When it comes to maintaining machinery designed for cold conditions, understanding the structure of the equipment is crucial for proper functionality and long-lasting performance. Each element of such machinery plays a vital role in ensuring smooth operation during the harshest winter months.

Familiarity with the different elements and their positions in the machine allows for quicker troubleshooting and more effective repairs. Recognizing the purpose and interaction of various mechanical parts ensures that any issues can be addressed efficiently, leading to improved reliability and safety.

In this guide, we will explore the key sections of winter maintenance machines, focusing on the internal mechanisms and external components that work together. By breaking down each aspect, you’ll gain a deeper understanding of how these machines operate and how to keep them in optimal condition for prolonged use.

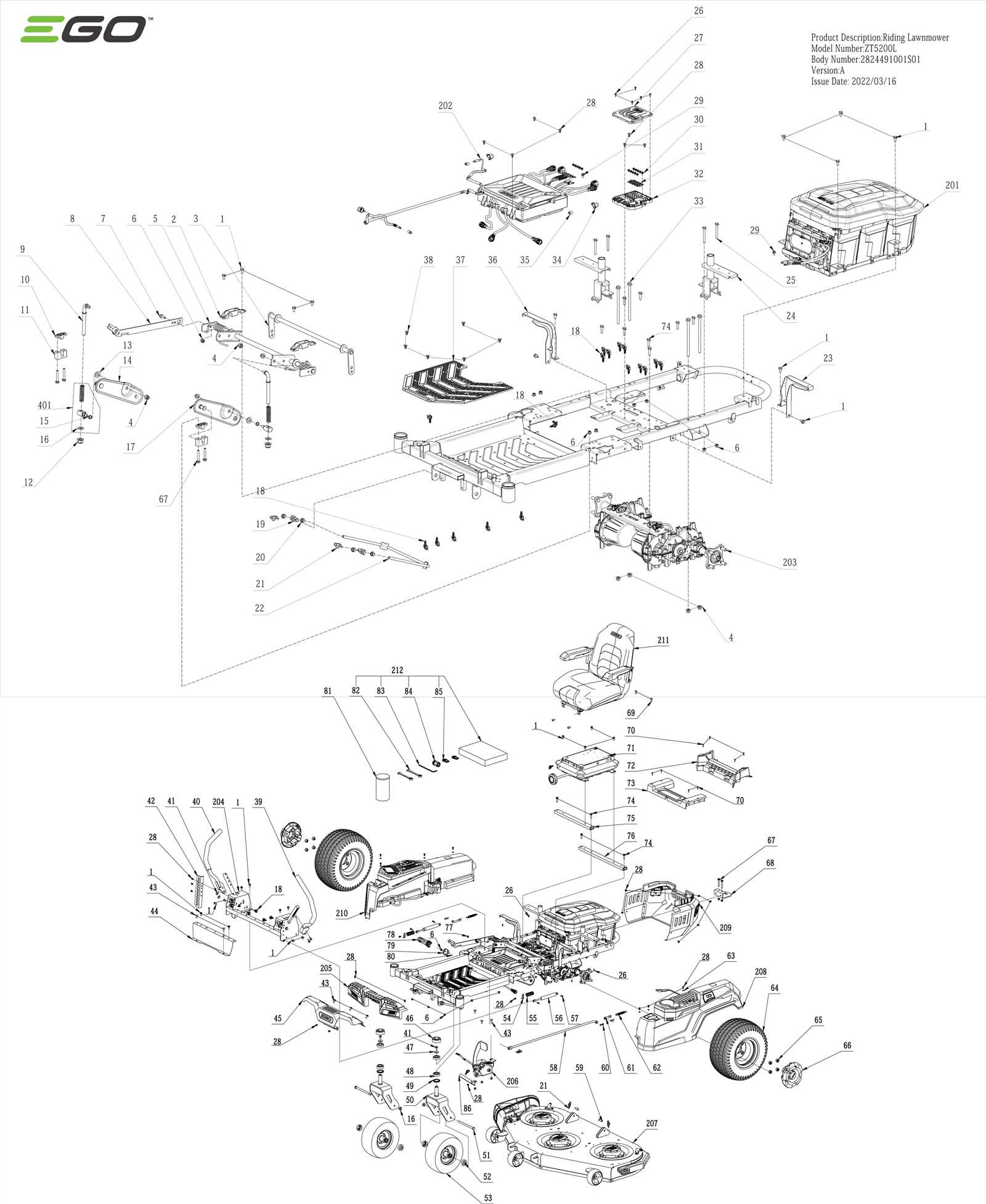

Key Components of a Snow Removal Machine

The primary elements of a modern snow removal machine are designed to efficiently clear pathways, ensuring smooth operation even in challenging conditions. These machines are equipped with essential mechanisms that work together to provide effective snow clearance and long-lasting durability.

