In the world of small engines, having a clear representation of the components can greatly enhance the maintenance and repair processes. These visual guides serve as invaluable tools for anyone working with engine machinery, providing insights into the various elements and their relationships. By familiarizing oneself with these illustrations, users can efficiently troubleshoot issues and streamline repairs.

Detailed schematics reveal how different components interact, ensuring that individuals can make informed decisions during repairs. Whether you are a seasoned mechanic or a DIY enthusiast, understanding these visual representations empowers you to tackle maintenance tasks with confidence. Such knowledge not only helps in resolving current issues but also aids in preventing future complications.

Briggs and Stratton 650 Series Overview

This section provides an insightful look into a well-known line of engines designed for various outdoor power equipment. These engines are recognized for their reliability and efficiency, making them a popular choice among users seeking robust performance for lawnmowers, generators, and other machinery.

The highlighted model features advanced engineering that promotes ease of use and maintenance. It boasts a compact design while delivering significant power output, catering to both casual and professional users. The design incorporates user-friendly elements, ensuring seamless operation and minimal downtime.

Furthermore, this engine line emphasizes durability, with high-quality materials and construction techniques that withstand challenging conditions. The commitment to innovation is evident in its features, enhancing overall functionality and performance.

Understanding Engine Components

Engines are intricate machines comprised of various elements that work together to generate power. Each component plays a crucial role in ensuring the overall efficiency and performance of the engine. By examining these individual parts, one can gain insight into how they interact and contribute to the engine’s functionality.

Key Elements of an Engine

Among the primary components are the cylinder, where combustion occurs, and the piston, which translates the energy produced into mechanical work. Other significant parts include the crankshaft, responsible for converting linear motion into rotational motion, and the camshaft, which regulates the timing of the engine’s valves. Understanding these key elements is essential for diagnosing issues and performing maintenance effectively.

The Importance of Each Component

Each element in an engine serves a specific purpose, influencing the overall performance. For instance, the fuel system ensures that the correct mixture reaches the combustion chamber, while the cooling system prevents overheating. Regular inspection and maintenance of these components are vital for prolonging the engine’s lifespan and optimizing its efficiency.

Parts Identification and Functions

This section focuses on the essential components of small engines, detailing their specific roles and how they contribute to the overall functionality of the machinery. Understanding these elements is crucial for effective maintenance and repair, ensuring optimal performance and longevity of the equipment.

