In the realm of power equipment, having a comprehensive understanding of the various components and their arrangement is essential for effective maintenance and repairs. A detailed layout can serve as a valuable resource for both novice users and seasoned professionals, enabling them to identify parts quickly and facilitate troubleshooting processes.

Moreover, recognizing the intricacies of each element enhances the overall efficiency of tool operation. By familiarizing oneself with the configuration of individual components, users can ensure optimal performance and longevity of their equipment. This knowledge not only simplifies repairs but also empowers users to undertake DIY maintenance with confidence.

Ultimately, investing time in understanding the structural organization of power tools can lead to improved functionality and reduced downtime. Whether for routine maintenance or unexpected repairs, having access to a clear representation of tool components significantly enhances the user experience.

This section explores the essential elements that make up a particular model of power tools designed for precision cutting. Understanding these components can help users maintain, repair, and optimize their equipment effectively. Each element plays a crucial role in ensuring smooth operation and overall efficiency.

The various parts of the tool can be categorized into several key groups, including the cutting mechanism, support structures, and power systems. Familiarity with these elements can aid users in troubleshooting issues and performing routine maintenance.

| Component | Description |

|---|---|

| Blade Assembly | Consists of the cutting blade and associated components that ensure precise cuts. |

| Base Plate | Provides stability and support during operation, allowing for accurate cutting angles. |

| Motor Unit | Drives the blade assembly and powers the entire tool, crucial for efficient performance. |

| Adjustable Fence | Facilitates straight cuts and can be adjusted to accommodate different material widths. |

| Power Switch | Controls the operation of the tool, ensuring safe and convenient use. |

