Every woodworking tool is a combination of various intricate elements working together to achieve precise results. Knowing how these elements interact can help ensure optimal performance and longevity of the equipment. Each component plays a crucial role in creating smooth edges and detailed finishes on materials like wood and plastic.

When familiarizing yourself with these components, it’s important to recognize how their individual functions contribute to the overall efficiency of the device. Regular maintenance and proper usage can extend the lifespan of the tool, ensuring that it operates with precision over time.

Whether you’re a seasoned craftsman or a beginner, having a solid understanding of the internal structure and key elements of your equipment can greatly improve your results. This knowledge enables better troubleshooting and easier replacement of worn-out pieces, helping to keep your projects on track without unnecessary delays.

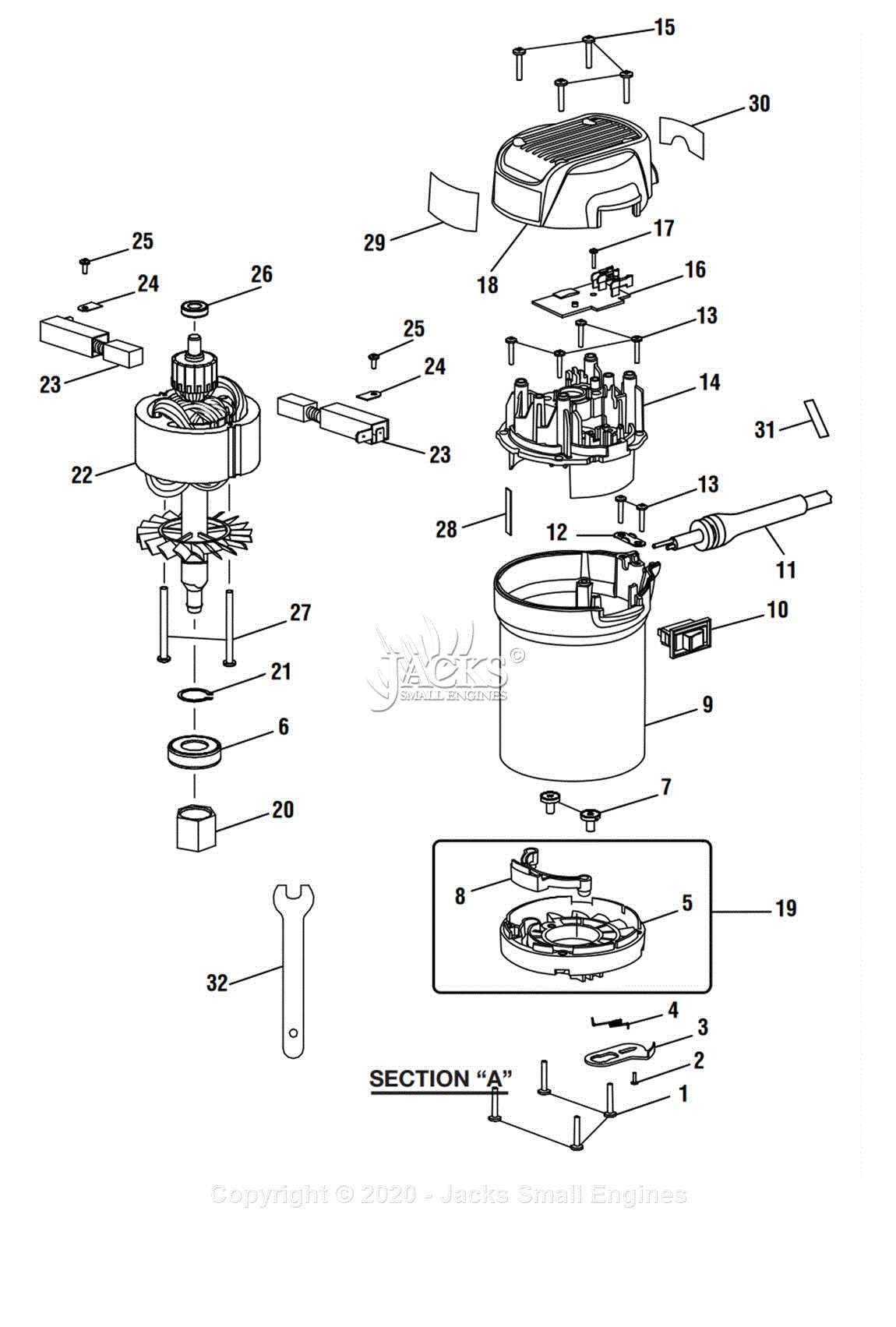

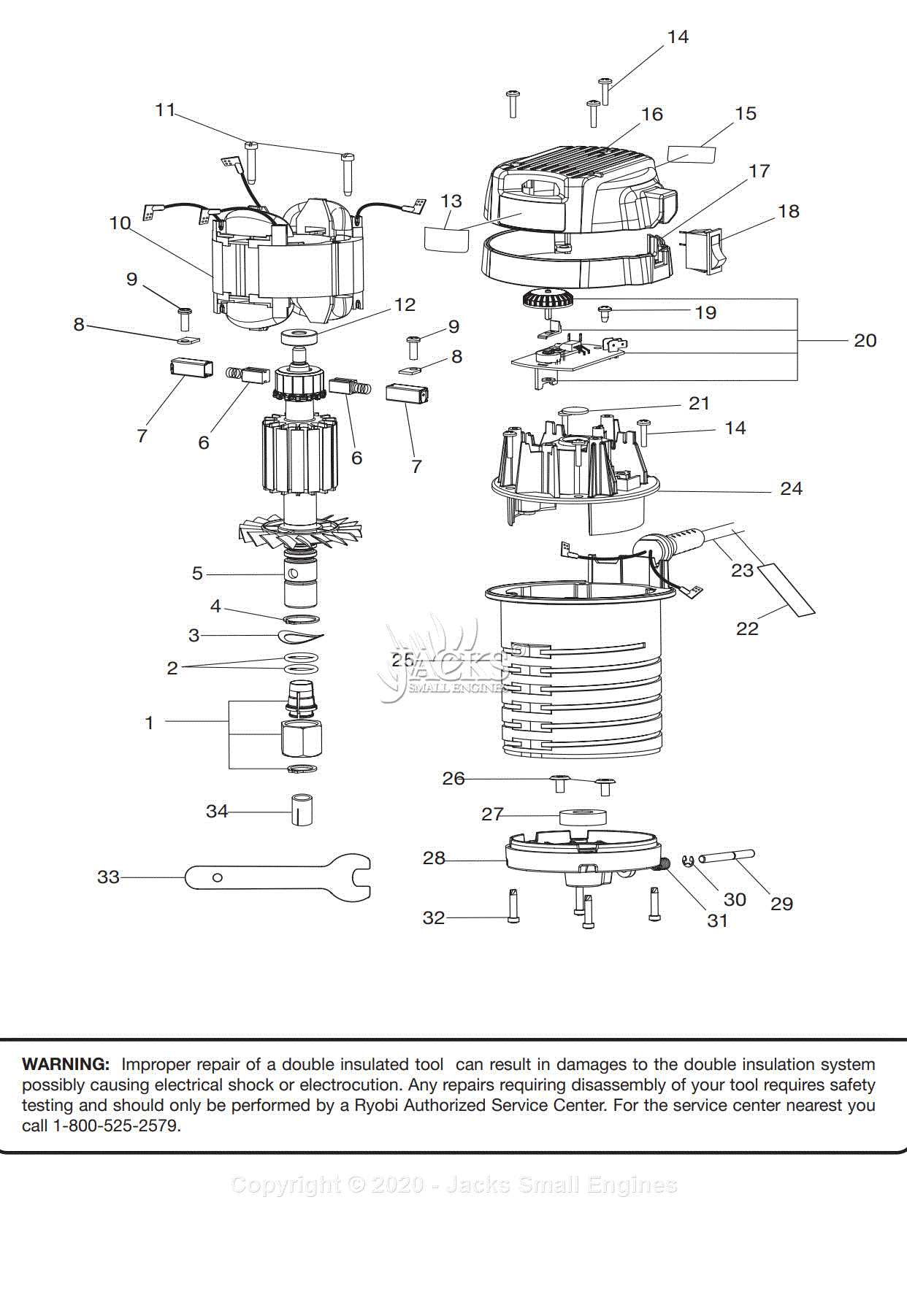

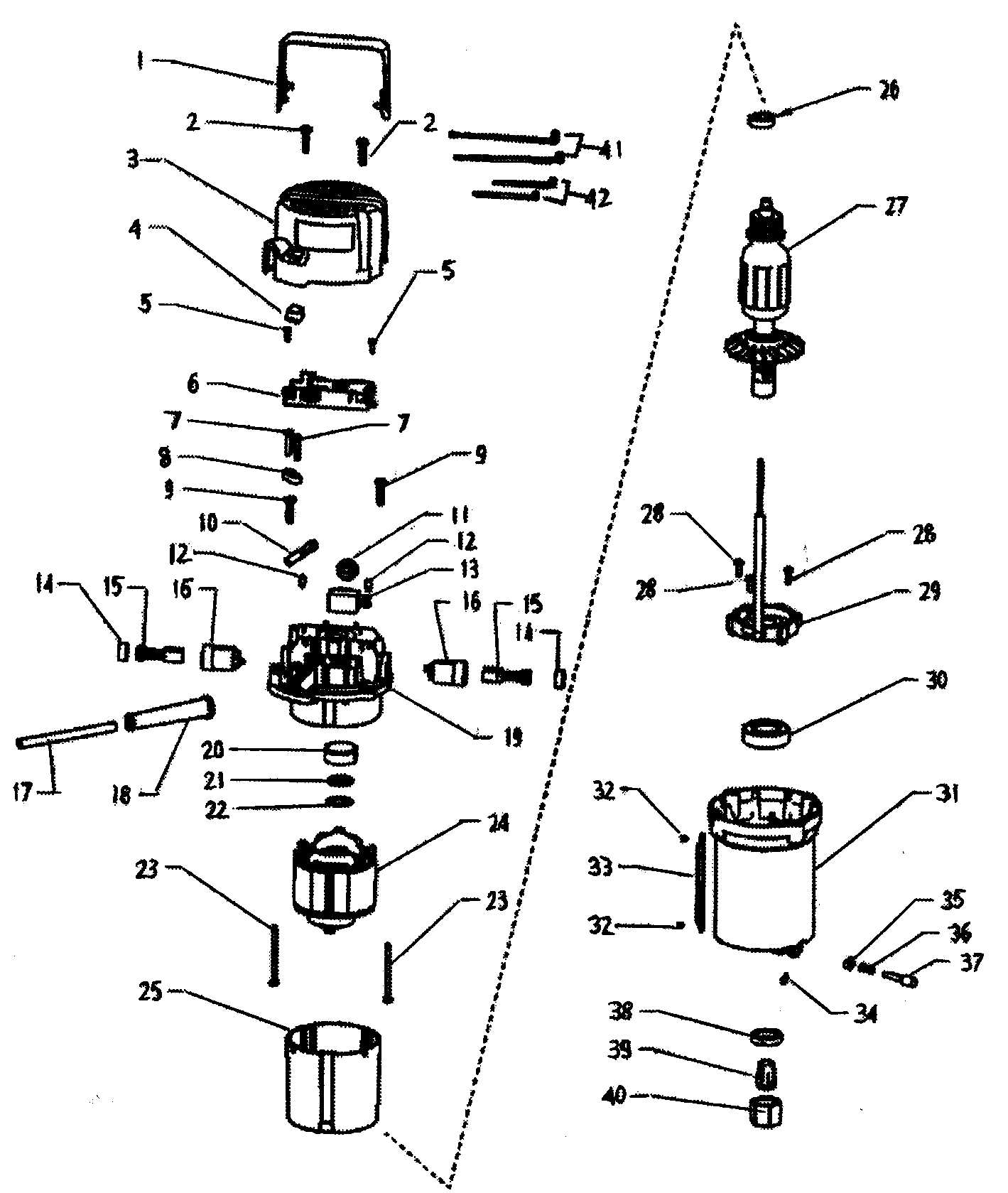

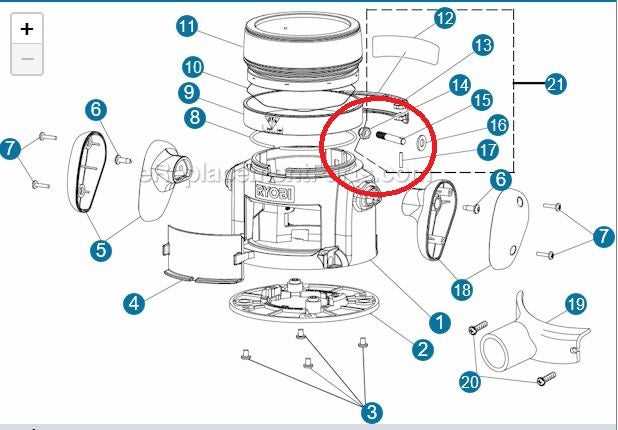

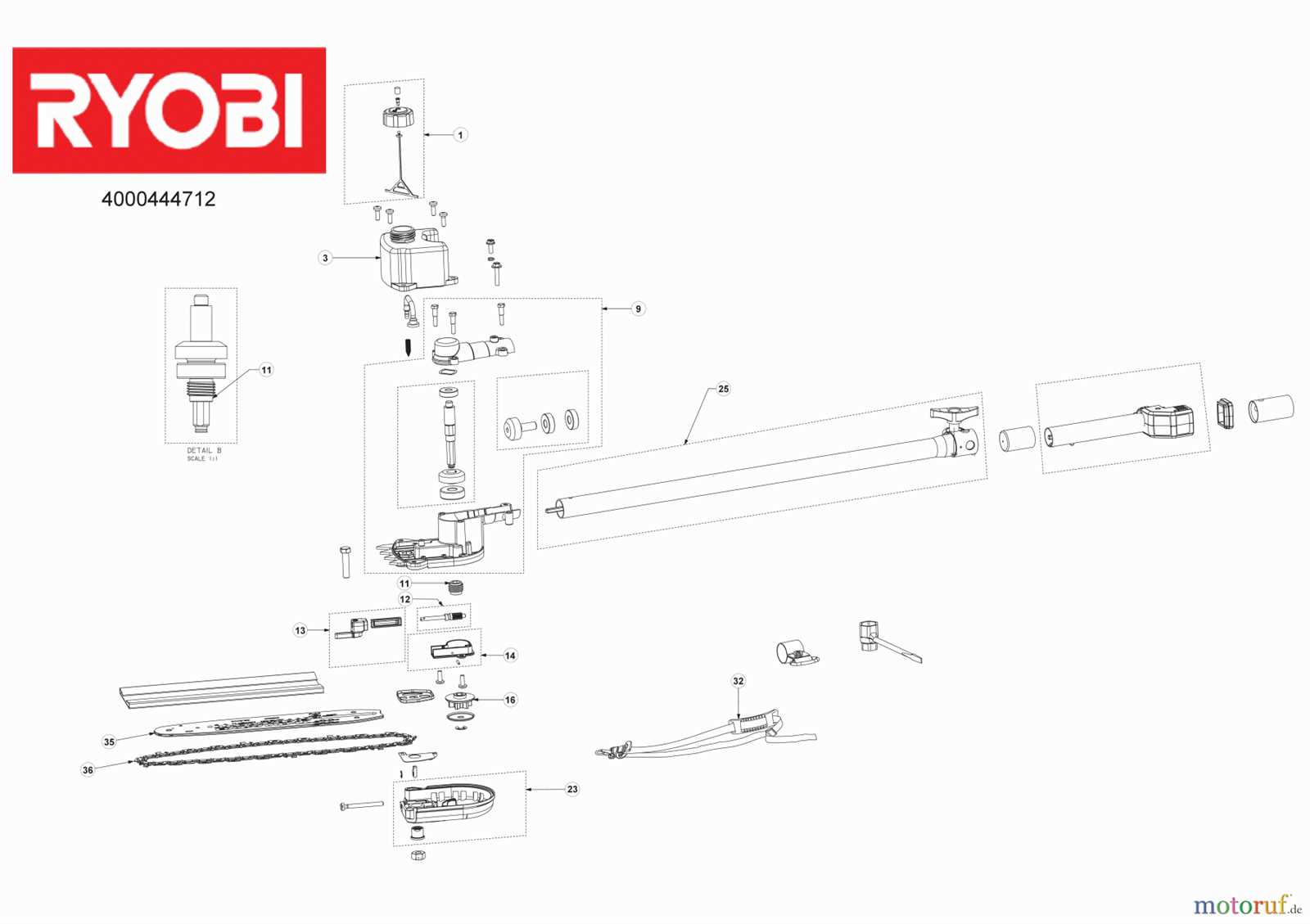

Ryobi Router Components Overview

The following section provides a detailed examination of the essential elements commonly found in handheld woodworking tools. These components work together to deliver precision and control, ensuring efficient performance across various tasks.

Key structural parts include the base, which ensures stability during operation, and the motor housing, which protects the internal mechanisms. The handles are designed for