When it comes to maintaining your outdoor equipment, having a clear visual representation of its components is essential. This guide aims to provide an insightful overview of the key elements that make up these machines, ensuring you have the ultimate understanding of how everything fits together.

By delving into the various sections and functions, users can identify crucial areas for repair and enhancement. This not only helps in troubleshooting common issues but also enables enthusiasts to optimize their machinery for better performance.

Whether you’re a seasoned operator or a novice, this exploration will equip you with valuable knowledge. Familiarizing yourself with the intricate workings of your equipment empowers you to take charge of its maintenance effectively.

Understanding Yardman Mower Components

To ensure the efficiency and longevity of your outdoor equipment, it is essential to be familiar with its key mechanical elements. Every machine is made up of various interconnected parts that work together, each serving a distinct function. Understanding how these components operate will help you maintain the equipment and troubleshoot any issues that may arise.

Engine and Power System

The power source is the heart of the equipment, driving all mechanical functions. It transfers energy to the operational mechanisms, allowing them to perform their tasks effectively. Regular maintenance of this system ensures smooth performance and prolongs its lifespan.

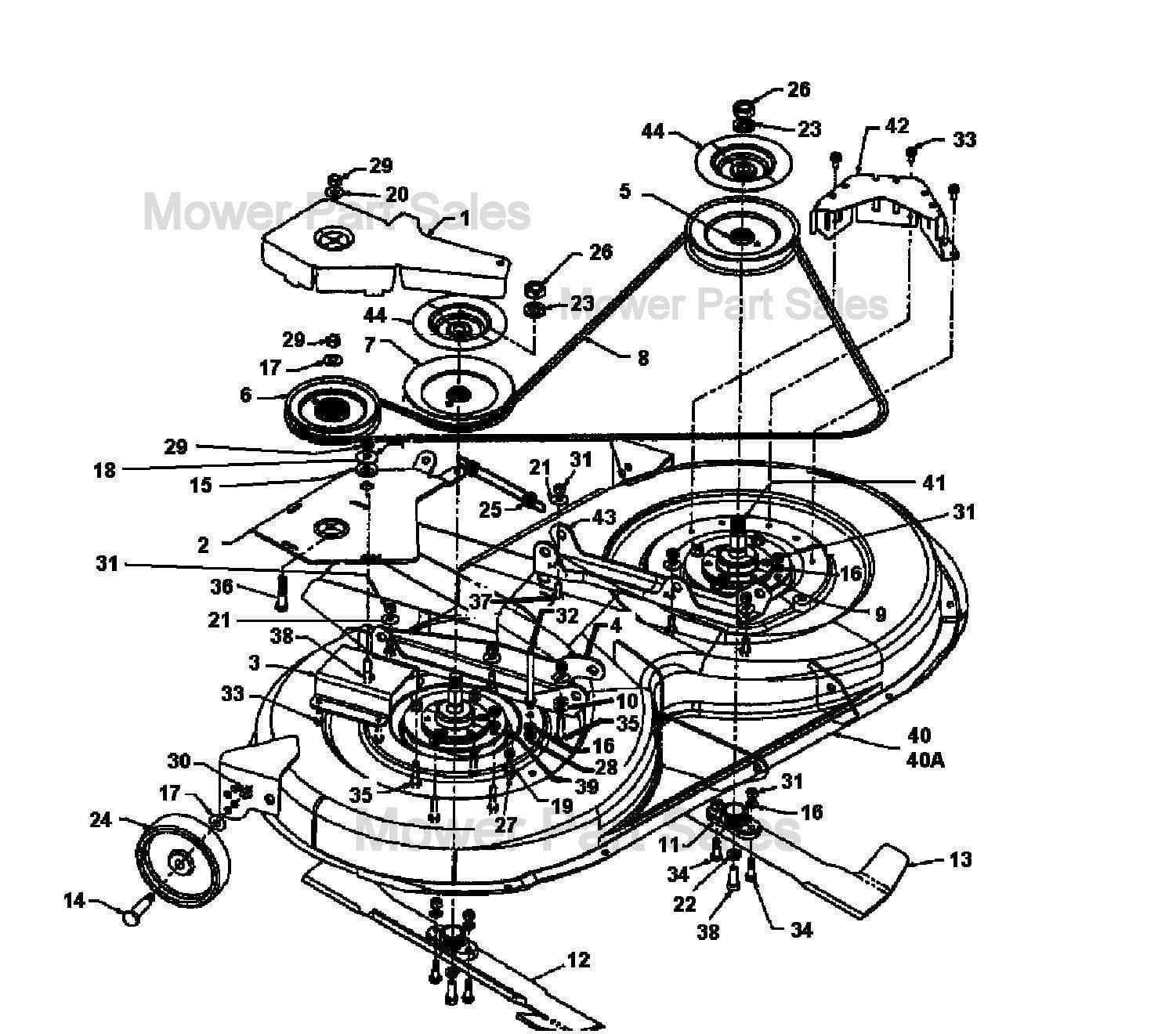

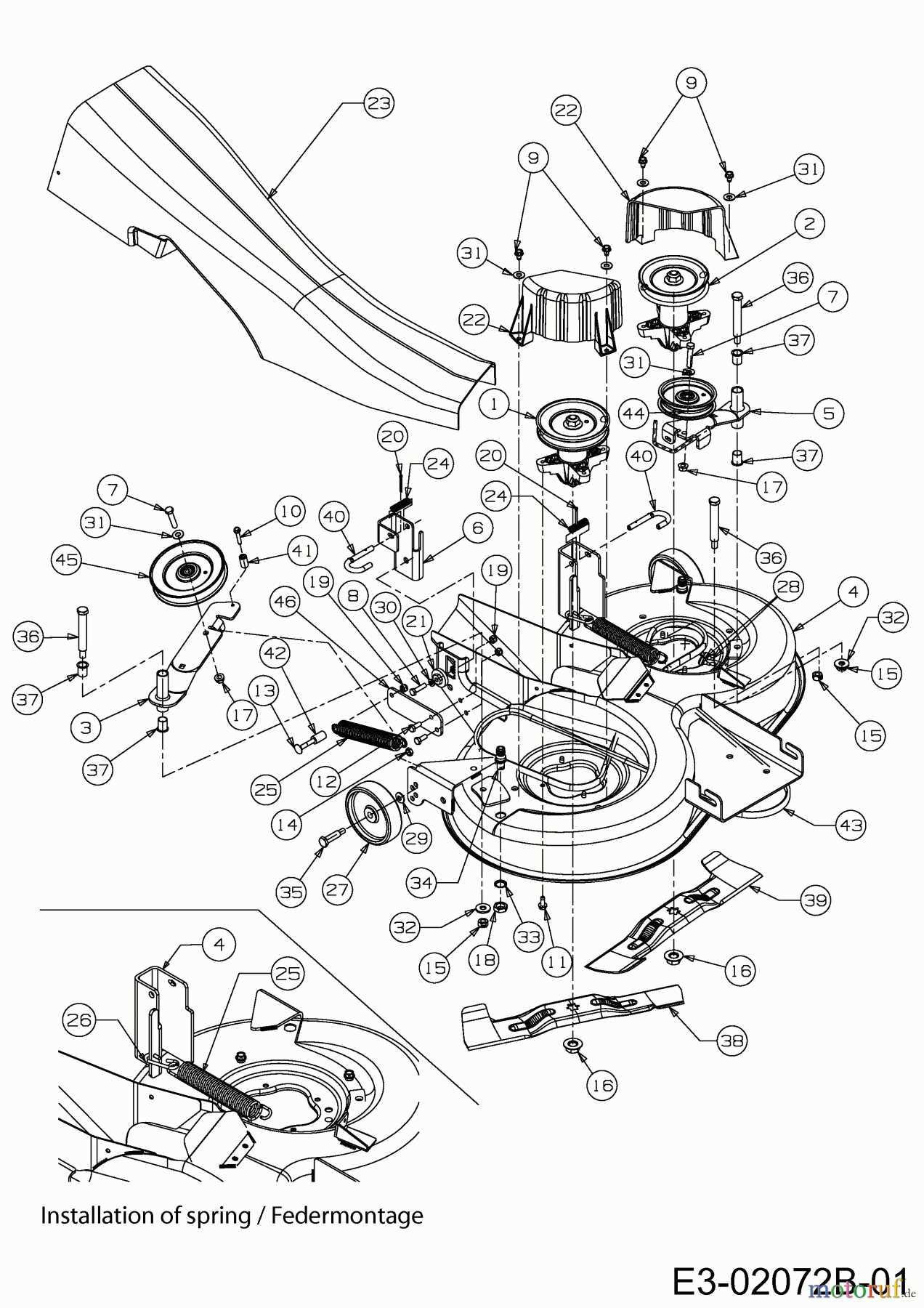

Blades and Cutting Mechanism

The cutting mechanism is responsible for the primary function of the device. It consists of sharp elements designed to handle different surfaces efficiently. Keeping these elements in good condition guarantees a clean and even result with each use.

Key Parts of a Riding Mower

Understanding the essential components of this type of machine is crucial for efficient operation and maintenance. These key elements work together to ensure the machine performs its task effectively and can withstand regular use.

- Engine: The powerhouse that drives the machine forward and operates the cutting system.

- Transmission: This part controls the speed and direction, making it easier to maneuver in different terrains.

- Cutting Deck: The section where the blades are housed, responsible for trimming vegetation at the desired height.

- Steering System: Ensures smooth navigation and precise control when driving the machine.

- Wheels and Tires: Provide stability and traction, ensuring the machine can move across various surfaces without slipping.

- Seat and Controls: The user interface, including the seat for comfort and the controls for managing speed, direction, and blade engagement.

- Blade Engagement System: Activates the blades when it’s time to start cutting, ensuring the machine functions safely and efficiently.

