When it comes to efficiently managing winter challenges, having a reliable clearing implement is essential. This machinery, designed to tackle heavy snow, relies on a variety of essential components working in harmony. A comprehensive understanding of these elements can greatly enhance maintenance and operational effectiveness.

Identifying each element of your equipment is crucial for ensuring optimal performance. By familiarizing yourself with the various sections and their functions, you can make informed decisions about repairs and upgrades. Clear visual aids serve as invaluable resources, allowing users to locate and comprehend the intricate parts.

In the following sections, we will delve into the specifics of the system’s makeup, offering insights into assembly and disassembly. This knowledge will empower you to keep your machinery in top condition, ready to face whatever winter may bring.

Overview of John Deere Snowblower

This section provides a comprehensive understanding of a powerful tool designed for managing winter weather challenges. With a robust design and reliable performance, this equipment is essential for maintaining clear pathways and driveways during snow events.

| Feature | Description |

|---|---|

| Power Source | Engine-driven, offering superior snow removal capabilities. |

| Width | Designed to cover significant ground, ensuring efficiency. |

| Auger System | Advanced design for effective snow intake and discharge. |

| Ease of Use | User-friendly controls for effortless operation. |

| Durability | Constructed with high-quality materials for longevity. |

Understanding Snowblower Components

When it comes to efficient winter equipment, recognizing the essential elements that contribute to optimal performance is crucial. Each component plays a significant role in ensuring effective operation, and a solid grasp of these parts can aid in maintenance and troubleshooting.

Key components typically include the following:

