When it comes to maintaining your machinery, having a clear representation of its components can be immensely helpful. This section aims to provide an insightful overview of the essential elements that ensure optimal performance during the colder months.

In exploring the intricacies of these mechanical devices, one can truly appreciate how each part plays a pivotal role in functionality. By identifying and understanding these key sections, you can enhance both the longevity and efficiency of your equipment.

Moreover, knowing how everything fits together allows for more effective troubleshooting. With a thorough grasp of the essential mechanics, users can navigate potential issues with greater confidence and ease.

Understanding Bolens Snowblower Components

When tackling winter challenges, having a solid grasp of essential machinery elements is crucial. Each component plays a pivotal role in ensuring efficient performance and reliability during snowy conditions. This section will illuminate the key aspects of these vital mechanisms.

Key Elements of the Machinery

The main assembly consists of various interrelated parts that contribute to overall functionality. For instance, the motor generates power, while the auger facilitates the movement of snow. Understanding how these components work together can enhance maintenance practices and improve operational effectiveness.

Maintenance and Care

Regular upkeep is essential for longevity and efficiency. Identifying wear and tear on critical components ensures that the machine operates at its best. Investing time in understanding these elements can ultimately save time and resources in the long run.

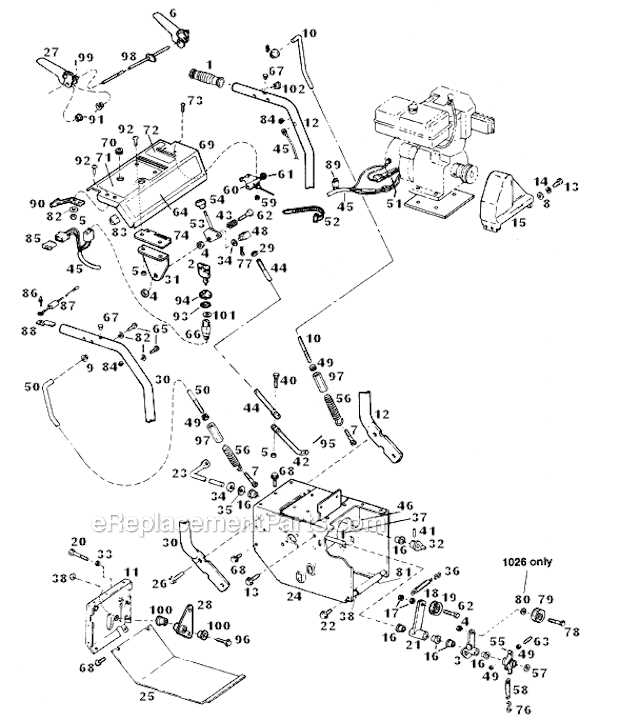

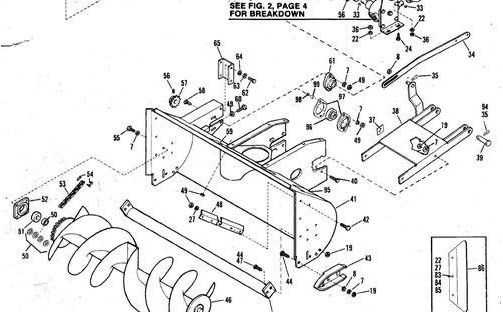

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Clear visual representations enable users to quickly identify each element, ensuring a smoother process when addressing issues or performing upgrades.

Benefits of Visual Guides

- Enhances comprehension of assembly and disassembly.

- Reduces the likelihood of errors during repairs.

- Saves time by providing a quick reference for locating components.

Facilitating Repairs

- Streamlines the identification of necessary tools and materials.

- Aids in troubleshooting by illustrating potential problem areas.

- Supports efficient communication between users and service professionals.

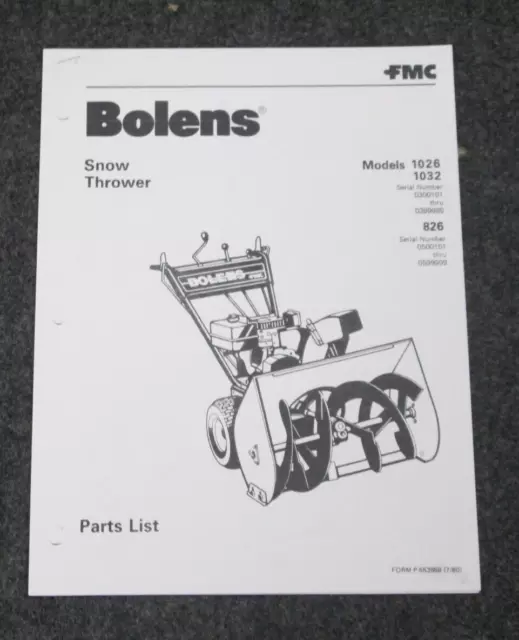

Common Bolens Snowblower Models

This section explores popular models from a renowned brand known for its winter equipment. Each variant features unique attributes and specifications, catering to different user needs and preferences. Understanding these options can help in selecting the right machine for efficient snow management.

