The proper functioning of any cleaning apparatus is closely linked to the efficient interaction of its internal mechanisms. Every system, no matter how advanced, relies on a set of key components working in harmony to deliver optimal results. Understanding how these elements interact allows users to maintain their equipment in peak condition, ensuring long-term reliability and performance. This section will guide you through the essential building blocks that contribute to the effectiveness of the machine.

Identifying and managing the key components can often make the difference between smooth operation and frequent malfunctions. With the right knowledge, it’s possible to troubleshoot issues, replace worn-out parts, and make adjustments that enhance overall functionality. In the following sections, we will explore how each component plays a critical role in the operation of the device.

Exploring these elements allows for a deeper appreciation of how well-maintained equipment can perform more efficiently, saving time and resources. A comprehensive understanding of its structure is not only beneficial for troubleshooting but also for maximizing the lifespan of the apparatus. As you familiarize yourself with each essential part, you gain the tools to ensure optimal use and a longer operational life for your machine.

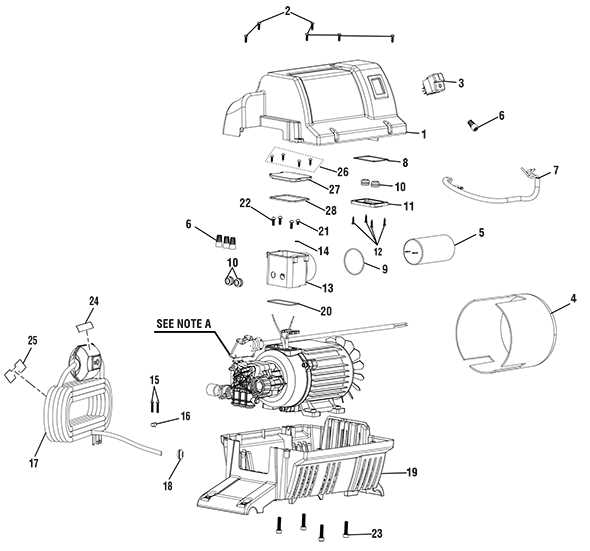

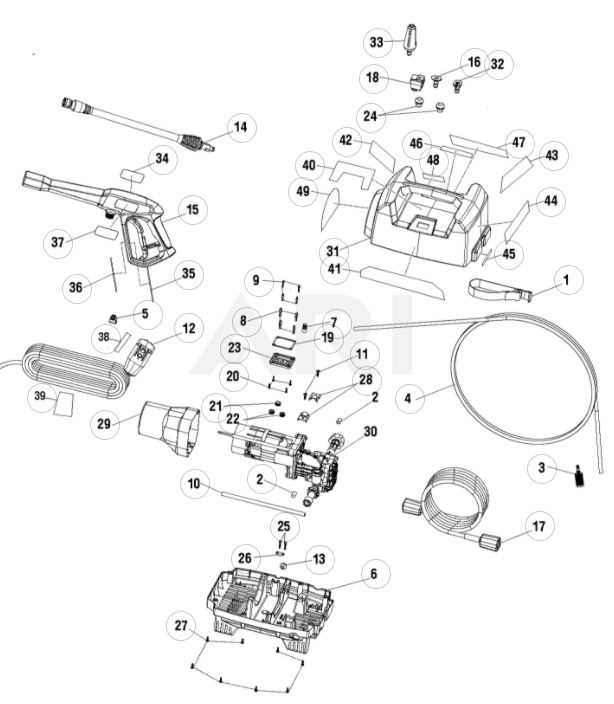

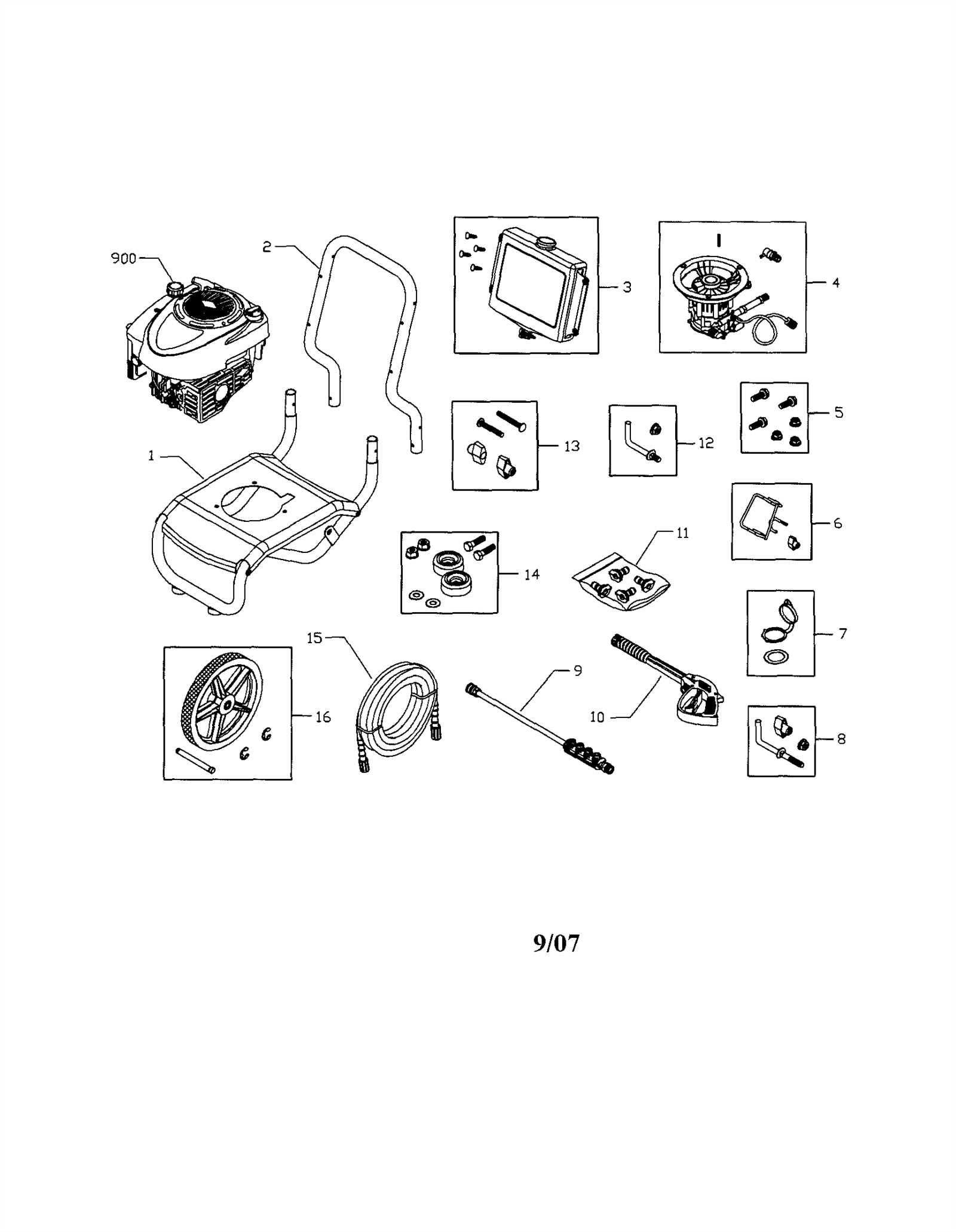

Understanding Key Components of a Power Washer

To effectively maintain and troubleshoot high-pressure cleaning equipment, it is essential to have a clear understanding of its core components. Each element plays a significant role in ensuring the equipment functions smoothly and delivers optimal performance during cleaning tasks.

Engine is the heart of the device, providing the necessary power to operate the entire system. It converts fuel or electricity into mechanical energy, enabling the movement of other components.

Water Pump is responsible for drawing in water and converting it into high-pressure flow. This pump is critical for controlling the intensity of the stream, ensuring it matches the cleaning requirements.

Hose is the channel through which the water is directed, allowing the user to control the spray’s direction and pressure. A durable hose is key to ensuring efficient performance and longevity.

Nozzle directs the water flow into a specific pattern, which is crucial for different cleaning jobs. Depending on the nozzle type, it can deliver varying pressure levels or spray angles to tackle different surfaces effectively.

Trigger Gun is the interface between the operator and the machine. By pulling the trigger, users can control water flow, making it easier to start and stop cleaning tasks without manually turning the system on or off.

Understanding how each component interacts is vital for maintaining efficiency, extending the lifespan of the equipment, and ensuring safety during operation. Proper care and regular inspection of these elements can prevent common issues and enhance performance.

