This section explores the intricate elements that contribute to the functionality of a textile construction device. By examining the various components, we can gain insight into how they work together to achieve precise results in fabric manipulation.

Each component plays a vital role, from the mechanism that drives movement to the elements that guide materials through the process. Understanding these functions enhances our appreciation of the technology involved in textile creation.

As we delve deeper into the intricacies, we uncover the ultimate synergy between design and functionality, revealing how each individual piece supports the overall efficiency of the apparatus.

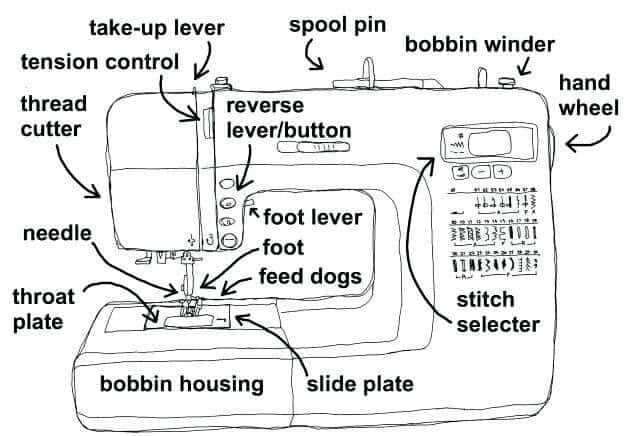

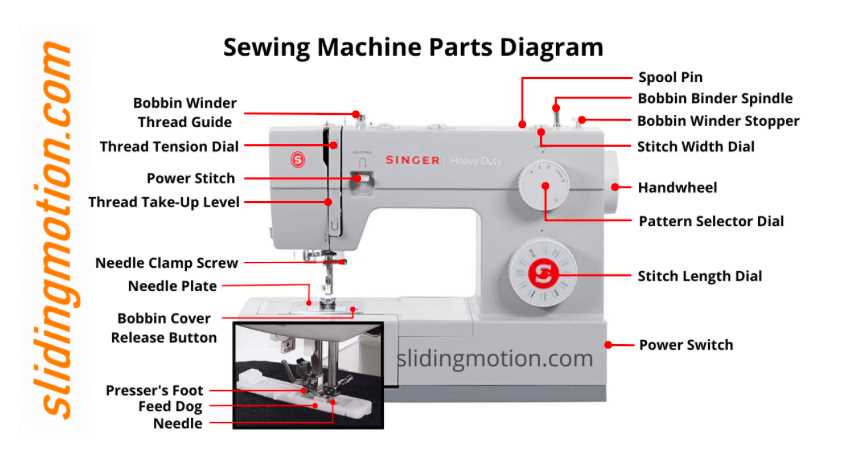

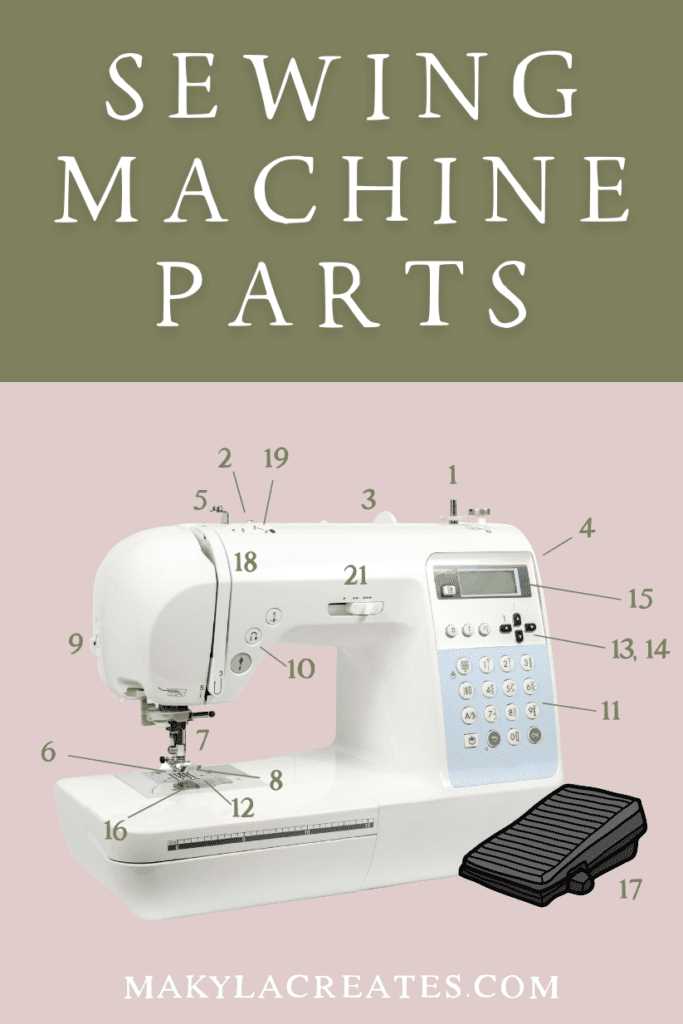

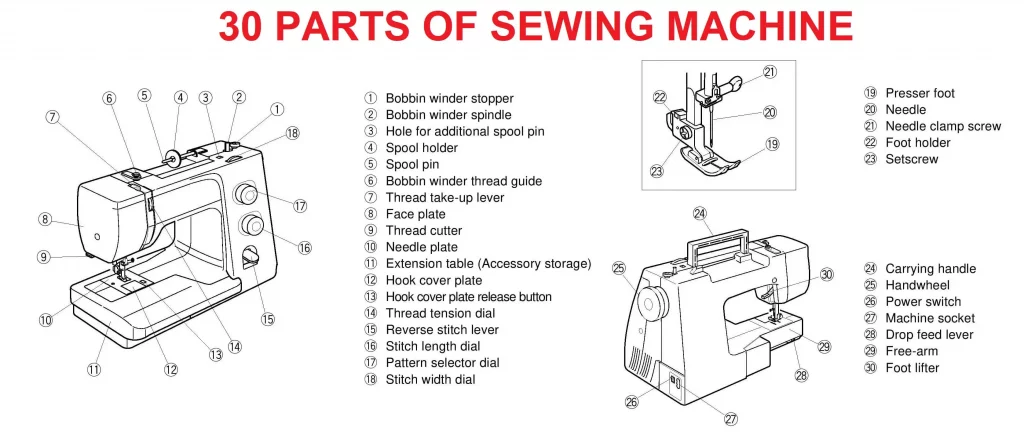

Overview of Sewing Machine Components

This section provides a comprehensive look at the essential elements that comprise a fabric-stitching apparatus. Understanding these components is crucial for efficient operation and maintenance.

Key components include:

- Frame: The structural foundation that supports all other elements.

- Needle: The tool responsible for piercing the fabric to create stitches.

- Presser Foot: Holds the material in place during stitching.

- Feed Dogs: Mechanism that moves the fabric through the machine.

- Bobbin: Contains the thread that forms the stitches from the underside.

Each of these elements plays a vital role in the functionality and effectiveness of the device. Proper knowledge of their positions and interactions can significantly enhance the user experience.

Additionally, various auxiliary components contribute to the overall efficiency:

- Thread Tension Mechanism: Regulates the tightness of the thread.

- Stitch Selector: Allows the user to choose different stitching styles.

- Foot Pedal: Controls the speed of the operation.

- Light Source: Illuminates the workspace for better visibility.

Recognizing the function of each part leads to better handling and troubleshooting skills, ensuring optimal performance during use.

Essential Elements of a Sewing Machine

The intricate design of a fabric manipulation device encompasses various critical components that work harmoniously to create stitches. Understanding these fundamental elements is essential for effective usage and maintenance. Each component plays a unique role, contributing to the overall functionality and efficiency of the apparatus.

Functionality of the Needle System

The needle system plays a crucial role in the overall performance of fabric manipulation tools. This component is essential for creating stitches and securing materials together, ensuring both efficiency and precision in the crafting process.

