When it comes to maintaining outdoor machinery, having a clear overview of its essential elements is crucial. Each component plays a vital role in ensuring optimal performance, especially during challenging weather conditions. Familiarity with these parts can help users identify issues and enhance functionality.

Visual aids are invaluable tools for this purpose, allowing operators to delve deeper into the structure of their machines. By studying these illustrations, one can quickly locate and comprehend each section, simplifying repairs and maintenance tasks. This approach leads to more efficient use and longevity of the equipment.

Whether you’re a seasoned user or a newcomer, understanding these fundamental components is the ultimate key to successful operation. With the right knowledge, you can ensure your machinery remains in peak condition, ready to tackle whatever challenges lie ahead.

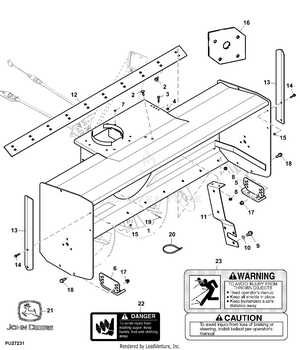

Understanding John Deere Snowblower Parts

When operating outdoor machinery designed for winter weather, having a clear grasp of its components is essential for optimal performance. Knowing how each piece functions contributes to effective maintenance and longevity, ensuring that the equipment operates smoothly during heavy snowfall.

Key components to familiarize yourself with include:

- Auger: This element is responsible for gathering and moving the snow toward the chute.

- Chute: Directs the expelled snow, allowing for customizable snow placement.

- Impeller: Works in conjunction with the auger to enhance snow discharge efficiency.

- Drive System: Engages the necessary power to operate the machinery effectively.

- Skid Shoes: Assist in maintaining the appropriate height during operation on various surfaces.

Understanding these components and their roles not only aids in troubleshooting potential issues but also informs better decisions regarding repairs and upgrades. Regular inspection and knowledge of how each part interacts can prevent costly breakdowns and enhance the overall performance of the machine.

For optimal operation, always consult your specific model’s manual to ensure compatibility and proper functioning of each component.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding machinery and equipment. They offer clarity on assembly, maintenance, and repair processes, ensuring that users can efficiently address issues as they arise. By providing a clear overview of all elements involved, these illustrations simplify complex tasks and enhance user confidence.

| Benefits | Description |

|---|---|

| Clarity | Illustrations help to visualize the arrangement and function of each component. |

| Efficiency | Streamlined processes reduce time spent on maintenance and repairs. |

| Accuracy | Ensures that replacements and repairs are conducted with the correct items. |

| Learning Tool | Serves as an educational resource for new users to understand equipment better. |