At the heart of the system lies the engine, powering the entire operation with enough force to handle deep and heavy layers of snow. The drive system plays a critical role, allowing users to maneuver the equipment with ease, even over uneven surfaces. The auger and impeller work together to chop and propel snow away from the path, ensuring thorough and efficient clearing.

Control levers and grips offer users the ability to adjust speed and direction quickly, improving overall handling. Additionally,

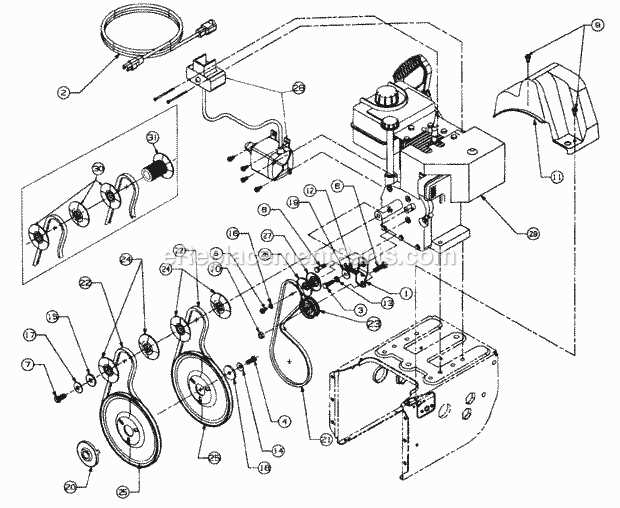

Exploring the Engine Assembly

The engine is the central component that powers the entire machine, driving its mechanisms and ensuring efficient operation. Understanding how the various elements of the motor system come together is essential for proper maintenance and troubleshooting. Each section of the engine contributes to smooth functionality, making it vital to grasp the interconnectedness of its parts.

Main Components of the Engine

- Cylinder: This part houses the piston and ensures combustion takes place properly.

- Piston: Moves up and down within the cylinder, converting fuel energy into mechanical motion.

- Crankshaft: Connected to the piston, it translates linear motion into rotational force.

- Carburetor: Mixes fuel and air in the right proportions for

How to Identify the Auger Parts

The rotating mechanism responsible for moving snow is made up of several key components. Understanding how these elements work together is essential for proper maintenance and replacement when necessary. Each section plays a crucial role in ensuring efficient operation.

Blades are the primary element that cuts through the snow. They are attached to the central shaft and rotate to gather the snow. Over time, these blades may wear down and require replacement.

The central shaft, or drive axle, is responsible for connecting the blades and ensuring their synchronized movement. This component often houses bearings to reduce friction and ensure smooth rotation.

Supporting the entire system is the housing, which encloses the mechanism. The housing also serves to channel snow into the collection area

Understanding the Drive System Mechanism

The drive mechanism plays a crucial role in ensuring smooth and efficient operation. It translates power from the engine into motion, allowing the machine to move across various terrains. This section explores how the drive system is designed to provide optimal performance and how its components work together to maintain control and stability.

Key Components of the Drive System

- Transmission: Responsible for transferring power from the engine to the wheels, enabling forward or reverse motion.

- Drive Belt: Connects the engine to the transmission, ensuring that the power is consistently delivered.

- Friction Disc: Engages with the drive plate to control the speed and direction of the movement.

How the Drive System Works

- The engine generates power, which is transferred through

Detailed Overview of Control Cables

The system of control cables is crucial for ensuring the proper functioning of mechanical equipment. These cables transmit force and motion, allowing for the efficient operation of various components. A well-maintained set of cables ensures that different mechanisms respond accurately to user input, contributing to overall performance.

Main Functions of Control Cables

Control cables serve multiple purposes, including managing speed, directing movement, and engaging specific features. Their role is to connect the operator’s controls with the relevant mechanical parts, translating manual inputs into physical actions. The integrity of these cables is vital for safe and reliable operation.

Maintenance and Adjustment

Regular inspection of control cables is essential to prevent wear and tear. Proper tensioning, lubrication, and timely replacement of worn components help maintain the smooth operation of the system. Ensuring the correct adjustment of these cables can significantly enhance efficiency and prolong the life of the equipment.

Skid Shoes: Function and Maintenance

Skid shoes play a vital role in the overall performance and functionality of outdoor equipment designed for handling snow and other debris. These components help guide the machine along the ground, ensuring that the unit operates efficiently while maintaining optimal clearance from the surface. Proper care and maintenance of these essential elements are crucial for extending their lifespan and ensuring effective operation.

Functionality of Skid Shoes

Primarily, skid shoes serve to protect the underside of the machine from wear and tear caused by contact with various surfaces. They facilitate smooth movement and stability, preventing damage to both the equipment and the terrain being navigated. By adjusting the height of the skid shoes, operators can control the depth at which the device works, allowing for versatility in different conditions.

Maintenance Tips

Regular inspection and maintenance of skid shoes are essential to ensure their longevity. Cleaning the shoes after each use helps prevent buildup of debris and ice, which can impede functionality. Additionally, checking for signs of wear or damage allows for timely replacement before issues escalate. Lubricating any moving parts associated with the skid shoes can further enhance their performance and reduce friction.

