Water control systems in homes rely on several integral mechanisms to ensure smooth operation. These setups are designed to regulate the flow and temperature of water with precision, providing both comfort and efficiency. Over time, it’s essential to become familiar with the elements that make up these systems to maintain functionality and address potential issues.

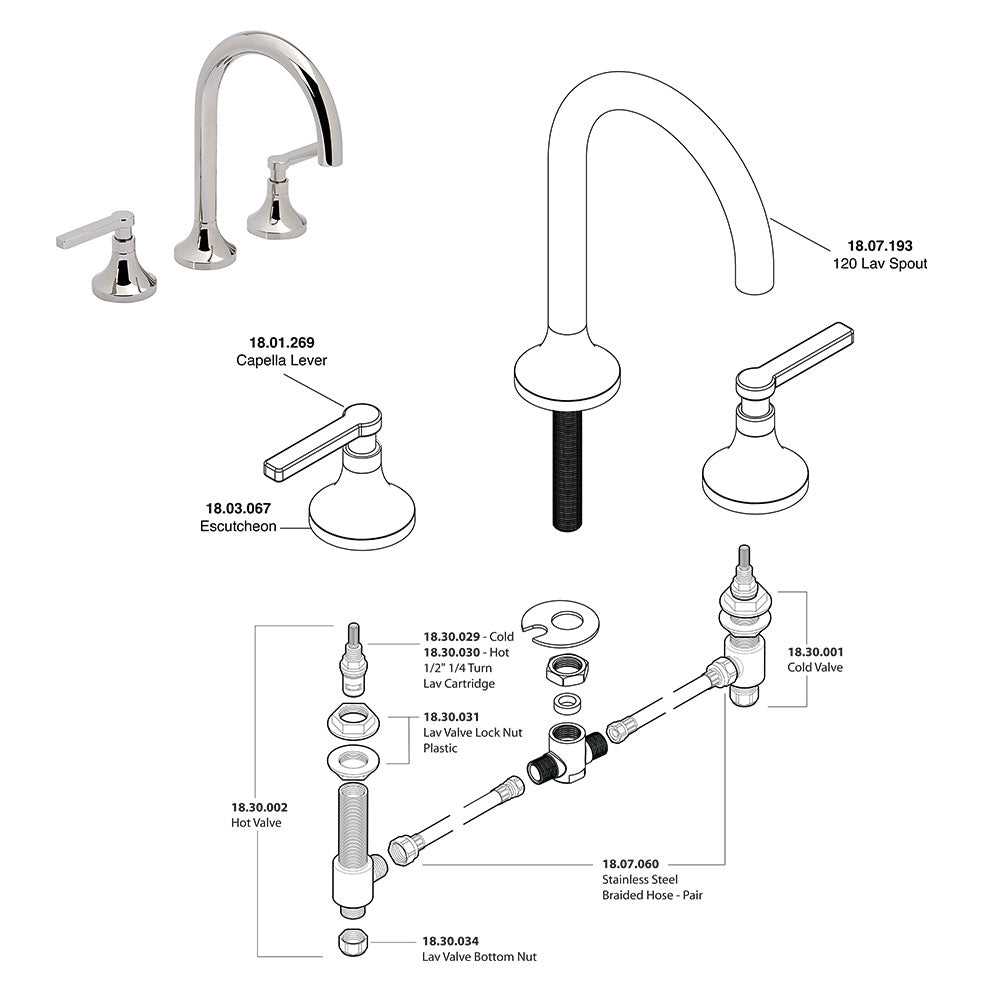

Each mechanism consists of multiple components that work together to manage the flow, balance pressure, and adjust the output. By examining the inner workings, we can gain insights into how these pieces interact to deliver optimal performance. Identifying the essential elements of this system is crucial for effective troubleshooting and maintenance.