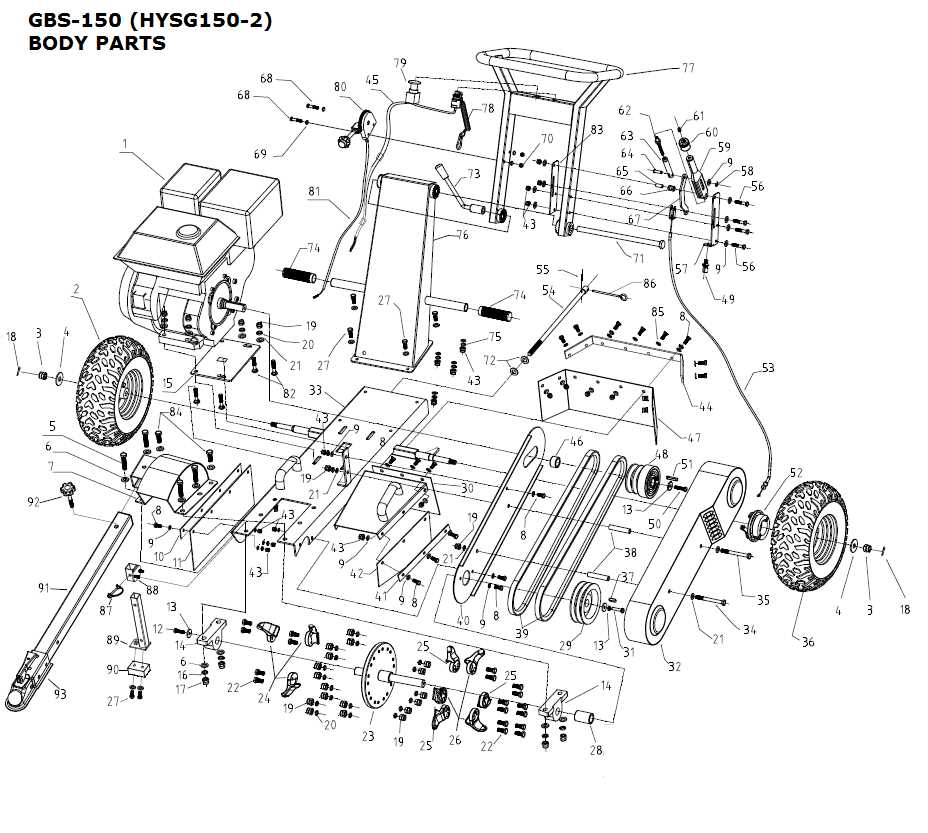

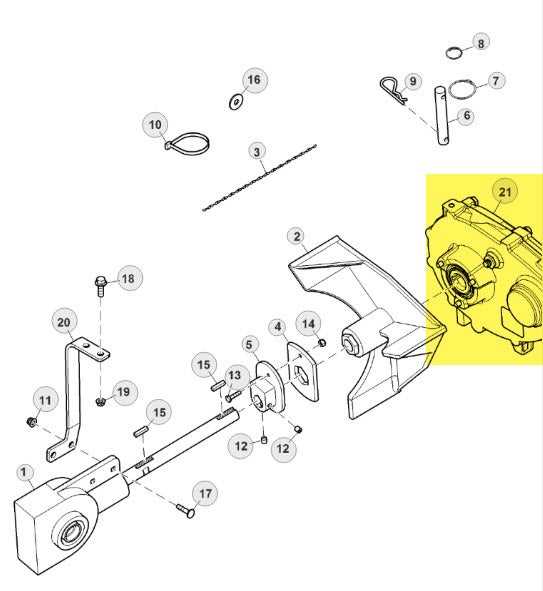

Common Components of 59 Inch Models

Understanding the essential elements of these large-scale clearing machines is crucial for effective maintenance and operation. Familiarity with the key components can enhance performance and prolong the lifespan of the equipment.

- Auger Assembly: This part plays a vital role in gathering and moving material toward the impeller.

- Impeller: Responsible for throwing the cleared material out of the discharge chute.

- Chassis: The framework that supports the entire system and houses various components.

- Drive Belt: Transfers power from the engine to the auger and impeller for efficient operation.

- Skids and Shoes: Allow the unit to glide over different surfaces while maintaining optimal clearance.

- Discharge Chute: Directs the expelled material away from the machine, adjustable for different angles.

Each of these components works in unison to ensure effective clearing capabilities. Regular inspections and maintenance of these parts are essential for optimal performance.

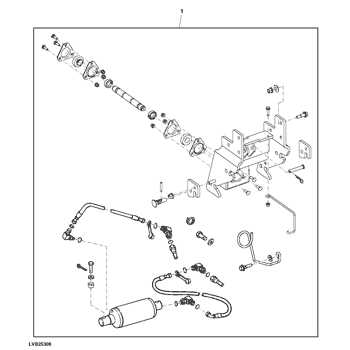

Identifying Key Replacement Parts

Understanding the essential components of your equipment is crucial for effective maintenance and repair. Recognizing which elements need replacement can significantly enhance performance and longevity. By familiarizing yourself with the critical pieces, you can ensure that your machine operates smoothly and efficiently.

Begin by examining the primary features that often require attention, such as belts, augers, and housing units. Each of these elements plays a vital role in the overall functionality. Regular inspection will help you spot wear and tear early, allowing for timely interventions.

Moreover, consulting detailed schematics can aid in identifying the exact specifications of the required components. This knowledge empowers you to select the right items, reducing the risk of mismatches and ensuring optimal operation. Prioritizing the right replacements can make all the difference in the performance of your machinery.

Maintenance Tips for Snowblowers

Proper upkeep is essential for ensuring the longevity and efficiency of your winter equipment. Regular attention can help prevent breakdowns and enhance performance during harsh weather conditions. This section provides valuable insights into effective care practices that will keep your machine in optimal shape.

1. Regular Inspection: Routinely check your equipment for any signs of wear or damage. Look for loose bolts, frayed cables, and other components that may need tightening or replacement. Early detection can save time and money in the long run.

2. Clean After Use: Snow and ice can build up on the exterior and internal parts of your machine. After each use, clear away any debris and moisture to prevent rust and corrosion. This simple step will prolong the life of various components.

3. Oil Changes: Regularly changing the oil is vital for maintaining engine health. Follow the manufacturer’s recommendations for oil type and change intervals. Clean oil reduces friction and helps the engine run smoothly.