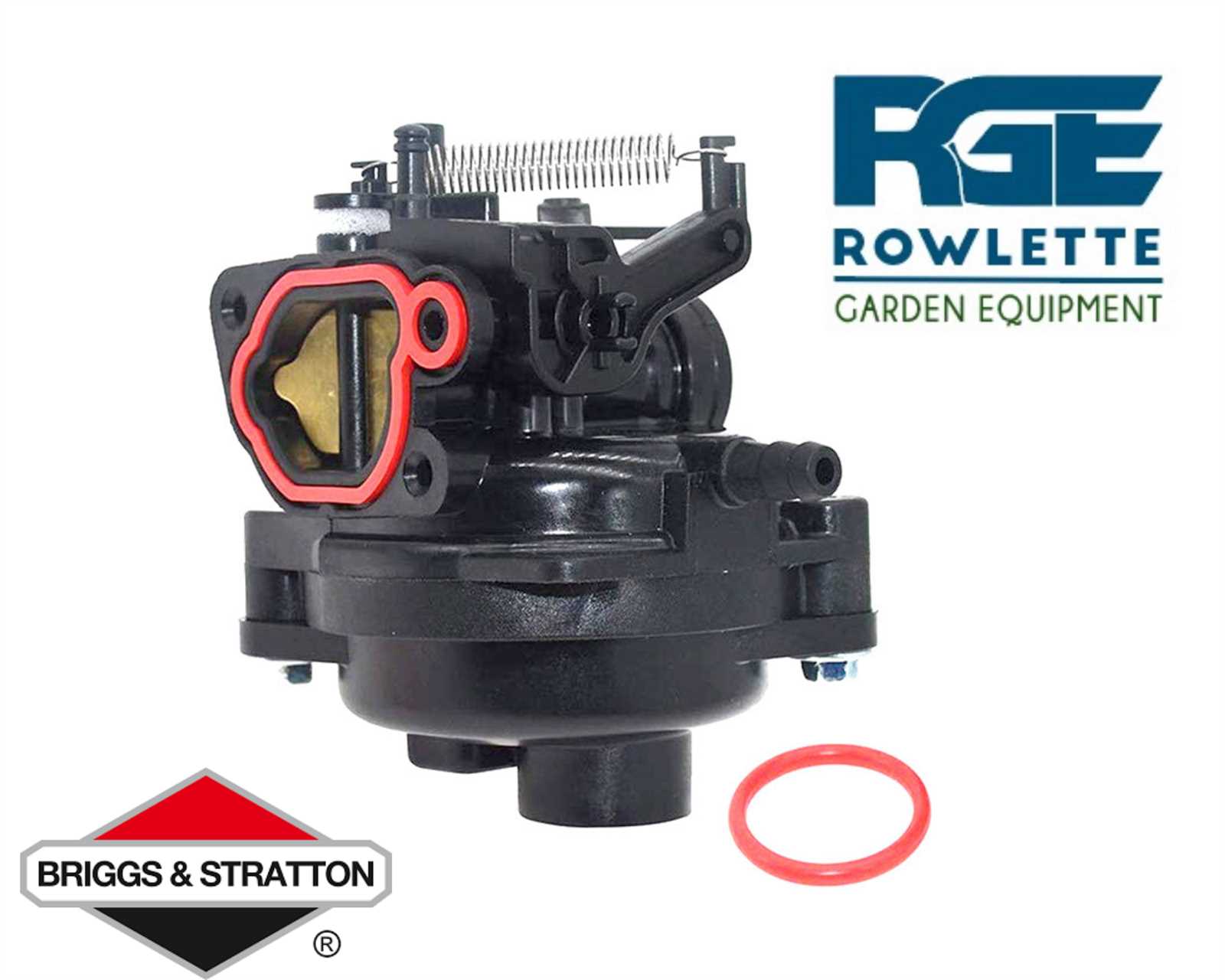

Each element within the engine serves a distinct purpose, from facilitating the combustion process to regulating airflow and fuel delivery. Key components include the ignition system, which generates the spark necessary for combustion, and the carburetor, responsible for mixing fuel with air in the correct proportions. Other vital parts encompass the fuel tank, which stores the gasoline, and the oil reservoir, ensuring proper lubrication of moving parts.

Moreover, the cooling system plays a critical role in preventing overheating, while the exhaust system directs emissions away from the engine. By familiarizing oneself with these components and their functions, operators can perform troubleshooting and repairs more effectively, ultimately enhancing the reliability of the equipment.

Common Issues and Solutions

Engines can encounter various challenges during operation, often leading to reduced efficiency or complete failure. Understanding these common problems and their corresponding remedies is essential for maintaining optimal performance. Below are some prevalent difficulties faced by users, along with practical solutions to address them effectively.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Difficulty starting | Fuel issues, clogged air filter, or faulty spark plug | Check fuel level, replace the air filter, and inspect or replace the spark plug. |

| Engine stalls | Dirty carburetor or low fuel | Clean the carburetor and ensure an adequate fuel supply. |

| Overheating | Low oil level, blocked cooling fins, or damaged fan | Add oil as necessary, clean cooling fins, and check the fan for proper operation. |

| Poor performance | Worn parts, incorrect fuel mixture, or air leaks | Inspect for wear, adjust fuel mixture, and seal any air leaks. |

| Excessive vibration | Loose components or unbalanced blades | Tighten all fasteners and ensure blades are balanced. |

Maintenance Tips for Longevity

Proper upkeep of small engine equipment is essential for ensuring durability and optimal performance. Regular maintenance not only extends the lifespan of the machine but also enhances its efficiency. Implementing a few straightforward practices can significantly contribute to the longevity of your equipment.

Routine Checkups

Consistent inspections are crucial. Check the oil level frequently, and replace it as recommended to prevent engine wear. Additionally, clean or replace the air filter regularly to ensure adequate airflow, which is vital for combustion efficiency.

