechanical system is the engine, a complex arrangement of interconnected components that work together to provide power. Understanding how these elements fit and function ensures smoother operation and extended lifespan. The following section offers insights into the core mechanisms and their roles within the engine’s overall structure.

Primary Components of the engine include the cylinder, crankshaft, and piston, which convert fuel into kinetic energy. Each part is meticulously designed to handle precise tasks, allowing the system to function efficiently. Maintaining these elements in proper working condition is crucial for optimal performance.

Additional Features such as the air filter, carburetor, and cooling system play key supporting roles in ensuring that the engine runs smoothly. These auxiliary parts prevent overheating, regulate airflow, and maintain a balance between fuel and air for combustion.

The combination of these parts enables the powertrain to perform its duties, driving the machine forward and handling diverse tasks. Regular inspection and care of these components are vital for long-term reliability

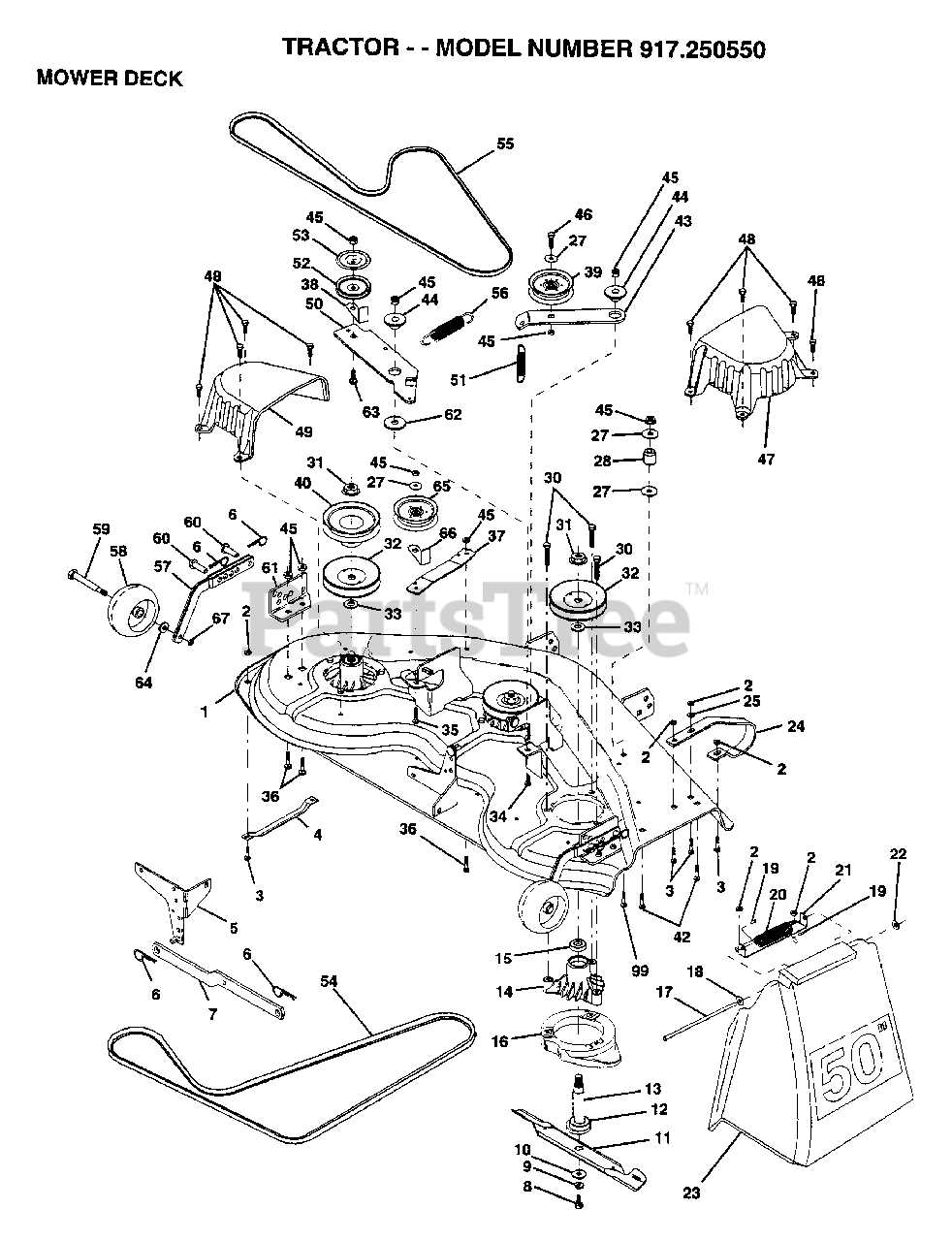

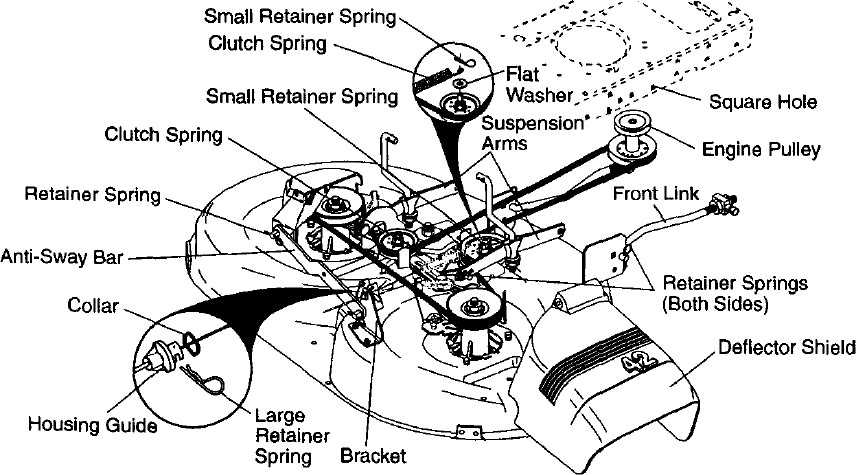

Exploring the Cutting Deck Mechanism

The cutting deck mechanism is an essential component for maintaining a well-groomed lawn. It is responsible for the smooth and efficient trimming of grass, ensuring even results across a wide area. Understanding how this system operates helps in identifying issues and optimizing performance for consistent outcomes.

Key Components and Their Functions

The mechanism consists of several vital elements working in tandem. Blades are the primary tools for cutting, rotating at high speed to trim grass to the desired length. They are mounted on spindles that allow the blades to spin freely. The belt transfers power from the engine to the blades, keeping the system running smoothly. Adjustments to the height of the deck enable control over the grass length, providing flexibility for different lawn conditions.

Maintenance and Optimization

Regular upkeep of the mechanism is crucial for long-term efficiency. Cleaning debris and inspecting the blades for sharpness ensures that the system operates at its best. Additionally, tightening belts and lubricating spindles contribute to the overall longevity and performance, helping to avoid uneven cuts or mechanical issues. Proper attention