Guide to the Impeller Section

The impeller is a crucial component in the operation of a snow-clearing machine, responsible for efficiently moving snow from the intake to the discharge chute. Understanding its function and design is essential for maintenance and optimal performance. This section provides insights into the impeller’s role, structure, and importance in ensuring effective snow removal.

Functionality of the Impeller

The primary function of the impeller is to create airflow that transports snow away from the unit. This is achieved through its rotational motion, which generates a force that propels the snow forward. Proper functioning of the impeller is vital, as any obstruction or damage can lead to decreased efficiency and potential breakdowns.

Maintenance Tips

Regular maintenance of the impeller section can enhance the longevity and performance of the machine. Ensure that the blades are free from debris and wear, as this can significantly affect efficiency. Inspecting the mounting and alignment regularly helps maintain optimal operation. Lubricating moving parts will also prevent friction and prolong the lifespan of the component.

Key Takeaways: Proper understanding and care of the impeller section can lead to improved efficiency and reduced wear on the machine.

Importance of the Gearbox in Operation

The gearbox serves a crucial role in the functionality of machinery, particularly in enhancing efficiency and performance. It acts as a vital component that facilitates the transfer of power from the engine to various operational parts. By optimizing speed and torque, the gearbox ensures that the equipment operates smoothly under different conditions.

Power Transmission

One of the primary functions of the gearbox is to manage power transmission effectively. It converts the engine’s rotational force into usable energy for the equipment, allowing it to perform tasks with precision. This conversion is essential for maintaining optimal performance, especially in demanding environments.

Durability and Maintenance

Regular maintenance of the gearbox is paramount for prolonging the lifespan of the machinery. A well-maintained gearbox minimizes wear and tear, ensuring reliable operation. Proper lubrication and periodic inspections can prevent potential issues, enhancing overall durability and reducing the risk of breakdowns during use.

Chute and Rotation System Explained

The chute and rotation mechanism plays a crucial role in the effective operation of a winter clearing machine. This system enables the user to direct the discharge of snow, ensuring optimal control over the area being cleared. Understanding how this mechanism functions can enhance efficiency and performance during snow removal tasks.

Components of the Chute Mechanism

The chute consists of several integral components that work together seamlessly. These include the main chute body, the deflector, and the control lever. Each part serves a specific purpose, contributing to the overall functionality of the system. The main chute body is responsible for directing the snow, while the deflector adjusts the height and angle of the discharge.

Operational Principles

To operate the chute effectively, the user manipulates the control lever, which activates the rotation system. This allows for precise adjustments in the direction of the snow flow. The rotation is typically powered by a belt or gear mechanism, enabling smooth and responsive movement.

Component Function Main Chute Body Directs snow discharge Deflector Adjusts discharge height and angle Control Lever Controls chute rotation Belt/Gear Mechanism Facilitates rotation Identifying the Belt and Pulley Components

Understanding the functionality and layout of the drive mechanism is crucial for effective maintenance and operation. This section focuses on the key elements responsible for power transmission, specifically the belt and pulley system. Recognizing these components will aid in troubleshooting and ensuring optimal performance of the equipment.

Belt Overview

The belt serves as the primary connector between various moving parts, facilitating the transfer of energy from the engine to the drive system. It is essential to inspect the condition of the belt regularly, looking for signs of wear, fraying, or cracking. A well-maintained belt ensures smooth operation and reduces the risk of mechanical failure.

Pulley Functionality

Pulleys play a vital role in directing the movement of the belt while also providing necessary tension. Each pulley is designed to accommodate specific belt sizes and types. Proper alignment and adjustment of the pulleys are necessary to prevent slippage and prolong the lifespan of both the belt and the pulleys. Regular checks will help identify any misalignments that could lead to performance issues.

Maintaining the Snowblower’s Shear Pins

Regular upkeep of the shear pins is essential for the optimal functioning of your outdoor equipment. These small but crucial components are designed to protect the machine’s mechanism from damage by breaking under excessive stress. Proper maintenance will not only extend the life of these pins but also enhance the overall efficiency of your machinery.

Importance of Shear Pins

Shear pins play a vital role in ensuring the safety and performance of your equipment. Here are some reasons why they are important:

- Prevents damage to the machine’s drivetrain.

- Ensures smooth operation during heavy use.

- Facilitates easy replacement if damaged.

Maintenance Tips

To keep the shear pins in good condition, follow these maintenance tips:

- Regular Inspection: Check the pins for any signs of wear or damage before each use.

- Replacement: Replace any worn or broken pins immediately to avoid further damage.

- Lubrication: Apply a light lubricant to the pins to prevent rust and ease removal when necessary.

- Correct Installation: Ensure that the pins are installed properly to avoid misalignment.

By implementing these maintenance practices, you can ensure that your machinery remains in peak condition, ultimately leading to better performance and longevity.