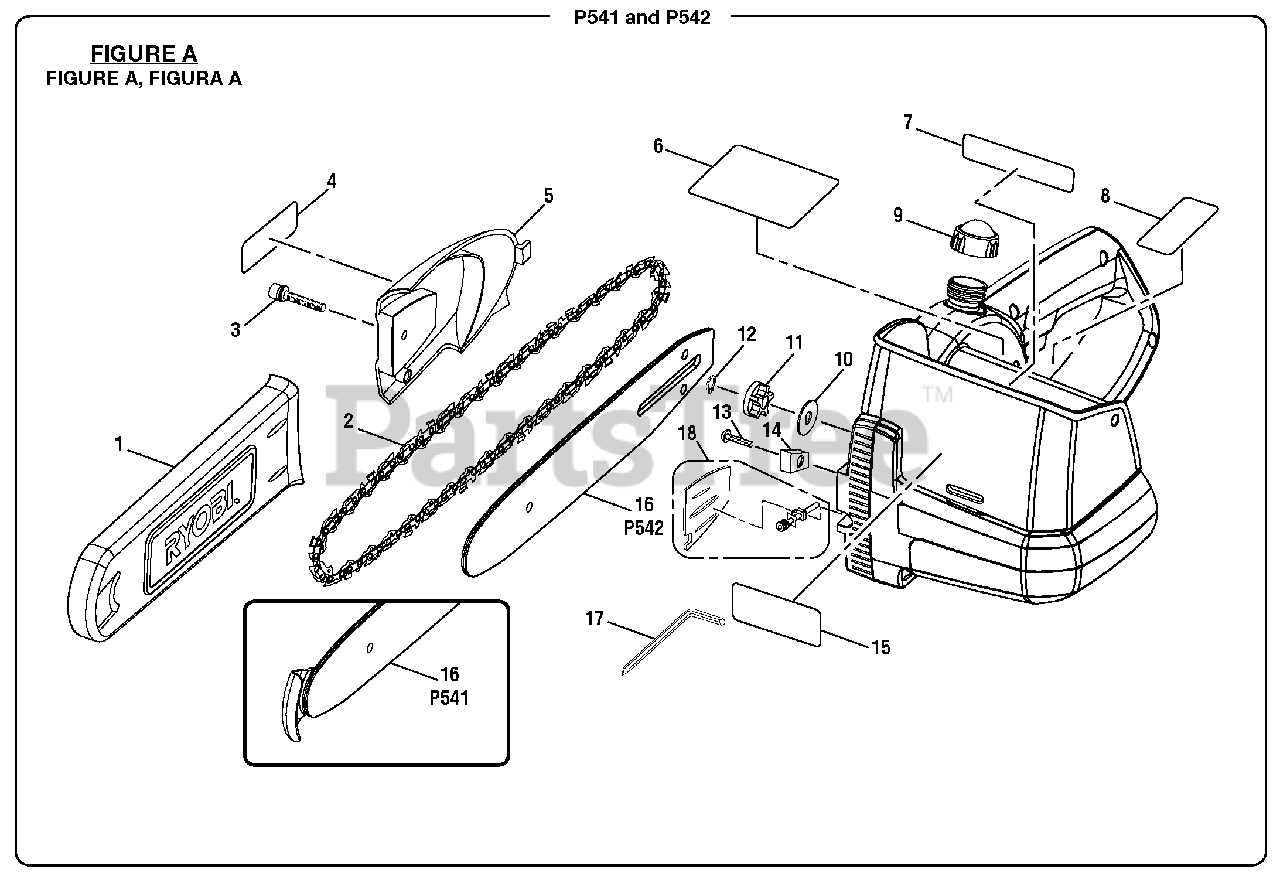

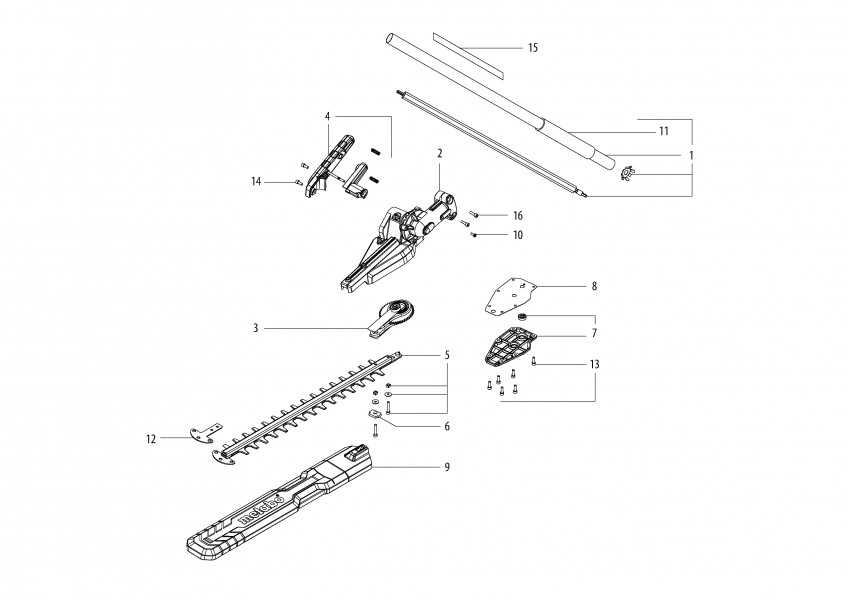

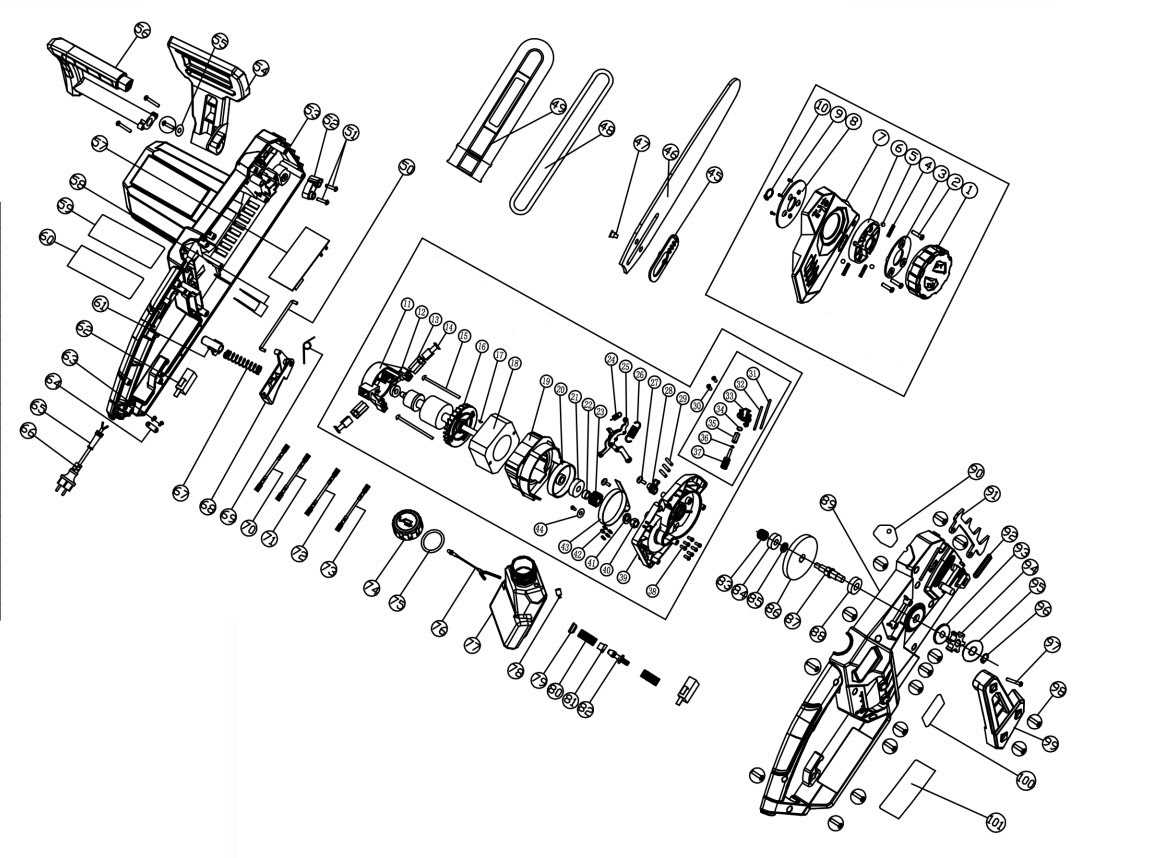

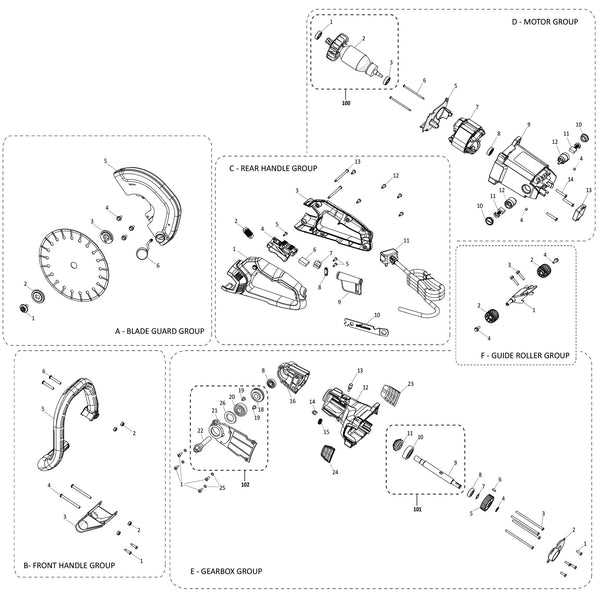

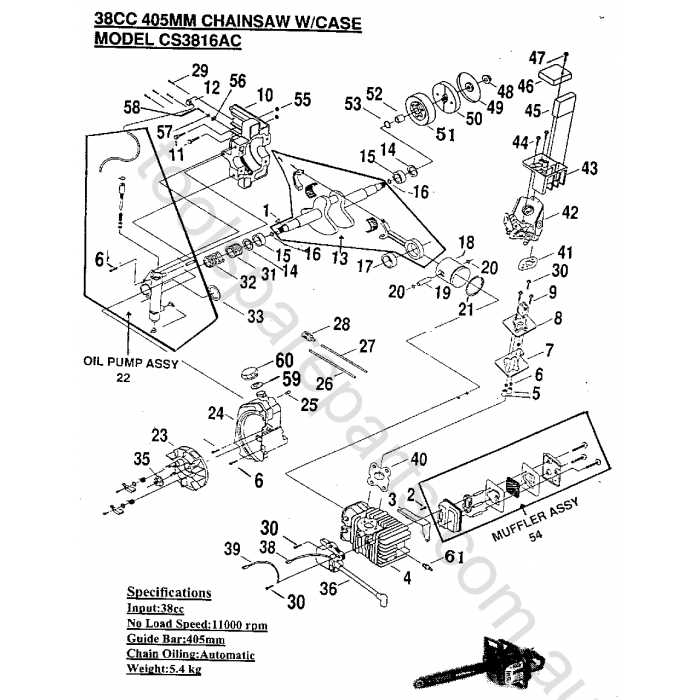

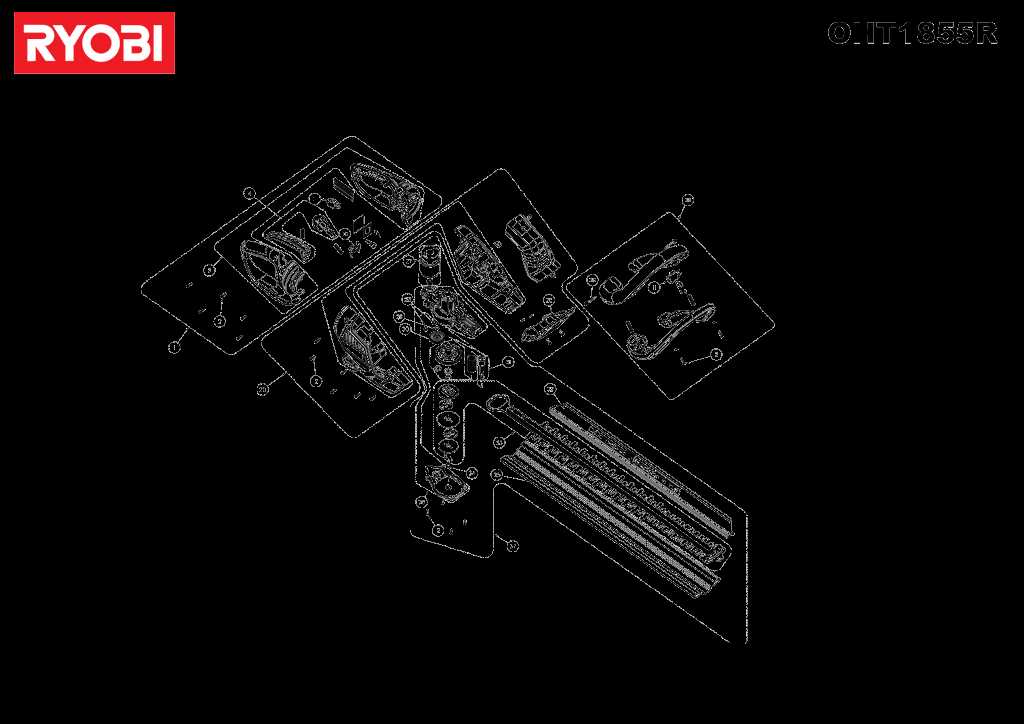

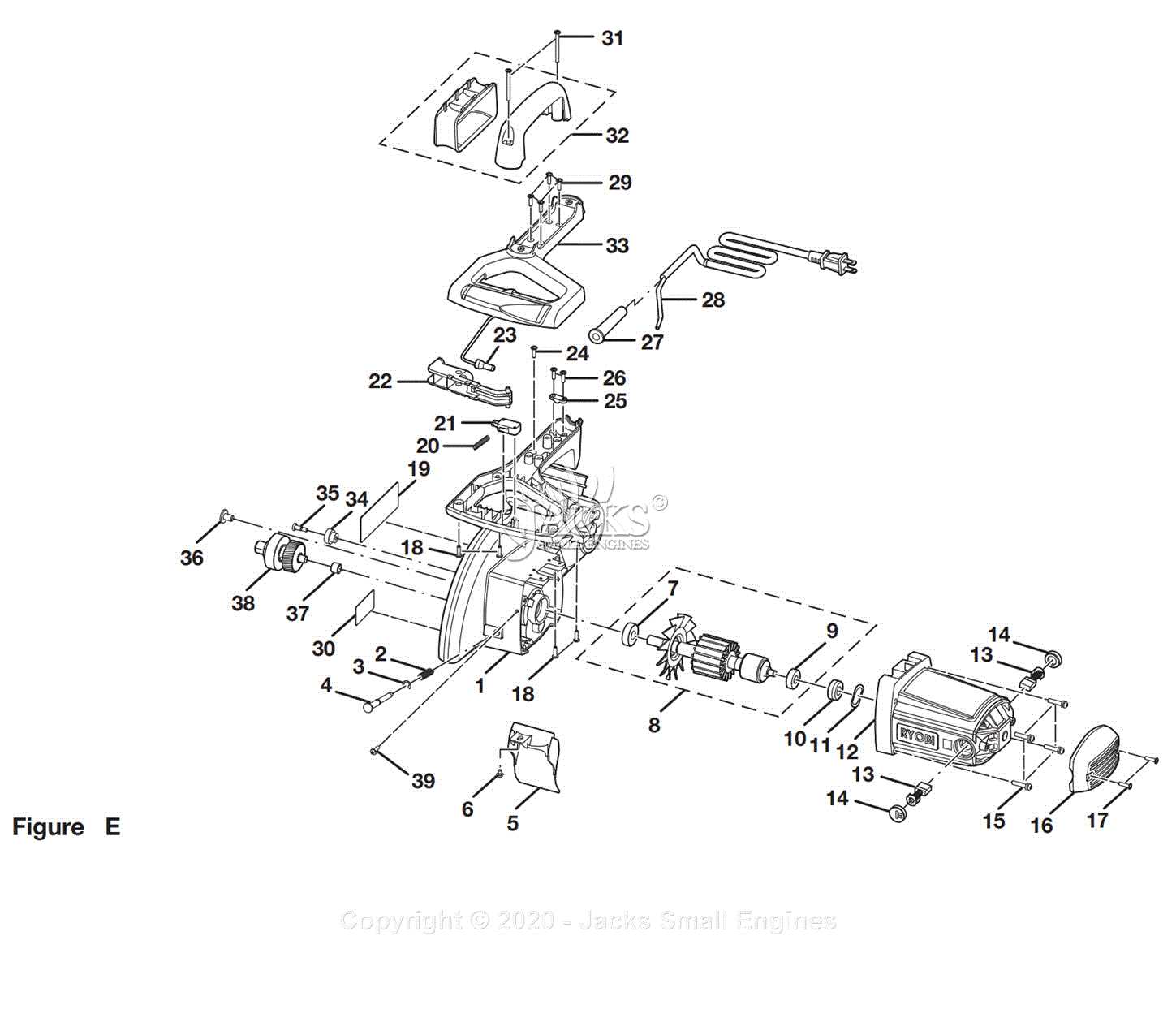

The efficient functioning of any outdoor power equipment relies heavily on the intricate assembly of its individual components. A clear comprehension of these elements is essential for users seeking to maintain or repair their devices effectively. In this section, we will explore the various segments that constitute this particular tool, highlighting their roles and interconnections.

