Understanding how the various elements of a tool come together is essential for effective maintenance and troubleshooting. The arrangement of these crucial elements can often provide insights into how the system functions and how each component interacts with the others. By exploring the structure and organization of these elements, users can gain a deeper appreciation of their tool’s overall operation.

A well-structured visualization of key elements helps identify the purpose and position of each part within the system. This approach allows for smoother repairs and better understanding of the technical workings behind the tool’s design. Whether for routine upkeep or more complex tasks, having a clear view of these elements is indispensable.

With a detailed breakdown of essential components, users are empowered to address issues more confidently. This structured approach

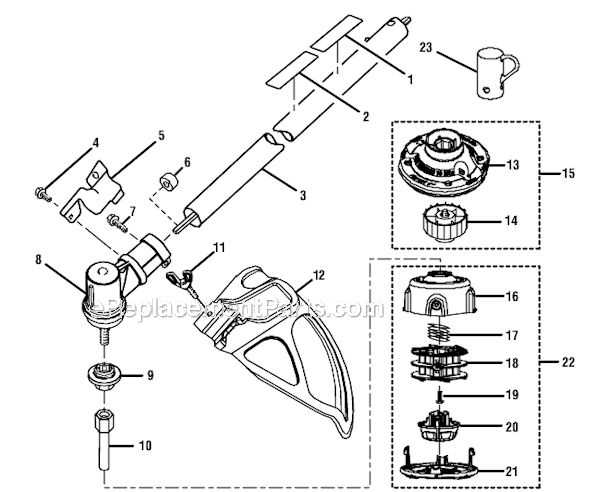

Ryobi ry40001a Parts Breakdown

This section provides a comprehensive overview of the components associated with a specific power tool model. Understanding the different elements that make up the device can enhance maintenance and repair efforts, ensuring optimal performance and longevity.

Key Components Overview

- Motor Assembly

- Gear Housing

- Power Switch

- Battery Housing

- Trigger Mechanism

- Protective Cover

Maintenance Tips

- Regularly inspect each component for wear and tear.

- Keep the device clean to prevent debris buildup.

- Ensure all screws and fasteners are tightened appropriately.

- Replace damaged parts immediately to maintain efficiency.

Exploring the Main Components

This section delves into the essential elements that contribute to the functionality and efficiency of the equipment. Understanding these key parts can enhance your overall experience and ensure optimal performance. Each component plays a significant role in how the machine operates, making it crucial to familiarize yourself with their characteristics and interrelations.

Core Elements

Among the core elements, the motor serves as the powerhouse, providing the necessary energy to drive the entire system. Additionally, the housing not only protects internal components but also contributes to the overall durability of the tool. Recognizing the importance of these fundamental parts is vital for effective usage and maintenance.

Supporting Features

Complementing the main components are various supporting features that enhance usability and performance. For instance, the ergonomic handles facilitate a comfortable grip, reducing fatigue during prolonged use. Furthermore, adjustable settings allow users to customize operations according to specific tasks, promoting versatility and efficiency.

Detailed View of the Engine Assembly

This section provides an in-depth look at the various components that make up the engine assembly. Understanding the structure and function of each part is essential for effective maintenance and troubleshooting. By examining the intricacies of the assembly, users can gain valuable insights into its operation and longevity.

Key Components of the Engine

The engine assembly consists of several vital elements, each contributing to the overall functionality. Key components include the cylinder, crankshaft, and piston, which work in harmony to convert fuel into mechanical energy. The proper alignment and condition of these parts are crucial for optimal performance.

Maintenance and Troubleshooting Tips

Regular inspection of the engine assembly is necessary to identify any wear or damage. Common issues may arise from inadequate lubrication or carbon buildup, leading to decreased efficiency. Ensuring that all components are clean and well-maintained can prevent costly repairs and extend the lifespan of the assembly.

How to Identify Small Parts Easily

Recognizing individual components can significantly simplify maintenance and repairs. Understanding how to distinguish these tiny items enhances your efficiency and reduces frustration during projects. With the right approach, anyone can master the identification process.

Utilize Reference Guides

Reference materials such as manuals and online resources provide valuable information about various elements. These guides often include detailed illustrations or descriptions that can aid in pinpointing specific items. Investing time in familiarizing yourself with these resources can save you from unnecessary confusion later.

Organize Components Methodically

Maintaining an orderly workspace is crucial for identifying small items effectively. By categorizing components based on size, shape, or function, you can streamline the identification process. Using containers or labeled sections can further enhance your ability to locate the necessary parts quickly.

Replacement Tips for Wearable Items

Maintaining and replacing components of wearable devices is crucial for ensuring optimal performance and longevity. By understanding the signs of wear and knowing when to replace specific items, users can enhance their experience and maximize functionality.

