In the realm of outdoor maintenance, having a clear understanding of your machinery’s components is crucial for optimal performance and longevity. This guide aims to provide you with valuable insights into the various elements that make up a snow-clearing device. By familiarizing yourself with these key aspects, you can ensure efficient operation during the cold months.

Recognizing the specific features and their functions can significantly enhance your ability to troubleshoot issues and conduct necessary maintenance. Each component plays a vital role, from the engine to the controls, contributing to the overall functionality of your device. Understanding how these parts work together will empower you to make informed decisions regarding repairs and upgrades.

Moreover, having access to a detailed visual representation of the various elements can simplify the process of identifying worn-out or damaged parts. This not only streamlines repairs but also minimizes downtime, allowing you to return to your outdoor tasks swiftly. Embracing this knowledge is essential for anyone looking to maintain their equipment effectively and maximize its operational efficiency.

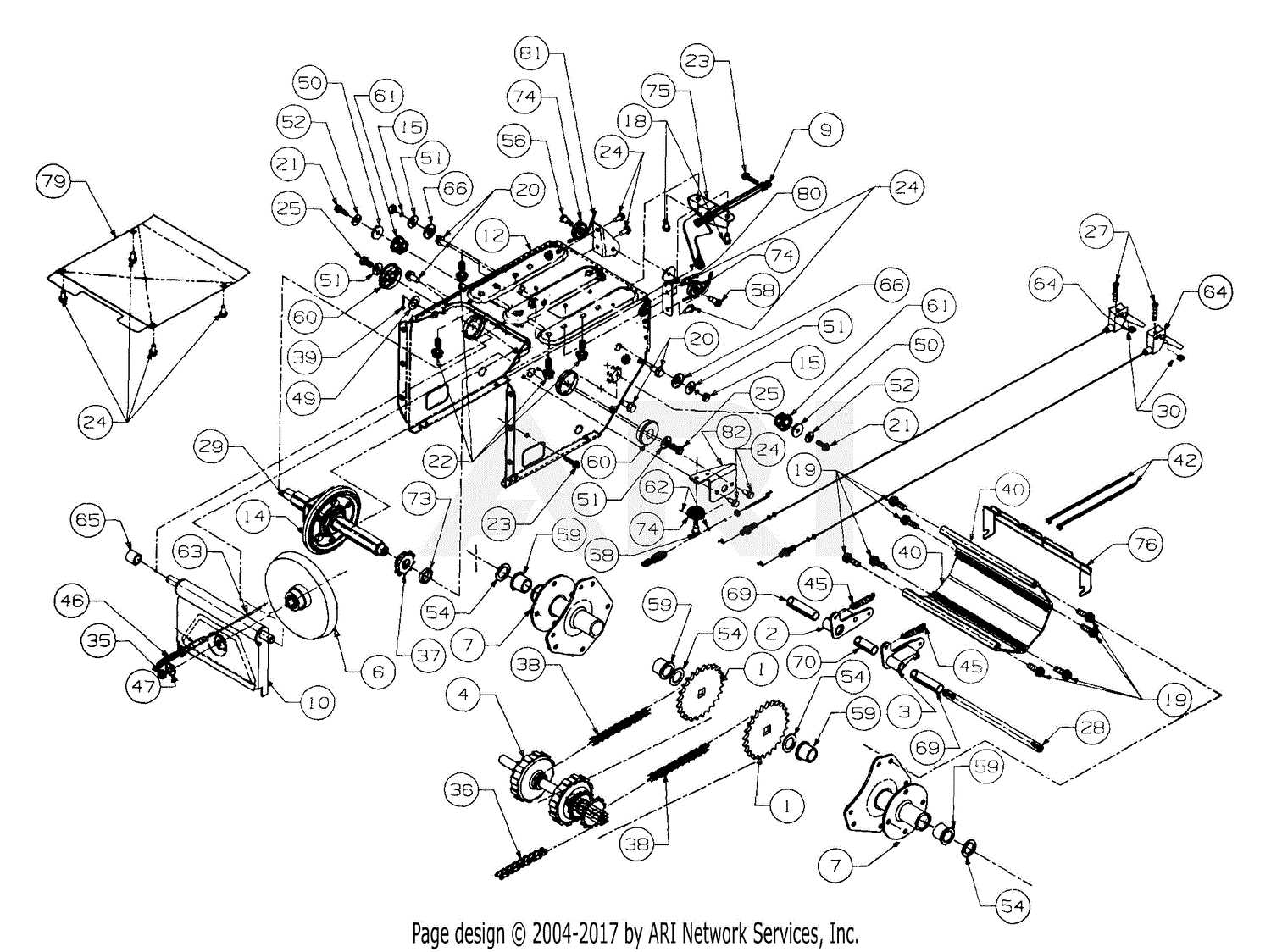

This section aims to provide a comprehensive overview of the various elements that contribute to the efficient operation of a snow-clearing apparatus. Understanding these components is essential for effective maintenance and troubleshooting, ensuring the machine performs optimally during winter conditions.

Each element plays a crucial role in the functionality of the equipment, and recognizing their positions and interactions can aid in identifying potential issues or necessary replacements.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire unit, responsible for initiating movement and clearing snow. |

| Auger | The rotating blade system that gathers snow and propels it toward the discharge chute. |

| Chassis | The frame that supports all components and provides stability during operation. |

| Discharge Chute | Directs the expelled snow away from the path, allowing for efficient clearing. |

| Controls | The mechanisms that allow the operator to adjust speed, direction, and other settings. |

Essential Parts Overview