4. Check Belts and Cables: Inspect belts for signs of wear and tear. Ensure that cables are functioning properly and are free from damage. Replacing these parts as needed will keep your equipment operating efficiently.

5. Fuel Care: Use fresh fuel and consider adding a fuel stabilizer if your machine will sit idle for long periods. Old fuel can lead to starting issues and decreased performance. Always empty the tank if you plan to store the equipment for an extended time.

6. Winter Preparation: Before the season begins, ensure that your machine is fully serviced and ready for use. This includes checking spark plugs, changing filters, and ensuring all controls operate smoothly. Being proactive can prevent issues when you need the equipment the most.

By following these maintenance tips, you can enhance the reliability and efficiency of your winter machinery, ensuring that it performs optimally when you need it most.

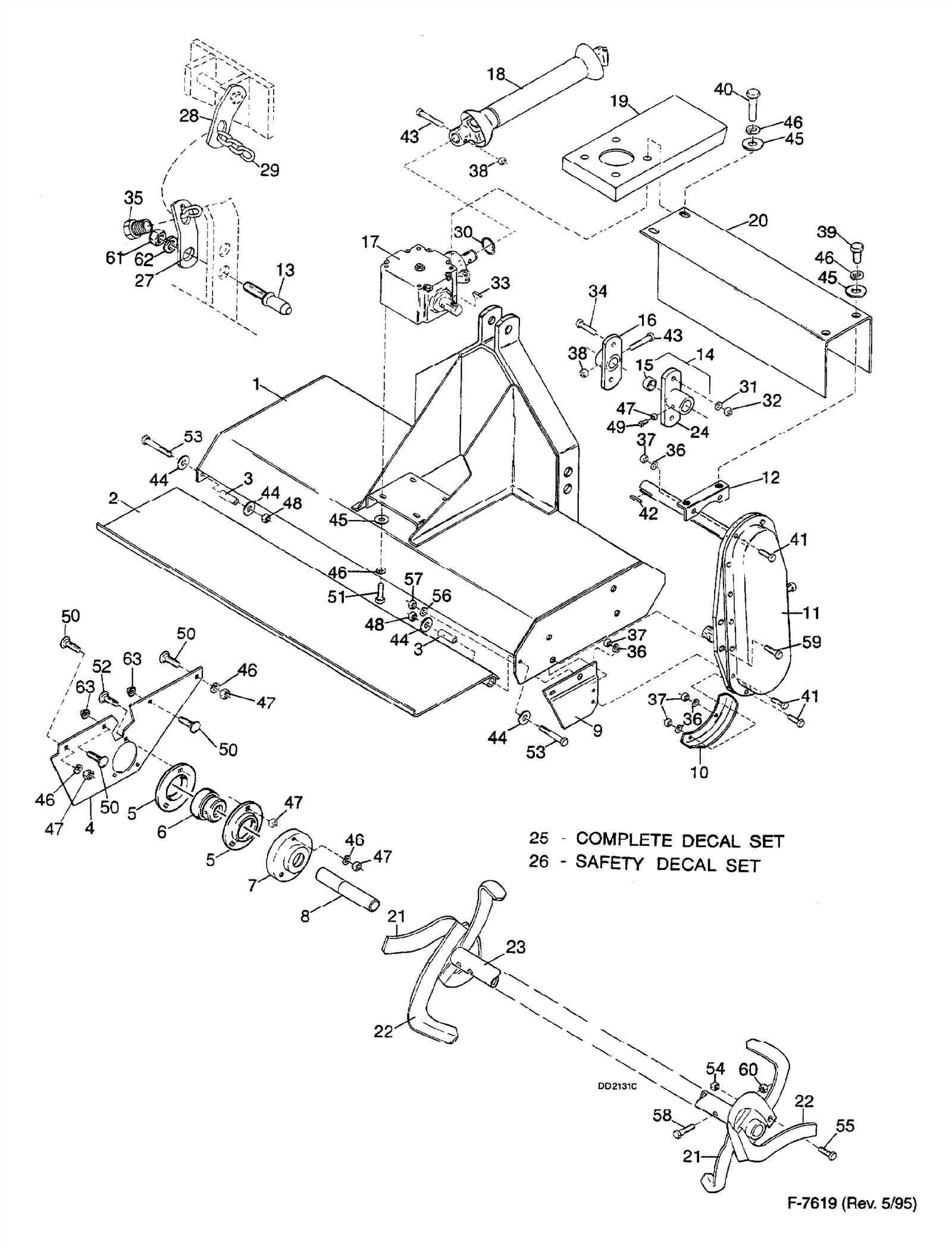

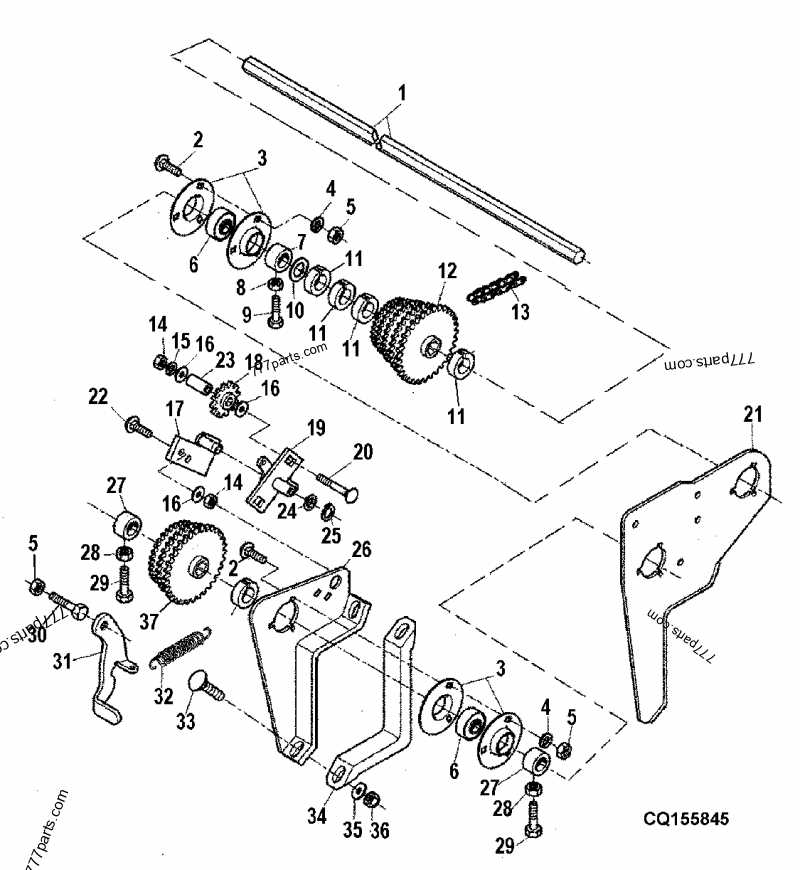

How to Read Parts Diagrams

Understanding schematics is essential for effectively maintaining and repairing machinery. These illustrations provide a visual representation of components, their arrangements, and how they interact within a system. Familiarizing yourself with these visuals can streamline the repair process and enhance your comprehension of equipment functionality.

Key Elements of Schematics

- Labels: Each component typically has a label indicating its name or part number. This helps in identifying the necessary items for repairs.

- Connections: Arrows and lines show how parts are connected, illustrating the flow of operation or assembly.

- Grouping: Similar items may be clustered together, providing clarity on which components work in unison.

Steps to Interpret the Visuals

