The intricate world of textile creation relies on a variety of essential elements working in harmony. Each individual piece plays a critical role in ensuring the seamless operation of the entire system. Recognizing the function and interplay of these components can greatly enhance one’s appreciation for the craft of fabric manipulation.

From the mechanisms that control movement to those that facilitate the actual stitching process, every segment contributes uniquely to the overall functionality. Analyzing these elements allows users to optimize performance and troubleshoot issues effectively. A comprehensive grasp of these interconnected units can lead to improved results in any fabric-based project.

By exploring the various components involved, enthusiasts and professionals alike can deepen their understanding of how these tools operate. This knowledge not only fosters better maintenance practices but also inspires innovation in design and technique, ultimately enriching the experience of anyone engaged in textile arts.

Understanding Basic Sewing Machine Components

When embarking on the journey of stitching, it is essential to familiarize oneself with the essential elements that facilitate the craft. Each component plays a crucial role in the functionality and effectiveness of the apparatus, contributing to the overall experience and outcome of fabric manipulation. Knowing how these pieces work together empowers users to enhance their skills and troubleshoot any issues that may arise.

Main Mechanisms

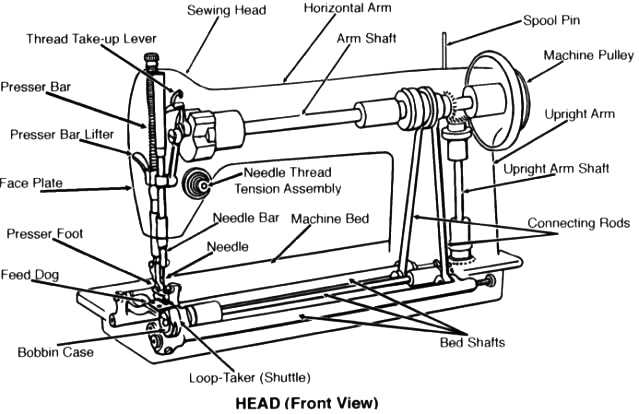

The core functionalities are driven by a few key mechanisms. The first is the needle, which pierces the material and interlocks threads to create stitches. Alongside the needle, the feed dogs work to move the fabric smoothly through the system, ensuring even and consistent feeding. Understanding these mechanisms allows one to appreciate the intricacies of stitching and the importance of maintaining them in optimal condition.

In addition to the main mechanisms, several supporting features enhance usability and precision. The tension control regulates the tightness of the threads, which is vital for achieving the desired stitch quality. Furthermore, the presser foot holds the fabric in place during operation, providing stability and control. Familiarity with these supporting components ensures a seamless stitching experience and can greatly affect the final results.

Function of the Needle and Presser Foot

The needle and presser foot play crucial roles in the overall functionality of textile construction. These components work in tandem to ensure that fabric is pierced and fed through the device smoothly, resulting in a clean and precise finish. Understanding their individual functions helps to appreciate the intricate processes involved in creating various textile projects.

The Role of the Needle

The needle serves as the primary tool for creating stitches. Its sharp point penetrates the fabric, allowing threads to intertwine and secure layers together. Different types of needles are designed for specific materials, affecting the quality and durability of the stitches produced. A well-chosen needle enhances performance, minimizes damage to the fabric, and ensures a seamless operation.

The Importance of the Presser Foot

The presser foot, on the other hand, acts as a guiding mechanism that holds the fabric in place while the needle performs its task. By applying consistent pressure, it prevents shifting or slipping, allowing for accurate stitching lines. Various designs of presser feet cater to different techniques, such as quilting or zipper application, making them essential for achieving desired results.