This section highlights the crucial components that contribute to the efficient operation of a winter clearing device. Understanding these elements is vital for maintenance and optimal performance, ensuring that the unit operates smoothly during snowy conditions.

Below is a summary of the primary components commonly found in these devices:

| Component | Description |

|---|---|

| Auger | Responsible for gathering and chopping snow before it is expelled. |

| Impeller | Helps in propelling the snow away from the machine after it has been collected. |

| Chassis | The frame that houses all essential elements and provides structural integrity. |

| Skid Shoes | Facilitate the machine’s movement over various surfaces while maintaining optimal clearance. |

| Throttle Control | Allows the operator to adjust the speed of the engine for better handling. |

| Fuel Tank | Holds the necessary fuel required for operation, ensuring adequate power supply. |

| Electric Starter | Facilitates easy ignition of the engine, especially in cold conditions. |

Identifying Key Snowblower Elements

Understanding the essential components of a winter clearing device is crucial for effective maintenance and operation. By familiarizing oneself with these key elements, users can enhance their experience and ensure optimal performance during harsh weather conditions.

The engine serves as the powerhouse, driving the entire mechanism and generating the necessary energy for operation. A well-maintained engine can significantly impact efficiency and reliability.

The auger plays a vital role in gathering and displacing snow. Its design and functionality are essential for effective snow removal, making it one of the most critical elements to monitor and maintain.

The chute directs the cleared snow away from the path, ensuring a clean and safe working area. Adjusting the chute’s angle is important for controlling the distance and direction of the snow being discharged.

The controls are the user interface for operating the device, allowing for adjustments in speed, direction, and other functions. Familiarity with these controls ensures smoother operation and responsiveness.

Regular inspections and knowledge of these fundamental components will not only extend the lifespan of the equipment but also improve overall performance during use.