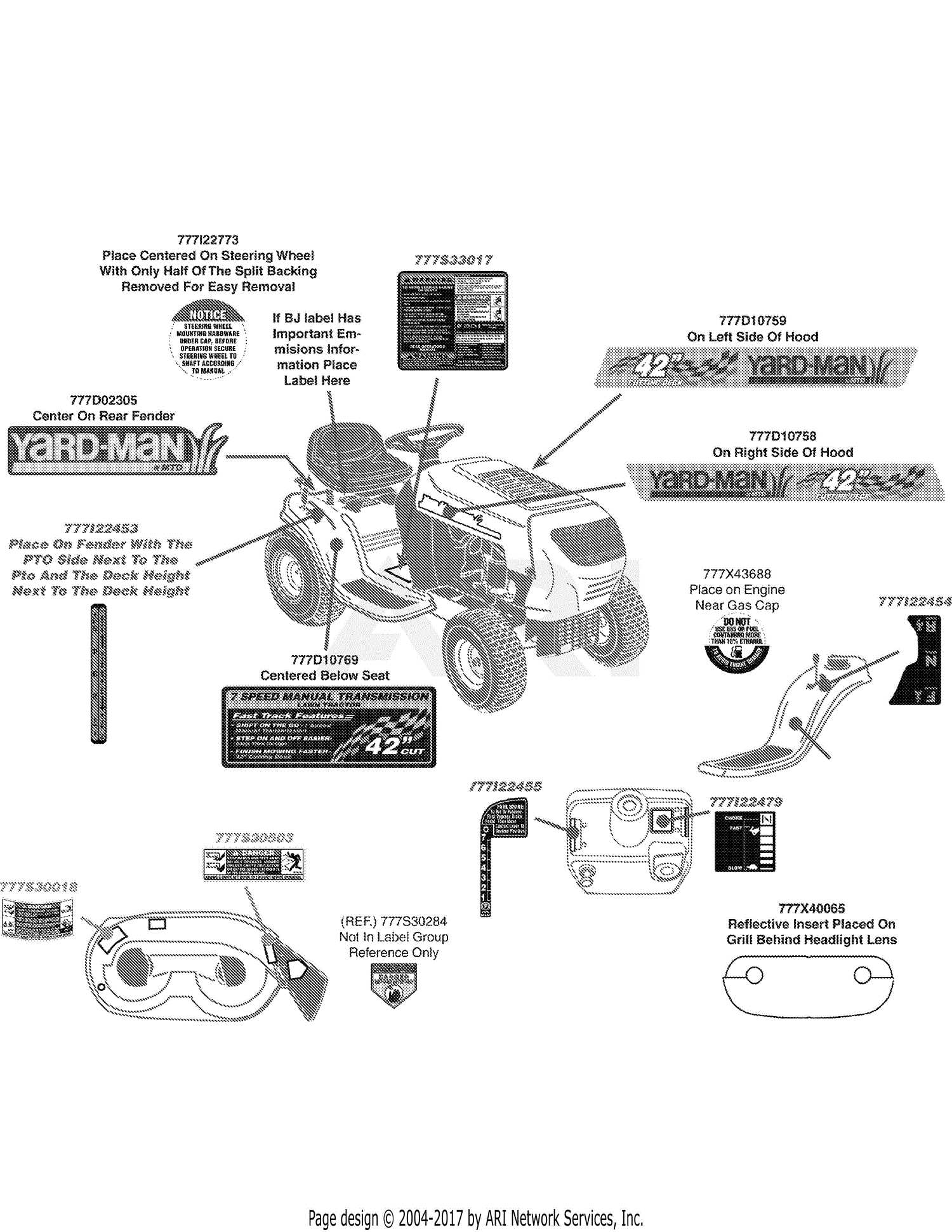

How to Read Parts Diagrams

Understanding equipment schematics is essential for efficient repairs and maintenance. These illustrations offer a clear overview of how different components are connected and function together, making it easier to identify issues and replace elements correctly. Here’s a guide to help you navigate these diagrams with ease.

- Identify symbols: Diagrams use various symbols to represent different components. Familiarize yourself with these symbols to quickly recognize key elements.

- Follow connections: Pay attention to how the elements are linked. Lines and arrows often indicate connections, pathways, or flow directions.

- Check part numbers: Each item is typically labeled with a number, helping to cross-reference with a list of available components or replacements.

- Groupings: Components are often grouped by function. Focus on sections of the diagram that represent specific assemblies or systems.

- Start by examining the overall structure of the diagram.

- Locate the sections that are relevant to your current needs or issues.

- Refer to the legend or key to understand symbols and labels.

- Take note of the part numbers for reference during the repair or replacement process.

Common Issues with Lawn Mower Parts

Equipment used for maintaining outdoor spaces often faces a variety of problems due to wear and tear, environmental conditions, or improper handling. Understanding the most frequent issues can help ensure efficient upkeep and minimize downtime. Below are some of the common malfunctions that can arise with different components.

Engine Troubles

One of the most typical problems is engine failure or difficulty starting. This can result from fuel system blockages, dirty air filters, or spark plug malfunctions. Regular maintenance and timely replacement of these components are essential for ensuring reliable operation.

Blade and Cutting Mechanism Issues