Seasonal Preparation

Before storing the equipment during off-seasons, perform a thorough cleaning to remove dirt and debris. Drain the fuel or use a fuel stabilizer to prevent clogging in the fuel system. This step is particularly important for avoiding issues when the equipment is needed again.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 25 hours of use |

| Air Filter Cleaning | Every 10 hours of use |

| Spark Plug Inspection | Annually |

| Fuel System Maintenance | Before storage |

Repairing Common Faults

Addressing frequent issues with small engines requires a systematic approach to identify and resolve problems effectively. Understanding the common malfunctions can significantly simplify the troubleshooting process, allowing for timely repairs and improved engine performance. This section will explore typical faults encountered in these engines and provide guidance on rectifying them.

Engine Won’t Start

One of the most prevalent issues is an engine that fails to start. This can stem from various causes, such as fuel starvation, electrical failures, or a clogged air filter. Begin by checking the fuel level and ensuring the fuel is fresh. Next, inspect the battery and starter components for any signs of damage. If necessary, replace the spark plug to promote optimal ignition.

Loss of Power

Experiencing a drop in power during operation can be frustrating. This may be due to a blocked exhaust, dirty air filter, or worn-out spark plug. To resolve this, clean or replace the air filter and ensure the exhaust system is free from obstructions. Regular maintenance and cleaning can prevent power loss and enhance the overall efficiency of the engine.

Replacement Parts Availability

Access to high-quality components is crucial for maintaining the performance of outdoor equipment. Users often seek reliable sources to find necessary items that ensure smooth operation and longevity of their machines. Fortunately, a variety of options are available for obtaining these essential elements, making the maintenance process more efficient.

Authorized Dealers

Authorized dealers provide a trusted avenue for acquiring genuine components. These vendors typically maintain a comprehensive inventory, ensuring that users can find the specific items required for repairs and replacements. Additionally, purchasing through authorized channels often guarantees product authenticity, which can be vital for performance and safety.

Online Retailers

Online platforms have become increasingly popular for sourcing replacement items. A wide array of e-commerce websites offers convenience and competitive pricing. Users can easily compare options, read reviews, and have components delivered directly to their doorsteps. This method not only saves time but also expands access to various brands and models that may not be available locally.