Transmission and Drive System Overview

The transmission and drive mechanisms play a crucial role in ensuring the smooth operation and efficient movement of the machine. These systems are responsible for translating engine power into motion, allowing for seamless transitions between different speeds and directions. Understanding the components and functionality of these systems is essential for maintaining optimal performance and longevity.

Transmission is the key element that manages power distribution. It regulates the machine’s speed and adjusts torque to suit different terrains and tasks. Whether it’s a manual or automatic system, proper upkeep is necessary to avoid wear and ensure smooth shifts during operation.

The drive system complements the transmission by controlling how power is transferred to the wheels. Various components, such as belts, pulleys, and gears, work in unison to provide the necessary traction and control. Regular inspection and maintenance of these elements can prevent issues related to slipping or loss of power.

Steering Mechanism and Linkage Parts

The steering system plays a crucial role in controlling the vehicle’s direction and overall maneuverability. This section provides an overview of the various components that contribute to the seamless operation of the steering assembly. These elements work together to ensure smooth handling, responsive feedback, and precise control, enhancing the overall driving experience.

Steering Wheel and Column Assembly

The steering wheel connects to the column, which transfers the driver’s input to the linkage system. The column assembly includes joints and bushings that allow for smooth rotation, maintaining proper alignment and minimizing resistance during operation. Ensuring these components are in good condition is essential for optimal performance and safety.

Linkage and Tie Rods

The linkage system consists of tie rods and connecting arms that transmit motion from the column to the wheels. These parts are responsible for translating rotational movement into the directional control of the front wheels. Proper alignment and maintenance of the linkage ensure that the vehicle turns accurately and responds effectively to steering inputs.

