When it comes to maintaining outdoor machinery, having a clear understanding of its various elements is crucial. A comprehensive overview of each part not only aids in effective repairs but also enhances overall performance. By examining a detailed representation of the individual components, users can identify potential issues and streamline their maintenance processes.

Effective troubleshooting begins with recognizing how each piece fits into the larger assembly. Whether you are a seasoned technician or a casual user, being familiar with the arrangement of these elements can significantly improve your experience. Additionally, this knowledge empowers you to make informed decisions during repairs and replacements.

In this exploration, we will delve into the essential features of these machines, providing insight into the configuration and functionality of their respective parts. By understanding the ultimate purpose of each component, you can ensure your equipment operates efficiently and remains in top condition.

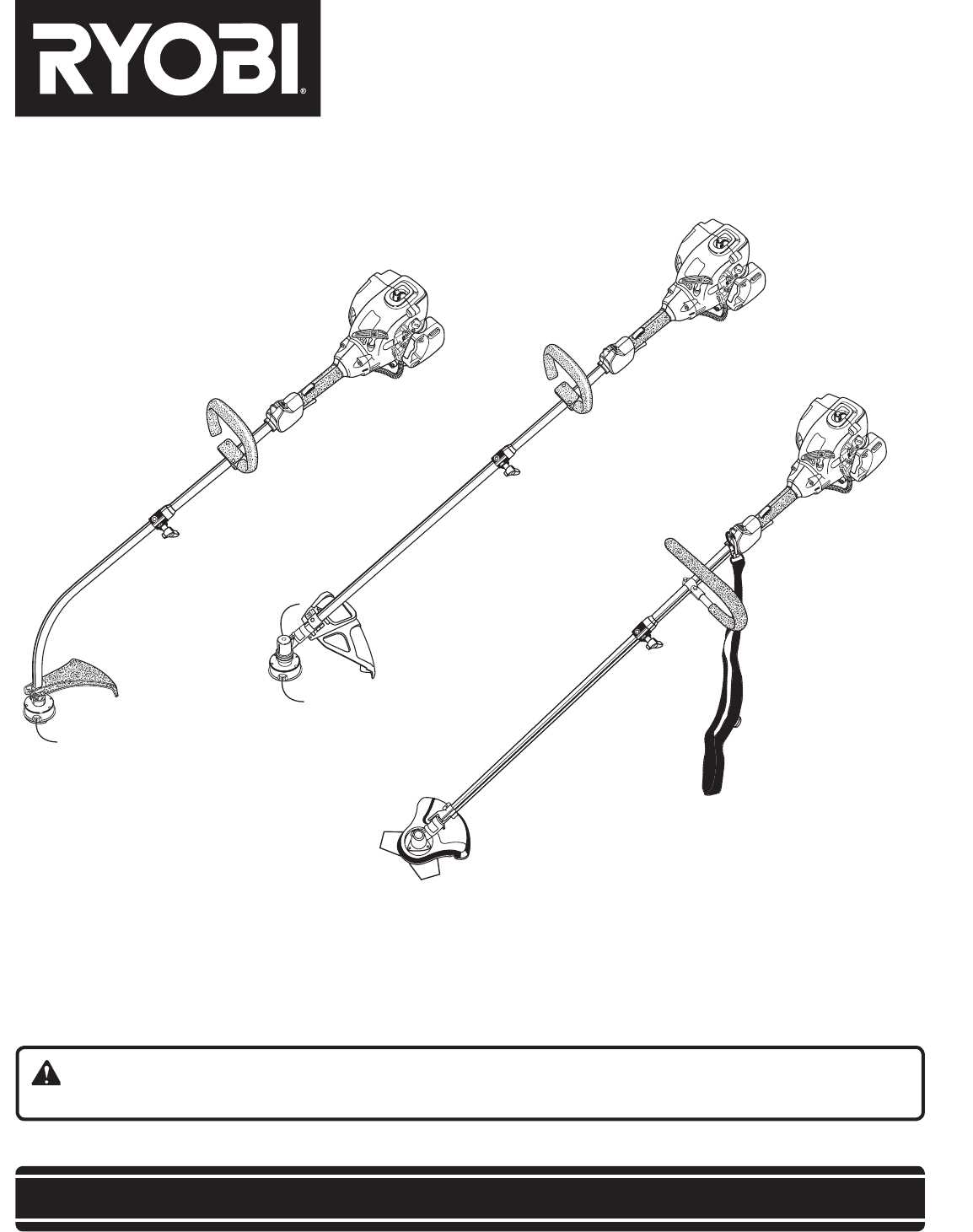

Understanding Ryobi CS26 Parts Diagram

Gaining insight into the components of a power tool is essential for effective maintenance and repair. Recognizing how each piece functions and interconnects can enhance performance and longevity. This section aims to clarify the essential elements involved, guiding users through the intricate layout of their equipment.

Key Components

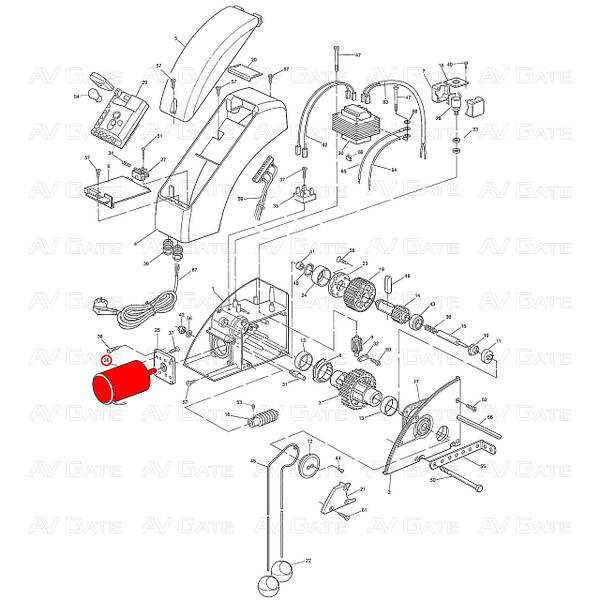

The main elements include the motor, blade assembly, and housing, each serving a critical role. Understanding their placements and functions allows for easier troubleshooting and part replacement, ensuring optimal operation.

Maintenance Tips

Regular inspection of these components can prevent issues before they arise. Keeping the tool clean and replacing worn parts promptly will contribute to its durability and performance. Prioritizing these practices leads to a smoother experience and extends the tool’s lifespan.

Overview of Ryobi CS26 Components

This section provides a comprehensive look at the essential elements that make up a specific tool designed for efficient performance. Understanding these components is crucial for effective maintenance and optimal operation.

- Engine: The powerhouse that drives the tool, ensuring adequate performance.