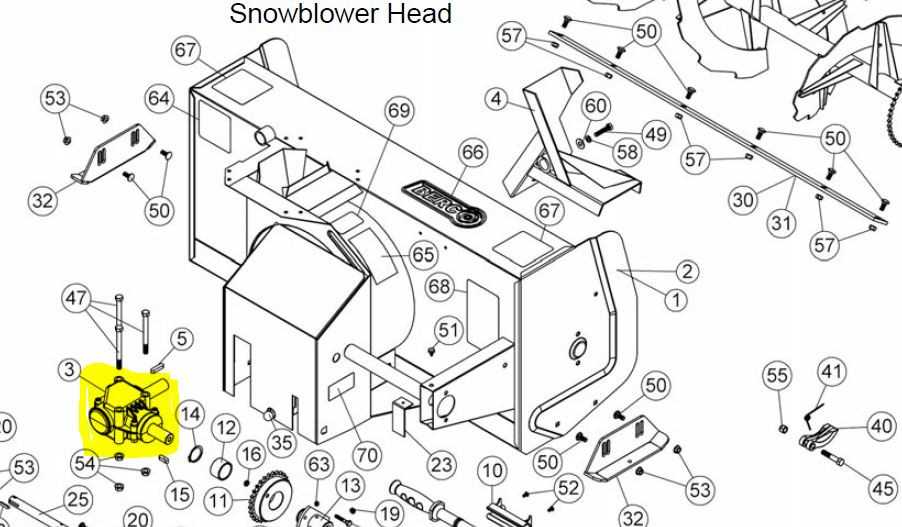

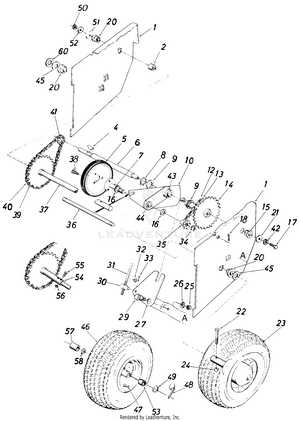

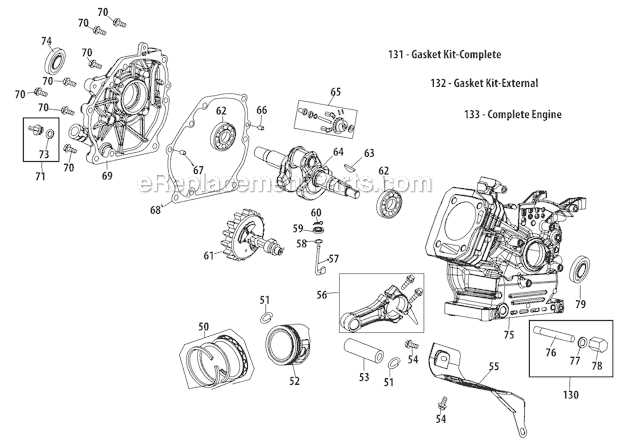

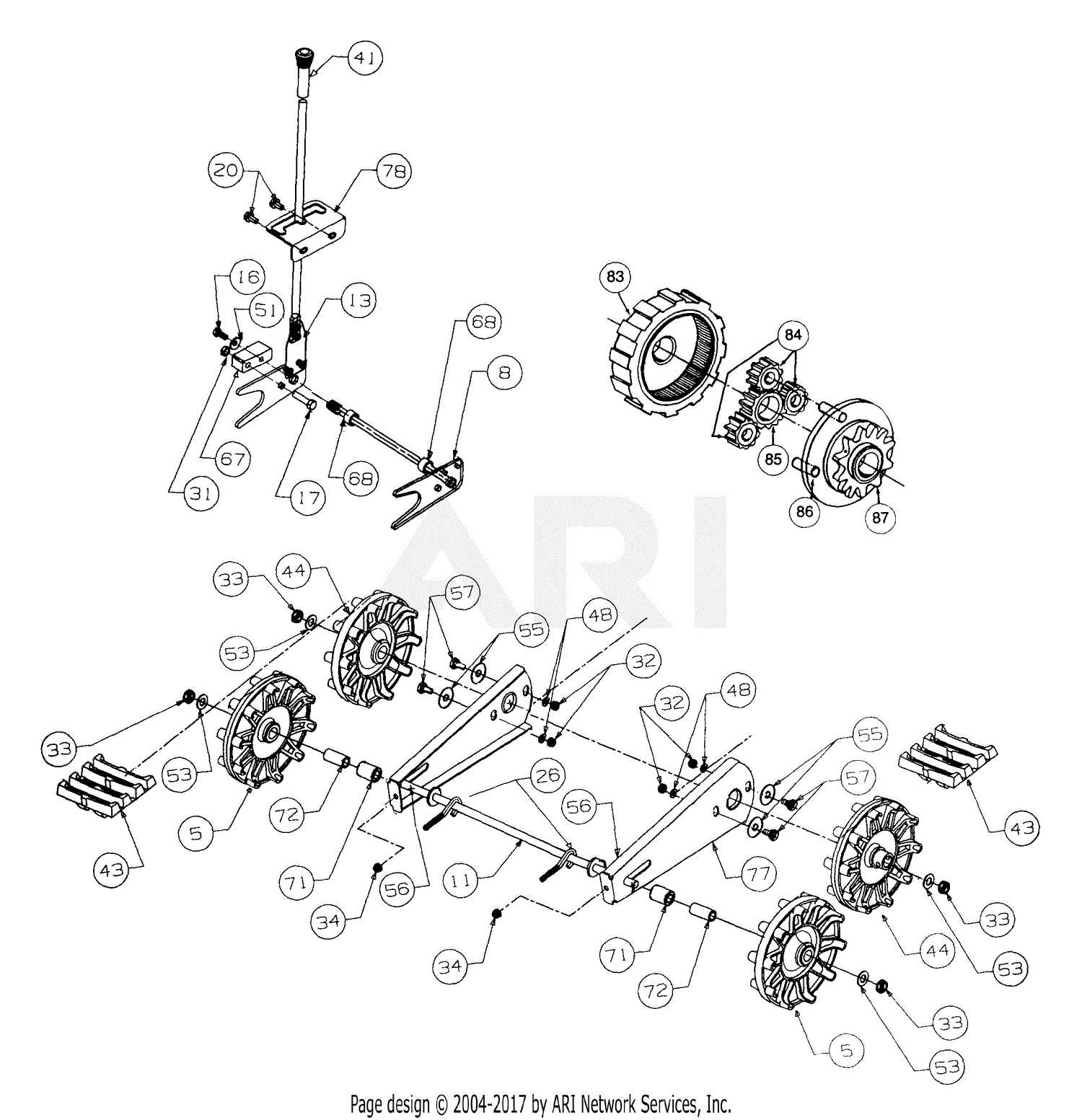

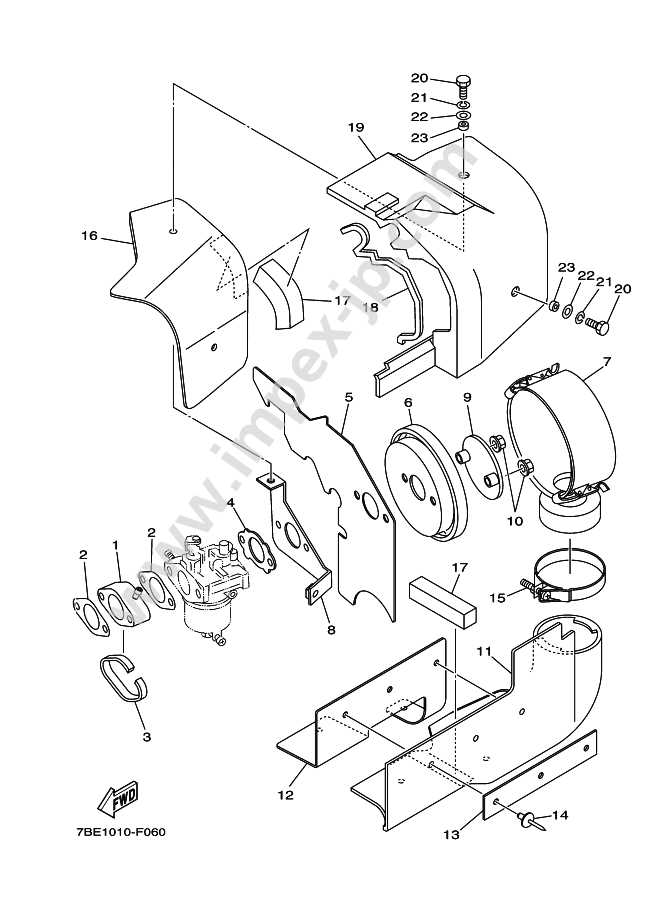

Detailed Parts Diagram Explanation

This section aims to provide a comprehensive overview of the components involved in the functioning of a specific device, focusing on their arrangement and interaction. Understanding these elements is crucial for proper maintenance and troubleshooting, as well as ensuring optimal performance.

Overview of Components

The following list highlights the key components essential for the effective operation of the equipment:

- Engine: The power source that drives the entire system.

- Transmission: Responsible for transferring power from the engine to the wheels.

- Auger: Designed to break up and collect the material.

- Chute: Directs the expelled material away from the device.

- Handlebars: Provide control and maneuverability for the user.