Inspecting the Blade Attachments

Ensuring optimal performance of your equipment involves a thorough examination of the cutting components. Regular checks can prevent uneven cutting and extend the lifespan of the attachments. Proper inspection routines can reveal wear and tear, allowing for timely maintenance and replacements, thereby enhancing efficiency during operation.

Checking for Wear and Damage

Begin by visually inspecting the blade attachments for any signs of damage. Look for chips, cracks, or excessive wear on the edges. These imperfections can compromise cutting performance and lead to further issues if not addressed promptly. Ensure that the blades are securely fastened and free from debris that could hinder their function.

Alignment and Height Adjustment

Next, verify the alignment of the cutting components. Misalignment can result in uneven cuts and increased strain on the equipment. Adjust the height settings to ensure the blades are positioned correctly for the intended cutting height. Regularly calibrating these settings is crucial for achieving the desired results and maintaining the integrity of the attachments.

How the Fuel System is Structured

The fuel system of a lawn care vehicle plays a crucial role in ensuring efficient engine performance and operation. It is designed to store, filter, and deliver the fuel to the engine while maintaining optimal pressure and flow. This system typically comprises several key components that work together to facilitate the combustion process effectively.

At the core of the fuel system is the tank, which serves as the reservoir for the fuel. From the tank, the fuel is drawn through a series of lines that connect to a fuel pump. This pump is responsible for transporting the fuel under pressure to the engine. In addition to the pump, a filter is integrated into the system to eliminate any contaminants that could potentially harm the engine. Proper filtration is essential for maintaining engine longevity and performance.

Once the fuel reaches the engine, it passes through a carburetor or fuel injector, where it is mixed with air before entering the combustion chamber. The precise ratio of fuel to air is vital for achieving efficient combustion and maximizing power output. Finally, the fuel system includes various valves and sensors that monitor and regulate the fuel flow, ensuring that the engine receives the right amount of fuel for different operating conditions.

Examining the Electrical System Layout

The electrical system in a lawn care vehicle plays a crucial role in ensuring efficient operation and optimal performance. Understanding the configuration of this system is essential for troubleshooting and maintenance. By exploring the arrangement of components, users can gain insights into how power is distributed and managed throughout the machinery.

In this section, we will delve into the various elements that comprise the electrical configuration, including:

- Batteries

- Wiring harnesses

- Fuses

- Switches

- Relays

- Ignition systems

Each component serves a specific function, contributing to the overall reliability and efficiency of the equipment. A clear understanding of their arrangement and interconnections can significantly aid in diagnosing issues and performing necessary repairs. Below are some key aspects of the electrical setup:

- Batteries: The primary power source, supplying energy to the system.

- Wiring Harnesses: These facilitate connections between various electrical parts, ensuring proper communication.

- Fuses: Acting as safety devices, fuses protect the system from overloads.

- Switches: Control the flow of electricity, enabling operation of different functions.

- Relays: Allow low-power circuits to control high-power devices.

- Ignition Systems: Essential for starting the engine, involving various electrical components.

By examining these elements and their relationships, operators can maintain the functionality of the machine and prevent potential electrical failures. Regular inspections and knowledge of the system’s layout are vital for ensuring a smooth operation.

Brake and Clutch System Components

The braking and engagement mechanisms of a lawn maintenance machine are crucial for ensuring safety and operational efficiency. Understanding the various elements that comprise these systems is essential for effective maintenance and troubleshooting. Each component plays a vital role in the overall functionality, providing both control and reliability during operation.

Key Components

- Brake Pedal: The primary interface for the operator to engage the braking system, allowing for controlled stopping.

- Clutch Pedal: This component facilitates the engagement and disengagement of the transmission, enabling smooth operation.

- Brake Pads: These elements create friction against the brake disc or drum to slow down or stop the vehicle.

- Clutch Disc: A friction component that transfers power from the engine to the transmission when engaged.

- Linkage System: A series of rods and connectors that transmit force from the pedals to the brakes and clutch, ensuring responsive control.

- Hydraulic System: In some setups, hydraulics are used to enhance the effectiveness of both braking and clutch engagement.

Maintenance Tips

- Regularly inspect the brake and clutch pedals for wear and proper operation.

- Check the condition of brake pads and replace them as needed to ensure effective stopping power.

- Lubricate the linkage system to prevent stiffness and ensure smooth operation.

- Monitor fluid levels in hydraulic systems and replace fluids as per the manufacturer’s recommendations.

