Understanding the intricate layout of essential outdoor machinery is key to maintaining peak performance. When dealing with equipment designed for large-scale landscape management, knowing how to identify and replace various elements can help prevent costly repairs and ensure smooth operation over time. This section will explore the critical components that make up these machines, providing insight into how they work together.

From the power system to the cutting blades, each piece plays a vital role in the overall functionality of the unit. Ensuring the proper care and timely replacement of these parts is crucial for the long-term efficiency of your equipment. We’ll delve into the specifics, helping you recognize and address potential issues before they become major concerns.

John Deere Riding Mower Parts Overview

Understanding the various components of a lawn maintenance vehicle is essential for proper upkeep and performance. Each element plays a role in ensuring smooth operation and efficient cutting. Knowing the layout and key features will help users maintain and repair their equipment effectively.

- Engine System: Powers the vehicle and drives the cutting mechanism. Regular maintenance ensures longevity.

- Blades and Cutting Deck: The primary tool for trimming grass, it requires regular sharpening and cleaning to maintain precision.

- Transmission: Controls the speed and movement of the vehicle, often needing inspection for smooth operation.

- Steering and Controls: The user interface for directing and controlling the vehicle’s movement.

- Wheels and Tires: Provide mobility across various terrains,

Key Components of a Riding Mower

Efficient operation of any lawn equipment depends on a number of essential elements working together. These units, often connected through a mechanical system, help ensure smooth functionality and proper maintenance of your garden tools.

Component Description Engine The heart of the machine, providing power for movement and cutting operations. Transmission Controls the speed and direction, ensuring proper maneuverability on various terrains. Cutting Deck Houses the blades and determines the width of the grass cut in a single pass. Understanding Engine Parts for Lawn Tractors

The internal components of a garden vehicle’s motor play a critical role in its overall performance and longevity. From systems responsible for combustion to those managing airflow, each element must work harmoniously for efficient operation. Recognizing these components allows for better maintenance and troubleshooting when issues arise.

Key Components and Their Functions

Engines in these outdoor machines typically consist of several vital sections, including the mechanisms responsible for starting, cooling, and fuel management. Understanding their functionality is essential for keeping the motor running smoothly.

Common Engine Parts Overview

Component Function Cylinder Where combustion occurs to generate power. Spark Plug Ignites the fuel-air mixture to start combustion. Carburetor How Transmission Systems Function

Transmission systems play a critical role in transferring power from the engine to the wheels, ensuring smooth operation and control. These mechanisms adjust speed and torque based on the needs of the terrain, optimizing performance and efficiency. Understanding how these systems operate is key to maintaining overall machine functionality.

Component Function Clutch Engages and disengages power from the engine to the transmission. Gearbox Regulates the torque by selecting different gear ratios for varying conditions. Drive Shaft Transfers rotational power from the transmission to the wheels. Differential Allows the wheels to rotate at different speeds, particularly when turning. Exploring Blade Assembly and Cutting Deck

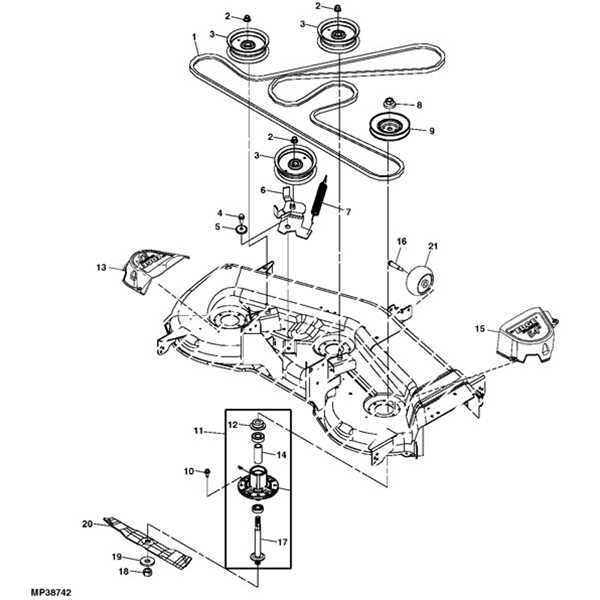

Understanding the structure and function of the cutting system is essential for efficient grass maintenance. The cutting deck, where the blades are housed, plays a key role in achieving smooth, even cuts. Proper assembly ensures that the blades rotate at the right speed and angle, which directly impacts the quality of the cut.