Each component serves a specific purpose, contributing to the overall performance and reliability of the equipment. From the motor to the cutting mechanism, understanding how these elements interact can greatly enhance user experience. By familiarizing oneself with these details, one can ensure proper maintenance and longevity of the tool.

Furthermore, gaining insight into the layout and functionality of these components empowers users to tackle potential issues proactively. Whether it involves routine upkeep or troubleshooting, knowing the intricacies of each segment can facilitate a smoother operational process.

tags: Understanding Ryobi Chainsaws”>

tags: Understanding Ryobi Chainsaws”>

This section aims to provide a comprehensive overview of a popular tool known for its efficiency in handling various cutting tasks. By breaking down its components and their functions, users can gain valuable insights into how to maintain and troubleshoot their equipment effectively.

Key Components of the Tool

Understanding the essential elements of this equipment is crucial for optimal performance. Each part plays a significant role in ensuring the machine operates smoothly and efficiently.

Functionality of Major Elements

Each major component contributes to the overall functionality, enhancing user experience. Familiarity with these elements aids in proper usage and maintenance.

| Component | Function |

|---|---|

| Motor | Powers the device, providing necessary energy for operation. |

| Guide Bar | Supports the cutting chain, guiding it during operation. |

| Cutting Chain | Designed to slice through various materials with precision. |

| Oil Reservoir | Holds lubrication oil, ensuring smooth movement of the chain. |