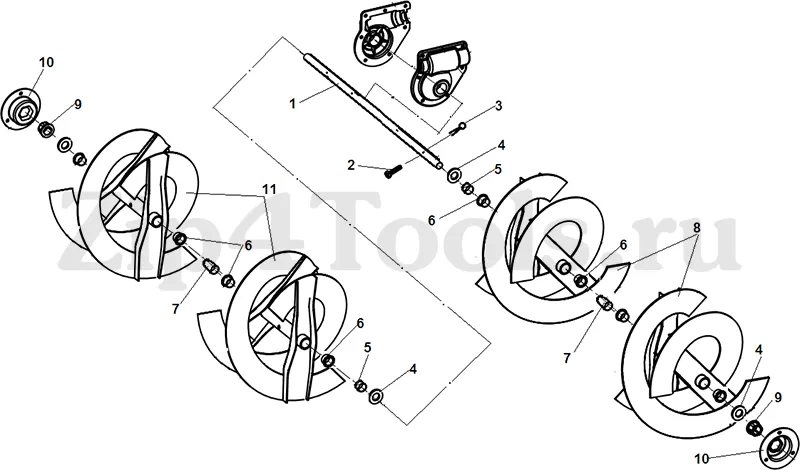

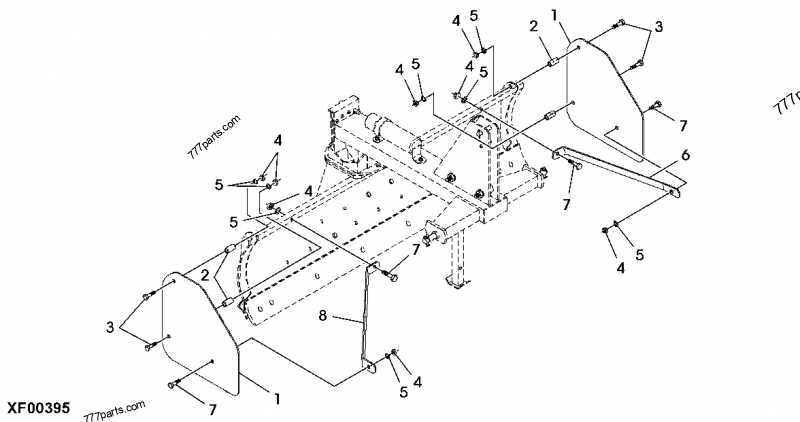

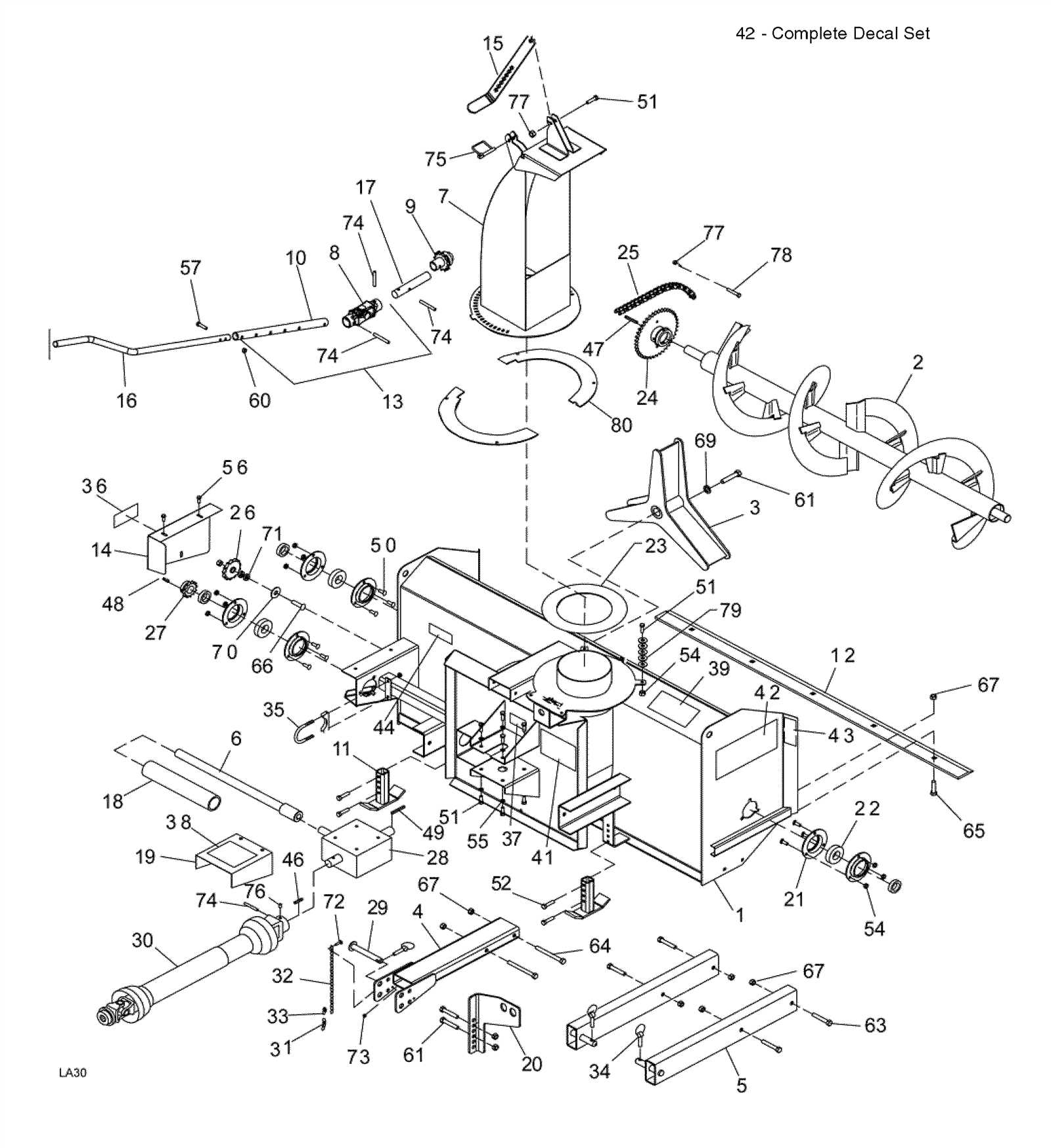

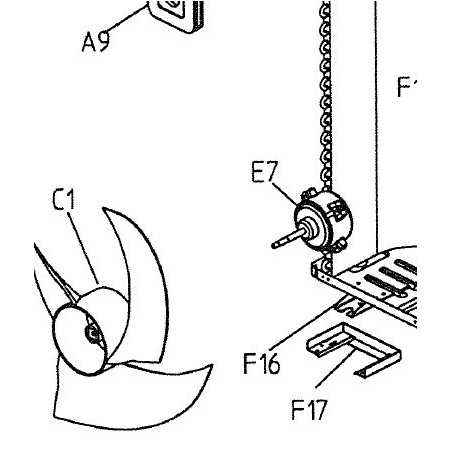

- Auger: This is the rotating part that gathers snow and directs it toward the chute.

- Chute: The mechanism that allows for the controlled discharge of snow in a specific direction.

- Impeller: It enhances the throwing distance by forcing the snow out of the chute with increased velocity.

- Skids: Adjustable feet that help maintain the proper height above the ground, preventing damage to surfaces.

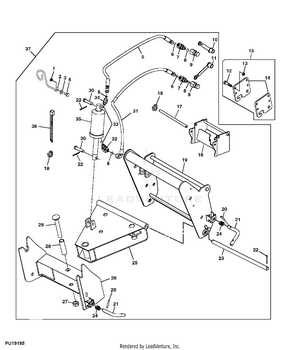

- Controls: The levers and buttons that allow the operator to adjust speed and direction of the discharge.