Blade assembly involves securely attaching the blades to the spindle, ensuring alignment and balance. Without proper calibration, the system may vibrate or deliver uneven results. Attention to this area can significantly enhance performance and longevity of the equipment.

Identifying Electrical System Elements

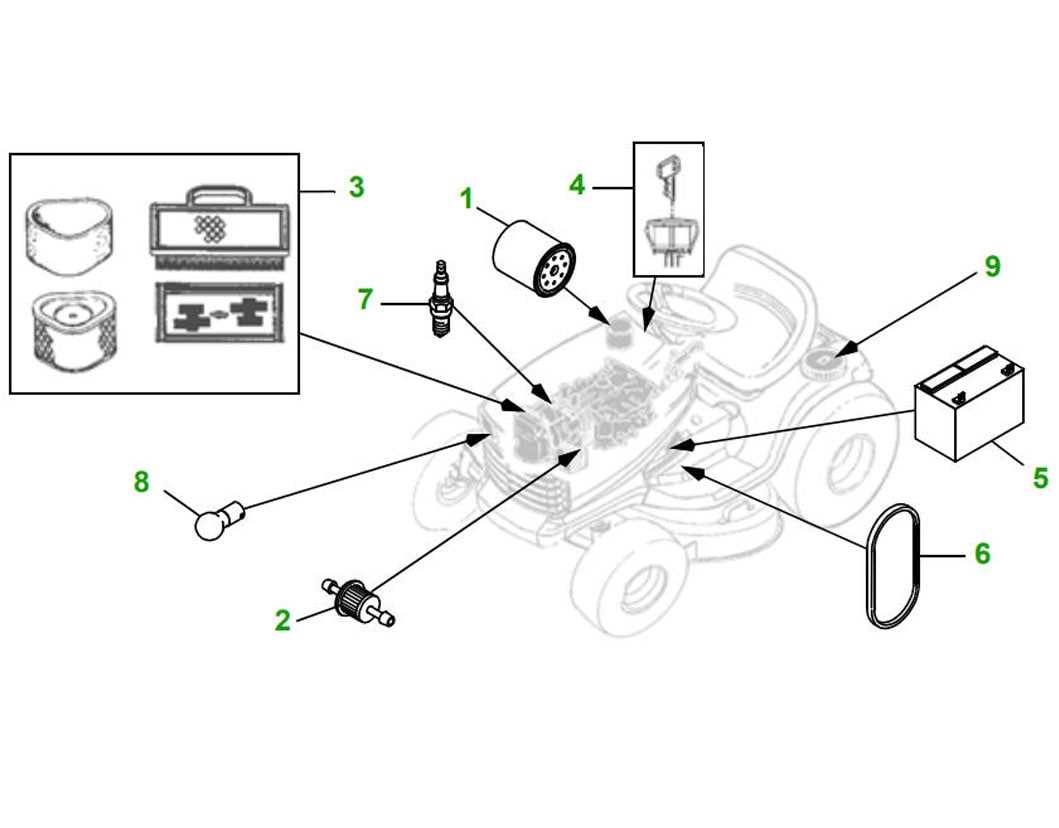

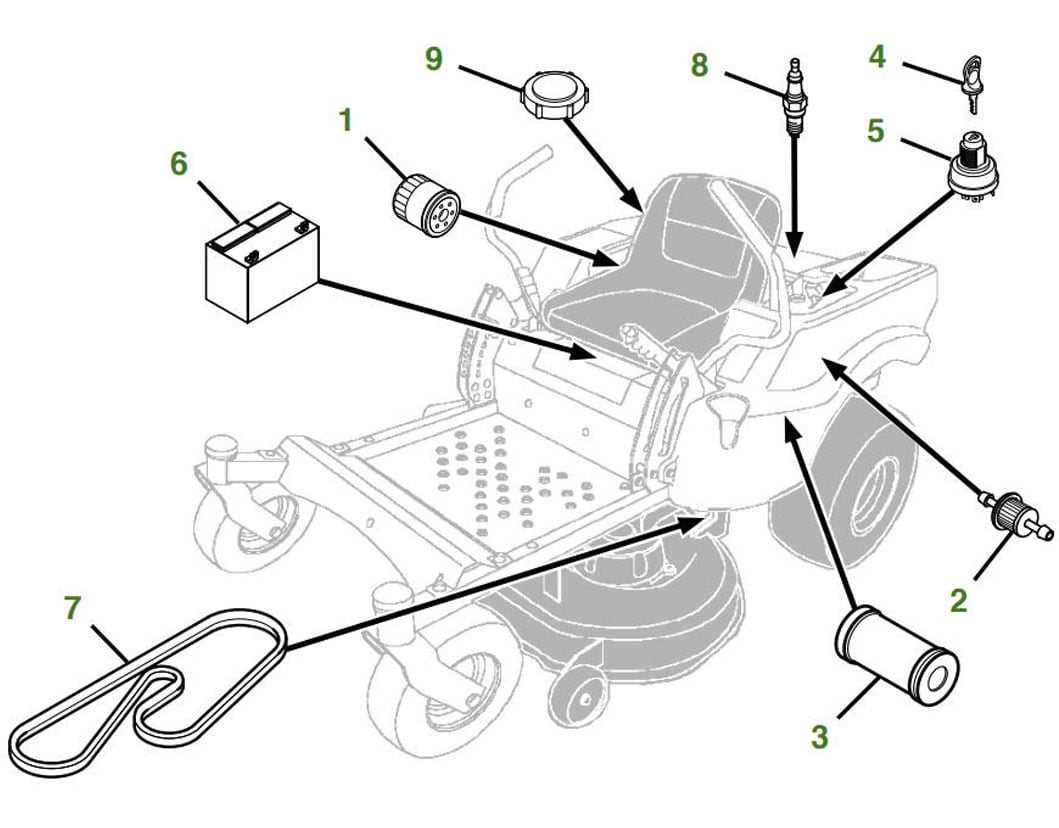

The electrical system in garden equipment plays a crucial role in ensuring optimal performance and functionality. Understanding its components is essential for effective troubleshooting and maintenance. By recognizing the key elements within the circuitry, operators can ensure reliable operation and identify potential issues before they escalate.

Key components of the electrical system typically include the battery, ignition switch, and various connectors. The battery provides the necessary power to start the engine and operate electrical accessories. The ignition switch controls the flow of electricity, allowing the user to start and stop the engine with ease. Connectors link different elements together, ensuring seamless communication within the system.

Additionally, wiring harnesses facilitate the organized routing of electrical signals throughout the machinery. Understanding these components and their functions can significantly enhance the user experience, prolonging the life of the equipment while minimizing downtime.

Fuel System Parts and Maintenance

The fuel system plays a crucial role in ensuring the efficient operation of your machine. Understanding its components and how to maintain them is essential for optimal performance. Proper upkeep not only enhances longevity but also prevents potential issues that can arise from neglect.

Key Components of the Fuel System