- Handle: Designed for comfort and control, it enables precise maneuvering.

- Blade: The cutting instrument that determines the tool’s effectiveness in various tasks.

- Fuel System: A critical component that supplies the necessary energy for operation.

Each of these parts plays a significant role in the overall functionality and longevity of the device, making it important to familiarize oneself with their characteristics and care requirements.

Importance of Accurate Parts Diagrams

Having precise visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as crucial references, guiding users through the assembly and disassembly processes while ensuring that every element is correctly identified and understood.

Clarity and Precision: Detailed schematics provide clarity, making it easier for individuals to locate specific items and comprehend their functions. This is particularly vital when dealing with complex machinery, where even a minor misunderstanding can lead to significant issues.

Time Efficiency: When individuals have access to accurate illustrations, they can save time during repairs. Knowing exactly what to look for reduces the chances of confusion, allowing for quicker and more efficient completion of tasks.

Reducing Errors: Well-crafted visual guides minimize the risk of mistakes during reassembly. By clearly showing how components fit together, these resources help prevent misalignments and other errors that could compromise the functionality of the equipment.

Enhanced Troubleshooting: Accurate visual aids are invaluable during troubleshooting processes. When issues arise, users can refer to these guides to identify faulty components and ensure that replacements are appropriate and effective.

Learning and Skill Development: For those new to repair work, these visuals serve as educational tools. They enhance understanding of how different parts interact and contribute to the overall operation, fostering skill development and confidence in handling machinery.

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to maintain and repair equipment. These illustrations provide a clear layout, helping users identify each piece and its function within the whole assembly. Familiarity with this format allows for efficient troubleshooting and replacement of specific items.

