In the realm of power tools, having a clear understanding of the individual elements that comprise a device is essential for effective maintenance and repair. This section delves into the intricate design and arrangement of the various components, providing users with a comprehensive view that aids in troubleshooting and assembly.

By examining the configuration of the different sections, users can gain valuable insights into the functionality of each part and how they interact with one another. This knowledge not only enhances the user’s ability to identify potential issues but also empowers them to make informed decisions regarding repairs and replacements.

Furthermore, a well-illustrated layout serves as an invaluable reference for both novice and experienced users alike. It simplifies the process of locating specific elements and understanding their roles within the overall system, ultimately contributing to the longevity and efficiency of the tool.

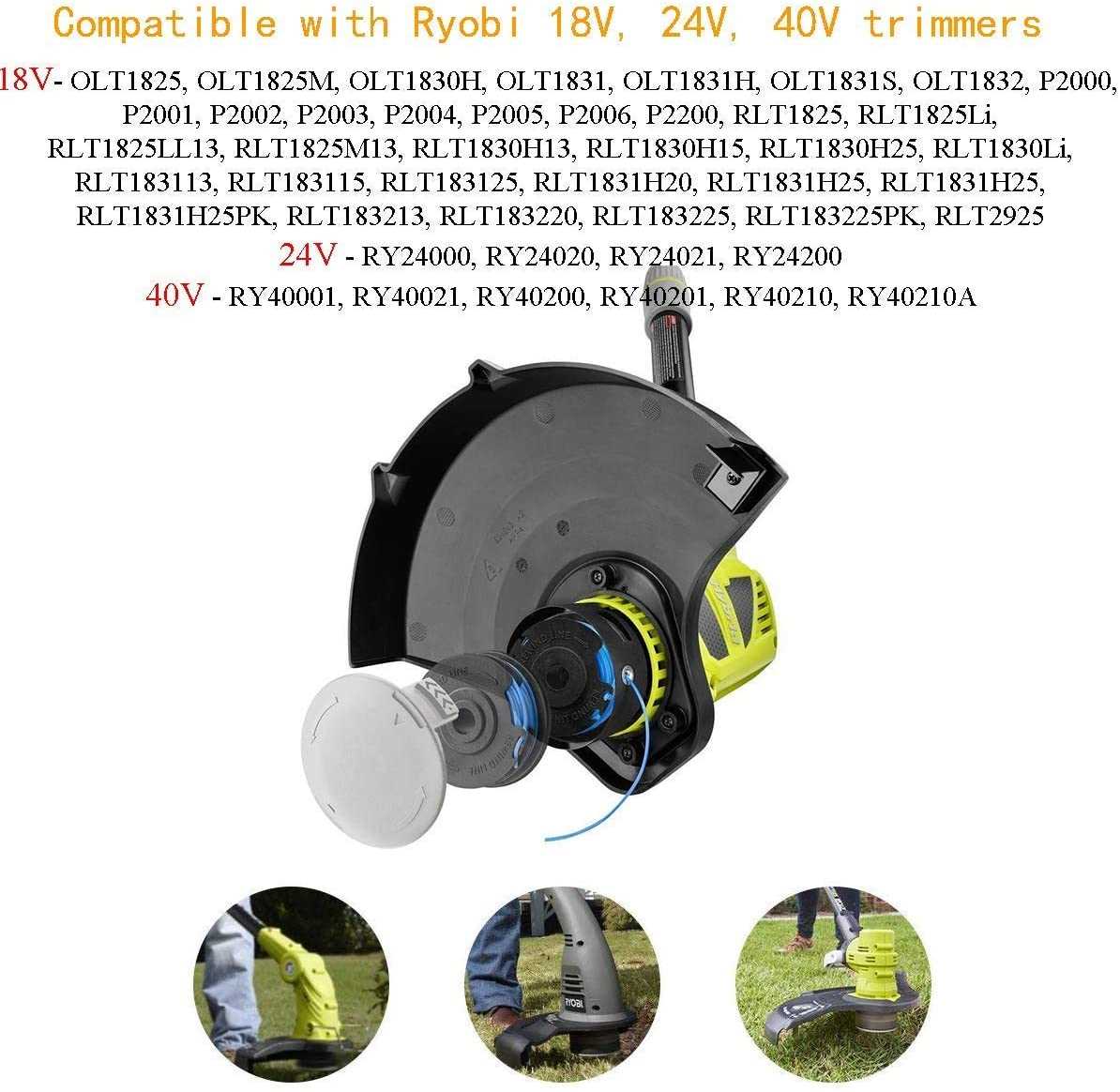

Overview of Ryobi Models

This section provides a comprehensive look at various offerings from a well-known manufacturer in the outdoor and power tool industry. The focus will be on the diverse range of models available, each designed to meet specific user needs and preferences. From gardening equipment to power tools, these products are engineered for efficiency and performance.

