When it comes to maintaining your energy-producing machinery, a comprehensive understanding of its internal structure is essential. Each unit is made up of various essential elements that work in unison to ensure optimal performance. Knowing the layout and function of these components can significantly enhance troubleshooting and repair processes.

In this section, we will delve into the intricacies of these systems, offering detailed insights into their configuration and roles. By exploring how each part contributes to the overall functionality, you can better appreciate the engineering behind the equipment.

Equipped with this knowledge, users can confidently approach maintenance tasks, ensuring longevity and reliability in their devices. Whether you’re a seasoned technician or a novice enthusiast, familiarizing yourself with the blueprint of your equipment can empower you to tackle any challenges that arise.

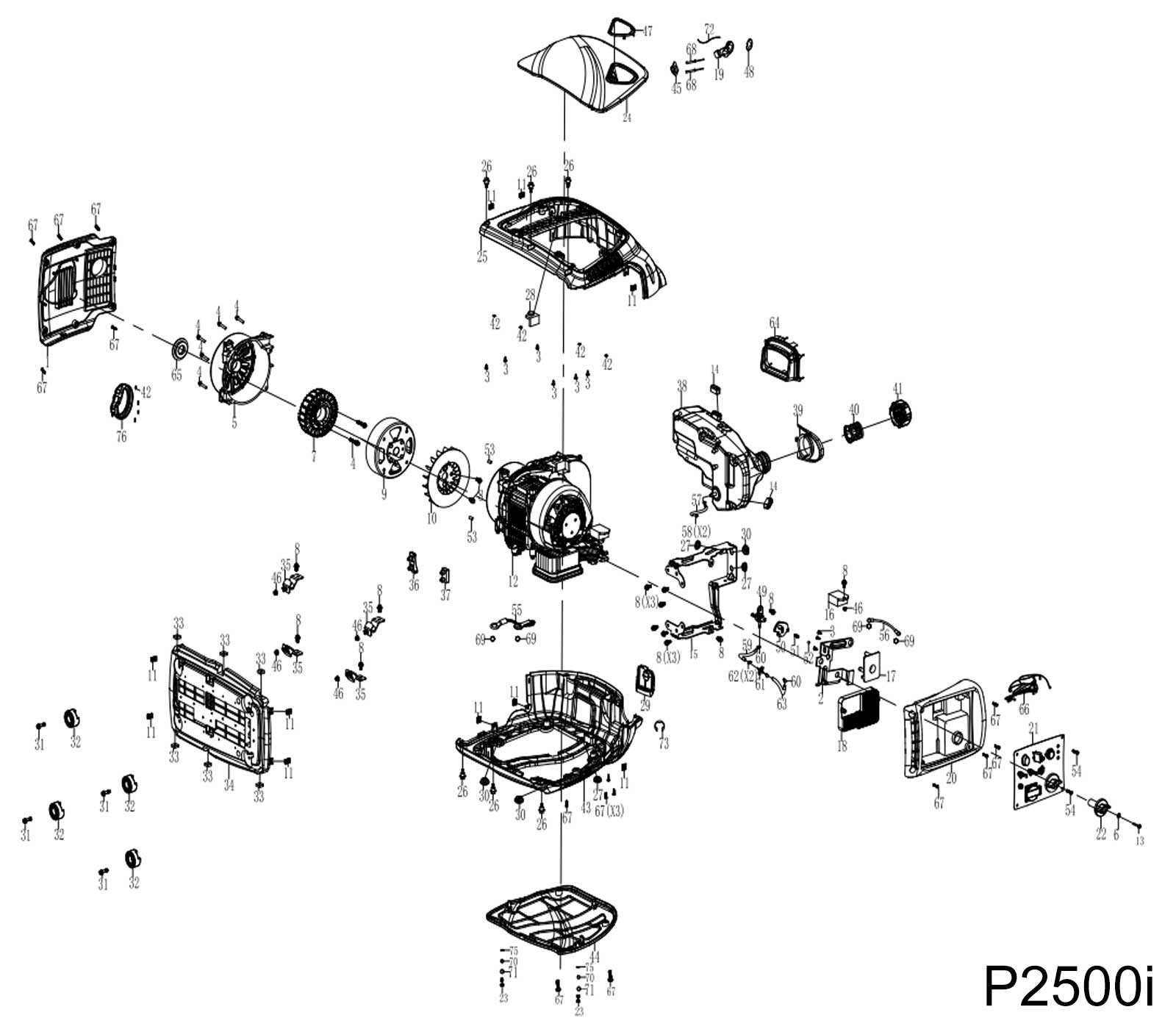

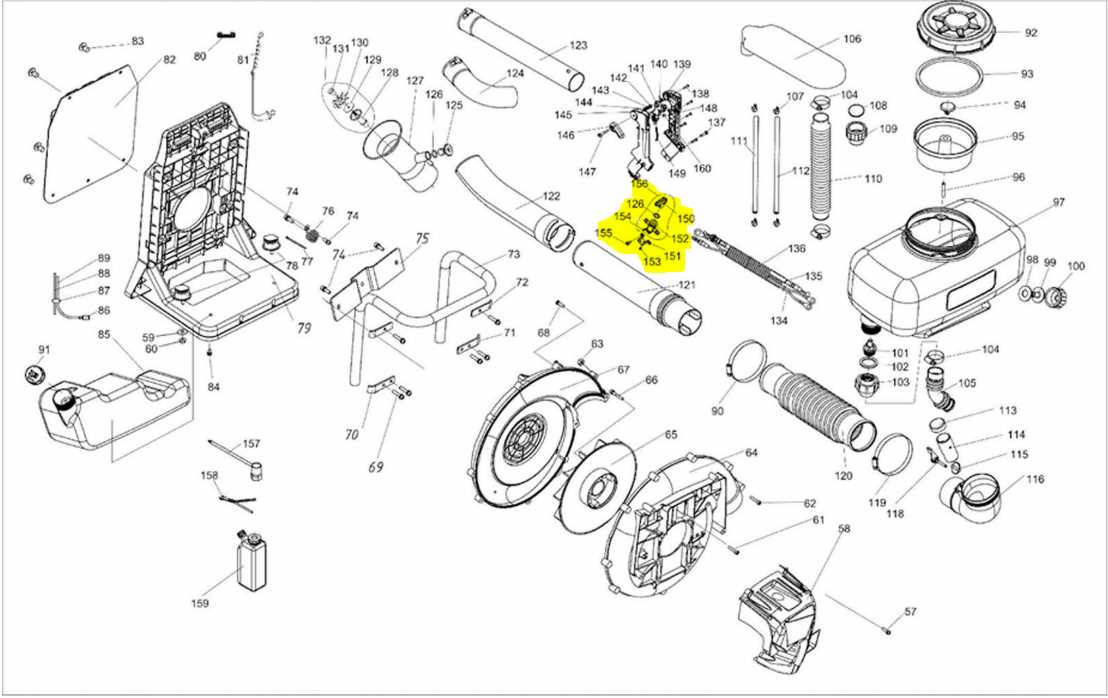

Understanding Ryobi Generator Parts

This section aims to clarify the various components that make up a portable energy source. Each element plays a crucial role in ensuring optimal functionality and reliability. Familiarity with these elements can aid in troubleshooting and maintenance, enhancing overall performance.

Key Components

At the heart of any energy-producing machine are its essential elements, including the engine, fuel system, and electrical output components. The engine serves as the powerhouse, converting fuel into mechanical energy. The fuel system is responsible for delivering the necessary resources for operation, while the electrical output manages the distribution of energy for various applications.

Maintenance and Care

Understanding these components also paves the way for effective maintenance. Regular inspection of the fuel lines, air filters, and spark plugs can prevent many common issues. Additionally, being aware of how these elements interact will enable users to make informed decisions when seeking replacements or upgrades.

Importance of Parts Diagrams

Understanding the structure and components of any mechanical system is essential for effective maintenance and repair. Visual representations serve as crucial tools for users, enabling them to grasp the relationships between various elements and facilitating efficient troubleshooting.

Benefits of Visual Guides

- Enhances comprehension of complex systems.

- Simplifies the identification of specific elements.

- Aids in the reassembly process after repairs.

- Provides clarity on component compatibility.

Efficiency in Maintenance

- Reduces time spent searching for issues.

- Minimizes the risk of errors during repairs.

- Promotes proper usage of tools and techniques.