Model Overview

Among the widely recognized variants, certain models stand out for their reliability and performance. Features may include varying engine sizes, operational capabilities, and user-friendly designs. These characteristics ensure that operators can effectively tackle diverse winter conditions.

Performance Features

Key elements such as engine power, clearing width, and throwing distance are vital for assessing efficiency. Some models incorporate advanced technology for enhanced maneuverability, while others prioritize rugged construction for durability. Evaluating these factors ultimately leads to informed choices for winter maintenance.

Identifying Key Components

Understanding the essential elements of a cold-weather clearing machine is crucial for effective maintenance and operation. Recognizing these components not only enhances performance but also facilitates troubleshooting and repairs.

Main Elements to Recognize

- Engine: Powers the entire system and is fundamental for operation.

- Auger: Responsible for gathering and moving the snow forward.

- Chute: Directs the snow to the desired location after it is collected.

- Skids: Help in adjusting the height and protect the machine while in use.

- Control Panel: Provides user interface for adjusting settings and speeds.

Maintenance Tips

- Regularly check the engine oil level and change as needed.

- Inspect the auger for wear and replace if necessary.

- Clean the chute to prevent blockages and ensure smooth operation.

- Adjust skids according to surface conditions to improve efficiency.

- Test the control panel functions before heavy use to avoid issues.

Where to Find Diagrams Online

Finding detailed illustrations for machinery can greatly enhance repair and maintenance efforts. Various online platforms offer a wealth of resources, enabling users to locate specific schematics easily. These resources often include visual aids that can assist in understanding the assembly and functionality of components.

Manufacturer Websites: Many original equipment manufacturers provide comprehensive resources on their official sites, including technical drawings and service manuals. Visiting these sites can ensure access to accurate information.

Forums and Community Sites: Engaging with online communities can yield valuable insights. Users frequently share their own finds, making these forums a treasure trove of knowledge.

Online Retailers: Some e-commerce platforms also feature parts listings accompanied by images and diagrams. This can be a convenient way to visualize the item you need.

DIY and Repair Websites: Numerous dedicated repair websites offer extensive libraries of illustrations. These can provide step-by-step guides along with corresponding visuals for enhanced clarity.

By exploring these avenues, you can effectively access the resources needed for successful equipment maintenance.

How to Read a Parts Diagram

Understanding the visual representation of components is crucial for effective maintenance and repairs. This guide will help you navigate the symbols and layout commonly found in these illustrations, enabling you to identify and source the necessary elements with ease.

Familiarize Yourself with the Layout

Begin by noting the overall structure, which typically includes labeled sections that indicate various groupings of components. Each area often corresponds to a specific function, making it easier to locate what you need.

Identify Symbols and Labels

Pay close attention to the symbols used in the illustration. These often represent different items or functions. Numbers or letters accompanying each component will guide you to corresponding lists or references for further details. Make sure to consult the accompanying documentation for complete clarity.

Maintenance Tips for Snowblowers

Keeping your winter machinery in top shape is essential for optimal performance and longevity. Regular upkeep not only ensures smooth operation but also helps prevent costly repairs and unexpected breakdowns when you need it most.

Begin with a thorough inspection before the season starts. Check fluid levels, replace any worn components, and ensure all belts and cables are in good condition. A clean machine runs better, so remove any debris and snow buildup after each use.

Sharpening the blades is crucial for efficient snow clearing. Dull edges can hinder performance and lead to additional strain on the engine. Always refer to the manufacturer’s guidelines for the correct sharpening technique.

Storing your equipment properly during the off-season is equally important. Drain any fuel and lubricate moving parts to prevent rust and deterioration. Covering the machinery can also protect it from dust and pests.

Finally, refer to the owner’s manual for specific maintenance schedules and recommended services. Following these practices will enhance durability and ensure that your equipment is ready for the next winter challenge.

Replacement Parts Availability

Accessing components for your equipment is crucial for maintaining its functionality and longevity. Whether you’re looking to fix a minor issue or perform a major overhaul, knowing where to find quality replacements is essential. Various suppliers offer a range of options, ensuring you can keep your machine in optimal working condition.

| Supplier | Availability | Delivery Options |

|---|---|---|

| Local Retailers | In-stock items available | Same-day pickup |

| Online Stores | Extensive inventory | Standard and express shipping |

| Authorized Dealers | Genuine components | Direct delivery |

| Aftermarket Suppliers | Cost-effective options | Varied shipping times |

Common Repairs and Their Parts

Maintaining your outdoor equipment is essential for optimal performance and longevity. Understanding the frequent issues that arise and their corresponding components can help you troubleshoot effectively and keep your machine running smoothly.