Understanding the Interrelationships

Each component plays a vital role and interacts with others to ensure smooth operation. Here’s how they connect:

- The engine generates power, which flows through the transmission.

- The auger receives power to rotate and collect material.

- The chute is positioned to efficiently expel collected material in a desired direction.

- Control mechanisms located on the handlebars allow the operator to manage the various functions.

By familiarizing oneself with these components and their relationships, users can effectively troubleshoot issues and enhance the performance of their equipment.

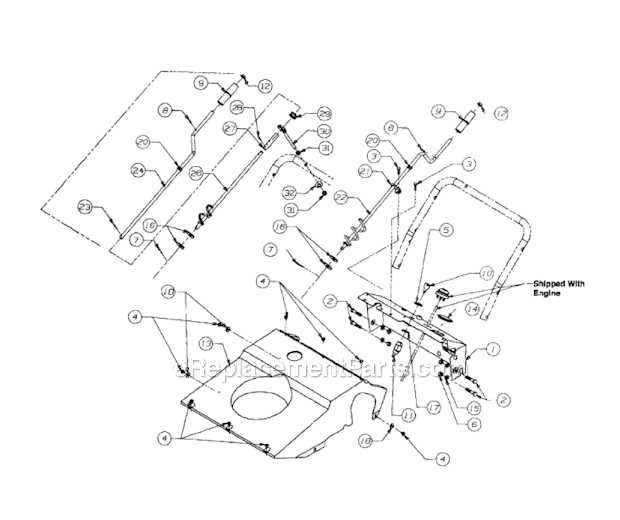

How to Read the Diagram

Understanding a technical illustration is essential for effective maintenance and repairs. Such illustrations provide a visual representation of components and their relationships within a system, enabling users to identify each element and comprehend its function. By familiarizing yourself with the structure of these visuals, you can streamline the troubleshooting process and enhance your overall efficiency.

Key Elements to Focus On

Begin by identifying the various symbols used in the illustration. Each symbol typically corresponds to a specific component, and it is crucial to familiarize yourself with these representations. Additionally, pay attention to the labels that accompany each symbol; they often provide essential information regarding sizes, specifications, or part numbers. Understanding these elements will greatly aid in locating and ordering the necessary components.

Interpreting Connections and Relationships

Next, observe the lines and arrows that connect different symbols. These connections often signify how parts interact or fit together within the larger assembly. Take note of any annotations that explain particular relationships or functionalities. This insight can be invaluable when disassembling or reassembling units, ensuring that everything is correctly positioned for optimal performance.

Common Issues with Snow Removal Equipment

When operating winter clearing equipment, users often encounter various challenges that can hinder performance. These issues may arise from wear and tear, improper maintenance, or environmental factors. Understanding these common problems can help users ensure their machinery functions optimally during the snow season.

Frequent Mechanical Failures

Mechanical malfunctions are a prevalent concern among operators. Components may become loose or damaged due to prolonged use or exposure to harsh conditions. Regular inspections and timely repairs can prevent these failures from escalating, ensuring efficient operation.

Ineffective Clearing Performance

Another common difficulty is inadequate snow displacement. This may result from clogged pathways or inefficient blade functioning. To maintain optimal clearing efficiency, it’s essential to check for blockages and ensure that blades are sharp and well-aligned.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular upkeep and attention. By following a systematic approach to care, you can significantly enhance its performance and lifespan. Simple actions can prevent wear and tear, ultimately saving time and money on repairs.

Regular Cleaning

Thoroughly cleaning your equipment after each use is essential. Remove any debris, ice, or snow to prevent corrosion and mechanical issues. Pay close attention to areas where moisture can accumulate, as this can lead to rust and deterioration over time.

Periodic Inspections

Conduct routine inspections to identify any signs of wear or damage early on. Check belts, cables, and other components for fraying or cracks. Addressing minor issues promptly can prevent more significant problems and extend the overall life of your equipment.

Additionally, ensure that all moving parts are properly lubricated according to the manufacturer’s recommendations. This not only improves efficiency but also reduces friction, which can lead to premature failure.

Replacement Parts: What You Need

When it comes to maintaining your equipment, understanding the essential components is crucial for optimal performance. Regular checks and timely replacements can ensure that your device operates efficiently and lasts longer. Identifying the necessary elements can help prevent potential breakdowns and enhance functionality.