How to Read Parts Diagrams

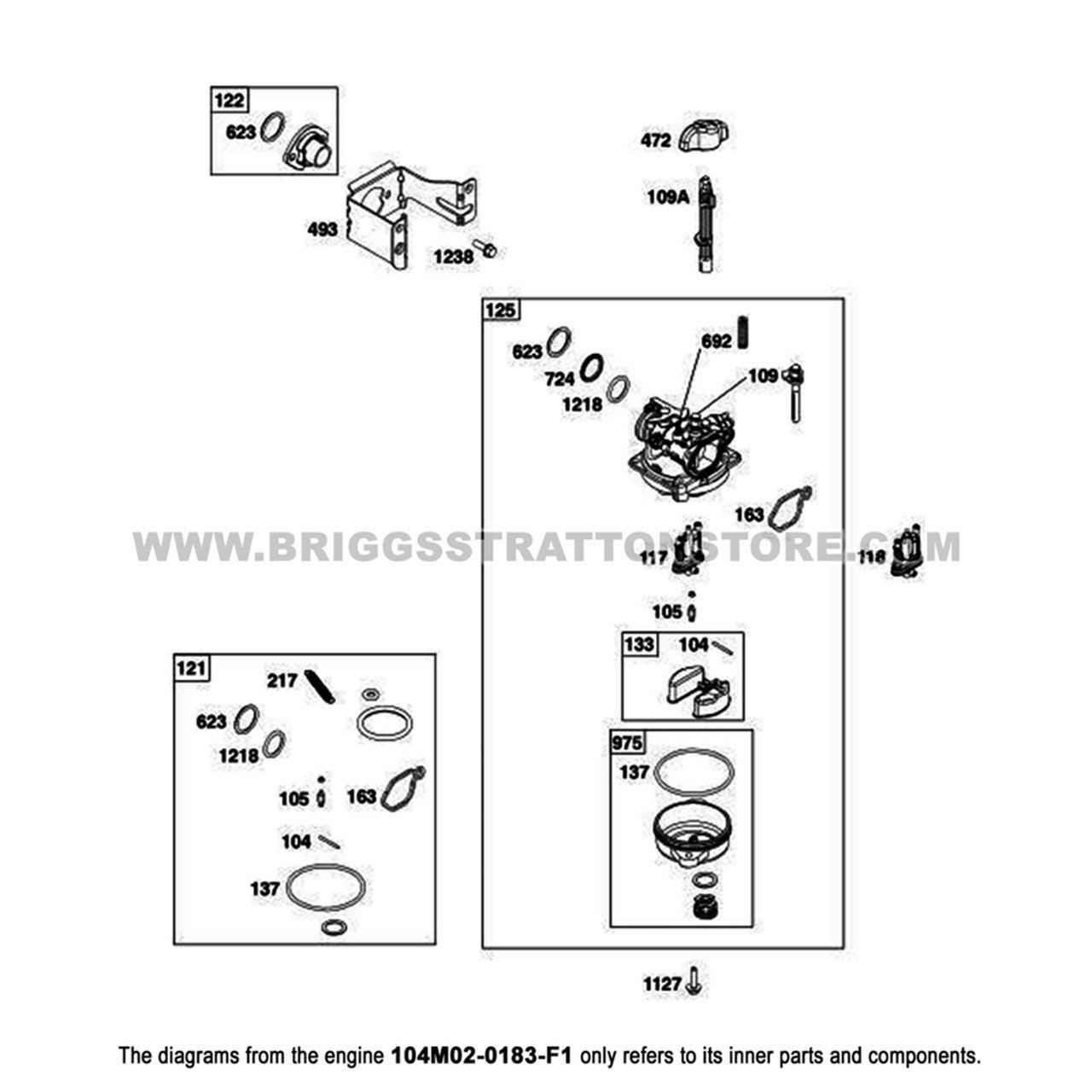

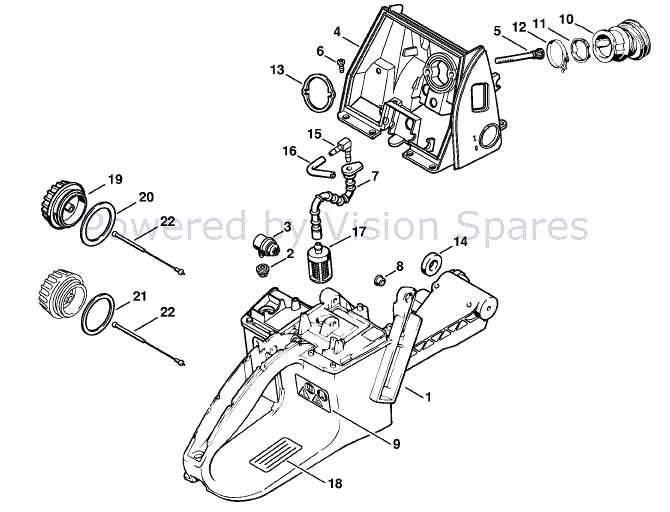

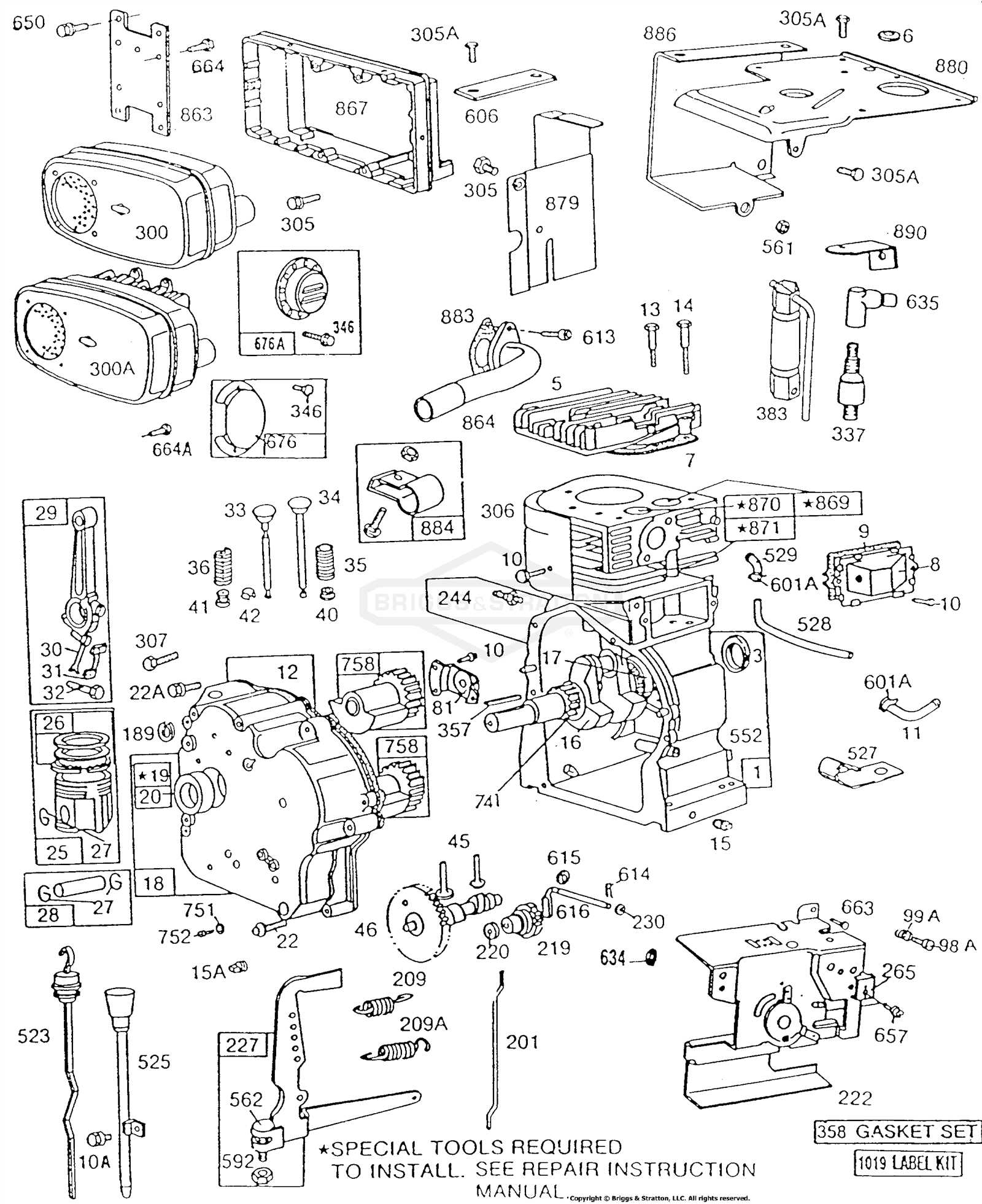

Understanding schematics for mechanical components is essential for effective maintenance and repairs. These visual representations offer a detailed look at various elements, their relationships, and how they fit together within a system. By grasping the basics of these illustrations, you can streamline the process of identifying necessary components and executing repairs.

Begin by familiarizing yourself with the layout of the illustration. Typically, each part is labeled with a unique identifier or number, which corresponds to a list detailing the specifications and availability of each item. This reference guide is crucial for pinpointing specific elements you may need to replace or troubleshoot.

Next, pay attention to the connections between components. Arrows or lines may indicate how parts interact with one another, helping you understand their functionality within the assembly. Observing these relationships can clarify how to approach disassembly or reassembly during repairs.

Lastly, make note of any special instructions or warnings included in the visual representation. These notes can provide important information regarding installation, torque specifications, or maintenance tips that enhance the longevity of the components.

By following these guidelines, you will enhance your ability to interpret mechanical schematics effectively, ensuring that your repair tasks are completed efficiently and accurately.

Tools Needed for Repairs

To ensure effective maintenance and troubleshooting of outdoor power equipment, having the right tools is essential. Properly equipped, you can address various issues, ensuring optimal performance and longevity of your machinery. The following tools are crucial for completing repairs efficiently and safely.