- Facilitates a systematic approach to troubleshooting.

Common Components of Ryobi Generators

Understanding the essential elements of portable power units can significantly enhance maintenance and troubleshooting efforts. Each device consists of several key components that work in unison to deliver reliable performance. Familiarity with these parts can help users optimize their experience and extend the lifespan of their equipment.

- Engine: The heart of the system, responsible for converting fuel into mechanical energy.

- Alternator: This component transforms mechanical energy into electrical energy, powering connected devices.

- Fuel Tank: Holds the fuel required for operation, typically designed for easy access and refueling.

- Control Panel: Houses the power outlets and switches, providing a user-friendly interface for operation.

- Chassis: The frame that supports all components, offering stability and protection during use.

Additional components also play crucial roles in the overall functionality and safety of the system:

- Air Filter: Ensures clean air intake, promoting optimal engine performance.

- Exhaust System: Directs harmful gases away from the unit, ensuring safe operation.

- Voltage Regulator: Maintains a consistent voltage output, preventing damage to connected devices.

- Starter System: Initiates the engine operation, commonly using either a recoil or electric start mechanism.

Recognizing these vital elements empowers users to better maintain their units and respond effectively to any issues that may arise.

How to Read a Parts Diagram

Understanding an illustration that outlines components can greatly enhance your ability to identify, locate, and replace elements within a machine. This visual representation serves as a crucial tool for both troubleshooting and maintenance, allowing you to grasp the relationship between various parts and their functions.

To effectively interpret such an illustration, follow these key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout and structure of the image. Look for labeled sections that indicate specific groups of components. |

| 2 | Identify the numbering system used. Each part is usually assigned a unique number or code that corresponds to a list or catalog. |

| 3 | Refer to the accompanying legend or key, which explains the symbols and annotations used in the illustration. |

| 4 | Cross-reference with the parts list to find detailed information about each component, including specifications and replacement options. |

| 5 | Note any additional information, such as installation instructions or compatibility details, which may be provided alongside the image. |

By following these steps, you can enhance your comprehension of the visual representation, making maintenance and repairs more efficient and effective.

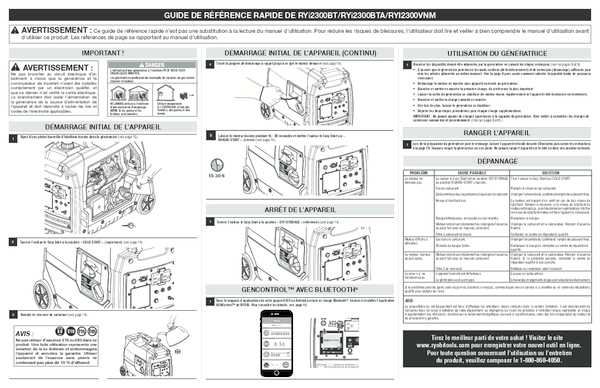

Identifying Your Generator Model

Understanding the specific model of your power source is essential for ensuring effective maintenance and sourcing the correct components. Each unit may have unique features and specifications that distinguish it from others, making identification crucial for optimal performance.

To accurately determine the model of your unit, consider the following steps:

- Locate the Model Number: Check for a label or sticker, usually found on the frame or near the engine. This number is often a combination of letters and digits.

- Consult the User Manual: If you have access to the original documentation, it typically lists the model details prominently.

- Examine Design Features: Take note of any distinctive characteristics such as size, shape, and controls, which may help in identifying the unit.

- Search Online: Utilize official websites or online forums where you can input your findings and receive assistance from the community or manufacturers.

By following these guidelines, you can ensure that you accurately identify your equipment, leading to better upkeep and performance enhancements.

Replacement Parts Availability

Access to quality components is crucial for maintaining the efficiency and longevity of any machinery. Availability of these essential elements ensures that users can promptly address any issues that arise, minimizing downtime and enhancing overall performance. A well-stocked inventory not only supports quick repairs but also fosters a sense of reliability in the equipment.

When searching for these necessary items, it’s important to consider various sources. Authorized retailers, online marketplaces, and specialized distributors often offer a wide selection. Additionally, some platforms may provide detailed schematics that facilitate easy identification of the required elements, making the replacement process straightforward for users.