Identifying Signs of Wear

Regularly inspecting wearable items can help detect signs of deterioration early. Common indicators include:

| Indicator | Description |

|---|---|

| Cracks or Breaks | Visible fractures that may affect structural integrity. |

| Discoloration | Fading colors or stains indicating material degradation. |

| Malfunction | Devices not performing as intended, suggesting component issues. |

Best Practices for Replacement

When replacing worn-out items, consider the following best practices:

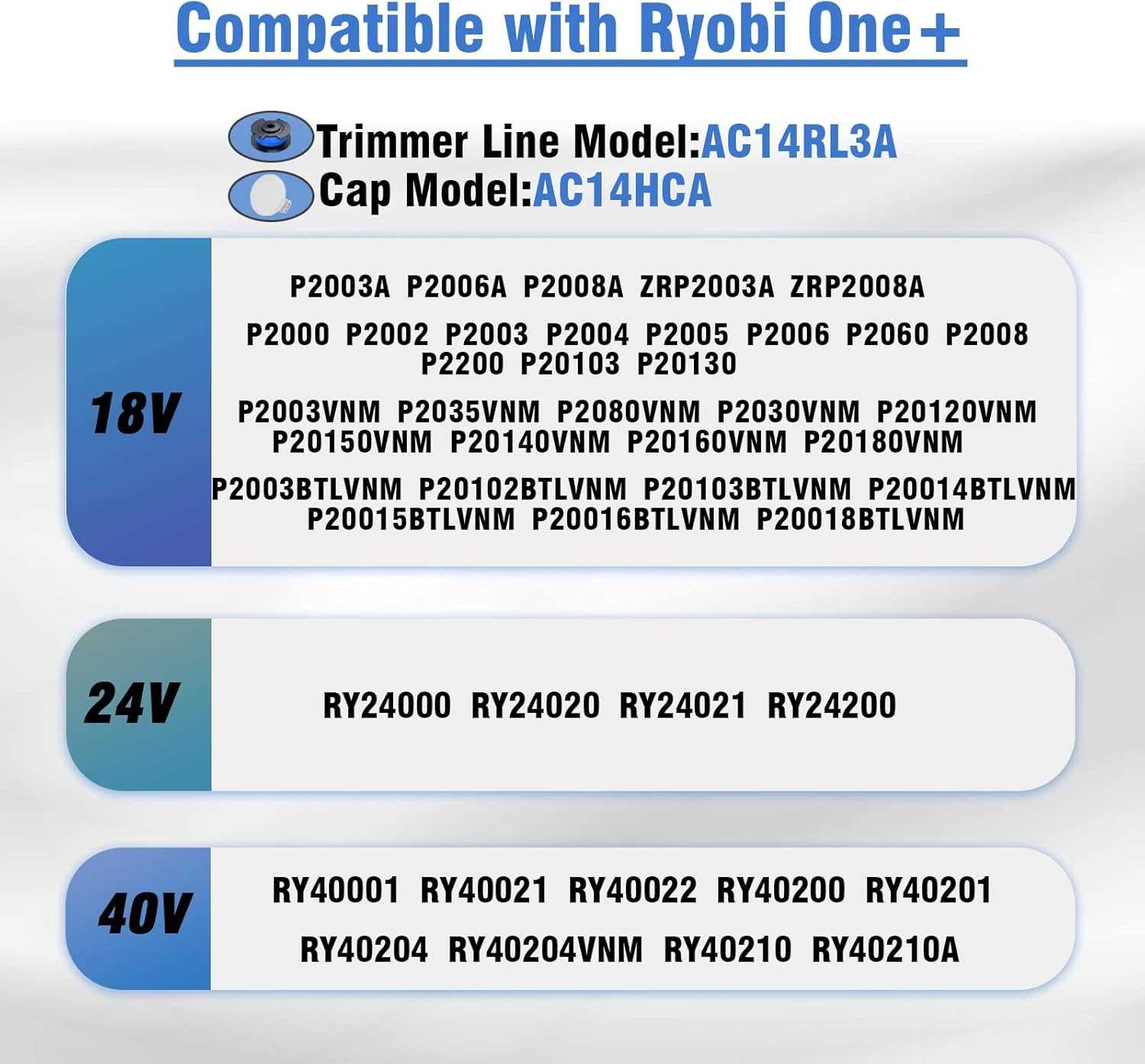

- Source original or compatible components to ensure compatibility.

- Follow manufacturer guidelines for replacement procedures.

- Keep a record of replacement dates to track wear patterns.

Visual Guide to the Motor Section

This section provides an overview of the motor components, offering a clear representation of how each part contributes to the overall functionality. Understanding the various elements involved is essential for proper maintenance and troubleshooting, ensuring optimal performance of the equipment.