This guide will walk you through the primary elements found in a typical setup, explaining how each part contributes to the overall operation. Understanding these connections can help ensure longevity and

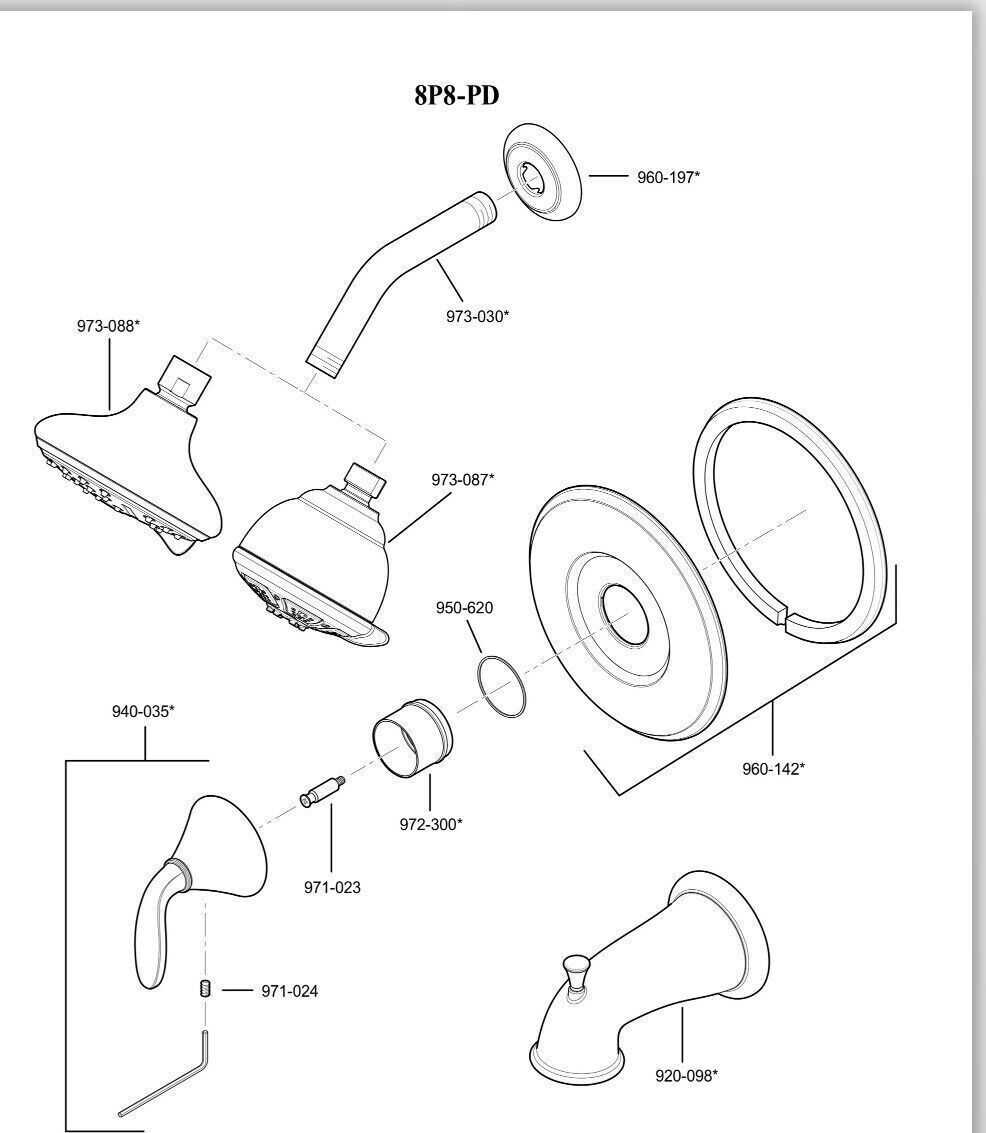

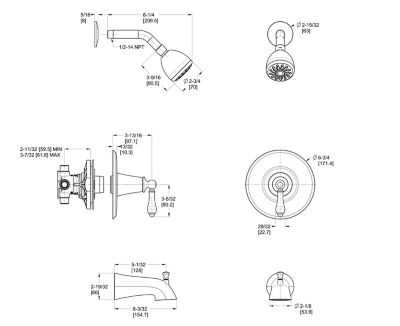

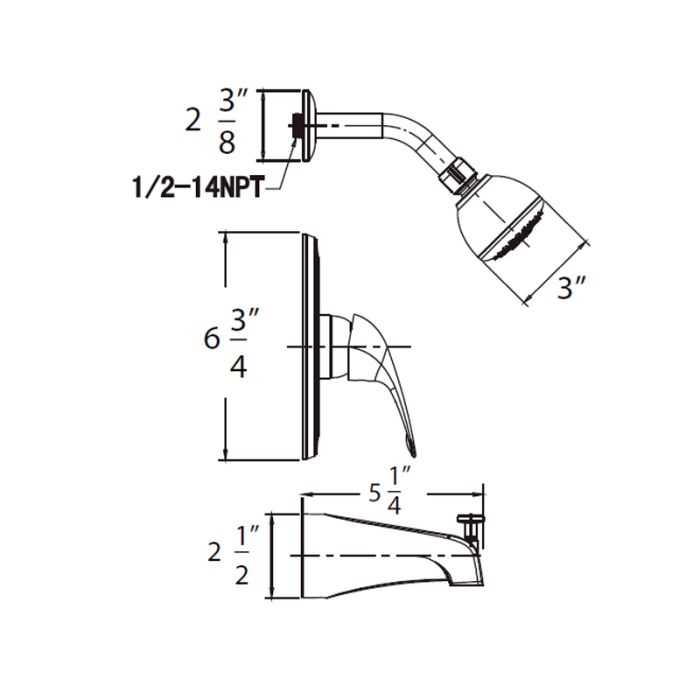

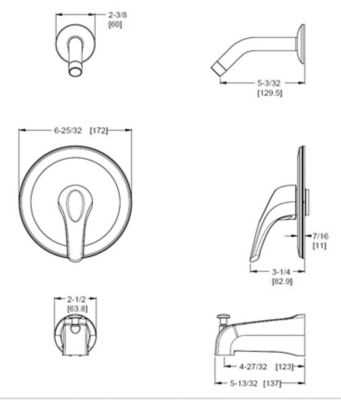

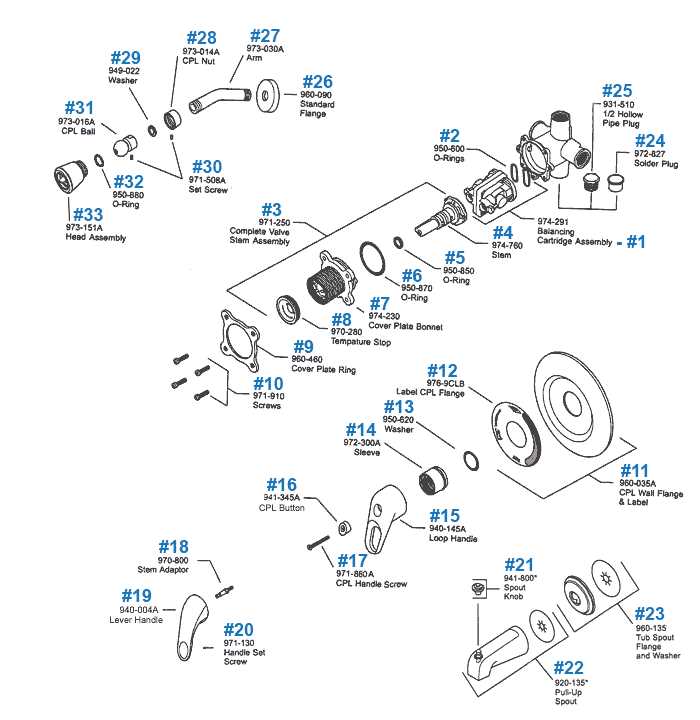

Pfister Shower Faucet Components Overview

In any system that controls water flow for household use, understanding the core elements is crucial for proper maintenance and repair. This section delves into the essential mechanisms responsible for regulating both temperature and water distribution. By identifying these integral components, users can troubleshoot common issues or upgrade specific elements for improved performance.