Basic Hand Tools

- Wrenches: A set of adjustable wrenches and socket wrenches is necessary for loosening and tightening various components.

- Screwdrivers: Flathead and Phillips screwdrivers in multiple sizes will help with fasteners found throughout the unit.

- Pliers: Needle-nose and regular pliers are useful for gripping and manipulating small parts.

Specialized Equipment

- Torque Wrench: Ensures that bolts and screws are tightened to the manufacturer’s specified torque settings.

- Feeler Gauges: Used to measure gap widths for precise adjustments, particularly in ignition systems.

- Multimeter: Essential for testing electrical components and diagnosing electrical issues.

Having these tools on hand not only streamlines the repair process but also minimizes the risk of damaging parts during maintenance. Regularly checking your tool inventory ensures you are always prepared for any tasks that may arise.

Ordering Genuine Briggs Parts

When it comes to maintaining your outdoor equipment, selecting authentic components is crucial for optimal performance and longevity. Using original parts ensures compatibility and reliability, providing peace of mind for users who demand the best for their machinery.

To acquire these genuine components, follow a straightforward process that guarantees quality. Here’s a summary of the steps involved:

| Step | Description |

|---|---|

| 1 | Identify the model number of your equipment to ensure you select the correct components. |

| 2 | Visit the official website or an authorized dealer to browse the catalog of available items. |

| 3 | Add the required components to your cart and proceed to checkout, ensuring that you enter accurate shipping information. |

| 4 | Complete your purchase and retain the receipt for future reference. |

By following these steps, you can ensure that your equipment continues to operate efficiently and effectively.

Comparison with Other Engine Models

This section provides an overview of how this particular engine compares to its counterparts in the market. Understanding the differences in performance, design, and application can help users make informed decisions when selecting an engine for various tasks.

Performance Analysis

When assessing performance, many engines deliver varying levels of power and torque output. This specific model is often noted for its reliability and efficiency, which are crucial for both residential and commercial applications. Competitors may offer similar power ratings, but differences in fuel consumption and durability can significantly impact long-term usage costs.

Design Features

In terms of design, this engine showcases unique elements that enhance functionality. Its construction often includes advanced materials and ergonomic layouts, contributing to ease of maintenance and longevity. Compared to other models, the focus on user-friendly features can make a significant difference in overall satisfaction and operational efficiency.

Upgrading Your Engine Components

Enhancing the performance of your engine can significantly improve its efficiency and longevity. By focusing on specific components, you can unlock greater power and responsiveness, ultimately transforming your equipment’s capabilities. Understanding which elements to upgrade can help you achieve optimal results, tailored to your specific needs.

When considering enhancements, evaluate the air intake and exhaust systems. Upgrading to high-performance filters and exhaust components can facilitate better airflow, allowing the engine to breathe more freely. This often results in increased horsepower and torque, making your machinery more efficient.

Additionally, consider enhancing the ignition system. High-performance spark plugs and ignition coils can lead to improved combustion, resulting in better fuel efficiency and reduced emissions. A stronger ignition can also aid in smoother engine operation and quicker starts.

Lastly, do not overlook the importance of lubrication. Using premium oil and oil filters can enhance the overall health of your engine, providing better protection against wear and tear. Regular maintenance and quality components ensure that your engine operates at peak performance.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on equipment is paramount. Following specific guidelines can help prevent accidents and injuries, making the repair process efficient and secure. It’s essential to be mindful of potential hazards that may arise during mechanical work.

Wear Appropriate Personal Protective Equipment

Utilizing the correct personal protective gear is crucial. This includes safety glasses to shield your eyes from debris, gloves to protect your hands from sharp edges and chemicals, and sturdy footwear to safeguard your feet. Wearing long sleeves and long pants can further minimize exposure to hazards.

Ensure Proper Ventilation

When working with machinery, it’s vital to ensure adequate airflow in the workspace. Proper ventilation reduces the risk of inhaling harmful fumes or gases, especially when dealing with fuel or oil. If possible, conduct repairs outdoors or in a well-ventilated area to promote safety and comfort.