Essential Components for Optimal Performance

To keep your equipment running smoothly, you need to be aware of the vital components that require attention. Key elements may include the engine, belts, and various fittings. Regularly inspecting these items for wear and tear can help you determine when replacements are necessary, ensuring that your device remains in excellent working condition.

Finding Quality Replacements

When searching for high-quality alternatives, consider purchasing from reputable suppliers who specialize in these specific components. Look for options that guarantee durability and compatibility with your equipment. Investing in reliable replacements not only enhances performance but also extends the lifespan of your device.

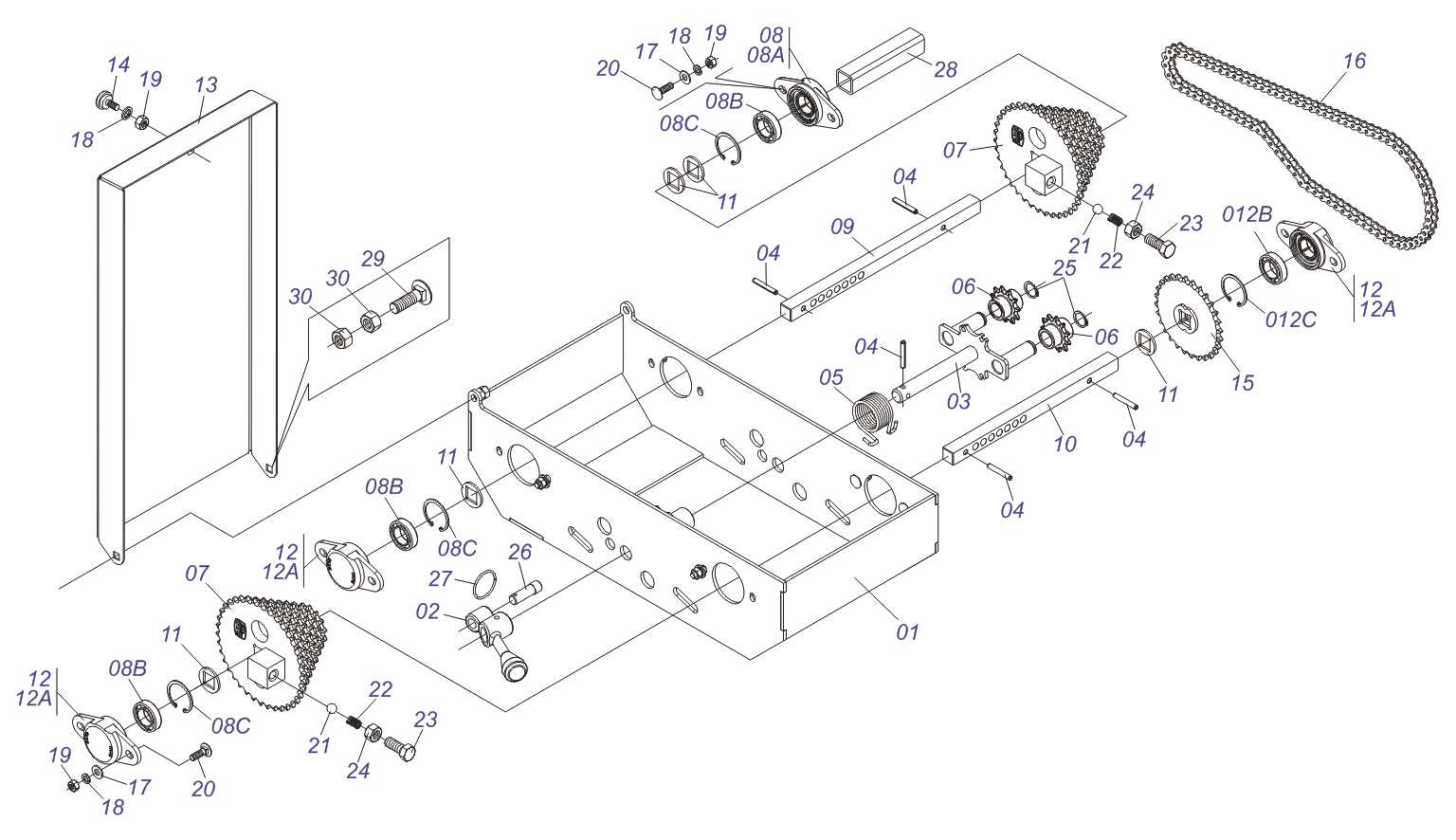

Assembly Instructions for Components

This section provides essential guidance on the correct installation of various elements within your equipment. Proper assembly ensures optimal performance and longevity, allowing you to efficiently navigate through winter conditions.