Valve Mechanism: The central feature that manages the mix of hot and cold streams, ensuring a balanced output. Its functionality depends on precision engineering, allowing for seamless temperature control with a single motion.

Cartridge: Acting as the primary mediator within the flow system, this part helps to adjust pressure and controls water output efficiently. Over time, it may require replacement to maintain optimal performance.

Main Functions of Shower Faucet Parts

The components of a water control system are designed to regulate the flow and temperature of water with precision. Each element has a specific role in ensuring a smooth and reliable user experience, balancing efficiency with comfort. Understanding the core responsibilities of these mechanisms helps in maintaining and troubleshooting the system.

Flow Regulator: This key element is responsible for adjusting the amount of liquid that passes through the system, ensuring the desired level of output.

Temperature Mixer: One of the most important features, this component combines hot and cold streams, maintaining a balanced temperature that can be adjusted as needed.

Pressure Controller: This mechanism protects the system from sudden changes in water pressure, ensuring a consistent and comfortable experience without unwanted fluctuations.

Seal Mechanism: Designed to prevent leaks, this part

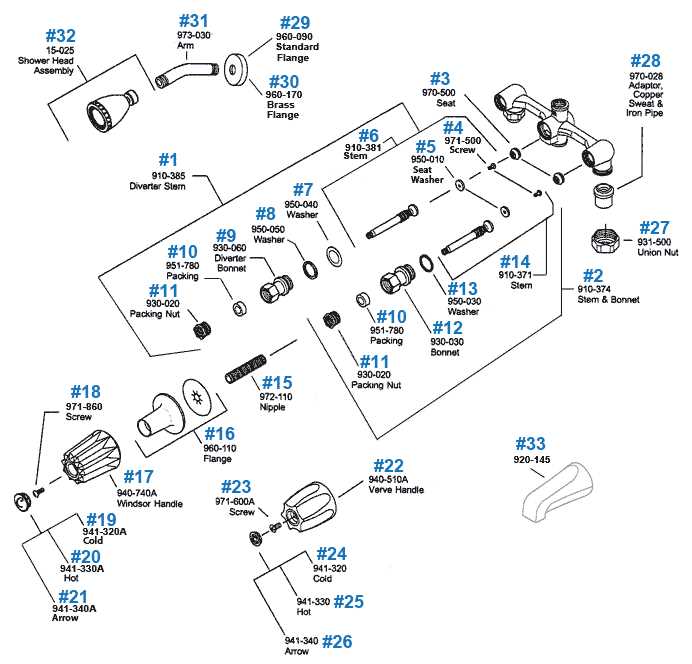

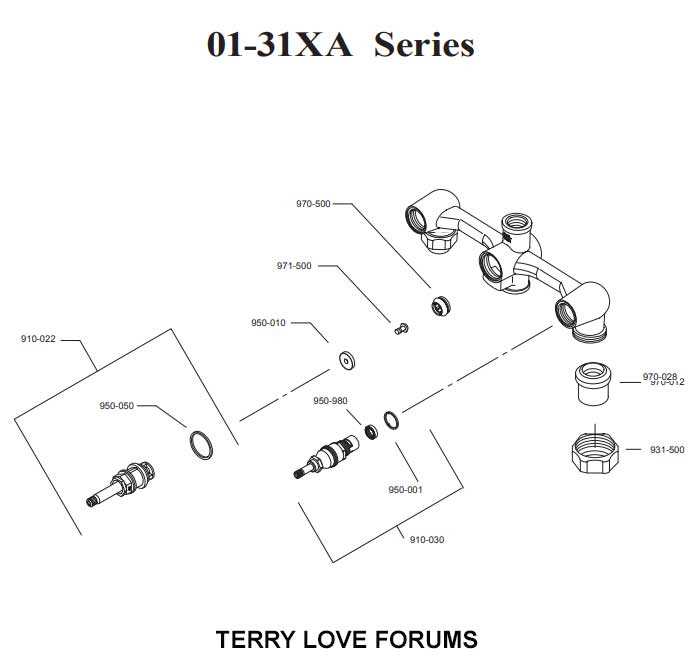

Understanding the Cartridge Mechanism

The cartridge mechanism plays a crucial role in controlling the flow and temperature of water within the system. Its function is essential for ensuring smooth operation, maintaining water balance, and preventing leaks. This component is designed to manage the internal pathways and regulate the interaction between hot and cold streams. To understand its importance, it’s necessary to explore how it works and the common issues that can arise from wear or malfunction.