ergonomics, offering the user a comfortable grip while maneuvering the tool. Additionally, depth adjustment features allow for fine-tuning the cutting depth, essential for achieving the desired finish.

Electrical components and switches play a vital role in regulating power and speed, allowing for adjustments based on the material being worked on. Finally, the cutting assembly, which includes interchangeable bits, is crucial for shaping and smoothing materials with accuracy.

Understanding the Structure of a Router

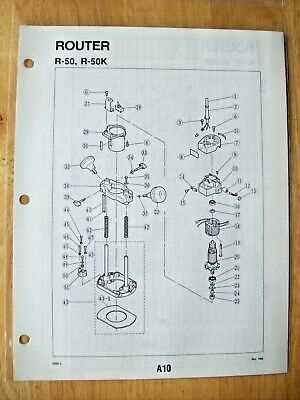

The design of a precision tool used for shaping materials can be complex, with numerous components working together to ensure smooth operation. Each element plays a crucial role in delivering accurate and reliable results, making it essential to understand how these parts interact to perform specific tasks efficiently.

Main Components and Their Functions

At the core of the system, there are several vital elements responsible for its overall functionality. These include mechanisms for power transmission, speed control, and the precise movement of the cutting edge. Understanding the purpose of each section will help users maintain optimal performance and safety.

Maintaining Efficiency and Longevity

Regular upkeep and proper use of this machinery ensure that it continues to function effectively over time. Key areas such as the motor, base, and cutting mechanism should be inspected f

Key Features of Ryobi Router Models

These versatile power tools are designed to handle a variety of woodworking tasks, offering both precision and power for various applications. Built