At its core, the needle is designed to penetrate the textile, allowing thread to be passed through without causing damage. This action is vital for forming consistent loops that connect different layers of fabric. The design of the needle, including its size and shape, influences the type of stitches produced, directly impacting the final outcome of the project.

Moreover, the needle system interacts with other elements, such as the thread tension and feed mechanisms. Proper alignment between these components is necessary to achieve optimal results, enhancing the ease of use and effectiveness of the crafting experience.

Role of the Feed Dogs

The feed dogs play a crucial function in the operation of textile tools, ensuring smooth and consistent material movement during the stitching process. Their design allows for precise control over the fabric, contributing significantly to the quality of the finished product.

Functionality

These components engage with the fabric from below, pushing it through the apparatus while the needle performs its task. This interaction is essential for creating even stitches and maintaining tension across the material.

Types of Movement

Feed dogs can exhibit various types of motion, affecting how the fabric is transported. The following table outlines the different movements:

| Movement Type | Description |

|---|---|

| Vertical | Rises to grip the fabric and then lowers to release it. |

| Horizontal | Shifts sideways to assist in guiding the fabric through. |

| Combined | Incorporates both vertical and horizontal actions for enhanced precision. |

Understanding the Bobbin Assembly

The bobbin assembly plays a crucial role in the overall functionality of textile stitching tools. It houses the thread that intertwines with the upper strand, enabling precise and secure seams. A thorough comprehension of this component is essential for effective operation and maintenance.

Components of the Bobbin Assembly

This assembly consists of several key elements that work together seamlessly:

| Component | Description |

|---|---|

| Bobbin | Holds the lower thread and ensures it feeds correctly. |

| Bobbin Case | Encloses the bobbin and secures it in place, allowing smooth rotation. |

| Tension Adjustment | Regulates the tension of the lower thread for optimal stitch quality. |

Maintenance Tips

Regular upkeep of the bobbin assembly is vital for consistent performance. Ensure that the bobbin is wound evenly and the case is free of lint and debris. Adjust tension as needed to maintain the integrity of the stitching process.