- Regulation of Water Flow: The mechanism allows precise control over the amount of water that flows through the system. It adjusts the pressure and ensures that the water delivery remains consistent.

- Temperature Mixing: One of the primary purposes is to blend

How to Replace a Worn O-Ring

Replacing a worn sealing component is essential for maintaining the integrity of your system and preventing leaks. This process ensures that connections remain tight and water flows smoothly without any unwanted drips. Below is a step-by-step guide to help you efficiently replace the worn part and restore proper functionality.

- Turn off the water supply: Before beginning, ensure that the flow is completely shut off to avoid any water leakage during the procedure.

- Disassemble the fixture: Carefully remove the handle and any surrounding components to access the internal sections. Take note of how parts are arranged for easy reassembly.

- Locate the O-Ring: Once the fixture is open, find the worn O-Ring. It’s typically located near the valve stem or in a groove designed to hold it in place.

- Remove the old O-Ring

Identifying Valve Stem Issues

The mechanism responsible for controlling water flow can occasionally experience wear and tear, leading to functionality problems. A malfunctioning internal component may cause difficulties in adjusting the water flow, temperature, or completely stopping the water. Recognizing early signs of damage is crucial to preventing further complications.

Common Symptoms

One of the first indicators of trouble is unusual stiffness or looseness when turning the control handle. This can signal internal degradation, such as worn-out seals or corroded metal parts. Additionally, dripping water even when the handle is fully turned off could point to deeper issues within the system.

Steps to Assess the Condition

Regular in

Common Diverter Malfunctions and Solutions

Understanding the typical issues that can arise with a switching mechanism is essential for effective maintenance and repair. These components play a crucial role in directing water flow, and any malfunction can lead to unsatisfactory performance. Here, we will explore frequent problems encountered with these mechanisms and their respective remedies.

1. Water Flow Issues

One of the most common problems is insufficient water flow or uneven pressure. This issue may stem from blockages caused by mineral buildup or debris within the system. To resolve this, it is advisable to disassemble the component and thoroughly clean all internal passages. Regular maintenance can prevent future occurrences.

2. Leaking

Leakage around the switching mechanism is another frequent concern. This can result from worn seals or improper installation. To address leaks, inspect the seals for signs of wear and replace them as necessary. Ensuring correct installation will also help mitigate this problem.

3. Sticking or Jammed Diverter

If the switching mechanism becomes sticky or jammed, it may fail to operate smoothly. This issue is often caused by corrosion or the accumulation of dirt. Applying a suitable lubricant can help restore functionality. In severe cases, replacing the mechanism may be necessary.

4. Inconsistent Temperature Control

Difficulty in regulating temperature can occur when the switching device does not properly mix hot and cold water. This malfunction may be due to internal wear or improper adjustment. Check for any obstructions and adjust the settings as needed to ensure a balanced mix.

By identifying these common issues and implementing appropriate solutions, one can ensure the longevity and proper functioning of the switching mechanism, enhancing overall user experience.

Water Pressure Regulation in Pfister Faucets

Effective management of water pressure is crucial for ensuring optimal performance and user satisfaction. A well-regulated system prevents issues such as sudden bursts or drops in flow, contributing to a more enjoyable experience during usage. Understanding the mechanisms behind pressure control can help in troubleshooting and maintenance, ensuring long-lasting functionality.