Understanding how these parts interact can significantly improve the functionality and lifespan of your equipment. Regular inspections and timely replacements can ensure seamless operation throughout the winter season.

In summary, familiarizing oneself with these key elements not only enhances operational efficiency but also empowers users to make informed decisions regarding maintenance and repairs.

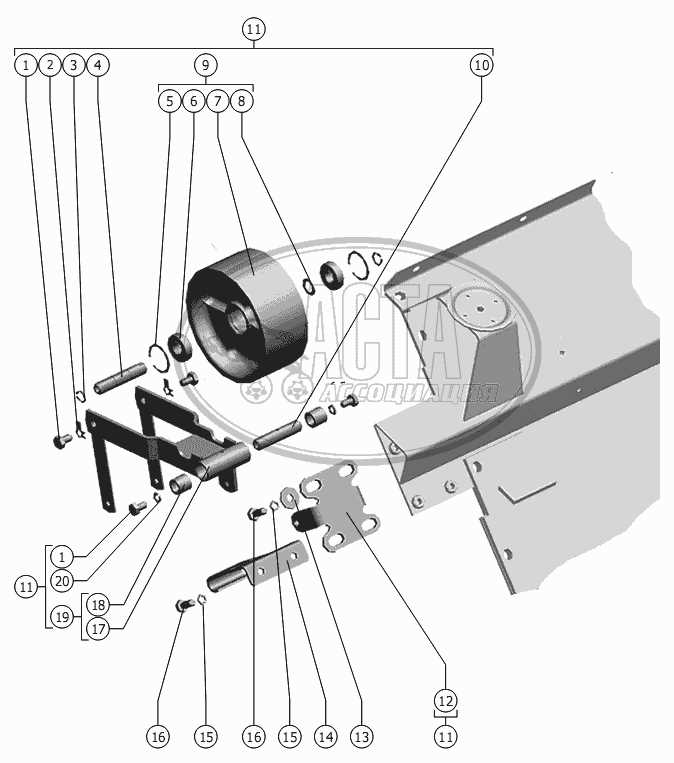

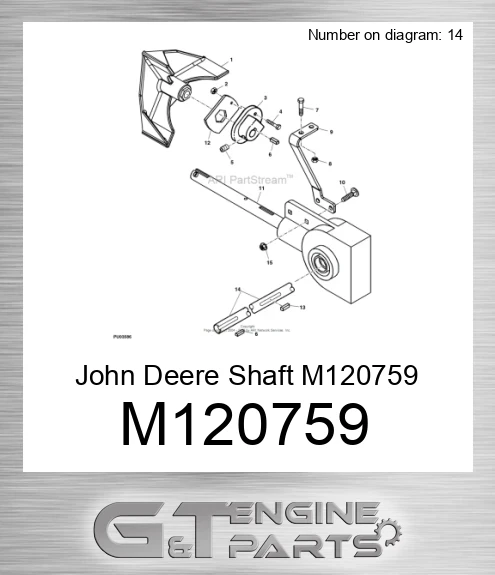

Importance of Parts Diagrams

Understanding the assembly and functionality of equipment is crucial for effective maintenance and repairs. Visual representations serve as essential guides, enabling users to identify components and comprehend their interconnections. These illustrations enhance the efficiency of troubleshooting processes, reducing downtime and ensuring proper functionality.

Accurate identification of each element is vital for seamless operation. Users can quickly locate necessary items, making the repair process straightforward and less daunting. Additionally, clear visuals minimize the risk of errors during assembly or disassembly, fostering confidence in handling machinery.

Moreover, having access to these resources can significantly extend the lifespan of equipment. Regular maintenance, guided by well-structured visuals, ensures that all components function optimally. In conclusion, effective representations are indispensable tools for anyone looking to maintain their machinery with precision and care.

Common Issues with 54” Snowblowers

When it comes to clearing snow efficiently, certain challenges can arise that impact performance and reliability. Understanding these common problems can help users maintain their equipment and ensure optimal functionality during the winter months.

Frequent Challenges

- Clogging: Snow accumulation can lead to blockages, especially in heavy, wet conditions. Regular maintenance is essential to prevent this issue.

- Starting Difficulties: Cold weather can affect ignition systems, making it harder to start the machine. Ensuring proper fuel and battery maintenance can mitigate this problem.

- Worn Blades: Over time, cutting edges can become dull or damaged, reducing efficiency. Regular inspections and replacements are necessary.

Maintenance Tips

- Keep the equipment clean to avoid buildup and maintain airflow.