Identifying Components

Begin by examining the key symbols and numbers associated with each element. Typically, a legend accompanies the image, detailing the names and specifications of the items. By cross-referencing these labels, you can pinpoint exactly what is required for repairs or upgrades.

Understanding Connections

Next, observe how the various components interact with one another. Pay attention to lines and arrows indicating relationships or assembly order. This insight is crucial for ensuring that everything fits together properly and functions as intended.

Common Issues with Ryobi CS26 Parts

When working with power tools, understanding potential challenges related to their components is essential for optimal performance. Various elements can wear out or malfunction, leading to reduced efficiency and safety concerns. Identifying these common issues can help users maintain their equipment and avoid costly repairs.

Wear and Tear: One of the most frequent problems arises from regular usage. Components can degrade over time, resulting in decreased functionality. Regular inspections are crucial to catch signs of wear early.

Misalignment: Parts may become misaligned due to improper assembly or physical impact. This misalignment can cause operational difficulties, leading to frustration and potential damage if not addressed promptly.

Clogging: Accumulation of debris within the mechanism can impede performance. Ensuring that all openings are clear and regularly cleaning the tool can mitigate this issue significantly.

Electrical Failures: Components related to power supply can sometimes fail, affecting the overall operation. Users should check wiring and connections periodically to ensure everything is intact and functioning properly.

Lubrication Problems: Insufficient lubrication can lead to overheating and increased friction between moving parts. Regular maintenance involving appropriate lubrication can extend the lifespan of the tool.

Addressing these common concerns can enhance performance and ensure safe operation, making it imperative for users to remain vigilant about their equipment’s condition.

Finding Replacement Parts Easily

Locating the right components for your equipment can often feel overwhelming, but it doesn’t have to be. Understanding how to navigate resources effectively can save time and reduce frustration. Whether you are performing maintenance or making necessary repairs, having a clear strategy for sourcing what you need is essential.

Start with Online Resources: The internet is a treasure trove of information. Many websites offer extensive catalogs that allow you to search for specific items based on model numbers or descriptions. Utilizing these resources can help you quickly identify the exact pieces you require.

Consult Manufacturer Guides: Official manuals often contain valuable information regarding compatible components. These guides typically include detailed illustrations and lists that make it easier to find the right replacements without confusion.

Join Community Forums: Engaging with fellow enthusiasts or professionals through online forums can provide insights and recommendations. Members often share their experiences, tips, and even direct links to trusted suppliers, making your search more efficient.

Local Hardware Stores: Don’t overlook local retailers. Many stock common components and can order specific items if they’re not readily available. Establishing a relationship with staff can also lead to personalized advice based on your needs.

Consider Aftermarket Options: In some cases, third-party manufacturers produce compatible alternatives that can be more affordable. While quality can vary, researching reviews and ratings can help you make informed choices.

By using these strategies, you can streamline the process of finding the components necessary for your equipment, ensuring it operates smoothly and efficiently.

Tools Needed for Ryobi Repairs

When it comes to maintaining and fixing outdoor equipment, having the right tools at your disposal is essential. A well-equipped toolkit not only streamlines the repair process but also ensures that you can tackle a variety of issues efficiently. Understanding which instruments to use can make all the difference in achieving successful outcomes.

Basic Hand Tools: Start with fundamental items like screwdrivers, wrenches, and pliers. These tools are indispensable for loosening or tightening screws and bolts, allowing you to access internal components easily.

Power Tools: In addition to hand tools, consider incorporating power tools such as drills and saws. These can expedite certain tasks, especially when dealing with larger repairs or modifications.

Safety Gear: Always prioritize safety by using protective equipment. Gloves, goggles, and masks will help shield you from debris and potential hazards during the repair process.

Specialty Tools: Some repairs may require specific instruments, such as torque wrenches or multimeters. Having these specialized tools on hand can significantly enhance your ability to diagnose and fix issues effectively.

By preparing with the right equipment, you can approach maintenance tasks with confidence and ensure your tools remain in optimal condition for years to come.

Step-by-Step Repair Process

Repairing outdoor equipment can seem daunting, but with a systematic approach, the task becomes manageable. Understanding the components and their functions is essential for effective troubleshooting and restoration. This guide outlines a clear method to help you navigate through the repair process efficiently.