| Handle | Provides grip and control, allowing for safe operation. |

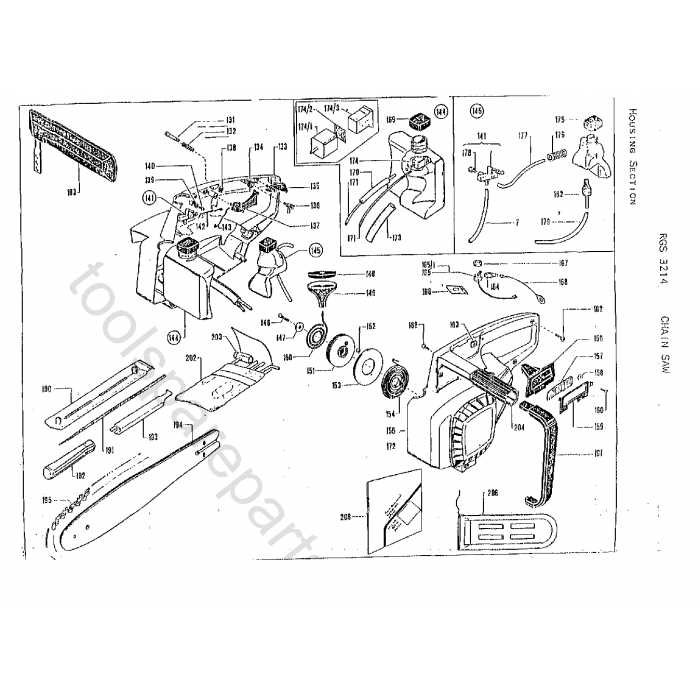

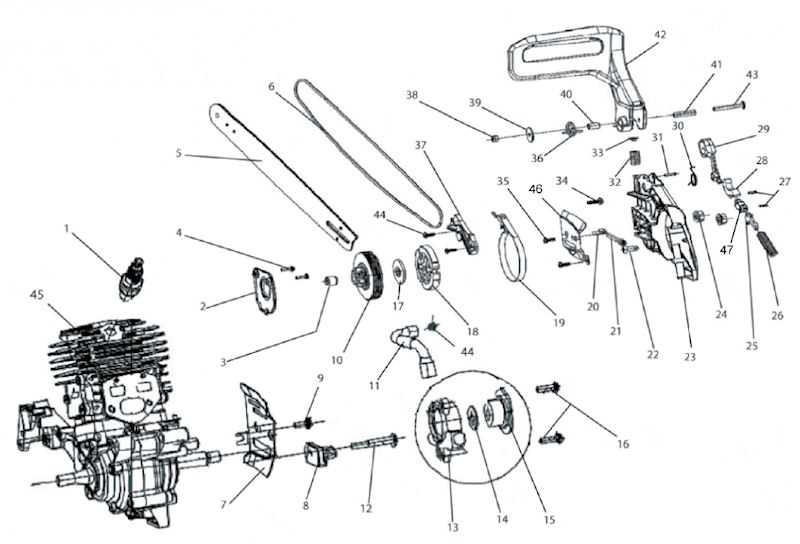

Components of a Chainsaw

Understanding the various elements of a cutting tool can greatly enhance its functionality and efficiency. Each component plays a critical role in ensuring smooth operation and effective cutting performance. Here, we will explore the essential features that contribute to the overall effectiveness of these machines.

- Motor: The heart of the tool, providing the necessary power to perform cutting tasks.

- Guide Bar: A long, flat piece that supports the cutting chain, guiding it during operation.

- Cutting Chain: A series of interlinked blades designed to slice through wood and other materials.

- Fuel System: Supplies energy to the motor, typically consisting of a tank and fuel lines.

- Handle: Offers grip and control, allowing the user to maneuver the tool safely.

- Chain Brake: A safety feature that stops the chain from rotating in case of kickback.

- Lubrication System: Ensures smooth operation of the cutting chain by reducing friction.

- Starter Mechanism: Facilitates the initial activation of the motor, often involving a pull cord.

Each of these components works together to create a powerful and efficient tool suitable for various cutting tasks. Familiarity with these features can aid users in maintenance and troubleshooting, enhancing overall performance and safety.

Functionality of Each Part

This section delves into the various components of a cutting tool, highlighting their specific roles and how they contribute to the overall operation. Understanding these functions is essential for maintaining efficiency and performance.

Key Components and Their Roles

- Motor: This is the powerhouse that drives the entire system, converting electrical energy into mechanical motion.

- Guide Bar: A crucial element that provides a track for the cutting chain, ensuring smooth and precise cuts.

- Cutting Chain: Designed with sharp teeth that effectively slice through material, its design influences cutting speed and efficiency.

- Chain Tensioner: This mechanism maintains the appropriate tension on the cutting chain, preventing slippage and ensuring optimal performance.

- Handle: Provides a secure grip, allowing for better control and maneuverability during operation.

Supporting Elements

- Lubrication System: Ensures that the cutting chain and guide bar remain well-lubricated, reducing friction and wear.

- Safety Features: Includes mechanisms that prevent accidental activation and protect the user from potential hazards.

- Housing: Protects internal components from dust and debris while providing structural support.