How to Read a Parts Diagram

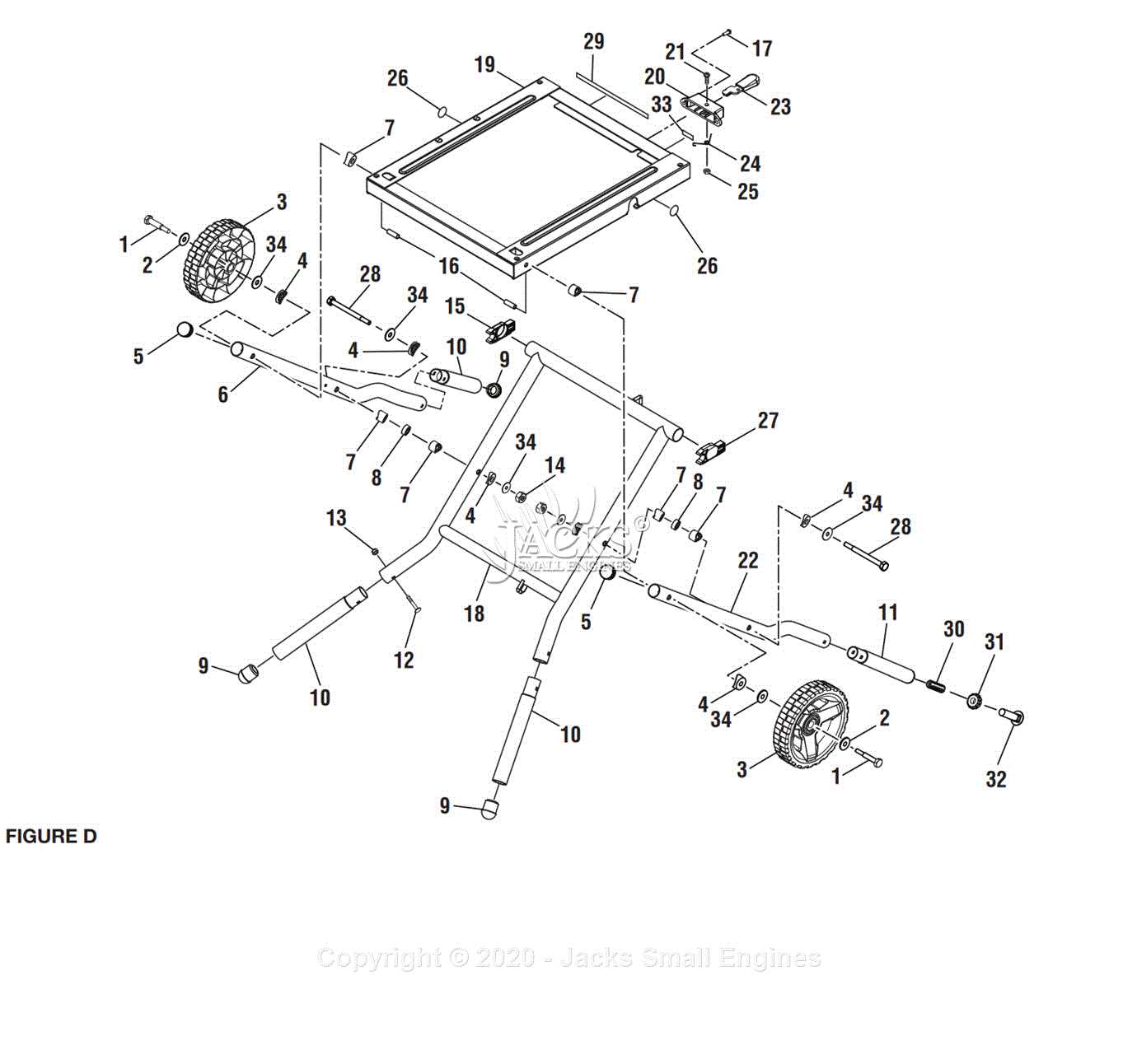

Understanding the components of a machine is essential for effective maintenance and repair. A visual representation of the various elements allows users to identify each part and comprehend how they interact within the system. This guide provides insights into interpreting such representations, facilitating smoother assembly and troubleshooting processes.

When examining a visual representation, start by familiarizing yourself with the layout. Each section typically corresponds to a specific area of the equipment, often organized logically to reflect the assembly order. Parts are usually labeled with unique identifiers, enabling easy cross-referencing with documentation or inventory lists.

| Identifier | Description | Location |

|---|---|---|

| A1 | Main Body | Center section |

| B2 | Control Panel | Front section |

| C3 | Power Source | Bottom section |

| D4 | Safety Guard | Top section |

Additionally, pay attention to any notes or legends that may accompany the illustration. These often provide further clarification on assembly techniques, torque specifications, or maintenance intervals, ensuring that users have all necessary information for effective operation.

Replacement Parts for Ryobi RTS23

When maintaining any power tool, ensuring access to suitable components is essential for optimal performance and longevity. Having reliable alternatives can greatly enhance the user experience and facilitate smooth operation. Whether you are performing routine maintenance or conducting a repair, identifying the correct replacements is crucial.

Various suppliers offer a wide selection of compatible components, including motors, blades, and safety features. Investing in high-quality substitutes not only extends the life of your equipment but also enhances its efficiency. Make sure to consult your tool’s manual or trusted resources to find the right matches for your specific needs.

Furthermore, consider reaching out to authorized dealers or specialized retailers for expert advice. They can provide valuable insights on compatibility and performance, ensuring you choose the best options available. With the right components, your equipment can continue to perform at its best, making your tasks easier and more efficient.

Maintaining Your RTS23 Equipment

Regular upkeep of your machinery is crucial for ensuring optimal performance and longevity. By adhering to a structured maintenance routine, you can prevent potential issues and enhance the efficiency of your tools. This section will outline essential practices to keep your equipment in top condition.

- Routine Cleaning: Ensure to remove dust and debris after each use. This prevents buildup that can affect functionality.

- Inspection: Regularly check components for wear and tear. Look for signs of damage or excessive wear that may require replacement.

- Lubrication: Apply suitable lubricants to moving parts as recommended. This reduces friction and prevents premature wear.

- Storage: Store the equipment in a dry and secure location. Protect it from moisture and extreme temperatures to avoid deterioration.

Implementing these maintenance strategies will not only extend the life of your machinery but also improve its overall performance. Make it a habit to perform these tasks regularly to ensure smooth operation during your projects.

Troubleshooting Common Issues

Addressing frequent problems is essential for maintaining optimal performance and prolonging the lifespan of your equipment. Understanding potential complications can help users identify and resolve issues efficiently, ensuring smooth operation during use.

One common concern is the device failing to start. This may be caused by a depleted power source, loose connections, or faulty components. Checking the battery charge and ensuring all connections are secure can often rectify the issue.

Another prevalent issue is inconsistent operation or lack of power. This can result from clogged filters or worn-out parts that hinder performance. Regular cleaning and periodic inspections of crucial elements can significantly enhance functionality.

Users may also encounter excessive noise or vibrations during operation. Such symptoms often indicate misalignment or the need for lubrication. Regular maintenance and prompt adjustments can mitigate these problems, ensuring a quieter and smoother experience.

Finally, if the equipment produces unsatisfactory results, examining the settings and making necessary adjustments can help achieve desired outcomes. Proper calibration and familiarity with operational parameters are vital for optimal performance.