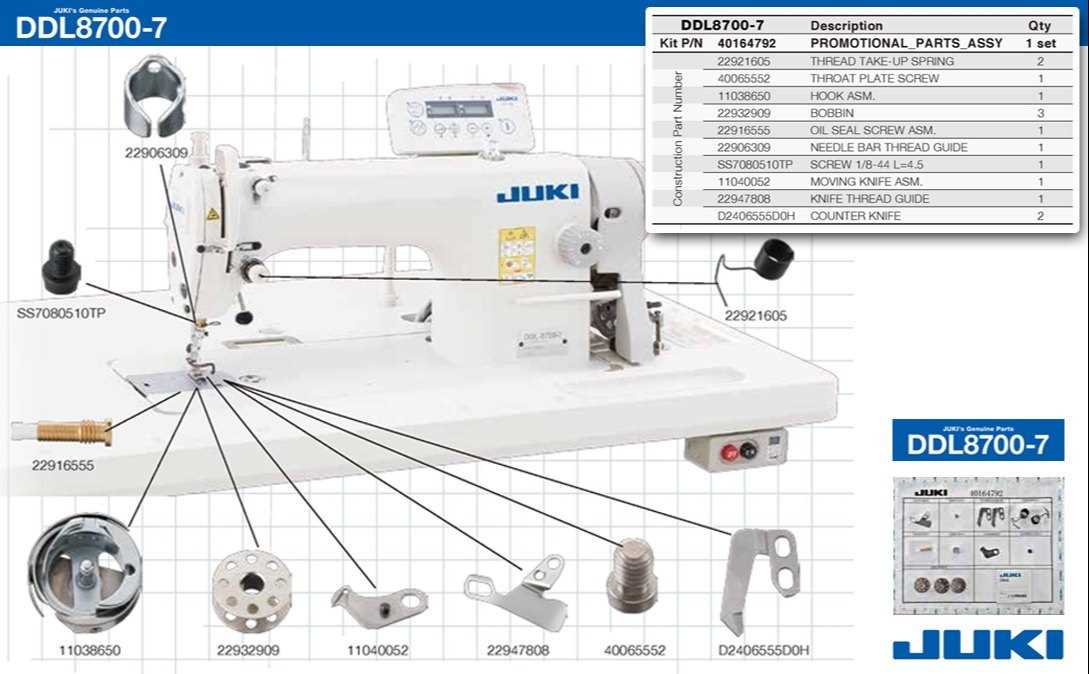

Exploring the Bobbin System

The bobbin system plays a crucial role in the functioning of textile crafting tools, ensuring the smooth creation of stitches. This component is essential for holding the thread that intertwines with the upper thread, forming secure seams. Understanding how this system operates can greatly enhance the crafting experience, enabling users to achieve precision and efficiency.

At its core, the bobbin mechanism consists of several key elements that work together seamlessly. Each part contributes to the overall performance, from winding the thread to securing it in place. Below is a table outlining the primary components of the bobbin system and their functions.

| Component | Function |

|---|---|

| Bobbin | Holds the lower thread, allowing it to be fed into the fabric. |

| Bobbin Case | Encases the bobbin, providing stability and control during operation. |

| Thread Tension Control | Regulates the tightness of the lower thread, ensuring even stitching. |

| Winder | Facilitates the process of winding the thread onto the bobbin. |

By familiarizing oneself with these elements, users can troubleshoot issues more effectively and enhance their overall crafting skill. Proper maintenance of the bobbin system is also vital, as it directly impacts the quality of the finished work.

The Role of the Feed Dogs

Feed dogs are crucial components that ensure the smooth movement of fabric during the stitching process. They create a seamless interaction between the needle and the material, allowing for precision and consistency in every project.

Functionality is the primary role of these elements; they grip the fabric and move it forward in a synchronized manner. This action not only enhances efficiency but also guarantees that the stitching occurs evenly, regardless of the fabric type.

Moreover, feed dogs can be adjusted to accommodate various materials, enabling users to delve into diverse techniques and styles. Their adaptability makes them an ultimate asset for both beginners and experienced crafters alike.

Types of Sewing Machine Tension

The balance of thread is crucial for achieving quality results in fabric manipulation. Various forms of tension exist to ensure that the threads interact harmoniously, allowing for seamless stitching. Understanding these variations can significantly impact the final outcome of any textile project.

Top Thread Tension

Top thread tension regulates how tightly the upper thread feeds through the needle. Adjusting this is essential for creating consistent stitches. If the tension is too tight, it can cause the thread to break; if it’s too loose, the stitches may appear uneven or looped.

Bobbin Tension

Bobbin tension, on the other hand, controls the lower thread’s tightness as it feeds into the fabric. Properly setting this is vital for maintaining stitch integrity. Similar to the upper tension, if this is not correctly calibrated, it can lead to problems such as puckering or loose stitches.