- Check and change oil regularly to ensure smooth operation.

- Inspect belts and cables for wear and replace them as needed.

Identifying Replacement Parts

When maintaining outdoor equipment, recognizing the necessary components for effective repair and upkeep is crucial. Understanding the layout and function of various elements can streamline the replacement process and ensure optimal performance.

Key Steps for Identification

- Consult the owner’s manual for reference on specific components.

- Take note of any model or serial numbers that can aid in sourcing replacements.

- Inspect worn or damaged elements to determine what needs to be replaced.

Resources for Finding Components

- Visit authorized dealers for genuine replacements.

- Explore online platforms that specialize in equipment parts.

- Engage with community forums for advice on compatible options.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and efficiency of your outdoor equipment. By following simple yet effective practices, you can enhance performance and extend the lifespan of your machinery.

- Clean the equipment after each use to remove debris and prevent rust.

- Check and change the oil regularly to ensure smooth operation.

- Inspect belts and cables for wear, replacing them as needed.

- Sharpen blades periodically to maintain optimal performance.

- Store in a dry, sheltered area to protect against the elements.

By implementing these strategies, you can significantly improve functionality and longevity, ensuring your equipment remains reliable season after season.

Where to Find Diagrams Online

Finding detailed schematics online can enhance your understanding of machinery and assist in repairs. Numerous resources offer visual guides that are essential for maintaining equipment effectively.

- Manufacturer Websites: Often provide official manuals and diagrams for their products.

- Online Retailers: Sites selling equipment parts frequently include diagrams to aid in selecting the right components.

- Forums and Communities: User-generated platforms where enthusiasts share insights and resources, including schematics.

- DIY Websites: Many sites focus on do-it-yourself projects and may have downloadable resources for various machines.

- Video Tutorials: Platforms like YouTube often include links to diagrams in the description for specific repair guides.

By exploring these avenues, you can delve deeper into your project and find the ultimate resources needed for successful maintenance.

Exploring OEM vs. Aftermarket Parts

When it comes to maintaining equipment, users often face the choice between original components and alternative options. Understanding the implications of each type can significantly influence performance and longevity. This section delves into the advantages and disadvantages associated with both categories, offering insights for informed decision-making.

Benefits of OEM Components

Original parts are designed to meet the manufacturer’s specifications, ensuring compatibility and reliability. They typically come with warranties and are known for their quality, making them a safe choice for maintaining performance.

Advantages of Aftermarket Options

Aftermarket components can provide cost-effective solutions and a wider selection. Many users find that these alternatives often match or even exceed the performance of OEM parts, allowing for greater flexibility in maintenance and repairs.

| Type | Pros | Cons |

|---|---|---|

| OEM | Quality assurance, compatibility, warranty | Higher cost, limited availability |

| Aftermarket | Cost-effective, variety, potential performance enhancement | Variable quality, possible compatibility issues |