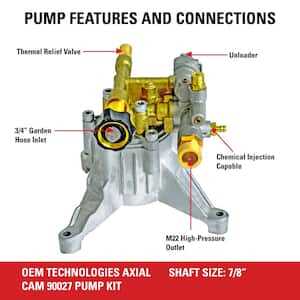

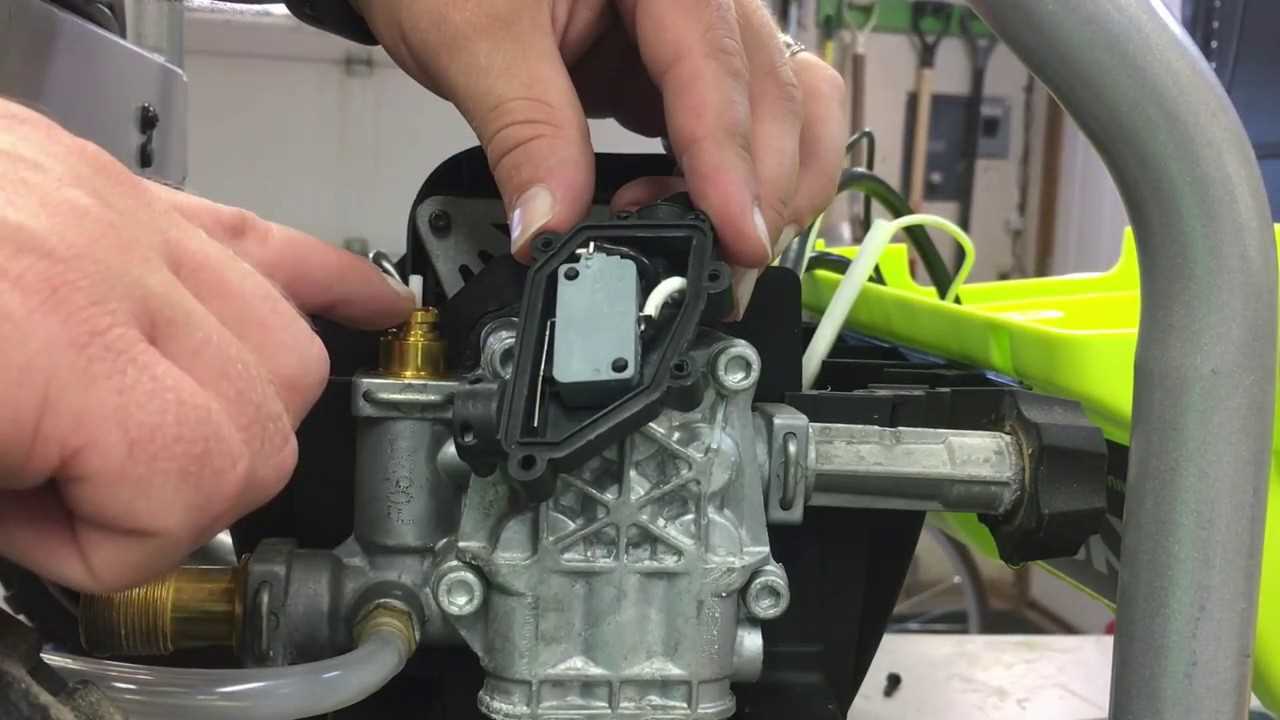

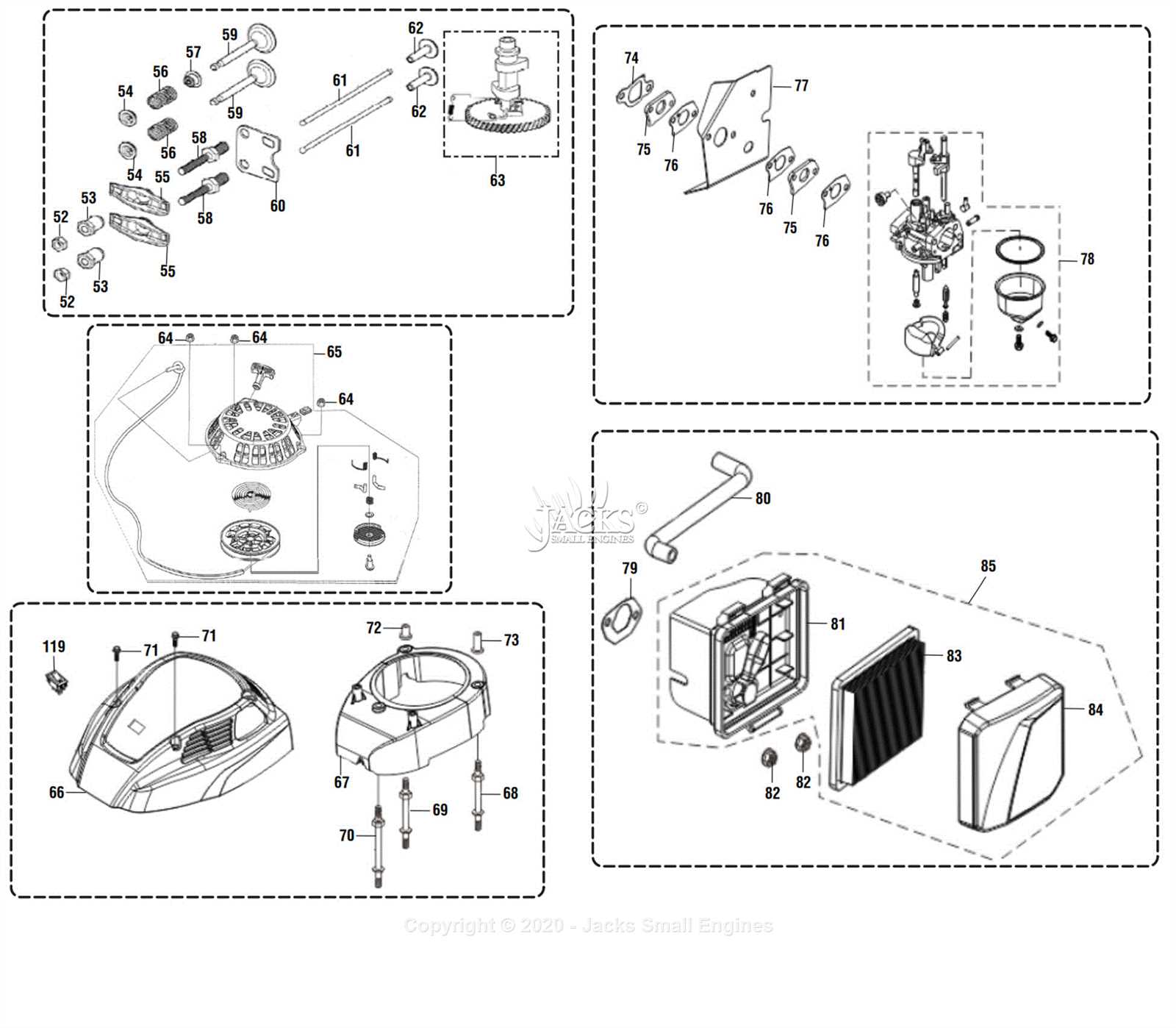

Pressure Pump Mechanisms and Functionality

The mechanism behind fluid propulsion in high-pressure devices involves a complex system of interworking components designed to efficiently increase water pressure for various cleaning applications. At the heart of this system is a pump, whose role is crucial in ensuring consistent performance by delivering the necessary force to the fluid. Understanding how the pump functions and the key parts that contribute to its operation is vital for maintaining the optimal working condition of the device.

The pressure pump is responsible for drawing in fluid and compressing it to high pressure before directing it out through the nozzle. This process begins with the intake valve, which opens to allow fluid to flow into the pump. As the pump’s internal mechanism, often a piston or diaphragm, compresses the fluid, the energy generated forces the water through a series of valves and into the hose, ultimately reaching the nozzle for spraying.

Key to the functionality of this system is the efficient operation of the pistons or diaphragms, which move in a cyclical pattern to maintain a steady flow. These components, often made from durable materials, ensure that the fluid is pressurized without loss of power, even during continuous use. Additionally, mechanisms like the unloader valve are integral for controlling the pressure and preventing damage to the pump when not in use.

How Water Flow is Controlled in Systems

In any fluid-based system, managing the movement of liquid is crucial for its overall performance and efficiency. The ability to control how water moves through the system impacts both pressure and distribution. This ensures that the flow reaches its intended destination with the correct force and volume.

Key Mechanisms for Regulating Flow

- Valves: Used to either restrict or allow the passage of liquid, valves are fundamental components in guiding the flow.