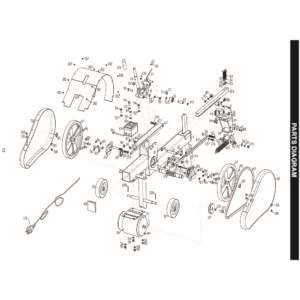

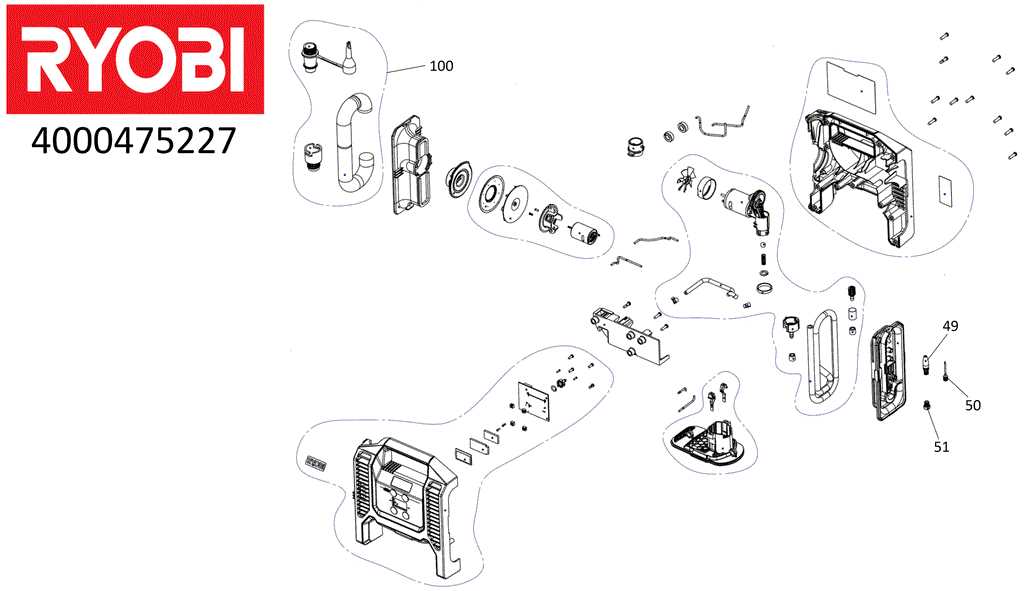

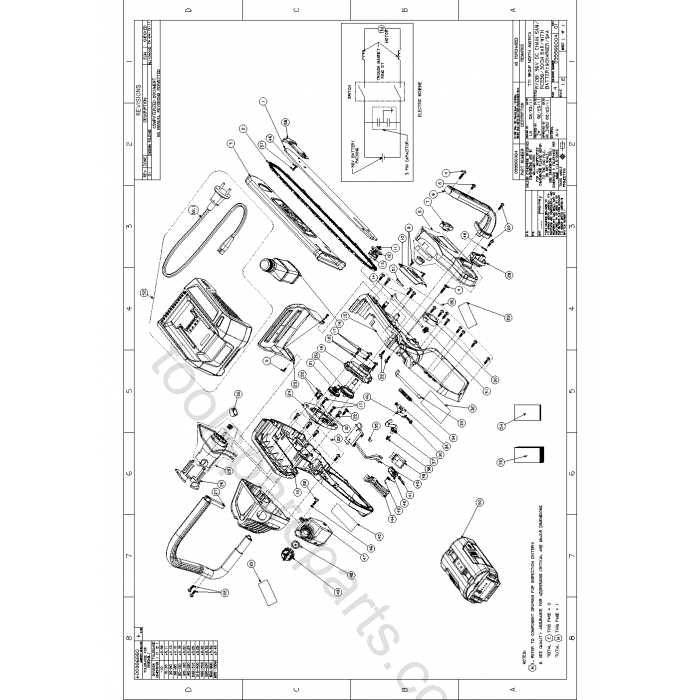

Identifying Key Assembly Areas

Understanding the critical components of a cutting tool is essential for effective maintenance and troubleshooting. Familiarity with various sections enhances the user’s ability to perform repairs or replacements efficiently.

Main Components Overview

Each segment plays a vital role in the overall function. The following areas are crucial:

- Power Unit: The engine or motor that drives the entire mechanism.

- Guide Mechanism: This part ensures accurate and stable operation during use.

- Cutting Assembly: The essential elements that engage with the material being cut.

Maintenance Considerations

Regular inspections of the identified areas are recommended to maintain optimal performance:

- Check for wear and tear in the power unit.

- Ensure that the guide mechanism is properly aligned.

- Inspect the cutting assembly for sharpness and integrity.

Common Issues with Chainsaw Parts

Operating a cutting tool can sometimes lead to challenges that affect its performance. Identifying these issues early on can help in maintaining the tool’s efficiency and extending its lifespan. Common problems often arise from wear and tear, improper maintenance, or assembly errors, which can hinder the functionality of the device.

Frequent Mechanical Failures

Mechanical failures are often observed in various components. Common symptoms include unusual noises, vibrations, or an inability to start. These can result from worn-out components, such as the drive mechanism or the tensioning system. Regular inspection and timely replacement of damaged parts are crucial to avoid serious malfunctions.

Fuel and Oil System Problems

Issues with the fuel and lubrication systems can significantly impact performance. Leaks or blockages may cause the engine to stall or operate inefficiently. Ensuring proper fuel quality and regularly checking the oil levels can prevent these complications. Proper maintenance routines are essential to keep the engine running smoothly.