Another frequent challenge involves the cutting system. Dull or damaged blades reduce performance and may leave uneven results. Keeping blades sharpened and properly aligned helps improve cutting precision and extends the equipment’s lifespan.

Maintenance Tips for Yardman Equipment

Proper upkeep of mechanical tools is essential to ensure long-term performance and avoid unexpected breakdowns. Regular attention to various components and thorough inspections will help maintain efficiency and prolong the service life of your outdoor machinery.

Regular Cleaning and Lubrication

Frequent cleaning of all moving parts is crucial to prevent the buildup of debris that could impede smooth operation. Applying lubricants to the necessary components can reduce friction and wear, ensuring that the device runs smoothly over time.

Inspecting Blades and Belts

Sharp cutting elements and tightly secured belts are essential for optimal functionality. It’s important to routinely inspect these components for wear and replace them when necessary. Maintaining sharp blades and properly tensioned belts will result in better performance and reduced strain on the motor.

Where to Find Replacement Parts

Locating suitable substitutes for worn-out components can be a crucial aspect of maintaining your outdoor equipment in top condition. Whether you’re dealing with mechanical issues or routine upkeep, finding the correct items is essential for optimal performance. Many owners turn to a variety of sources to ensure their equipment continues functioning as intended.

Authorized dealers are often a trusted option for acquiring original products, ensuring compatibility and reliability. Additionally, online marketplaces offer a vast selection of alternatives, from official replacements to more affordable third-party options. Local repair shops can also be a valuable resource, as they may carry compatible items or provide helpful guidance in sourcing the correct components.