for durability and ease of use, they cater to professionals and hobbyists alike, ensuring consistent performance across multiple projects.

| Feature | Benefits | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Variable Speed Control | Allows for greater control over cutting speed, making it easier

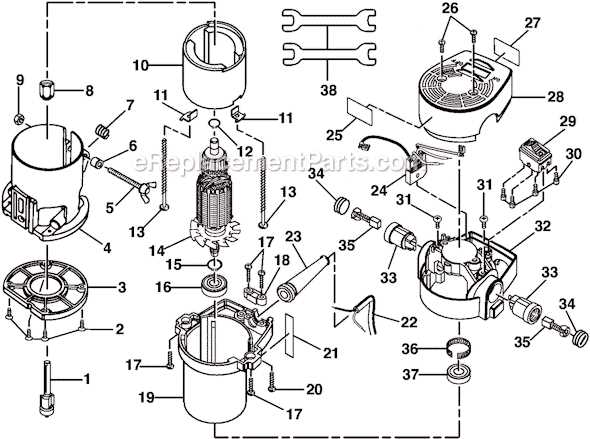

Exploring the Router’s Motor AssemblyThe motor assembly plays a crucial role in the functionality of a woodworking tool, providing the necessary power and stability for smooth operations. Understanding its structure and key elements is essential for proper maintenance and optimization. In this section, we will delve into the essential components of this power unit and how each part contributes to its overall performance. Key Components of the Motor System

