Every machine designed to tackle heavy-duty tasks during the cold months requires precise coordination of its internal mechanisms. Whether you’re clearing pathways or maintaining outdoor spaces, it’s essential to have a clear understanding of the various elements that keep the device functioning smoothly. This knowledge is the key to ensuring longevity and optimal performance, even in the toughest conditions.

The mechanics of such devices are intricate, with numerous interconnected elements working together to deliver reliable power and control. Identifying and understanding these specific elements can make maintenance and repair much simpler, providing you with the confidence to address any issues that arise. Proper care ensures that your machine remains in top shape, ready for use whenever you need it.

Murray Snowblower: Key Component Breakdown

In this section, we will explore the essential elements that ensure smooth operation and functionality. By understanding how each part interacts, you can maintain and repair the machine with greater efficiency, prolonging its lifespan and ensuring reliable performance.

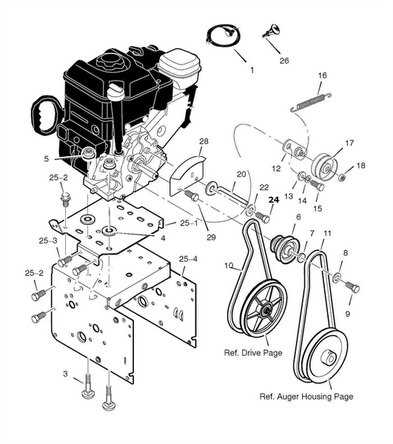

Primary Mechanical Elements

At the core of the machine, several mechanical components work together to ensure proper movement and handling. These include elements responsible for power transmission, propulsion, and steering, all crucial for maneuverability and stability in harsh conditions.

Power and Control Systems

Power generation and control systems govern the overall performance and user interaction. These systems ensure that energy is properly distributed, while controls allow the operator to manage speed, direction, and other key functions with ease.

| Component | Function | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control Type | Adjustment Method | Recommended Frequency |

|---|---|---|

| Throttle | Check for responsiveness; adjust tension if needed. | Before each use |

| Choke | Ensure smooth operation; adjust cable length as necessary. | Seasonally |

| Speed Control | Test varying speeds; modify linkages for proper range. | Monthly |

By following these guidelines, you can achieve better control and enhance the overall functionality of your equipment. Regular adjustments not only improve performance but also extend the lifespan of your machinery.

Safety Features and Their Importance

In any machinery designed for outdoor tasks, the incorporation of safety measures is essential to ensure user protection and prevent accidents. Understanding these protective mechanisms helps users operate equipment confidently and responsibly. These features not only enhance safety but also promote efficiency in operation.

Key Safety Mechanisms

Emergency stop buttons and automatic shut-off systems are critical components that allow users to quickly disable the machine in case of an emergency. Such features significantly reduce the risk of injury and equipment damage by enabling swift responses to unexpected situations.

Enhancing User Awareness

Clear warning labels and instruction manuals play a vital role in educating users about potential hazards and proper handling techniques. By promoting awareness of safe practices, these elements contribute to a safer working environment and help minimize accidents during operation.

Where to Find Spare Parts

Locating replacement components for your outdoor equipment can significantly enhance its longevity and performance. Several resources are available to help you track down the necessary items to keep your machinery running smoothly.

Consider exploring the following avenues:

- Local Retail Stores: Check nearby hardware and home improvement stores, which often carry essential items for various models.

- Online Retailers: Numerous websites specialize in providing components for outdoor machinery. Popular platforms may have a wide selection and competitive prices.

- Manufacturer’s Website: Visit the official site for a comprehensive catalog of available items, along with detailed descriptions and compatibility information.

- Repair Shops: Reach out to local repair services that might stock spare items or can order them for you.

- Online Marketplaces: Platforms like eBay and Amazon frequently list new and used items from various sellers, allowing for potential savings.

- Community Forums: Engaging with online communities dedicated to outdoor equipment can yield recommendations for sourcing components and even direct links to suppliers.

By utilizing these resources, you can ensure that your outdoor machinery remains functional and effective for years to come.

Upgrading Your Snowblower for Better Performance

Enhancing the functionality of your winter equipment can significantly improve its efficiency and longevity. By implementing various upgrades, users can optimize performance and tackle even the toughest conditions. This section explores effective modifications to elevate your machine’s capabilities.

One of the most impactful upgrades involves replacing the existing motor with a more powerful alternative. A robust motor can deliver higher torque and better handling of heavy snow. Additionally, upgrading the auger blades to more durable materials can enhance cutting efficiency, allowing for smoother operation and less wear over time.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Motor Replacement | Install a higher horsepower motor. | Increased torque and speed. |

| Auger Blades | Switch to heavy-duty, corrosion-resistant blades. | Improved cutting efficiency and durability. |

| Chassis Modifications | Reinforce the frame for better stability. | Enhanced handling in difficult conditions. |

| Transmission Upgrade | Upgrade to a multi-speed transmission. | Greater control over speed and handling. |

Investing in these enhancements not only maximizes your equipment’s performance but also provides a more enjoyable experience when managing winter challenges. Consider evaluating your current setup and exploring these upgrades for optimal results.