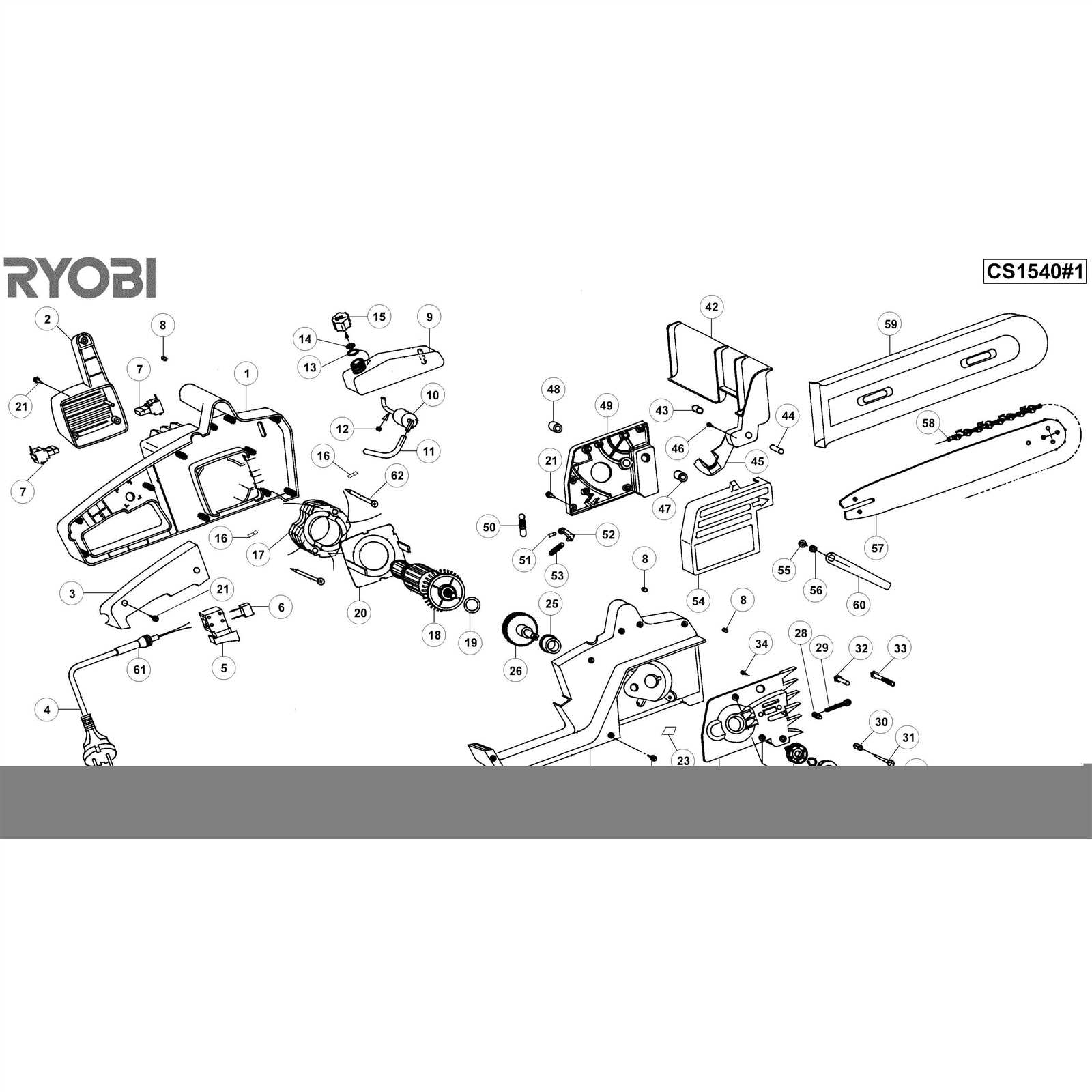

How to Access Parts Diagram

Understanding the components of your equipment is essential for maintenance and repairs. Accessing the visual representation of these elements can significantly simplify the process. This section will guide you through the methods to find these illustrations effectively.

Online Resources

One of the most convenient ways to view component illustrations is through online platforms. Many manufacturers provide digital versions of their product manuals, which often include detailed visuals. A simple search with the model name can lead you to the official website where these resources are available.

Manuals and Guides

In addition to online resources, physical manuals that come with your equipment typically contain useful visuals. If you have the original documentation, refer to it for comprehensive information about each element. These guides can be invaluable for identifying specific parts during repairs or replacements.

Maintenance Tips for Chainsaw Components

Proper upkeep of the various elements of cutting tools is essential for ensuring optimal performance and longevity. Regular maintenance helps prevent wear and tear, reduces the likelihood of malfunctions, and enhances overall safety during operation.

First and foremost, routinely check and clean the cutting blade to remove any debris or sap buildup. A clean blade ensures efficient cutting and minimizes strain on the motor. Additionally, inspect the tension of the blade regularly; it should be tight enough to prevent slipping but not so tight that it causes damage.

Next, pay attention to the lubrication system. Ensure that the oil reservoir is filled with appropriate lubricant, as this reduces friction and prolongs the life of moving parts. Periodically inspect the oil filter to ensure it is not clogged, which can impede oil flow.

Lastly, consider the housing and casing of the tool. Regularly check for any signs of cracks or damage, as these can compromise safety and functionality. Keeping the exterior clean and free from dirt will also help in spotting potential issues early on.