This system typically includes various elements such as the fuel tank, fuel lines, filter, and pump. Each part serves a specific function, contributing to the overall efficiency of fuel delivery to the engine. Regular checks of these components help identify wear and tear, allowing for timely replacements.

Maintenance Tips

Routine maintenance is vital for the fuel system’s health. Regularly inspect the fuel lines for cracks or leaks, replace the filter as recommended, and ensure the tank is clean and free of debris. Additionally, using high-quality fuel can prevent clogs and promote better engine performance.

Troubleshooting Common Hydraulic Issues

Hydraulic systems are vital for the effective operation of various equipment, providing the necessary force to perform tasks. However, these systems can experience issues that hinder performance and efficiency. Identifying and resolving common hydraulic problems can help restore functionality and prolong the lifespan of the machinery.

Low Fluid Levels: One of the most frequent issues is insufficient fluid in the reservoir. Ensure the fluid is at the recommended level, as low fluid can lead to inadequate pressure and system failure.

Leaking Components: Inspect the hoses, fittings, and seals for signs of leakage. A leak can drastically reduce pressure and cause operational failures. Replace any damaged components promptly to prevent further issues.

Contaminated Fluid: Fluid contamination can lead to significant problems within the hydraulic system. Regularly check for contaminants and replace the fluid if necessary. Using high-quality fluid will enhance system performance and reliability.

Poor Connection: Loose or corroded connections can disrupt fluid flow. Ensure all connections are tight and in good condition to maintain optimal pressure and functionality.