Key Components of the Motor Assembly

The motor assembly consists of several crucial parts that work together to produce power. Key components include the rotor, stator, and various fasteners that hold everything in place. Each element plays a specific role in the operation, influencing efficiency and durability.

Maintenance Tips for Motor Parts

Understanding the Electrical Connections

The effective operation of any electrical device hinges on the proper management of its connections. Understanding how these connections work is crucial for troubleshooting and maintaining performance. This section delves into the various aspects of electrical linkages, emphasizing the importance of correct wiring and secure contacts.

Types of Electrical Linkages

There are several types of electrical linkages found in devices, each serving a specific purpose. Wiring harnesses are commonly used to bundle multiple wires together, ensuring a neat and organized setup. Connectors play a vital role in enabling easy disconnection and reconnection, which is essential during repairs. Understanding these components can greatly aid in diagnosing issues.

Importance of Proper Connections

Ensuring that all connections are secure and correctly aligned is critical for the safe operation of any electrical system. Loose or faulty connections can lead to malfunctions or even hazards like short circuits. Regular inspection of these linkages can prevent potential problems and extend the lifespan of the equipment.

Blades and Accessories Overview

This section focuses on the essential cutting implements and supplementary components that enhance the functionality of power tools. Understanding these elements is crucial for optimizing performance and achieving desired results in various tasks.

Different types of cutting tools and accessories are available, each designed for specific applications. Here are some common options:

- Circular Blades: Ideal for making clean, straight cuts in wood and other materials.

- Reciprocating Blades: Suitable for demolition work and cutting through a variety of surfaces.

- Jigsaw Blades: Perfect for intricate cuts and curves in different materials.

- Sanding Accessories: Designed for smoothing surfaces and finishing tasks.

- Drill Bits: Essential for creating holes in various materials, with options for different sizes and styles.

Additionally, users can enhance their tools with various accessories:

- Adapters: Allow for compatibility between different tool types and accessories.

- Carrying Cases: Provide convenient storage and transport options for tools and their components.

- Replacement Parts: Ensure longevity and maintain optimal performance over time.

By selecting the appropriate cutting tools and accessories, users can significantly improve their productivity and achieve better outcomes in their projects.

Common Issues with Ryobi ry40001a Parts

When dealing with equipment components, several frequent challenges can arise, affecting performance and efficiency. Understanding these common problems can help users troubleshoot and maintain their devices more effectively, ensuring optimal functionality and longevity.

Worn Out Components

Over time, certain elements may wear down due to regular usage, leading to diminished performance. This wear can manifest as decreased efficiency, unusual noises, or even failure to operate. Regular inspection and timely replacement of these elements can prevent more significant issues and extend the lifespan of the equipment.

Improper Assembly or Installation

Incorrect assembly can lead to a variety of problems, such as misalignment or failure to function altogether. Ensuring that all components are correctly positioned and securely fastened is crucial for reliable operation. Following manufacturer guidelines during installation can help avoid these complications and ensure that the equipment performs as intended.

Maintenance Tips for Longer Lifespan

Ensuring the longevity of your equipment requires a dedicated approach to upkeep and care. By implementing a few essential practices, you can enhance performance and extend the life of your tools significantly. Regular maintenance not only keeps your devices running smoothly but also helps prevent costly repairs.

Here are some effective maintenance strategies:

| Tip | Description |

|---|---|

| Regular Cleaning | Keep your tools free from dust, debris, and residue to ensure optimal functionality. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Inspection | Conduct periodic checks for signs of wear or damage to catch issues early. |

| Storage | Store equipment in a dry and protected environment to prevent rust and corrosion. |

| Battery Care | If applicable, follow guidelines for charging and storing batteries to prolong their lifespan. |

How to Order Correct Replacement Parts

When it comes to maintaining and repairing equipment, ensuring you acquire the right components is essential for optimal performance. A systematic approach can help streamline the ordering process, making it more efficient and effective.

1. Identify Your Equipment Model: Start by confirming the exact model of your device. This information is crucial as it dictates the specifications of the required components.

2. Consult the Manufacturer’s Resources: Many manufacturers provide comprehensive manuals or online resources that list compatible components. Referencing these materials can prevent errors in your selection.

3. Verify Compatibility: Before finalizing your order, double-check that the components you intend to purchase match the specifications of your equipment. This step can save time and reduce the likelihood of returns.

4. Use Reputable Suppliers: Purchase from well-known and trusted suppliers to ensure the authenticity and quality of the components. Reading customer reviews can provide insight into their reliability.

5. Keep Records: Maintain a record of your orders, including model numbers and supplier details. This documentation can simplify future purchases and help track any warranty information.