At the heart of pressure regulation is the cartridge, which plays a vital role in balancing flow rates. This component adjusts the water’s velocity and maintains a steady output, preventing excessive force that could lead to damage or discomfort. Additionally, some designs incorporate pressure-balancing valves that work to equalize hot and cold water supply, minimizing temperature fluctuations.

Another important aspect is the use of flow restrictors, which limit the amount of water released, promoting conservation without sacrificing performance. By managing the flow rate, these elements contribute to energy efficiency while maintaining the desired pressure level. Proper installation and regular maintenance of these components are essential to ensure they function correctly over time.

For individuals experiencing inconsistent pressure, it is advisable to check for potential blockages or wear in these critical components. Regular inspections can help identify issues before they escalate, allowing for timely repairs and ensuring continued efficiency. Understanding the role of each component within the system empowers users to make informed decisions regarding maintenance and upgrades.

Handles and Their Role in Control

Control mechanisms are essential components that allow users to manage the flow and temperature of water in various fixtures. The design and functionality of these mechanisms significantly impact user experience, ensuring ease of use and efficiency. Understanding how these elements interact can enhance both the aesthetic and practical aspects of a bathroom environment.

Operational Efficiency: The primary function of these control devices is to regulate the output of water, making it vital for them to operate smoothly. A well-designed handle can provide precise adjustments, allowing individuals to quickly attain their desired settings. This not only saves time but also conserves water, contributing to overall sustainability.

Ergonomic Design: Comfort and accessibility are crucial in the design of control mechanisms. Handles should be designed to fit comfortably in the hand, allowing for easy manipulation, especially when hands are wet. An ergonomic design enhances usability, reducing strain and providing a more enjoyable experience.

Aesthetic Appeal: Beyond functionality, these components also contribute to the visual appeal of the installation. A variety of styles, finishes, and designs are available, allowing for personalization that complements the overall décor. This aesthetic consideration adds a layer of sophistication to any space, making it more inviting.

Durability: Quality construction is paramount for longevity. Handles must withstand frequent use and resist wear over time. Choosing robust materials can ensure that these mechanisms remain functional and visually appealing for years, reducing the need for replacements and maintenance.