Ultimately, mastering these tension types allows for precise control and enhances the overall quality of textile work.

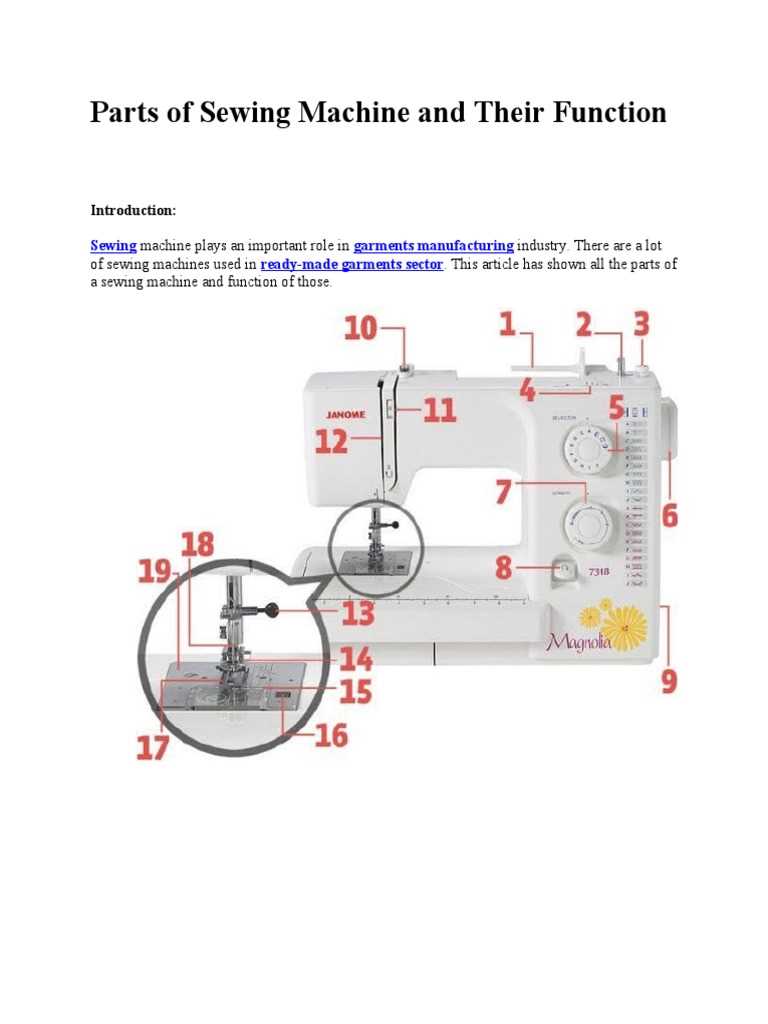

Importance of the Stitch Selector

The functionality of any fabric crafting device greatly relies on its ability to adapt to various techniques and materials. A pivotal feature that facilitates this versatility is the stitch selector, which enables users to choose from a variety of stitching options to achieve their desired outcomes.

Enhancing Creative Possibilities

The stitch selector opens up a world of creative expression, allowing artisans to explore different patterns and textures. By selecting the appropriate stitch, individuals can enhance the aesthetic appeal of their projects, whether they are crafting garments, home décor, or accessories. This feature not only promotes creativity but also encourages experimentation with diverse styles.

Optimizing Functionality

Moreover, the stitch selector plays a crucial role in optimizing the functionality of the crafting tool. Different tasks require specific stitching techniques for optimal results. For instance, a zigzag stitch is ideal for finishing edges, while a straight stitch is perfect for seams. By offering a range of options, the stitch selector ensures that users can complete their projects efficiently and effectively, tailoring their approach to the demands of each task.

Examining the Machine’s Motor

The heart of any textile apparatus lies in its power source, which drives the entire mechanism with precision and efficiency. Understanding this crucial component is essential for both functionality and maintenance.

Types of Motors

- Direct Drive Motors

- Servo Motors

- Stepper Motors

Key Functions

- Providing rotational force for the needle and feed dogs.

- Regulating speed for various fabric types.

- Facilitating reverse stitching and other advanced functions.

Each type of power source has its unique benefits and applications, making it vital to select the right one for specific tasks. Regular inspection and upkeep can significantly extend the life and performance of this essential element.