- Pumps: These devices increase pressure, ensuring water is moved throughout the

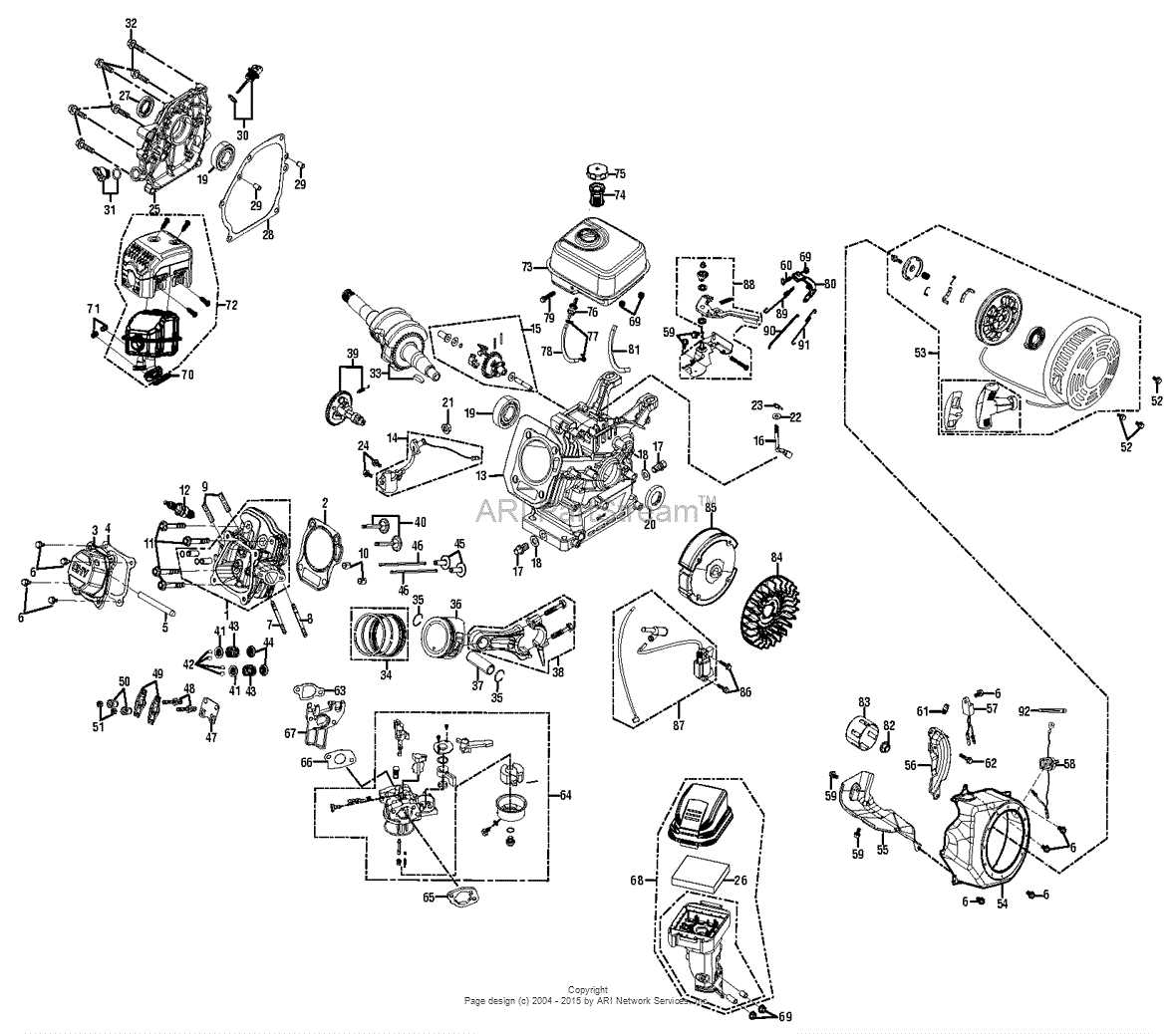

Motor Specifications and Their Role

The heart of any high-performance cleaning equipment lies in the efficiency of its motor. Properly understanding motor specifications ensures that the device runs at optimal power, meeting all necessary demands for reliability and endurance. Knowing the motor’s capabilities allows users to maximize performance, ensuring that every component is used effectively.

Key Factors in Motor Design

Several factors, including voltage, current, and rotational speed, directly influence the motor’s output. These aspects determine the overall force generated and how efficiently the system operates under varying conditions. The right combination of these parameters leads to improved performance and longevity.