Replacement Parts Availability

Ensuring the continuous functionality of your outdoor power equipment often requires access to necessary components. Availability of these items can greatly affect the maintenance and repair process, providing users with the assurance they need to keep their tools in optimal condition.

Where to Find Components

When looking for replacement items, consider the following sources:

- Authorized retailers and service centers

- Online marketplaces and specialty websites

- Local hardware and home improvement stores

Factors Influencing Availability

The accessibility of replacement components may vary based on several factors:

- Regional demand for specific items

- Inventory levels at different retailers

- Newer models and their compatibility with older versions

Tools Needed for Repairs

To effectively carry out maintenance or troubleshooting tasks, having the right instruments on hand is essential. Proper tools not only streamline the repair process but also enhance safety and efficiency. Here, we will outline the necessary equipment to ensure smooth operations during repair activities.

Essential Instruments

The following tools are crucial for any repair endeavor:

- Screwdrivers: A set of both flathead and Phillips screwdrivers will allow you to tackle various fasteners.

- Wrenches: Adjustable and socket wrenches are important for loosening and tightening bolts.

- Pliers: Needle-nose and slip-joint pliers are versatile for gripping and manipulating components.

- Hex Keys: Also known as Allen wrenches, these are vital for hexagonal screws.

Safety Gear

In addition to the tools, don’t forget about personal protective equipment:

- Gloves: Protect your hands from sharp edges and potential injuries.

- Safety Glasses: Shield your eyes from debris and flying particles.

- Ear Protection: Noise-cancelling headphones can be beneficial when working in loud environments.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring and maintaining your equipment. By following a structured process, you can ensure effective troubleshooting and proper functionality.

- Gather Necessary Tools:

- Wrenches

- Screwdrivers

- Replacement components

- Safety gear

- Assess the Issue:

Identify the symptoms of malfunction to determine the root cause. Take notes on any unusual sounds, leaks, or performance issues.

- Disassemble Carefully:

Remove the outer casing and access internal mechanisms with caution. Ensure that all fasteners are kept organized for reassembly.

- Inspect Components:

Check for wear, damage, or contamination in key parts. Pay close attention to the functionality of critical elements.

- Replace Faulty Parts:

Swap out damaged pieces with new or refurbished alternatives. Ensure compatibility and secure all connections firmly.

- Reassemble and Test:

Put everything back together in the reverse order of disassembly. After reassembly, conduct a thorough test to verify proper operation.

Safety Precautions During Repairs

When performing maintenance on mechanical equipment, ensuring personal safety and proper procedures is crucial. Awareness of potential hazards and adherence to safety guidelines can prevent accidents and injuries, allowing for a smooth repair process.

Essential Safety Gear

Always equip yourself with appropriate safety gear before starting any maintenance task. This includes wearing protective goggles to shield your eyes from debris, gloves to protect your hands from sharp objects, and sturdy footwear to minimize the risk of slips and falls. Proper attire enhances safety and allows you to focus on the repair without distractions.

Work Area Safety

Ensure your workspace is clean and well-lit to avoid accidents. Remove any clutter or obstacles that could cause tripping hazards. Additionally, use a stable surface to support the equipment during repairs, reducing the likelihood of slips or unintended movements. Maintaining an organized work area significantly contributes to a safer repair environment.

Upgrading Your Chainsaw Components

Enhancing the efficiency and performance of your cutting tool can significantly improve your overall experience. By replacing or upgrading various components, you can achieve better functionality and adapt your device to specific tasks or preferences. This section explores essential upgrades that can elevate the performance of your equipment.

| Component | Benefits | Considerations |

|---|---|---|

| Bar Length | Increased cutting capacity and efficiency for larger tasks. | Ensure compatibility with your model; longer bars may require more power. |

| Chain Type | Improved cutting speed and smoother operation. | Choose the right type based on the material and intended use. |

| Chain Tensioner | Enhanced ease of adjustment for optimal performance. | Look for user-friendly designs for quick and safe adjustments. |

| Motor Upgrade | Increased power and efficiency for demanding tasks. | Ensure electrical compatibility and consider professional installation. |

Benefits of Regular Maintenance

Routine upkeep of equipment is essential for ensuring optimal performance and longevity. By committing to consistent care, users can prevent potential issues and enhance the efficiency of their tools. Regular checks not only address wear and tear but also contribute to safety and reliability during operation.

Increased Efficiency

Maintaining equipment regularly helps to identify and rectify minor problems before they escalate into significant failures. This proactive approach ensures that tools function smoothly, resulting in better performance and reduced downtime.

Enhanced Safety

Regular maintenance plays a critical role in user safety. Well-maintained equipment minimizes the risk of malfunctions that could lead to accidents or injuries. Ensuring that all components are in good condition fosters a safer working environment.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Cleaning | After each use | Prevents buildup of debris and enhances performance |

| Inspecting Components | Monthly | Identifies wear and extends tool lifespan |

| Lubricating Moving Parts | Every few uses | Reduces friction and improves efficiency |

| Replacing Worn Parts | As needed | Prevents breakdowns and ensures safety |