- Consult the maintenance manual for specific adjustments and part replacement guidelines.

Understanding the Seat and Safety Switches

The relationship between seating mechanisms and safety switches is critical for ensuring safe operation of lawn equipment. These components work together to enhance user safety by preventing accidental engagement of the machinery when the operator is not in a secure position. Recognizing how these elements function is essential for both effective maintenance and safe usage.

Typically, the seating area is designed to accommodate the operator comfortably while incorporating vital safety features. Here are some key aspects to consider:

- Seat Design: The seat is engineered for ergonomic support, allowing users to operate the equipment with ease.

- Safety Mechanisms: Safety switches are integrated to ensure that the engine will not run unless the operator is properly seated.

- Importance of Proper Function: Regular checks on the seat and associated switches are necessary to ensure they are functioning correctly. A malfunction could lead to unexpected equipment behavior.

In conclusion, understanding the interplay between the seat and safety switches is essential for both effective usage and maintenance. Ensuring these components are in good condition will contribute significantly to a safer working environment.

The Role of Wheels and Tires in Performance

The significance of wheels and tires in enhancing functionality cannot be overstated. They serve as the primary interface between the equipment and the ground, influencing various aspects such as traction, stability, and maneuverability. Optimal performance relies heavily on the appropriate selection and maintenance of these components.

Impact on Traction and Stability

Wheels and tires are crucial for maintaining grip on various terrains. The tread pattern and rubber composition play vital roles in how well the machinery can navigate challenging surfaces. Adequate traction minimizes slippage, allowing for effective handling during operation. Stability is equally important, as wider tires can distribute weight more evenly, reducing the risk of tipping over on slopes.

Influence on Maneuverability

The design of wheels also affects how easily the equipment can change direction. Smaller, more agile wheels enable sharper turns, while larger wheels can provide a smoother ride over uneven ground. This balance between size and agility is essential for achieving desired performance outcomes in different environments.

| Feature | Importance |

|---|---|

| Traction | Prevents slippage and enhances control |

| Stability | Reduces risk of tipping and improves safety |

| Maneuverability | Facilitates easier navigation and operation |

| Tread Pattern | Affects grip and performance on different surfaces |

Mower Belt Routing and Maintenance Tips

Ensuring optimal performance of your lawn care equipment requires a proper understanding of the belt configuration and routine upkeep. The belt system plays a crucial role in the functioning of the machine, transmitting power efficiently. Regular maintenance and correct routing are essential for preventing wear and tear, ensuring longevity, and maintaining performance.

Correct Routing of the Drive Belt

Proper alignment of the drive belt is vital for smooth operation. Following the designated routing paths helps in preventing slippage and unnecessary friction. Below is a simple table illustrating the general routing steps for the drive belt:

| Step | Action |

|---|---|

| 1 | Locate the tensioner pulley and release the tension. |

| 2 | Position the belt around the engine pulley first. |

| 3 | Guide the belt over the idler pulley. |

| 4 | Ensure the belt is securely placed on the driven pulley. |

| 5 | Reapply tension using the tensioner pulley. |

Maintenance Practices

Routine inspection and maintenance of the belt system are imperative for effective operation. Here are some tips to keep in mind:

- Check for signs of wear, such as cracks or fraying.

- Ensure that the belt is properly tensioned to prevent slipping.

- Clean debris from pulleys to avoid obstruction.

- Lubricate moving parts periodically to reduce friction.

- Replace worn belts promptly to maintain efficiency.

Accessories and Attachments for Versatility

Enhancing functionality is key to maximizing the potential of your equipment. By incorporating various accessories and attachments, users can expand the range of tasks that their machines can handle. These additional components not only improve efficiency but also allow for customized operation tailored to specific needs.

Common Attachments

There is a variety of attachments designed to complement the base machine. Snow blowers are ideal for winter conditions, clearing driveways and pathways effortlessly. Bagging systems assist in maintaining a clean lawn by collecting grass clippings and debris, while plow blades make light work of snow removal or leveling soil.

Functional Accessories

Accessories play a significant role in enhancing performance. Weights can be added for improved traction, especially on uneven terrain. Mulching kits allow for finer grass clipping distribution, enriching the soil and promoting a healthier lawn. Additionally, striping kits provide an aesthetic touch, leaving beautifully defined patterns on your lawn.