Where to Buy Spare Parts

Finding the right components for your equipment can be crucial for its longevity and performance. Numerous avenues exist for acquiring replacement elements, ensuring that your tools remain functional and efficient. Whether you are looking for specific pieces or general supplies, it’s essential to know the best sources available to you.

Online Retailers

One of the most convenient ways to locate components is through online stores. Websites specializing in tool accessories often provide extensive catalogs, allowing you to search by category or specific requirements. Be sure to read reviews and compare prices to find the best deals.

Local Supply Stores

Your nearby hardware or supply store can also be a valuable resource. These establishments typically stock a variety of equipment essentials and may assist in ordering specialized items. Engaging with staff can offer insights and recommendations tailored to your needs.

Compatibility with Other Ryobi Models

This section explores the interoperability of various tools and equipment within the same brand, focusing on their components and overall functionality. Understanding how different models relate to each other can enhance user experience and expand the versatility of your toolkit.

Many devices within the same brand line share similarities in design and technology, making them compatible with one another. This allows users to interchange certain parts and accessories, reducing the need for multiple purchases. For example, if a particular component is not available for one model, it might be found in another, facilitating easier repairs and maintenance.

When considering the interchangeability of tools, it is important to check specifications and compatibility guides. Many manufacturers provide detailed information on which models can effectively work together, ensuring that users can make informed decisions when selecting additional equipment or replacement parts.

In summary, exploring the relationships between different tools within the same brand can significantly enhance their utility and efficiency. By leveraging compatible models, users can maximize their investment and simplify maintenance efforts.

Safety Tips for Using RTS23

When operating power tools, prioritizing safety is crucial to prevent accidents and injuries. Understanding essential precautions can significantly enhance your experience while ensuring protection for yourself and others in the vicinity.

Always Wear Personal Protective Equipment: Equip yourself with appropriate safety gear, including goggles, gloves, and ear protection. This attire safeguards against flying debris and minimizes exposure to noise, ensuring a safer working environment.

Maintain a Clean Workspace: Keep your area tidy and free of obstructions. Clutter can lead to slips, trips, or falls, so organizing tools and materials helps maintain focus and reduces hazards.

Inspect Your Equipment Regularly: Before use, examine your tools for any signs of wear or damage. Addressing issues promptly ensures optimal performance and reduces the risk of malfunction during operation.

Follow the Manufacturer’s Guidelines: Adhering to operational instructions is vital for safe usage. Familiarize yourself with the equipment’s features and limitations to operate it effectively and safely.

Use Proper Technique: Ensure you are familiar with the correct methods for handling the tool. Improper technique can lead to loss of control, resulting in potential accidents.

Keep Hands and Body Clear: Always maintain a safe distance from moving parts. Being aware of your position in relation to the tool’s operation prevents accidental injuries.

Stay Focused and Avoid Distractions: Concentrate on the task at hand. Distractions can lead to mistakes, so it’s important to stay engaged and alert while operating power tools.

Upgrades and Modifications Options

Enhancing performance and functionality can significantly improve the efficiency of any tool. Various options are available for those looking to customize their equipment. These enhancements can range from simple accessory additions to more complex upgrades that alter the machine’s capabilities.

When considering modifications, it is essential to focus on compatibility and overall utility. Below are some popular upgrade paths that can be explored:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Blade Replacement | Swapping out the standard blade for a high-quality or specialized blade. | Improved cutting efficiency and accuracy. |

| Motor Upgrade | Installing a more powerful motor to increase operational speed. | Enhanced performance for tougher materials. |

| Dust Collection System | Adding an effective dust collection accessory. | Cleaner workspace and improved visibility during use. |

| Stability Enhancements | Incorporating additional supports or bases to reduce vibration. | Greater precision and less fatigue during operation. |

Before making any modifications, it is advisable to conduct thorough research to ensure that upgrades align with the intended use and safety standards. Proper installation and adherence to manufacturer guidelines will help achieve the best results.

Resources for Further Assistance

Accessing reliable sources of information can significantly enhance your experience with tools and equipment. Whether you are seeking troubleshooting advice, maintenance tips, or replacement components, various platforms are available to assist you. Utilizing these resources effectively can ensure optimal performance and longevity of your device.

Online Communities and Forums

Engaging with online communities provides a platform for users to share their experiences and solutions. Forums dedicated to tool enthusiasts often feature discussions on common issues, modifications, and best practices. Participating in these groups can offer valuable insights and practical advice from experienced users.

Manufacturer and Retailer Support

Official manufacturer and retailer websites typically host a wealth of information, including user manuals, troubleshooting guides, and contact information for customer support. These resources are crucial for obtaining accurate and reliable assistance, ensuring you have access to expert guidance when needed.