Enhancing Longevity through Maintenance

Regular upkeep of the motor is essential for maintaining its full functionality. Ensuring the motor is properly lubricated, free of debris, and operating within safe temperature ranges can significantly extend its operational life, reducing wear and tear on the system.

Essential Safety Features to Consider

When dealing with high-pressure cleaning equipment, ensuring user safety is of paramount importance. Modern devices are often equipped with several key elements that are designed to protect both the operator and the equipment itself. Understanding these features can significantly reduce the risk of accidents and prolong the lifespan of the machinery.

Feature Description Automatic Shutoff Prevents overheating by turning off the unit when idle for a set period, conserving energy and minimizing wear. Pressure Relief Valve Regulates excessive buildup within the system, ensuring consistent performance while preventing dangerous spikes. Safety Lock Trigger Exploring the Hose Connections and Fittings

Understanding the various links and couplings involved in fluid transportation systems is essential for maintaining efficiency and preventing leaks. Properly selecting and attaching the right components ensures smooth operation and maximizes performance.

Types of Connections

- Quick-connect adapters for easy setup and removal.

- Threaded fittings offering a secure and stable attachment.

- Compression-style couplings designed for high-pressure applications.

Choosing the Right Fitting

When selecting a connector, consider compatibility, pressure ratings, and material durability. Each type serves a specific purpose and affects overall system reliability.

- Check the diameter of the tubes to ensure proper fit.

- Opt for corrosion-resistant materials for longer lifespan.

- Ensure that all seals are intact

Maintenance Tips for Longevity

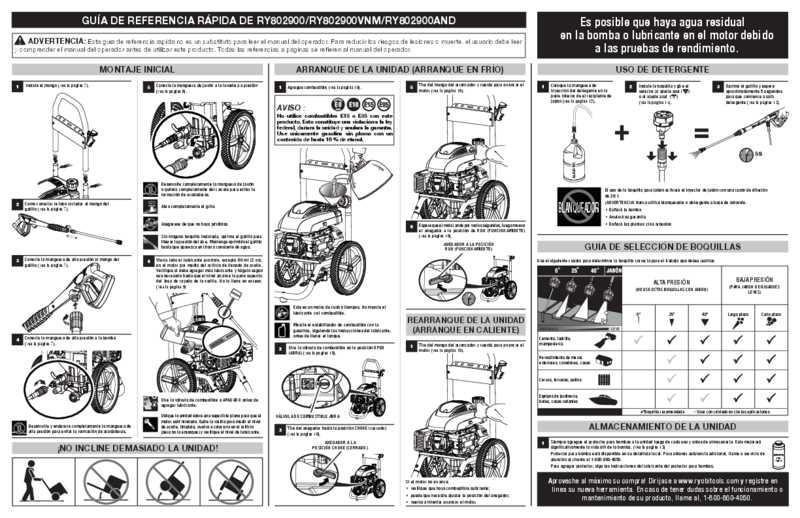

Proper upkeep is essential to ensure the lasting functionality of any cleaning equipment. By following simple care routines, you can significantly extend the life of your device, keeping it in optimal condition for years to come.

- Regularly inspect all connections to ensure they are secure and free of wear.

- Keep the machine clean and dry after each use to prevent corrosion and buildup of debris.

- Check hoses and seals for leaks or damage and replace them if necessary.

- Use the appropriate detergents and solutions, avoiding harsh chemicals that could damage internal components.

- Store the unit in a cool, dry place, especially during colder months, to prevent freezing or other weather-related damage.

- Follow the

How to Troubleshoot Common Issues

Identifying and addressing frequent malfunctions can significantly enhance the longevity and performance of your cleaning equipment. Understanding the underlying problems and knowing how to fix them ensures a more efficient operation. This section provides a structured approach to resolving common operational challenges.

Low Water Pressure

If you experience a drop in water pressure, there are several areas to inspect. Low pressure can stem from simple blockages or more complex mechanical faults. Follow these steps to troubleshoot:

- Check for any kinks or blockages in the hose.

- Ensure that the water supply is fully open and functioning properly.

- Inspect the nozzle for clogs or debris and clean it if necessary.

- Make sure the pump is operating without any visible damage.

Machine Fails to Start

When your equipment refuses to power on, the cause could be related to electrical or fuel

Gaskets and Seals: Their Importance

In any mechanical system, the role of gaskets and seals is critical to maintaining functionality and preventing damage. These components act as barriers, ensuring that fluids or gases remain confined within the designated areas while also blocking contaminants from entering sensitive spaces. Without proper sealing, even the most advanced systems can suffer from leaks, corrosion, or reduced efficiency.

