Maintenance and repair of outdoor machinery are crucial for optimal performance and longevity. Familiarity with the intricate components is essential for ensuring smooth operation during the colder months. Knowing how each element interacts can significantly enhance efficiency and reduce downtime.

When it comes to winter machinery, recognizing the various sections and their functionalities allows users to tackle issues proactively. Comprehensive knowledge enables effective troubleshooting and informed decision-making. Thus, delving into detailed illustrations and schematics can provide invaluable insights.

In this guide, we will explore the critical elements of a specific model, helping you to identify, replace, or upgrade components as necessary. By understanding the arrangement and function of each piece, you can achieve the ultimate maintenance strategy for your machine.

Overview of John Deere 1032 Snowblower

This section provides an insight into a robust equipment designed for effective snow removal. Known for its efficiency and reliability, this machine is favored by many for handling harsh winter conditions. It combines advanced technology with user-friendly features, making it suitable for both residential and commercial use.

Key Features

The equipment boasts a powerful engine that ensures high performance, even in the heaviest snowfall. Its adjustable chute allows for precise control of snow direction, while the wide clearing path enhances productivity. Additionally, the machine’s sturdy construction ensures durability and longevity, providing excellent value over time.

Maintenance and Care

Proper upkeep is crucial for optimal performance. Regular inspections and timely replacement of worn components can significantly extend the life of the equipment. Users are encouraged to consult the manufacturer’s guidelines for maintenance schedules and troubleshooting to ensure consistent operation during the winter months.

Key Features of the 1032 Model

This model is designed for efficient snow removal, boasting several standout characteristics that enhance its performance and usability. Users can expect a combination of power, durability, and innovative features that make winter maintenance tasks more manageable.

Powerful Engine

The robust engine ensures optimal performance, allowing for effective clearing of heavy snowfall. With high torque and reliability, it is equipped to tackle the toughest winter challenges.

User-Friendly Design

Featuring an intuitive control layout, the model allows for easy maneuverability. Additionally, the adjustable chute provides enhanced versatility, making it suitable for various snow conditions.

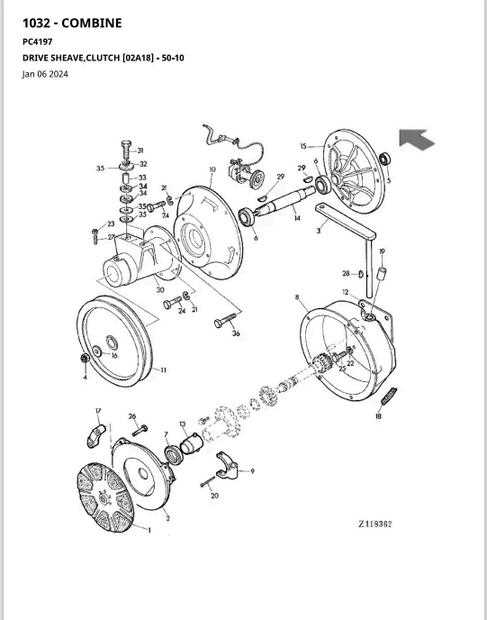

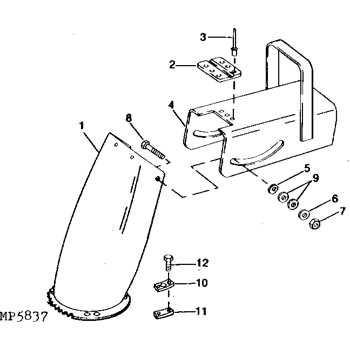

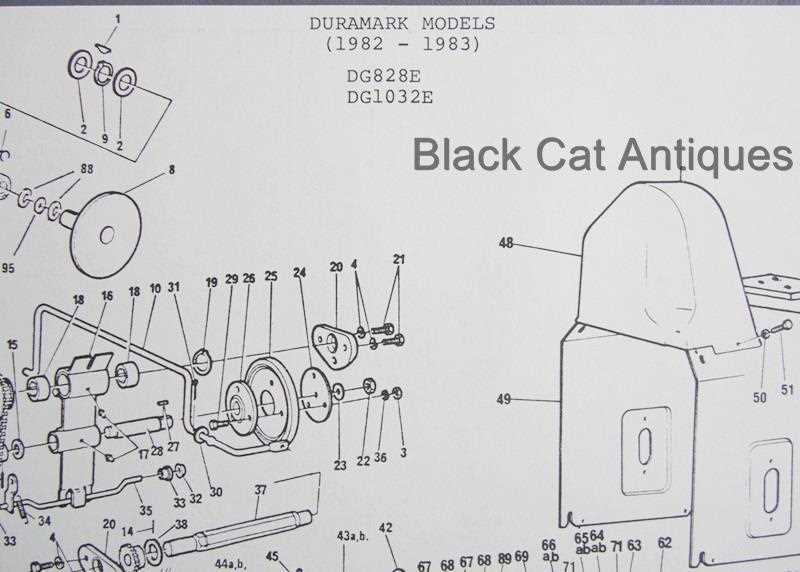

Importance of Parts Diagrams

Understanding the layout and components of any machine is crucial for effective maintenance and repair. Visual representations serve as essential tools that simplify the complex relationships between various elements. By utilizing these illustrations, users can gain insights into how each part functions and interacts with others.