Each model features unique characteristics and capabilities, catering to both amateur and professional users. Whether it’s a compact unit for home use or a robust machine for heavy-duty tasks, the selection includes options that emphasize innovation and reliability.

Understanding the distinctions between different models can significantly enhance user experience. By recognizing the specific functionalities and design elements, consumers can make informed decisions tailored to their requirements. This knowledge is essential for anyone looking to invest in durable and effective tools that align with their projects.

Common Components in Power Tools

Power tools are essential for various applications, from home improvement projects to professional construction tasks. Understanding the typical elements that comprise these devices can enhance usability and maintenance. Familiarity with these parts can lead to better performance and longevity of the tools.

One of the most crucial components is the motor, which serves as the powerhouse of the equipment. This element converts electrical energy into mechanical energy, allowing the tool to perform its intended function. Additionally, gears play a vital role in transferring power efficiently, ensuring that the tool operates smoothly and effectively.

Switches are also fundamental, providing users with the ability to control the tool’s operation with ease. These mechanisms can vary in complexity, ranging from simple on/off toggles to more advanced variable speed settings. Furthermore, housing protects internal components while providing a comfortable grip for users. The material and design of the housing can significantly influence the tool’s durability and ergonomics.

Finally, attachments or accessories can expand the functionality of power tools, allowing them to tackle a variety of tasks. Whether it’s a different type of blade for cutting or a specialized bit for drilling, these components enable versatility and efficiency in various projects.

Understanding Parts Functionality

Every machine is composed of various components that work together to achieve specific tasks. Grasping the purpose and interrelation of these elements is crucial for effective maintenance and operation. This section delves into the essential roles of individual components and their contributions to the overall performance of the device.

- Motor: The driving force that powers the equipment, converting electrical energy into mechanical energy.

- Gear System: Responsible for adjusting the speed and torque, enabling precise control over the tool’s operation.

- Switch: A critical element for user control, allowing for the activation and deactivation of the machinery.

- Housing: Provides structural integrity and protects internal components from external damage.

- Battery: Supplies the necessary power, ensuring mobility and convenience for cordless functionality.

Understanding how these elements function not only enhances efficiency but also aids in troubleshooting and repairs. Regular inspection and knowledge of each component’s role can significantly prolong the lifespan of the equipment.

- Identify key components and their functions.

- Regularly maintain and inspect these elements.

- Utilize proper techniques for repairs or replacements.

By familiarizing oneself with the workings of individual parts, users can make informed decisions regarding usage and maintenance, ultimately leading to better performance and durability.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of any equipment requires regular care and attention. By implementing simple yet effective maintenance practices, users can significantly enhance the durability and efficiency of their tools. This section outlines essential strategies to keep your equipment in optimal condition for years to come.

Regular Cleaning

Keeping your device clean is fundamental to its longevity. Dust, dirt, and debris can accumulate, leading to potential malfunctions. Establish a routine cleaning schedule, and use appropriate cleaning agents and tools to avoid damaging sensitive components.

Scheduled Inspections

Periodic checks are crucial for identifying wear and tear before it escalates into serious issues. Pay close attention to moving parts and connections. If any signs of damage or abnormal functioning are observed, take immediate action to rectify the problem.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Cleaning | Weekly | Use soft cloths and non-abrasive cleaners. |

| Inspection | Monthly | Check for loose components and wear signs. |

| Lubrication | Quarterly | Apply lubricant to moving parts as needed. |

| Storage | As Needed | Store in a dry, cool place when not in use. |

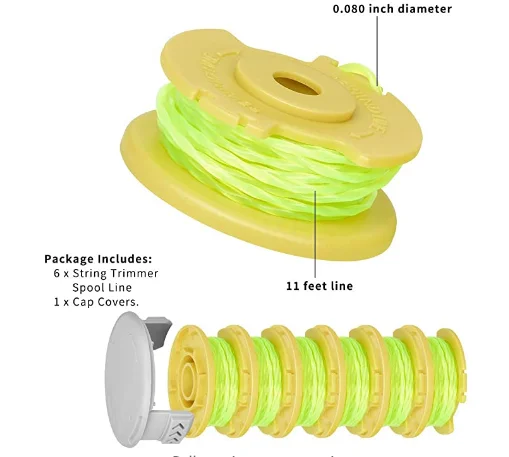

Identifying Replacement Parts

Understanding how to locate and identify components for your equipment is crucial for maintaining its performance and longevity. This section focuses on various strategies and resources that can assist users in pinpointing the necessary elements to ensure their machinery operates effectively.

Utilizing Manufacturer Resources

One of the most reliable methods for identifying components is to refer to the resources provided by the manufacturer. Many manufacturers offer detailed guides, including exploded views and lists of individual components, which can be invaluable in recognizing the specific items required for repairs or replacements.