To begin, gather all necessary components and tools. Refer to your user manual for specific requirements regarding screws, brackets, and other fastening devices. It’s crucial to follow the recommended sequence for assembly, which often starts with the base structure.

Next, securely attach the frame components using the designated hardware. Ensure each connection is tight, as loose fittings can lead to malfunction during operation. Pay particular attention to any alignment markings to maintain proper orientation.

Once the frame is assembled, proceed to install the functional units, such as the engine and drive system. Consult the instructions for precise locations and installation techniques to avoid damaging any components. Always double-check your work before moving on to the next step.

Finally, perform a thorough inspection of all assembled components. Look for any signs of misalignment or loose fittings. Completing these assembly steps carefully will enhance the efficiency and safety of your equipment.

Safety Precautions When Operating

When utilizing outdoor equipment designed for snow removal, it is essential to prioritize safety to prevent accidents and injuries. Proper handling and awareness of potential hazards can ensure a smooth and secure operation.

Before starting the equipment, always review the manufacturer’s guidelines for safety measures. Ensure that the working area is clear of obstacles, and keep bystanders at a safe distance to avoid any unintended incidents. Wearing appropriate personal protective gear, such as gloves, goggles, and sturdy footwear, can significantly reduce the risk of injury.

During operation, maintain focus and avoid distractions. It is crucial to be aware of your surroundings and to operate the equipment at a safe speed. If any unusual noises or vibrations occur, immediately stop the machine to inspect for possible issues. Additionally, never attempt to clear clogs or perform maintenance while the engine is running.

Following these safety protocols will not only enhance your personal safety but also contribute to the longevity and efficiency of the equipment. Practicing caution ensures that snow removal tasks can be completed effectively and securely.

Diagnosing Mechanical Problems

Identifying mechanical issues is a critical step in ensuring optimal functionality and performance of any equipment. By recognizing symptoms early, users can prevent minor inconveniences from escalating into major malfunctions. A systematic approach can help isolate the problem effectively, allowing for accurate repairs.

Begin by observing any unusual noises or irregular behavior during operation. These indicators can provide valuable insights into underlying issues. Checking the essential components for signs of wear or damage is vital, as this can often pinpoint the source of the problem. Regular maintenance and visual inspections can aid in spotting potential concerns before they develop into serious complications.

If the machine fails to start, consider examining the fuel system and ignition components first. Ensure that fuel is present and clean, and verify that all connections are secure. Electrical systems should also be assessed for any loose wires or faulty connections, as these can disrupt performance significantly.

In cases of reduced efficiency, inspect the moving parts for obstructions or accumulation of debris. Cleaning and lubricating components as necessary can restore functionality and enhance performance. If problems persist, consulting a professional may be beneficial for more complex mechanical issues.

Where to Find Spare Parts

When it comes to maintaining your outdoor equipment, locating the right replacement components is crucial for ensuring optimal performance. Fortunately, there are various resources available for sourcing the necessary items, whether for repairs or upgrades.

Here are some reliable options to consider:

- Local Dealers: Authorized dealers often stock genuine components and can assist with identifying the correct items for your equipment.

- Online Retailers: Numerous e-commerce platforms offer a vast selection of replacement items. Websites dedicated to outdoor tools frequently have detailed catalogs for easy navigation.

- Manufacturer Websites: Visiting the official website of the equipment’s manufacturer can lead you to their online store, where you can find authentic replacements and accessories.

- Automotive Stores: Some auto parts retailers also carry a range of components suitable for various types of machinery, including those used in gardening and landscaping.

- Salvage Yards: For those seeking budget-friendly options, salvage yards can be a treasure trove of usable components from older models.

Before making a purchase, ensure that you verify compatibility with your specific equipment model. Checking for reviews and recommendations can also guide you toward reliable sources.