Furthermore, it is beneficial to keep track of frequently needed components to streamline future maintenance. This proactive approach can prevent unexpected breakdowns and promote a seamless operational experience. Users should also explore the option of OEM and aftermarket selections, which can provide both cost-effective and high-quality solutions tailored to specific needs.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment requires a consistent maintenance routine. Regular care not only enhances functionality but also prevents costly repairs and replacements. By following a few essential practices, you can significantly extend the lifespan of your machine.

Regular Inspection

Conducting frequent checks is crucial for identifying potential issues before they escalate. Pay attention to the following components:

| Component | Frequency of Inspection | Notes |

|---|---|---|

| Air Filter | Every 10 hours of use | Clean or replace as necessary |

| Oil Level | Every use | Top up or change if dirty |

| Fuel System | Monthly | Check for leaks and cleanliness |

Proper Storage

How you store your equipment can greatly influence its durability. Follow these tips for effective storage:

- Keep in a dry, sheltered area to prevent rust.

- Use a cover to protect from dust and debris.

- Store with a full tank of fuel to avoid moisture buildup.

Tools Needed for Repairs

When it comes to maintaining equipment, having the right instruments at your disposal is essential for effective repairs. This ensures that the job is done efficiently and safely, leading to optimal performance of the machinery.

Some of the essential tools include screwdrivers, wrenches, and pliers, which are fundamental for loosening or tightening components. Additionally, a good multimeter can help diagnose electrical issues, while a set of sockets is invaluable for various fasteners. Keeping these tools organized will streamline the repair process.

Lastly, having safety equipment such as gloves and goggles is crucial to protect yourself during repairs. This not only enhances safety but also contributes to a smoother workflow.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when undertaking maintenance tasks. Adhering to specific guidelines not only protects the individual but also enhances the efficiency of the repair process. Familiarity with the equipment and surroundings can significantly reduce risks.

Always disconnect power sources before beginning any work. This prevents accidental activation and reduces the risk of electric shock. Wearing appropriate personal protective equipment, such as gloves and goggles, is essential to shield against potential hazards.

Maintain a clutter-free workspace to minimize the chances of accidents. Utilize the right tools for the job, as using improper equipment can lead to injuries or damage. Regularly inspect tools for wear and tear to ensure their effectiveness.

Lastly, stay focused and avoid distractions while performing repairs. Taking your time and being mindful of safety protocols will ultimately lead to a successful maintenance experience.

Ordering Genuine Ryobi Parts

When it comes to maintaining your outdoor equipment, sourcing authentic components is essential for optimal performance and longevity. Quality replacements ensure that your machinery operates smoothly and efficiently, reducing the risk of failures.

Why Choose Authentic Components?

Utilizing genuine items not only guarantees compatibility but also enhances the overall reliability of your tools. Counterfeit or substandard alternatives can lead to complications, affecting the functionality and safety of your equipment.

How to Order

To procure the right components, visit authorized retailers or the official website. Look for detailed information and clear images to help identify the correct item. Additionally, consulting the user manual can provide valuable guidance for your specific model.

FAQs About Generator Parts

This section addresses common inquiries regarding components of power systems, helping users better understand their functionality and maintenance.

- What are the essential components of a power system?

- Engine

- Alternator

- Fuel system

- Control panel

- How do I know when to replace a component?

- Unusual noises

- Poor performance

- Visible wear and tear

- Frequent breakdowns

- Where can I find replacement components?

- Authorized dealers

- Online marketplaces

- Local repair shops

- Manufacturer’s website

- How can I maintain my equipment?

- Regularly check oil levels

- Clean air filters

- Inspect connections

- Schedule professional servicing

Where to Find Additional Resources

For anyone seeking to deepen their understanding or troubleshoot their equipment, a variety of resources are available. These can enhance your knowledge and ensure optimal performance through reliable information and support.

Online Forums and Communities

Engaging with online communities can provide valuable insights and tips. Consider these platforms:

- Dedicated discussion boards

- Social media groups focused on maintenance

- Specialized Reddit threads

Manufacturer Support and Documentation

Direct assistance from the manufacturer is often the most reliable source. Explore the following options:

- Official websites for user manuals and guides

- Customer support hotlines for personalized help

- Instructional videos on video-sharing platforms