Community and Online Support

Engaging with online forums and communities can provide additional insights. Users often share their experiences and knowledge, helping others troubleshoot issues and find suitable replacements. Utilizing these platforms can enhance your understanding of the available options and potential substitutes.

Tools Required for Repairs

When undertaking repairs, having the right equipment is essential to ensure efficiency and accuracy. Various instruments and materials can facilitate the process, making it smoother and more effective. Whether you are replacing components or conducting routine maintenance, being prepared with the necessary tools will streamline your tasks.

Essential Hand Tools

For most repair tasks, basic hand tools such as screwdrivers, pliers, and wrenches are indispensable. Screwdrivers in various sizes and types are crucial for loosening or tightening screws. Pliers provide the grip needed for manipulating small parts, while wrenches are essential for fastening nuts and bolts securely.

Power Tools and Safety Equipment

In addition to hand tools, power tools can significantly enhance repair efficiency. Drills and saws are commonly used for cutting or drilling into materials with precision. Equally important is safety equipment; wearing gloves and safety goggles helps protect against potential hazards during repair work. Ensuring that you have both the right tools and protective gear will not only facilitate repairs but also promote a safe working environment.

Common Issues and Solutions

Every mechanical device can encounter problems over time, and understanding these common issues is essential for maintaining optimal performance. Addressing these concerns promptly can prevent further complications and extend the lifespan of the equipment.

Electrical Failures

One frequent problem is electrical malfunction, which may manifest as the unit failing to start or intermittent power loss. This can often be attributed to faulty connections or worn-out components. Regularly inspecting the electrical system and ensuring all connections are secure can help mitigate these issues. If problems persist, replacing damaged wires or connectors may be necessary.

Mechanical Wear

Mechanical wear and tear can also affect performance, particularly in moving parts. Symptoms may include unusual noises or reduced efficiency during operation. Lubricating moving components and checking for signs of wear can help maintain functionality. In cases where parts are excessively worn, timely replacement is crucial to restore full operation.

Where to Buy Authentic Parts

When it comes to maintaining your equipment, sourcing genuine components is crucial for optimal performance and longevity. Finding reliable suppliers can ensure that you receive high-quality items that meet the manufacturer’s specifications, reducing the risk of compatibility issues and enhancing the overall functionality of your tools.

Authorized Retailers

One of the best places to start your search for original components is through authorized dealers. These retailers are recognized by the manufacturer and typically offer a wide selection of genuine items.

- Visit local hardware stores that are certified distributors.

- Check online platforms that partner with official suppliers.

- Inquire about warranty and return policies to ensure customer satisfaction.

Manufacturer’s Website

Another effective way to purchase authentic items is directly from the manufacturer’s official website. This option often provides access to the most up-to-date inventory and exclusive offers.

- Utilize the website’s search function to locate specific components.

- Take advantage of online support for assistance in identifying the right pieces.

- Sign up for newsletters to receive notifications about new arrivals and special promotions.

Ensuring you obtain genuine items is essential for the longevity and efficiency of your equipment. By exploring authorized retailers and the manufacturer’s online resources, you can confidently make informed purchases that meet your needs.

Comparative Analysis of Models

This section delves into a thorough examination of various equipment iterations, highlighting their distinct features and functionalities. By analyzing these variants, we aim to provide a clearer understanding of how each model meets specific user needs and preferences.

Performance Variability: Different iterations can exhibit varying performance levels based on their design and specifications. Some models may excel in power output, while others prioritize energy efficiency or ease of use. This variability influences user choice, depending on the intended application.

Feature Set: A comprehensive assessment reveals that while certain versions may include advanced features like enhanced safety mechanisms or integrated technology, others focus on fundamental functionalities. Evaluating these aspects can guide potential buyers in selecting the model that best aligns with their requirements.

Durability and Maintenance: Another crucial factor in model comparison is longevity and ease of upkeep. Certain designs might incorporate robust materials and simpler assembly processes, contributing to reduced maintenance needs. Understanding these differences can significantly impact long-term satisfaction and usability.

Price Considerations: Lastly, the cost of various versions varies considerably, influenced by their capabilities and added features. Conducting a cost-benefit analysis allows consumers to make informed decisions that balance budget constraints with performance expectations.

Customer Reviews and Feedback

Customer insights play a crucial role in understanding the effectiveness and reliability of a product. Users often share their experiences, highlighting both positive aspects and areas for improvement. This feedback provides valuable information for potential buyers, helping them make informed decisions.

Many users express satisfaction with the performance and durability of the equipment, noting how it meets their expectations in various tasks. Testimonials frequently emphasize ease of use and the practicality of features that enhance the overall experience. Customers appreciate the quality materials and thoughtful design, which contribute to a more efficient workflow.

However, some feedback points out potential challenges, such as assembly difficulties or specific components that may require additional attention. These insights can guide manufacturers in addressing issues and improving future models, ensuring a better user experience. Engaging with customer reviews not only fosters trust but also encourages ongoing dialogue between users and producers.