Ensuring System Integrity

Gaskets and seals are designed to preserve the integrity of a system by preventing leaks and ensuring proper compression between connected parts. They help maintain the balance between moving and stationary elements, enabling smooth operation without compromising performance. Using quality materials and ensuring regular inspection can greatly enhance the longevity of these components.

Protecting Against Wear and Tear

Another key function of these components is to shield various mechanisms from

Upgrading Components for Enhanced Performance

Improving the efficiency of your cleaning equipment often requires more than regular maintenance. By upgrading certain elements, you can significantly boost its functionality and longevity. Thoughtfully chosen enhancements can reduce operational strain and ensure more reliable operation in demanding situations.

Enhanced nozzles are a great starting point, offering a variety of spray patterns to better suit different cleaning tasks. This allows for more effective and precise cleaning, depending on the surface or material.

Another potential upgrade involves investing in durable hoses. High-quality hoses can withstand greater pressure and provide more flexibility, reducing the risk of kinks or wear. This can directly impact the machine’s overall performance and ease of use.

Finally

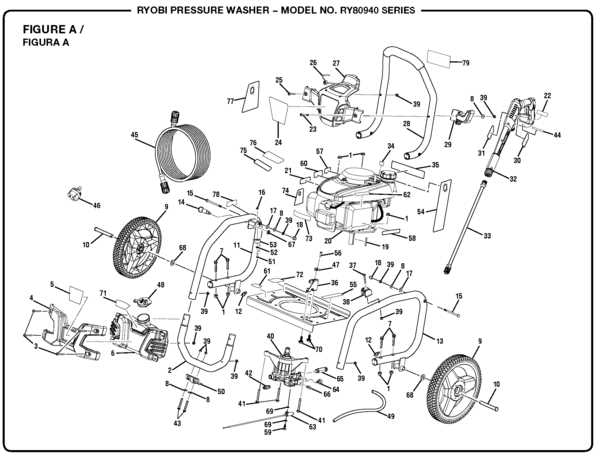

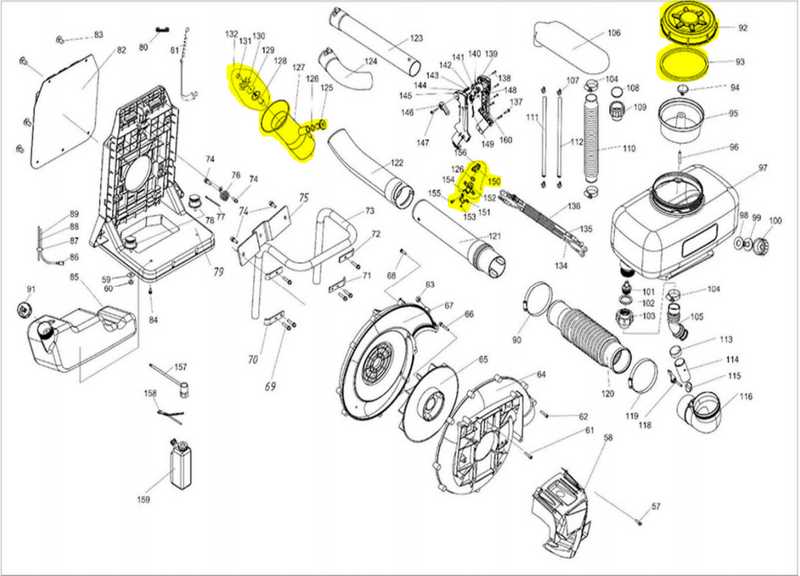

Reading and Interpreting Diagrams Effectively

Understanding visual representations of complex systems requires a structured approach. These visual guides offer detailed information about the components and their connections, allowing users to troubleshoot, repair, or enhance the system’s functionality.

To interpret these visuals effectively, it is essential to familiarize yourself with the symbols and conventions used. By following a systematic process, you can extract useful information and apply it correctly in real-world scenarios.

- Identify the key symbols and their meanings, often found in the legend or key.

- Examine how components are arranged and connected, focusing on flow or functionality.

- Look for numbered or labeled sections that indicate specific parts or areas of interest.

- Cross-reference different sections to ensure the connections or pathways are clear.

- Analyze any provided measurements, tolerances, or specifications to ensure