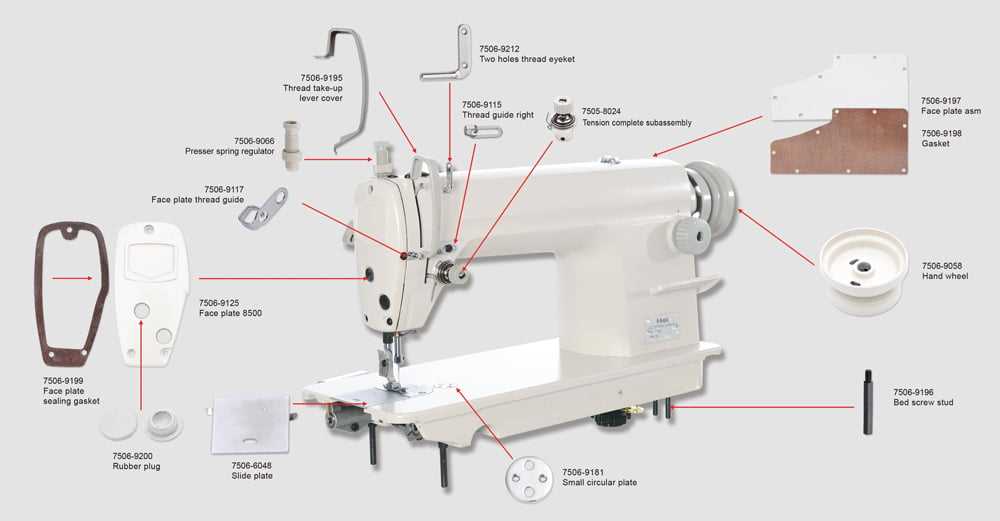

How the Thread Guides Work

Thread guides play a crucial role in ensuring smooth operation by directing the filament through various paths. Their design is essential for maintaining tension and preventing tangles, allowing for seamless fabric manipulation.

Functionality

These components work by positioning the thread at optimal angles, which minimizes friction during movement. Proper alignment helps achieve consistent stitches and enhances overall performance.

Types and Variations

Different configurations exist to cater to specific needs, each providing unique benefits. Some guides are adjustable, offering flexibility, while others are fixed for reliability. Understanding their functionality can ultimately improve the crafting experience.

Significance of the Throat Plate

The throat plate plays a crucial role in the overall functionality of textile creation tools. It serves as a foundation for various operations, ensuring stability and precision during the crafting process. Understanding its importance can enhance the quality of the final product.

Key Functions

This component provides support and guides the fabric, preventing unwanted movement. It also aids in maintaining a consistent stitch length, which is essential for achieving professional results.

Material and Maintenance

Typically made from durable materials, the throat plate requires regular maintenance to prevent wear and tear. Keeping it clean and free of debris is vital for optimal performance.

| Function | Importance |

|---|---|

| Stability | Ensures even feeding of fabric |

| Guidance | Helps in precise stitching |

| Durability | Resists wear over time |

Maintaining the Sewing Machine Frame

Proper upkeep of the structural components is essential for ensuring longevity and optimal performance. Regular attention to these elements can prevent unnecessary wear and tear, allowing the device to function seamlessly.

Cleaning and Lubrication

Routine cleaning is crucial to remove dust and debris that can accumulate. Lubrication of moving elements with the appropriate oil enhances efficiency and reduces friction, ultimately prolonging the life of the frame.

Inspection and Adjustments

Periodic inspection is vital to identify any signs of damage or misalignment. Adjusting components as needed ensures that everything remains in perfect harmony, preventing potential issues before they escalate.

Identifying Electrical Components

Understanding the various electrical elements in mechanical devices is crucial for effective troubleshooting and maintenance. Recognizing these components enables users to ensure optimal performance and longevity of the equipment.

Key Electrical Elements

Among the essential elements are motors, which convert electrical energy into mechanical motion, and switches, responsible for controlling the flow of electricity. Wires and connectors play a vital role in transmitting power, while capacitors can store and release energy as needed.

Importance of Identification

Accurate identification of these components aids in efficient repairs and enhances overall functionality. Familiarity with each element allows for informed decision-making when addressing any issues that may arise.