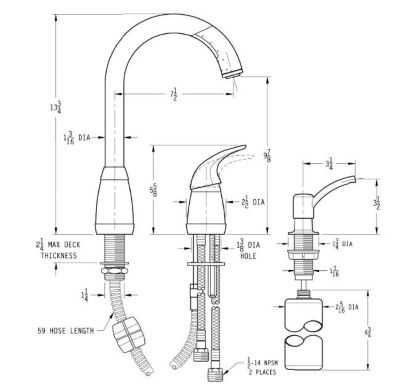

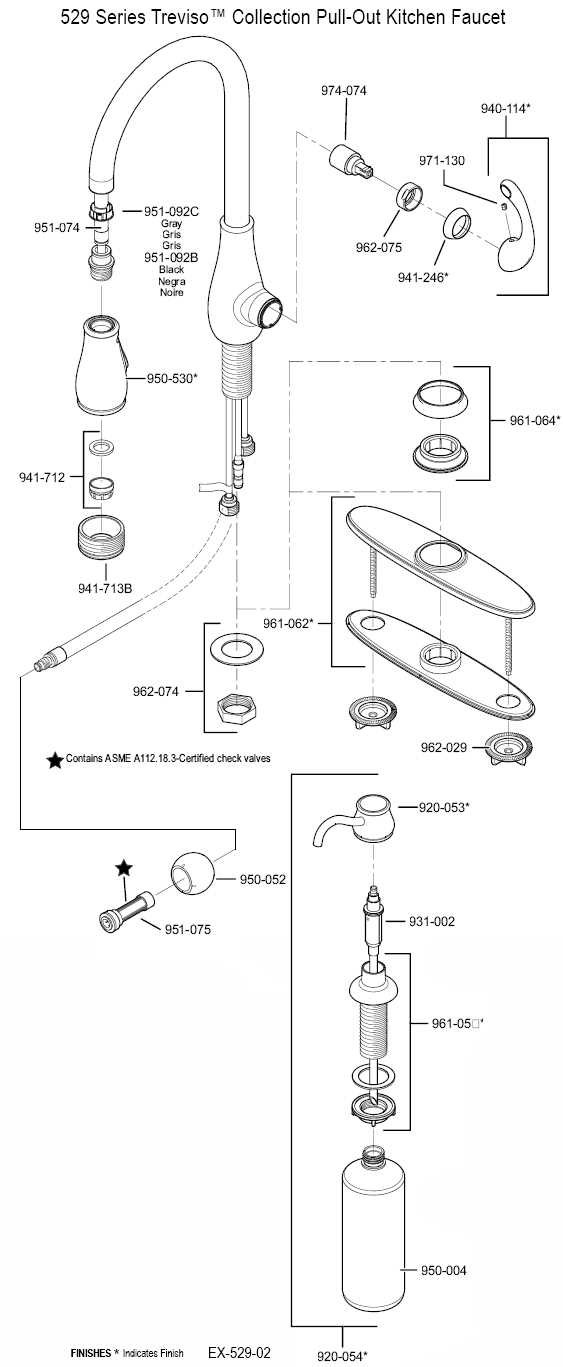

Spout Features and Maintenance Tips

Understanding the essential characteristics of a water outlet can enhance both functionality and aesthetic appeal in any bathing space. This section provides insights into common features and offers practical maintenance advice to ensure longevity and optimal performance.

Key Features of Water Outlets

- Design Variety: Available in various styles, ranging from modern to classic, allowing for customization based on personal preferences.

- Material Durability: Crafted from materials such as brass or stainless steel, providing resilience against corrosion and wear.

- Water Flow Control: Equipped with mechanisms that regulate water pressure, ensuring a consistent and enjoyable experience.

- Easy Installation: Many designs come with user-friendly features, simplifying the installation process for DIY enthusiasts.

Maintenance Recommendations

- Regular Cleaning: Wipe down the exterior with a soft cloth to prevent mineral buildup and maintain shine.

- Inspect for Leaks: Periodically check connections for signs of leakage and tighten as needed to prevent water waste.

- Replace Washers: If water flow becomes irregular, consider replacing worn washers or seals to restore function.

- Avoid Harsh Chemicals: Use gentle cleaners to avoid damaging the finish or components of the outlet.

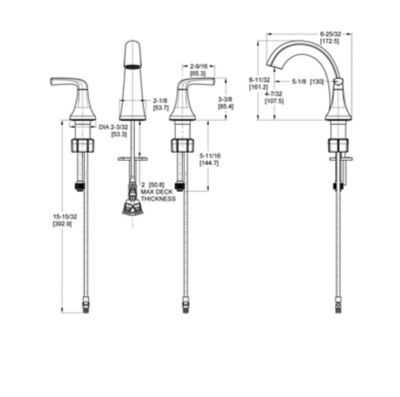

Showerhead Compatibility with Pfister Faucets

When it comes to enhancing your bathing experience, the choice of head is crucial. Ensuring that your selected device works seamlessly with your existing installation can significantly improve water flow and overall enjoyment. Understanding the nuances of compatibility will help you make an informed decision.

Several factors should be considered to guarantee a perfect fit:

- Connection Size: Most fixtures require a specific connection size. Standard measurements typically range from ½ inch to ¾ inch. It’s essential to confirm your current setup to avoid any mismatches.

- Thread Type: Ensure that the thread type of your chosen model aligns with your existing configuration. Common types include IPS (Iron Pipe Size) and BSP (British Standard Pipe).

- Water Pressure Compatibility: Different devices may operate optimally under various pressure conditions. Verify the compatibility of your selection with the water pressure in your system to prevent issues like low flow or leaks.

- Style and Functionality: Consider the design and features you prefer. Options range from fixed to handheld varieties, and certain models may offer advanced features like massage or mist settings.

Before making a purchase, it is advisable to consult user reviews and product specifications. Compatibility guides provided by manufacturers can also be valuable resources in selecting the ideal head for your needs.