Types of Sewing Machine Tension

Understanding the different forms of adjustment for thread tightness is essential for achieving quality results in fabric work. Each variety plays a crucial role in the overall performance and output of your projects.

Key Categories

- Top Tension: This setting governs the tightness of the upper thread as it moves through the needle.

- Bobbin Tension: This element influences how the lower thread interacts with the upper thread, impacting stitch formation.

Adjusting Tension

Properly managing these types requires a balance to ensure that both threads work in harmony. Regular testing on scrap fabric can help in fine-tuning the settings for optimal results.

Importance of the Presser Foot

The presser foot is a crucial component in the realm of textile crafting, serving as a vital tool that enhances the functionality and precision of the stitching process. It ensures that the fabric remains securely in place while guiding it through the needle’s path.

This element plays a significant role in achieving consistent results, as it influences the tension and feeding of the material. By providing the necessary pressure, it allows for smoother movement and reduces the likelihood of puckering or shifting, which can compromise the quality of the finished product.

Moreover, the versatility of the presser foot allows crafters to tackle a variety of techniques and styles, from straight stitches to decorative finishes. Different types can be employed depending on the desired outcome, making it an essential accessory for anyone looking to enhance their creative projects.

Exploring the Stitch Selector Mechanism

The ability to create various patterns and designs is fundamental to crafting with fabric. Central to this versatility is a particular mechanism that allows users to choose different styles of stitching. This system enhances creativity by providing options that cater to a range of projects and preferences.

Understanding how this mechanism functions is essential for achieving the desired results. It typically involves a combination of gears and levers that align and adjust components to create specific stitch types. This intricate setup ensures precision and consistency, making it easier for individuals to execute their artistic visions.

Additionally, maintaining this system is crucial for optimal performance. Regular cleaning and proper adjustments can prolong its lifespan and enhance overall effectiveness. By being aware of its operation, users can fully leverage the capabilities of their crafting tool, turning ideas into tangible creations.

Significance of the Throat Plate

The throat plate plays a crucial role in enhancing the functionality and performance of a fabric crafting device. It serves as a supportive surface, providing stability while ensuring precise movements during the stitching process. This component contributes significantly to the overall efficiency and quality of the finished product.

Key Functions

One of the primary roles of the throat plate is to guide the fabric smoothly, allowing for consistent feed as the needle penetrates. Additionally, it helps prevent fabric bunching or shifting, ensuring neat and uniform stitching. Its design often features markings that aid in accurate alignment, further enhancing the user’s ability to achieve professional results.

Maintenance Considerations

Regular cleaning and maintenance of the throat plate are essential to maintain optimal performance. Dust and debris can accumulate, affecting the movement of the fabric and potentially causing errors. Users should be vigilant about inspecting this area for any signs of wear or damage, as it can significantly impact the overall crafting experience.

| Function | Description |

|---|---|

| Stability | Provides a solid foundation for fabric manipulation. |

| Guidance | Ensures accurate feeding of materials during the stitching process. |

| Alignment | Features markings for precise fabric placement. |

| Protection | Prevents damage to the needle and fabric from misalignment. |

Power Sources for Sewing Machines

In the world of textile crafting, various energy options play a crucial role in driving devices that enhance creativity and efficiency. Understanding the different sources of energy available is essential for optimizing performance and ensuring consistent functionality.

Typically, these devices can be powered through direct electrical connections or portable units that offer flexibility. Standard electric outlets provide a reliable and continuous flow of energy, making them ideal for stationary setups. Alternatively, battery-operated systems allow for mobility and convenience, enabling users to operate away from fixed power sources.

Additionally, some advanced models incorporate renewable energy systems, such as solar power, promoting sustainability while performing tasks. These innovations contribute to a more eco-friendly approach to crafting, aligning with modern values of conservation and efficiency.

Ultimately, selecting the appropriate power source can significantly impact the overall experience, enhancing the effectiveness and enjoyment of creative endeavors.

Maintenance Tips for Machine Parts

Proper upkeep of the various components of your equipment is essential for ensuring longevity and optimal performance. Regular attention to these elements can prevent issues and enhance functionality.

Regular Cleaning

Keeping the surfaces clear of dust and debris is crucial. Here are some steps to follow:

- Use a soft brush or cloth to gently remove particles.

- Vacuum around the areas where buildup is likely.

- Wipe down with a damp cloth to eliminate stubborn grime.

Lubrication Practices

Applying the right lubricant can significantly reduce friction and wear. Consider these points:

- Check manufacturer recommendations for suitable lubricants.

- Apply a small amount to moving elements as needed.

- Avoid over-lubrication to prevent attracting dust.