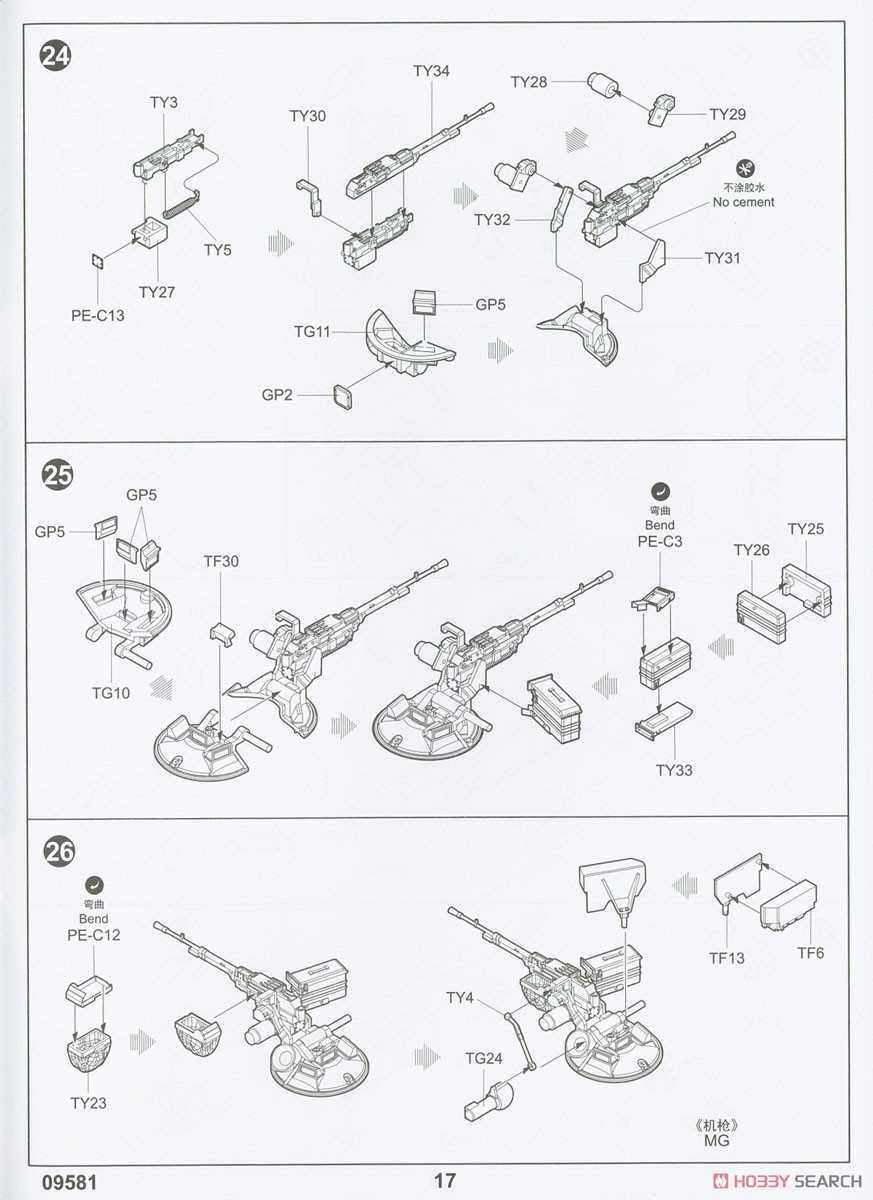

Disassembly and Reassembly Instructions

This section provides a comprehensive guide for the disassembly and reassembly of the equipment, ensuring a smooth and efficient process. Understanding each step is crucial for maintaining the device’s functionality and performance.

To begin the disassembly, ensure that the device is powered off and disconnected from any power source. Gather the necessary tools, such as screwdrivers and pliers. Start by removing any covers or casings, carefully loosening screws and gently prying apart components as needed. Take note of the order of disassembly, as this will aid in the reassembly process.

Once the device is fully disassembled, inspect each part for wear or damage. Clean components where necessary to ensure optimal performance. For reassembly, follow the reverse order of disassembly. Ensure all parts are aligned correctly and securely fastened. Double-check connections and covers to confirm everything is in place before powering on the device.

Upgrading Ryobi ry40001a: What

Enhancing the performance and functionality of your equipment can lead to a more efficient and enjoyable experience. This section explores various options available for those looking to elevate their tools, focusing on improvements that can make a significant difference in usability and effectiveness.

Performance Enhancements

Consider upgrading components that directly affect the overall efficiency of your tool. High-quality batteries, for instance, can provide longer run times and quicker charging capabilities. Additionally, exploring aftermarket attachments may offer specialized functionalities that cater to specific tasks, ultimately enhancing your productivity.

Maintenance and Care

Regular maintenance is crucial for longevity and optimal performance. Investing in quality replacement parts and performing routine checks can prevent common issues and ensure that your equipment operates smoothly. Understanding the importance of proper care will help you maintain the reliability of your tool for years to come.