Typical Issues and Solutions

-

Engine Starting Problems:

When the engine fails to start, it may be due to:

- Defective spark plug

- Clogged fuel filter

- Weak battery or starter issues

-

Auger Malfunctions:

If the auger isn’t rotating properly, consider inspecting:

- Drive belts

- Shear pins

- Gearbox assembly

Maintenance Components

-

Oil:

Regular oil changes prevent engine wear and improve efficiency.

-

Air Filter:

A clean air filter ensures proper airflow, enhancing engine performance.

-

Fuel System:

Inspect and clean the fuel lines and tank to avoid clogs and ensure smooth operation.

By addressing these common issues with the right components, you can ensure your equipment remains reliable throughout its use. Regular checks and timely repairs will save you time and money in the long run.

DIY vs. Professional Repairs

When it comes to fixing equipment, individuals often face a choice between handling repairs themselves or seeking the expertise of a professional. Each approach has its own merits and drawbacks, influencing both time investment and cost. Understanding these factors can help make the ultimate decision easier.

Advantages of DIY Repairs

Taking on repairs independently can be fulfilling and cost-effective. Many enthusiasts appreciate the hands-on experience, gaining knowledge and skills that can be beneficial in the long run. Moreover, DIY projects can be tailored to individual schedules, allowing flexibility.

Benefits of Professional Assistance

On the other hand, hiring an expert guarantees a level of quality and reliability that might be difficult to achieve solo. Professionals often have access to specialized tools and knowledge that can expedite the repair process and ensure safety. This option may also provide peace of mind, especially for those unfamiliar with the intricacies of their equipment.

| Factor | DIY Repairs | Professional Repairs |

|---|---|---|

| Cost | Generally lower | Higher due to labor |

| Time | Variable, often longer | Typically quicker |

| Skill Level | Requires some knowledge | Expertise guaranteed |

| Satisfaction | High if successful | Less personal satisfaction |

Safety Precautions When Repairing

When undertaking maintenance on outdoor machinery, ensuring personal safety is of utmost importance. Familiarizing yourself with essential guidelines can prevent accidents and injuries, ultimately leading to a smoother repair process.

Always wear appropriate protective gear, including gloves and safety goggles, to shield yourself from sharp edges and flying debris. Using ear protection is advisable when operating loud equipment to avoid hearing damage.

Before starting any repair work, disconnect the power source to prevent accidental activation. Make sure the equipment is on a stable surface and never work in wet conditions to reduce the risk of electric shock.

Be mindful of loose clothing and hair that could get caught in moving parts. Maintain a clean workspace to avoid tripping hazards and ensure tools are in good condition.

Finally, read the manufacturer’s guidelines thoroughly before attempting any repairs. Understanding the machinery’s specific requirements will enhance your safety and efficiency during the process.

Upgrading Your Snowblower Parts

Enhancing your machine can significantly improve its efficiency and longevity. By investing in superior components, you not only boost performance but also ensure reliability during harsh winter conditions. This approach ultimately leads to a more enjoyable and effective experience when tackling the challenges of snow removal.

Consider the following upgrades:

- High-Quality Blades: Opt for durable materials that provide better cutting and clearing.

- Enhanced Engine: A more powerful engine can greatly increase operational speed.

- Ergonomic Controls: Upgrading to user-friendly controls can enhance comfort during use.

By taking the time to explore these improvements, you can delve into a world of efficiency and ease, transforming your machine into a reliable ally for winter tasks.

Customer Support for Bolens Products

Ensuring customer satisfaction is paramount for any brand, particularly when it comes to outdoor equipment. The support provided to users plays a critical role in enhancing their experience and addressing any concerns that may arise during ownership. A dedicated team is essential to guide customers through inquiries, offering expertise and assistance tailored to their specific needs.

Comprehensive Assistance

For those seeking guidance, a range of resources is available. From troubleshooting common issues to offering maintenance tips, the support team is equipped to help users make the most of their equipment. Additionally, users can access a wealth of information online, including manuals and instructional content, making it easier to resolve concerns independently.

Connecting with Support

Customers can reach out through multiple channels, including phone, email, and live chat. This flexibility ensures that help is readily available, regardless of the user’s preferred method of communication. Prompt responses and knowledgeable staff are key components in fostering a positive relationship with customers, ultimately enhancing their loyalty to the brand.