Identifying Wear and Tear Signs

Recognizing early signs of wear is essential to ensuring the smooth operation of any mechanical equipment. Over time, components undergo stress and can degrade, which may lead to reduced efficiency or even failure. By identifying these signs early, you can prevent larger issues and prolong the machine’s lifespan.

Common Indicators of Component Deterioration

- Unusual noises during operation, such as grinding or screeching sounds.

- Increased vibration, signaling imbalance or misalignment of internal elements.

- Visible cracks or deformities on various parts, which indicate material fatigue.

- Overheating or burning smells, often a result of excessive friction or lack of lubrication.

Inspection Tips to Prevent Further Damage

- Regularly check and replace worn belts or chains that drive essential mechanisms.

- Examine bearings and joints for excessive play or looseness, which can affect overall stability.

- Ensure that moving parts are properly lubricated to minimize friction and wear.

- Keep an eye on fasteners and bolts, tightening any that have loosened over

Tools Needed for Repairs

When it comes to performing maintenance or fixing mechanical equipment, having the right set of tools is crucial for ensuring a smooth and efficient process. Proper tools not only help you work faster but also reduce the risk of causing further damage.

Basic Hand Tools

Essential hand tools such as wrenches, screwdrivers, and pliers are necessary for most repair tasks. These tools allow you to tighten, loosen, and adjust various components without much effort. It’s also a good idea to have a set of sockets in different sizes to fit different types of fasteners.

Specialized Equipment

Depending on the complexity of the repair, you may need specialized equipment like a torque wrench or a pulley remover. These tools are designed to handle more specific tasks that regular hand tools cannot perform effectively, ensuring a more precise repair outcome.

Exploring Different Yardman Models

When looking at various models available on the market, it’s important to understand the unique features that each version offers. These machines cater to different needs and sizes of outdoor spaces, making them versatile tools for maintaining your environment. Depending on the type of terrain and the size of the area, you may need specific functionality to achieve optimal results.

Compact Versions are ideal for smaller areas where maneuverability and ease of use are key. These models often include user-friendly controls and efficient engines designed for quick and straightforward operations.

Larger Variants are built to handle expansive spaces with rugged terrain. They come equipped with more powerful engines and enhanced durability, making them suitable for tougher tasks and extended use.

Overall, selecting the right version depends on the specific requirements of your property, ensuring that your equipment provides the necessary performance and reliability for any task.

Safety Precautions During Repairs

Ensuring safety is crucial when performing maintenance or replacing components in mechanical equipment. Prioritizing proper techniques and using the right tools can prevent accidents and injuries. Careful preparation and understanding the steps involved in repair tasks are essential to avoid mistakes that could lead to harm.

Use of Protective Gear

Always wear appropriate protective gear such as gloves, safety glasses, and sturdy clothing. This minimizes the risk of injury from sharp edges, moving parts, or debris. Make sure to inspect your gear regularly to ensure it remains in good condition.

Work in a Safe Environment

Perform repairs in a well-lit, ventilated area with a clean and stable surface. Avoid distractions, and ensure all tools and materials are within reach. Before starting, disconnect the power source to prevent accidental activation during the repair process.

Upgrading Your Mower’s Components

Enhancing the functionality of your machine can lead to improved performance and efficiency. By investing in high-quality components, users can ensure a smoother operation and extend the lifespan of their equipment. Whether it’s optimizing cutting efficiency or increasing fuel economy, thoughtful upgrades can significantly enhance the overall experience.

One of the first areas to consider for enhancement is the engine. Upgrading to a more powerful or efficient engine can lead to noticeable improvements in speed and performance. Additionally, exploring advanced cutting blades can result in a cleaner cut, making your yard look its best.

Another essential aspect to focus on is the transmission system. Replacing outdated or inefficient components can provide smoother gear shifts and better control during use. Don’t overlook the importance of tires as well; investing in high-quality, durable tires can greatly improve traction and stability on uneven terrain.

Regular maintenance and timely upgrades not only enhance performance but also contribute to safety. Ensuring all components are in optimal condition reduces the risk of accidents and mechanical failures. Always consult with professionals to determine the best upgrades for your specific model and requirements.