- Start by identifying the legend or key, which explains the symbols used.

- Familiarize yourself with the layout by tracing the connections between different elements.

- Cross-reference labels with your inventory to ensure you have the correct components for replacement.

- Use the illustration to plan your disassembly and reassembly processes efficiently.

Finding Authentic John Deere Parts

Locating genuine components for your machinery is essential for maintaining optimal performance and longevity. Whether you’re repairing a unit or upgrading its features, ensuring that you use authentic items is key. This not only enhances efficiency but also protects your investment from potential damage caused by inferior alternatives.

When seeking these genuine items, it’s crucial to consider several factors that can help you identify reliable sources. Understanding the marketplace and knowing what to look for will save you time and money in the long run.

| Tip | Description |

|---|---|

| Authorized Dealers | Always start by visiting authorized dealers who specialize in your specific machinery brand. They are more likely to stock authentic items. |

| Official Website | Check the official website for a list of approved suppliers and parts. This ensures that you’re accessing legitimate resources. |

| Part Numbers | Use part numbers when searching for components. This helps confirm that you’re purchasing the correct items designed for your machine. |

| Reviews | Look for customer reviews and feedback about the suppliers. This can provide insight into their reliability and the authenticity of their products. |

By following these guidelines, you can ensure that you are sourcing the right components for your equipment, thus maintaining its efficiency and extending its operational life.