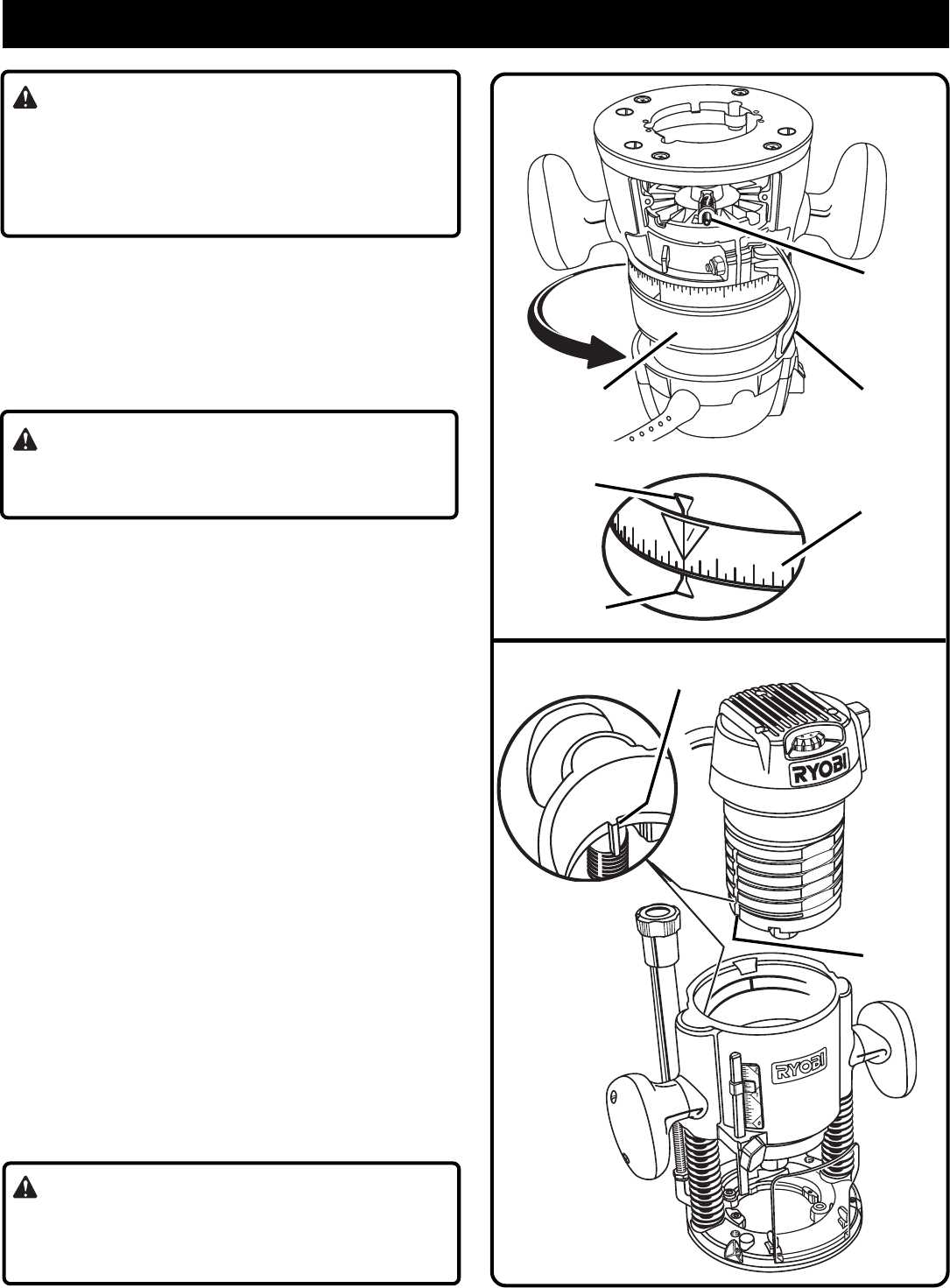

The central power unit is made up of several critical parts that work together to produce the desired results. These include the electric motor, which drives the rotation, and various support components that ensure smooth operat How the Base Plate Affects RoutingThe base plate is a key component in ensuring precision and stability during cutting operations. Its influence on the outcome can be substantial, as it determines the level of control and smoothness of movements. By providing a steady foundation, the base plate allows for better maneuverability, ensuring clean and accurate results across different materials. Stability and BalanceA well-designed base plate enhances the balance of the tool, reducing vibrations and unwanted shifts. This stability is crucial when handling delicate or intricate patterns. The size and shape of the plate can significantly impact how evenly pressure is distributed, allowing for more consistent results and minimizing errors. Material CompatibilityThe material and design of the base plate play a role in determining how well it glides over various surfaces. Some plates are tailored for smoother finishes, while others are designed to withstand rougher conditions. Choosing the right base Adjustable Depth Settings and Their UsesAdjustable depth controls play a crucial role in precision woodworking, allowing users to customize the cutting depth based on project requirements. This feature ensures that the tool can be adapted for various tasks, from shallow grooves to deep cuts, offering flexibility and accuracy. By adjusting the depth, users can achieve clean, professional results while enhancing safety and ease of use. Benefits of Custom Depth Adjustment

The ability to fine-tune the depth of cuts allows for greater versatility. Whether creating intricate designs, trimming edges, or hollowing out wood, the adjustable depth ensures that each task can be completed with the desired precision. Consistency in depth control is key to maintaining uniformity across different pieces, making it an essential feature for both novice and experienced craftsmen. Common ApplicationsCustomizing depth settings is particularly useful for tasks like dovetailing, edge profiling, and mortising. Each of these requires different cutting depths to achieve the correct fit and finish. By fine-tuning the depth, users can prevent material wastage and ensure optimal performance for every cut, contributing to a smoother workflow and better final product. Different Types of Router Bits Explained

When working with wood, selecting the right cutting tool is essential for achieving precise and professional results. These tools come in various shapes and sizes, each designed for specific tasks, whether it’s shaping edges, hollowing out sections, or making decorative cuts. Understanding the differences between these tools can help ensure that every project is completed efficiently and to the highest standard. Common Types of Cutting Tools