Enhanced Troubleshooting

When issues arise, having a visual reference can significantly expedite the diagnosis process. Users can:

- Quickly identify problematic components.

- Understand assembly configurations.

- Locate specific areas that require attention.

Streamlined Maintenance

Regular upkeep becomes more manageable with clear visuals. Users benefit from:

- Knowing which components need periodic checks.

- Easily locating replacement items.

- Following step-by-step maintenance procedures.

In summary, visual references are invaluable for ensuring both efficient troubleshooting and effective maintenance strategies.

Common Parts Needed for Repairs

Understanding the essential components required for maintenance can significantly enhance the efficiency and longevity of outdoor equipment. Identifying the most frequently needed items helps ensure that users are always prepared for any necessary repairs, minimizing downtime and maximizing performance.

Key Components

Belts play a crucial role in the functionality of machinery. Regular inspections and replacements are vital to prevent slippage or breaks that could hinder operations.

Additional Essentials

Another important item includes shovels, which can aid in clearing paths during extensive use. Keeping a stock of fasteners is also recommended, as they are often needed for securing various elements of the equipment.

Understanding Snowblower Mechanisms

Mastering the intricacies of these machines is essential for optimal performance during winter conditions. By exploring their core components, users can appreciate how each element contributes to effective snow removal.

- Auger: This rotating component is responsible for gathering and lifting snow into the machine.

- Impeller: After the snow is collected, this part propels it out of the chute, ensuring efficient discharge.

- Chassis: The frame houses all mechanisms, providing stability and support.

- Drive System: This system allows for movement, offering different speed options for maneuverability.

By comprehensively understanding these mechanisms, users can enhance maintenance practices and troubleshoot effectively, ensuring longevity and reliability.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a roadmap, helping users identify and locate various elements within a machine. Familiarizing yourself with the symbols and layout will streamline your work process and enhance your efficiency.

Key Components to Focus On

- Symbols: Each shape or icon corresponds to specific parts or features.

- Labels: Descriptive text provides additional information about each item.

- Connections: Arrows indicate how parts interact or fit together.

Steps to Interpret Effectively

- Start with the legend or key, if available, to understand the symbols.

- Identify the main components that require attention.

- Follow the connections to comprehend the assembly or disassembly process.

- Cross-reference with the manual for any specific instructions.

Replacement Parts Availability and Sources

Ensuring optimal performance of outdoor machinery often hinges on the accessibility of suitable components. A well-maintained unit requires reliable sources for obtaining necessary replacements, which can greatly enhance its longevity and efficiency. Understanding where to find these essential items is crucial for any owner.

Authorized Dealers: One of the most dependable avenues is through authorized retailers. These dealers often provide genuine components that are specifically designed for compatibility, ensuring that your equipment operates at peak efficiency. Additionally, they may offer warranty protection on new acquisitions.

Online Marketplaces: The rise of e-commerce has made it easier than ever to locate specific items. Numerous platforms allow users to search for and purchase components directly, often at competitive prices. It is essential to verify the seller’s reputation and read customer reviews to ensure quality.

Local Repair Shops: For those seeking hands-on assistance, local repair facilities can be invaluable. These shops frequently stock a variety of components and may also provide expert advice on installation and maintenance, enhancing the overall experience for the customer.

Second-Hand Options: Exploring second-hand markets can also yield significant savings. Many individuals sell unused or lightly used components that can be just as effective as new items. Caution should be exercised to ensure the functionality and compatibility of such offerings.

Ultimately, the availability of replacement components significantly influences the usability of your outdoor machinery. By exploring multiple sources, owners can make informed decisions that support their maintenance needs and ensure continued operation.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the durability and efficiency of outdoor equipment. By following a few straightforward practices, you can enhance performance and extend the lifespan of your machinery, keeping it in optimal working condition for years to come.

Here are some key maintenance tips to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Regularly replacing the oil helps prevent engine wear and maintains performance. |

| Inspect Belts | Every season | Check for signs of wear or damage to ensure proper functioning and safety. |

| Clean Filters | Monthly | Keeping air filters clean promotes efficient airflow and prevents overheating. |

| Check Spark Plug | Every 100 hours | Inspecting and replacing spark plugs as needed can improve starting and fuel efficiency. |

| Lubricate Moving Parts | Every use | Regular lubrication reduces friction and prevents premature wear of components. |

By adhering to these maintenance guidelines, you can ensure that your equipment remains reliable and performs at its best, ultimately saving time and resources in the long run.