Begin by gathering the necessary tools and materials. A clean workspace will enhance your efficiency and safety. Ensure you have all required items at hand, such as wrenches, screwdrivers, and replacement components.

Next, carefully disassemble the unit, taking note of the arrangement of parts. Documenting the sequence can be beneficial for reassembly. Inspect each component for wear or damage, and make a list of any items that need replacement.

Once you have identified the faulty parts, proceed to replace them. Follow the manufacturer’s instructions to ensure correct installation. Secure each piece firmly to avoid future malfunctions.

After reassembly, conduct a thorough inspection of the entire unit. Check all connections and ensure everything is properly aligned. Once satisfied, perform a test run to confirm that the repairs have resolved the issues.

Finally, keep a record of the repairs performed and any parts replaced. This documentation will be helpful for future maintenance and can provide insights into the longevity of the equipment.

Maintenance Tips for Longevity

Proper upkeep of your outdoor power equipment is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some effective practices to extend the lifespan of your machinery.

Routine Cleaning

Keep the exterior and interior components clean to prevent the buildup of dirt and debris. Regularly check and clear air filters and vents, as blockages can lead to overheating and reduced efficiency. A clean machine operates more smoothly and lasts longer.

Scheduled Inspections

Perform systematic checks on all mechanical parts to identify wear and tear early on. Pay attention to blades, belts, and other critical components. Replace worn parts promptly to avoid further damage and ensure safe operation. Following the manufacturer’s recommendations for inspection intervals can significantly enhance durability.

Additionally, store your equipment in a dry, protected environment when not in use, and consider using protective covers. These simple steps can make a notable difference in maintaining the functionality and extending the life of your tools.

Where to Purchase Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. This ensures that your machinery functions reliably and safely, avoiding potential issues that could arise from inferior substitutes.

Here are several options to consider when looking for genuine components:

- Manufacturer’s Website: The most reliable source for original components is directly from the manufacturer’s official website. They often provide a comprehensive selection along with detailed specifications.

- Authorized Dealers: Locate local retailers or online stores that are recognized as authorized distributors. These establishments typically carry a wide range of authentic items and can offer expert advice.

- Specialty Shops: Some stores specialize in specific types of machinery and their components. These shops often stock genuine items and provide personalized service to help you find exactly what you need.

- Online Marketplaces: Well-known online platforms can also be a source for authentic components, but it’s essential to verify the seller’s credibility and check for authenticity guarantees.

By choosing these avenues, you can ensure that you are acquiring quality components that will enhance the performance and durability of your equipment.

Customer Support Resources for Ryobi

When it comes to maintaining and repairing outdoor power tools, having access to reliable assistance is essential. Various resources are available to ensure users can find the information they need to troubleshoot issues, obtain replacement components, and enhance their overall experience with their equipment. Understanding where to seek support can make all the difference in keeping tools running smoothly.

Official Support Channels

The primary source for assistance is the official website, where users can access a wealth of information, including user manuals, FAQs, and contact details for customer service. Additionally, many brands offer online chat options and forums where enthusiasts can exchange tips and solutions.

Community and Social Media Resources

Social media platforms and community forums serve as valuable venues for connecting with other users. Engaging with fellow enthusiasts allows for sharing experiences, troubleshooting advice, and even discovering unofficial resources that can aid in repairs and maintenance. These interactive spaces foster a sense of camaraderie among users, promoting a collective approach to problem-solving.

Exploring Upgrade Options for CS26

Enhancing the performance and efficiency of your cutting tool can significantly improve your overall experience. By exploring various modifications and accessories, users can tailor their equipment to better suit specific tasks and preferences. This section delves into potential upgrades that can optimize functionality and extend the lifespan of your device.

Performance Enhancements

Upgrading the motor or blade type can lead to a noticeable improvement in cutting capabilities. Consider investing in high-quality blades designed for different materials. Additionally, adjusting the power settings or incorporating advanced technology can enhance precision and reduce operational strain.

Ergonomic and Convenience Features

Improving comfort during use is essential for prolonged tasks. Look into accessories such as padded grips, shoulder straps, or vibration dampening systems. These features not only enhance user experience but also promote safety by reducing fatigue and maintaining control during operation.