By addressing these common issues, operators can ensure their hydraulic systems function effectively, reducing downtime and enhancing overall performance.

Steering and Control Mechanism Breakdown

The steering and control system of a lawn vehicle plays a crucial role in ensuring precise maneuverability and comfort during operation. This section delves into the essential components that facilitate smooth navigation and effective handling, allowing the user to maintain optimal control over the machine.

Central to this mechanism is the steering wheel, which is connected to a series of linkages and gears that translate the operator’s input into directional movement. Additionally, the throttle and brake controls are strategically positioned to enhance accessibility and responsiveness, enabling quick adjustments as needed. Understanding the interaction between these elements is vital for proper maintenance and troubleshooting.

Chassis and Frame Parts Explained

The framework and structural components of a vehicle are critical to its overall functionality and stability. Understanding these elements is essential for effective maintenance and repairs, ensuring the machinery operates efficiently and safely. This section delves into the various structural components, highlighting their roles and significance in the overall design.

Key Structural Components

Within the framework, several key components play vital roles in supporting the vehicle’s weight, facilitating movement, and housing other essential systems. Each part contributes to the durability and performance of the machinery.

Common Features and Functions

Many structural elements exhibit unique features that enhance the performance and longevity of the vehicle. Recognizing these characteristics aids in identifying the right components for replacement or repair.

Component Description Function Frame The main supporting structure Holds all components together and absorbs stress Chassis The base structure including wheels Supports the engine and drivetrain Axles Rod connecting wheels Transfers power to the wheels for movement Brackets Support structures for attachments Secure various components in place Guide to Wheel and Tire Components

The functionality of any landscaping equipment heavily relies on the wheel and tire assembly. This section delves into the essential elements that constitute this critical aspect, enhancing the overall performance and stability of the machinery. Understanding these components is vital for maintaining efficiency and ensuring a smooth operation on various terrains.

Wheels are the foundation that supports the weight of the equipment while providing a stable platform for movement. They come in different sizes and materials, designed to handle specific loads and conditions. The choice of wheel influences traction, maneuverability, and durability.

Tires, on the other hand, are the contact points with the ground, affecting grip and stability. Available in various tread patterns, they are tailored for different surfaces, such as grass, gravel, or uneven terrain. Selecting the right tires can significantly improve traction and minimize slippage, ensuring safe navigation during operation.

Additionally, it is crucial to consider components like wheel bearings and rim assemblies, which play a significant role in the functionality and longevity of the equipment. Regular inspection and maintenance of these elements will help in optimizing performance and preventing premature wear.

Seat, Steering Wheel, and User Controls

The functionality and comfort of a machine heavily depend on its seating arrangement, control mechanisms, and steering apparatus. This section delves into the components that ensure ease of operation and provide the operator with the necessary tools for effective maneuvering.

Comfortable Seating Arrangement

A well-designed seat enhances the user’s experience during operation. Comfort is paramount, especially for extended periods of use. Adjustable features allow operators to customize their seating position, reducing fatigue and improving overall efficiency.

Control Mechanisms

The layout of the steering wheel and control elements plays a crucial role in the usability of the equipment. Intuitive designs enable quick access to essential functions, making the operation smooth and straightforward. Below is a table summarizing key components and their functions:

Component Function Seat Provides comfort and support to the user. Steering Wheel Allows precise control of direction. Throttle Control Regulates engine speed for optimal performance. Brake Pedal Facilitates stopping and safety. Lift Lever Controls the height of attachments. Tips for Maintaining Mower Attachments

Proper upkeep of lawn care implements is essential for ensuring their longevity and optimal performance. By following a few straightforward guidelines, users can enhance the functionality and reliability of these essential tools. Regular attention to maintenance not only helps in achieving better results but also minimizes the risk of unexpected breakdowns.

Regular Inspections

Conducting routine checks is vital for identifying wear and tear early. Examine the implements for any signs of damage, such as rust, cracks, or loose components. Replacing worn parts promptly can prevent further issues and maintain efficiency.

Cleaning and Lubrication

After each use, ensure that all attachments are thoroughly cleaned to remove grass clippings, dirt, and debris. Applying appropriate lubricants to moving parts reduces friction and helps maintain smooth operation. Regular cleaning and lubrication will enhance the lifespan of the attachments and ensure they work at peak performance.