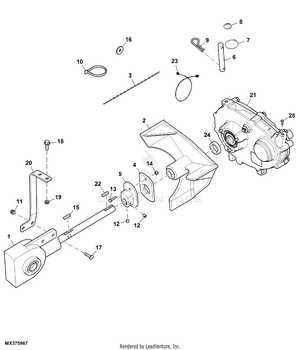

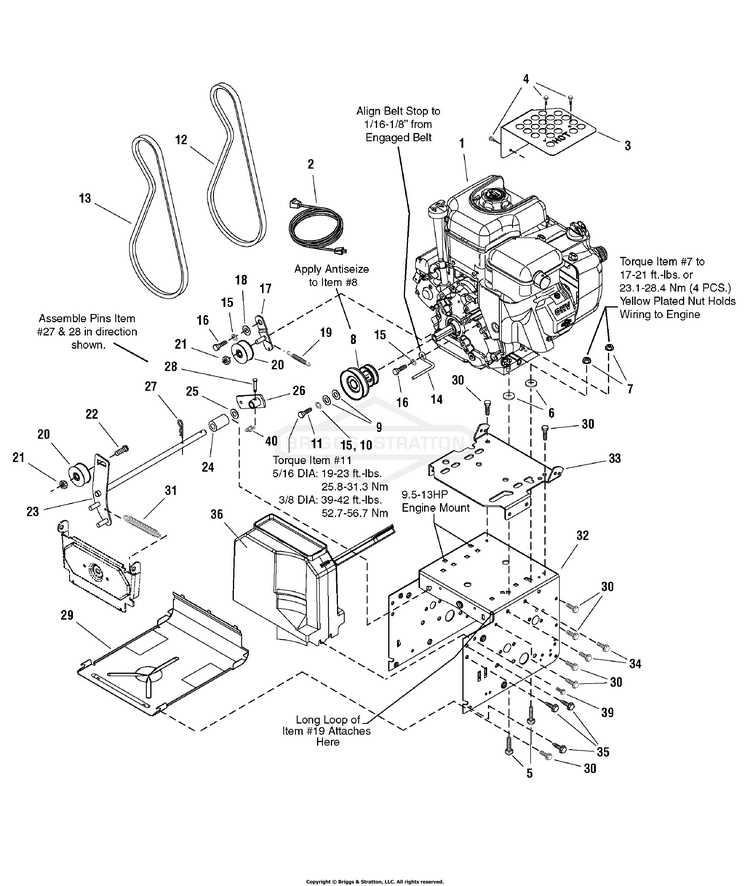

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling your equipment efficiently and effectively. By following each stage meticulously, you can ensure optimal performance and longevity.

1. Gather Tools and Materials: Begin by collecting all necessary tools and components. Ensure you have everything within reach to streamline the assembly process.

2. Review the Manual: Familiarize yourself with the provided documentation. Understanding the layout and instructions will enhance your assembly experience.

3. Start with the Base: Assemble the foundational structure first. Secure all connections tightly to establish stability.

4. Attach Functional Elements: Proceed by affixing the operational components. Double-check alignment to ensure proper functionality.

5. Final Adjustments: After all elements are in place, make necessary adjustments. Ensure everything operates smoothly before completing the assembly.

6. Safety Check: Conduct a thorough inspection of the entire assembly. Verify that all parts are secured and functioning as intended.

By adhering to these steps, you can achieve a well-assembled unit ready for use.

Tools Required for Repairs

When tackling maintenance or fixes, having the right instruments is essential for ensuring efficiency and accuracy. A well-equipped toolbox not only streamlines the process but also enhances safety while working on machinery.

Basic Hand Tools: A set of wrenches, screwdrivers, and pliers will form the backbone of your toolkit. These essentials are necessary for loosening or tightening various components.

Power Tools: An electric or cordless drill can expedite tasks like removing screws or bolts. Additionally, a reciprocating saw may be useful for more intensive modifications.

Specialized Equipment: Depending on the model, you might need specific tools, such as torque wrenches or socket sets, to ensure proper assembly and maintenance.

Safety Gear: Don’t overlook the importance of protective eyewear and gloves. Safety should always be a priority during any repair work.

By gathering these necessary tools, you’ll be prepared to delve into any repair task effectively and with confidence.

Safety Precautions During Repairs

When conducting maintenance or repairs on outdoor machinery, safety should be the top priority. Taking the necessary precautions helps to prevent accidents and ensures a smooth repair process. Understanding the risks associated with the equipment and adhering to safety guidelines can protect both the technician and the machine.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and sturdy footwear.

- Disconnect the power source before starting any repair work to prevent accidental activation.

- Ensure that the work area is clean and free of hazards to avoid slips and falls.

- Use tools that are suitable for the task and in good condition to minimize the risk of injury.

Proper Handling Techniques

- Read the manufacturer’s manual thoroughly to understand the machinery’s specific safety recommendations.

- Maintain a clear line of sight while working on the equipment to avoid mishaps.

- Secure loose clothing and long hair to prevent entanglement in moving parts.

- Have a first aid kit readily available in case of emergencies.

By implementing these safety precautions, individuals can ensure a safer working environment, leading to more effective and efficient repairs.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and accessories essential for optimal performance. Understanding these aspects can help users make informed decisions and maintain their equipment efficiently.

What should I consider when purchasing replacements? Ensure compatibility with your model and review specifications to avoid mismatches.

How can I identify the right component? Refer to the user manual or consult online resources that provide detailed information on various elements.

Are there generic alternatives available? Yes, many aftermarket options exist, but verify their quality and fitment to ensure reliability.

How often should I replace specific components? Regular inspections can help determine wear and tear, guiding you on replacement intervals.

Where can I find comprehensive information? Numerous websites and forums offer insights and discussions that delve into different aspects of maintenance and parts selection.

Customer Reviews on Replacement Parts

This section highlights the feedback from users regarding various components used in their machinery. Insights from actual experiences can guide potential buyers in making informed decisions and enhance their understanding of quality and reliability.

| Component | Rating | Review |

|---|---|---|

| Auger Assembly | 4.5/5 | Durable and efficient. Perfect fit for my model. |

| Drive Belt | 4/5 | Good performance but a bit tricky to install. |

| Shear Pins | 5/5 | Essential for protection. Easy to replace and affordable. |

| Chassis | 3.5/5 | Sturdy but heavier than expected. |