Aftermarket vs. OEM Parts

In the world of equipment maintenance, there exists a choice between factory-produced components and those created by independent manufacturers. This decision can significantly impact performance, longevity, and overall satisfaction with the equipment.

Benefits of OEM Components

- Designed specifically for optimal compatibility.

- Manufactured to meet strict quality standards.

- Often come with a warranty for added peace of mind.

Advantages of Aftermarket Components

- Potentially lower cost compared to original options.

- A wider variety of choices available.

- Innovative features that may enhance performance.

Ultimately, the choice between these two options depends on individual needs, preferences, and budget considerations.

Tools Needed for Assembly

Assembling outdoor equipment requires specific implements to ensure efficiency and precision. Utilizing the right tools can streamline the process, making it both effective and enjoyable.

Essential Tools: Gather a screwdriver set, which includes both flathead and Phillips types, to manage various fasteners. A wrench set is crucial for tightening bolts, while a socket set enhances accessibility in tight spaces.

Additionally, a hammer may be necessary for securing components, and a tape measure helps maintain accurate dimensions during assembly. Lastly, keep a work light handy to illuminate your workspace, especially in dim conditions.

Common Repair Issues Explained

Maintenance of outdoor machinery often reveals recurring challenges that can impact performance and efficiency. Understanding these common issues is crucial for timely intervention and smooth operation. This section explores typical malfunctions, providing insight into their causes and potential remedies.

Clogs and Blockages

One of the most frequent problems encountered involves clogs in the system. These can occur due to the accumulation of debris, ice, or other materials, hindering functionality. Regular cleaning and inspection can help mitigate this issue. If a blockage is detected, promptly clearing it can restore optimal performance.

Mechanical Failures

Another prevalent concern is mechanical failure, which may stem from worn-out components or improper assembly. Signs include unusual noises, decreased efficiency, or unexpected stops. Regular maintenance checks, along with timely replacement of worn parts, are essential to prevent more extensive damage and ensure reliable operation.

Safety Precautions During Maintenance

Maintaining outdoor machinery is essential for optimal performance, yet it requires strict adherence to safety protocols to prevent accidents. Understanding and implementing these precautions can significantly reduce the risk of injury while ensuring effective upkeep.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and sturdy footwear to protect against potential hazards during servicing. Proper attire minimizes risks associated with sharp components and moving parts.

Proper Tools and Procedures

Utilize the correct tools and follow the manufacturer’s guidelines during maintenance. Neglecting these aspects can lead to dangerous situations. Ensure the machinery is powered down and disconnected before starting any work to guarantee your safety throughout the process.

Seasonal Checklists for Snow Equipment

Preparing your machinery for winter conditions is essential for optimal performance and longevity. A systematic approach to maintenance can help ensure that your equipment is ready to tackle the challenges of harsh weather. This guide outlines key tasks to consider before the snow season begins.

Start by inspecting all mechanical components for wear and tear. Check belts, chains, and gears for any signs of damage or excessive wear. Replace any worn parts to avoid breakdowns during critical times. Ensure that all fasteners are tight and secure to maintain stability during operation.

Next, focus on the power source. Change the oil and replace the oil filter, as this will help improve efficiency and extend the life of the engine. Check the fuel system for leaks and replace the fuel filter as needed. Ensure that the battery is fully charged and connections are clean and tight.

Don’t forget about the attachment and discharge systems. Clear any debris from these areas and inspect for blockages. Lubricate moving parts to ensure smooth operation and reduce friction, which can lead to premature wear.

Lastly, review safety features. Test lights, alarms, and other safety mechanisms to ensure they are functioning correctly. Having fully operational safety systems is crucial for preventing accidents and ensuring a secure working environment.

By following these guidelines, you can maximize the reliability and efficiency of your equipment throughout the winter season, allowing you to focus on the task at hand.

Resources for Further Assistance

Finding the right tools and guidance can greatly enhance your experience with machinery maintenance and repair. This section provides valuable resources that can aid in troubleshooting and obtaining the necessary components for optimal performance.

Online Forums and Communities

Engaging with fellow enthusiasts can lead to insightful advice and shared experiences. Numerous online platforms host discussions where users exchange tips and solutions.

Manufacturer Websites

Official websites often provide extensive documentation, including manuals and instructional videos. These resources are essential for understanding specific equipment functionalities.

| Resource Type | Description | Link |

|---|---|---|

| Forums | Community discussions for sharing knowledge. | Visit Forum |

| Manufacturer | Official documentation and support. | Visit Website |

| Videos | Step-by-step guides for repairs and maintenance. | Watch Videos |