Specialized Cutting Tools

Guide to Replacing Worn Router Parts

Over time, tools used for shaping wood can wear out, leading to decreased performance and safety concerns. Knowing when and how to replace these worn components is crucial for maintaining efficiency and accuracy. Regular maintenance ensures that your equipment operates smoothly and prolongs its lifespan. Identifying worn parts is the first step in the process. Look for signs such as unusual noises, lack of precision, or visible wear on the tool. Once you’ve determined what needs replacing, refer to the manufacturer’s guidelines for the correct parts and replacement procedures.

Once you’ve gathered the necessary components, follow the step-by-step instructions for disassembly and assembly. Always ensure the tool is unplugged before starting any work. Take your time to properly install each part to maintain the tool’s integrity and safety. Maintaining the Router for LongevityRegular upkeep of your woodworking tool ensures optimal performance and extends its lifespan. Proper care can prevent early wear and tear, ensuring it remains efficient and functional for years. Focusing on routine maintenance will help you avoid costly repairs and maintain peak functionality. Key Maintenance Practices

Storing Your Tool

Common Issues with Router ComponentsWhen working with precision tools, various issues may arise due to wear, misuse, or poor maintenance of key elements. Understanding common challenges can help address and prevent malfunctions, ensuring smooth and efficient operation.

Regular inspection and maintenance can significantly reduce the occurrence of these problems, extending the tool’s lifespan and improving the quality of work. Safety Features in Ryobi Routers

When working with power tools, ensuring safety is paramount. Modern equipment incorporates various protective mechanisms to minimize risk during operation. These mechanisms are designed to prevent accidents and provide users with greater control over the device. Enhanced Grip and Control: Tools often feature ergonomic designs and textured handles that reduce the likelihood of slippage, allowing for better stability during use. Automatic Shut-off Mechanism: Many models include a safety feature that automatically shuts down the device when it detects irregular behavior, preventing potential damage or injury. Blade Guard and Safety Shields: Equipped with protective guards, the device helps to shield the user from direct contact with moving parts, reducing the chances of injury. Dust and Debris Management: Advanced systems in tools also focus on maintaining a clean working environment by efficiently managing dust and debris, which not only improves visibility but also minimizes inhalation risks. |