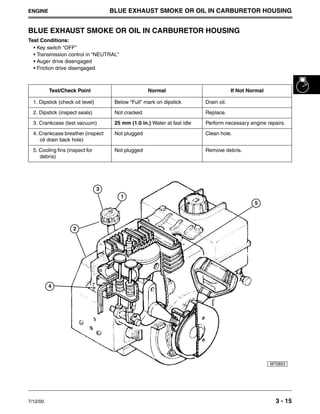

Identifying Faulty Components

Recognizing malfunctioning elements in your equipment is crucial for ensuring optimal performance and longevity. By paying attention to specific signs and symptoms, you can effectively diagnose issues before they escalate into more significant problems. This section outlines the common indicators that suggest a component may be compromised and provides guidance on how to approach the assessment.

Common Symptoms of Malfunction

Many times, visible signs can alert you to potential failures. Unusual noises, such as grinding or rattling, can indicate wear or misalignment. Additionally, decreased efficiency in operation, such as sluggish performance or poor output, may signify that a critical part is not functioning as intended. Always observe your machine closely for these indicators.

Assessment and Troubleshooting Techniques

When you suspect a component is faulty, a systematic approach to evaluation is essential. Begin with a thorough visual inspection to identify any obvious damage or wear. Following that, consider using diagnostic tools to test specific parts. Documentation of your findings can also assist in tracking issues over time, helping to pinpoint recurring problems and informing future maintenance strategies.

DIY Repairs: Tools Required

When tackling maintenance and fixes on outdoor equipment, having the right tools at your disposal is essential for efficiency and effectiveness. A well-equipped workspace not only simplifies the process but also enhances safety.

- Wrenches: Essential for loosening and tightening various fasteners.

- Screwdrivers: Both flathead and Phillips types for versatile use.

- Pliers: Useful for gripping, bending, and cutting tasks.

- Socket set: Provides additional leverage and reach for hard-to-access bolts.

- Torque wrench: Ensures fasteners are tightened to the correct specifications.

Additionally, consider the following:

- Safety gear: Gloves and goggles to protect yourself during repairs.

- Worklight: Adequate lighting helps you see small details clearly.

- Parts cleaner: Keeps your components free from debris and dirt.

With these essential tools, you’ll be well-prepared to delve into any repair project and achieve the ultimate results.

Safety Precautions During Repairs

When undertaking maintenance tasks on outdoor equipment, ensuring safety is paramount. Proper precautions can prevent accidents and injuries, allowing for a smoother repair process. Understanding potential hazards and preparing accordingly is essential for anyone engaged in mechanical work.

Before starting any repair, always disconnect the power source. This simple step minimizes the risk of unexpected starts that could lead to serious harm. Additionally, wear appropriate personal protective equipment, such as gloves, safety glasses, and steel-toed boots, to safeguard against flying debris and sharp edges.

It’s crucial to work in a well-ventilated area, particularly when dealing with fuels or chemicals. Ensure that your workspace is clean and organized to avoid tripping hazards and misplaced tools. Furthermore, having a fire extinguisher nearby can be a wise precaution when working with flammable materials.

Lastly, always refer to the manufacturer’s guidelines for specific safety recommendations related to the equipment. Staying informed and prepared is the best way to conduct repairs safely and effectively.

Comparative Analysis with Other Models

This section provides a thorough examination of various machinery designs, highlighting key differences and similarities that influence performance and user experience. By analyzing specific models, we aim to understand how each variant meets the needs of users in distinct operational environments.

Performance Metrics

When comparing different machinery, performance metrics such as power output, efficiency, and handling capabilities play a crucial role. For instance, certain models may excel in clearing heavy snow, while others are more suited for lighter, occasional use. Understanding these metrics helps users make informed decisions based on their specific requirements.

Design and Durability

Another essential aspect of comparison is the design and durability of the equipment. Some models feature robust construction materials that enhance longevity, while others prioritize lightweight designs for easier maneuverability. This variance in design philosophy impacts user satisfaction and overall functionality, making it vital for prospective buyers to consider these factors carefully.

Customer Reviews and User Experiences

This section explores the insights and feedback from users who have interacted with the equipment, providing a comprehensive view of its performance and reliability. Such testimonials can guide potential buyers in making informed decisions based on real-life experiences.

Overall Satisfaction

- Many users praise the efficiency and power of the machine.

- Common remarks highlight ease of use and maintenance.

- Customers appreciate its durability in harsh conditions.

Areas for Improvement

- Some reviewers mention the weight as a challenge for maneuverability.

- A few users report occasional issues with specific components.

- Suggestions for enhancements include better ergonomic features.