When it comes to tackling winter’s harsh conditions, understanding the crucial elements of your machinery is paramount. Familiarity with the various components can significantly enhance performance and longevity, ensuring that your equipment is always ready for action.

By examining the intricate relationships between each part, users can not only troubleshoot issues but also optimize their machines for the ultimate efficiency. This knowledge is invaluable for both casual users and seasoned professionals.

In this section, we will delve into a detailed exploration of essential elements that contribute to effective winter operations. Whether you are performing routine maintenance or addressing specific concerns, a comprehensive understanding of these components will empower you to make informed decisions.

Toro S200 Snowblower Overview

This compact and efficient outdoor machine is designed to tackle winter challenges with ease. Its robust construction and reliable features make it a popular choice for homeowners looking to manage snowfall effectively. The following highlights provide an overview of its capabilities and specifications.

- Powerful engine ensures reliable performance in various snow conditions.

- Compact size allows for easy maneuverability in tight spaces.

- User-friendly controls simplify operation, even for beginners.

With its durable build and effective design, this model excels in clearing paths and driveways, providing convenience during harsh winter months. Whether dealing with light flurries or heavier accumulations, it offers consistent results.

- Efficient clearing width ensures quick snow removal.

- Adjustable chute direction helps in directing snow away from cleared areas.

- Maintenance-friendly design promotes longevity and reliability.

Investing in this versatile machine equips users with the necessary tools to combat winter weather effectively, enhancing safety and accessibility around the property.

Understanding Snowblower Component Functions

When dealing with machines designed for clearing winter precipitation, it’s crucial to comprehend the roles of various elements within the system. Each component works in harmony to ensure efficiency and effectiveness, enabling smooth operation during harsh weather conditions.

Engine: The power source of the device is essential for generating the necessary force. Its performance directly affects how well the machine can handle heavy loads of frozen moisture.

Auger: This spiral blade is responsible for breaking up and gathering the snow. It collects the material and pushes it toward the discharge chute, facilitating a quick and efficient clearing process.

Impeller: Located behind the auger, this fan-like structure propels the gathered material out of the chute. Its design is crucial for achieving the desired distance and speed of snow ejection.

Chassis: The framework provides stability and support, housing all other components. A sturdy chassis is vital for ensuring that the machine can withstand the rigors of frequent use in challenging conditions.

Controls: User interfaces allow operators to adjust settings and manage the machine’s functions. Intuitive controls enhance usability and enable effective operation, especially in adverse weather.

By understanding these key components and their functions, users can better maintain their equipment, troubleshoot issues, and ultimately improve performance during the winter season.

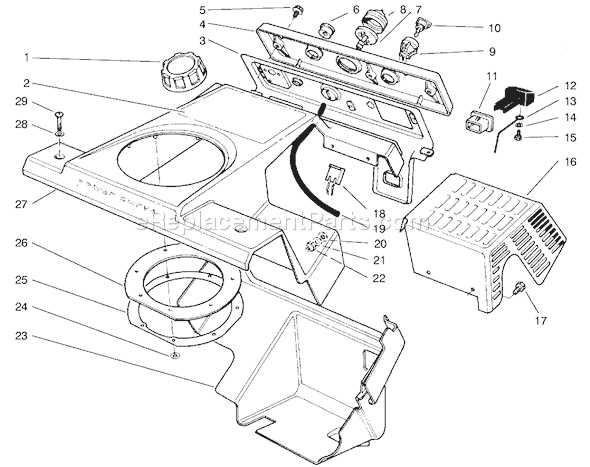

Parts Diagram: Essential Components Explained

Understanding the intricate assembly of your equipment is crucial for maintenance and optimal performance. Each segment plays a vital role, contributing to the overall functionality and efficiency. This section provides an overview of the key elements, enhancing your familiarity with their purposes and interconnections.

Chassis: The foundational structure supports all components, ensuring stability and durability during operation. Its design facilitates easy access to other vital sections for maintenance and repairs.

Engine: Serving as the powerhouse, this component generates the necessary energy for operation. Its performance directly influences the efficiency and effectiveness of the entire system.

Auger: This rotating element is responsible for breaking up and gathering material. Its design is optimized for various conditions, ensuring reliable performance regardless of the environment.

Impeller: Positioned behind the auger, this part propels the gathered material outward. Its efficiency is crucial for achieving optimal throwing distance and speed.

Controls: These mechanisms allow the operator to manage settings and functions. Intuitive design ensures ease of use, contributing to a smoother operational experience.

Skids and Shoes: These components provide support and stability, allowing the machine to navigate different surfaces. Their adjustability helps in adapting to varying ground conditions.

Familiarity with these essential elements not only aids in effective troubleshooting but also promotes informed decisions regarding maintenance and upgrades. A comprehensive understanding fosters a proactive approach to care, ensuring longevity and peak performance.

Common Issues with Toro S200

Many users encounter several recurring challenges when operating their outdoor clearing machines. Understanding these issues can significantly enhance performance and prolong the lifespan of the equipment.

- Starting Problems: Difficulty in ignition is a frequent complaint. This can stem from issues with the spark plug or fuel system.

- Ineffective Clearing: If the unit struggles to remove snow, it may be due to a clogged chute or dull blades.

- Unusual Noises: Grinding or rattling sounds may indicate internal component wear or loose parts.

- Vibration: Excessive shaking during operation can signal imbalances or misalignment in the machinery.

Regular maintenance and prompt attention to these issues can help ensure efficient operation and reliability.

How to Identify Replacement Parts

Identifying components for repair or maintenance can often seem daunting. However, with the right approach, you can easily determine what you need to restore functionality to your equipment. Understanding the structure and terminology associated with these items is crucial.

First, consult the user manual or product specifications, as these documents usually contain essential information about each component. Second, inspect the current condition of the item to identify any visible wear or damage. This can guide you in selecting the appropriate replacements.

Finally, online resources and forums can provide valuable insights from other users who have faced similar issues. Engaging with the community can lead you to the ultimate solutions for your needs.

Benefits of Using Original Parts

Utilizing authentic components for maintenance and repair brings several advantages that enhance performance and longevity. Here are some key benefits:

- Quality Assurance: Genuine items are manufactured to meet high standards, ensuring reliability.

- Perfect Fit: These components are designed specifically for your equipment, minimizing installation issues.

- Durability: Original parts typically have a longer lifespan, reducing the need for frequent replacements.

- Warranty Protection: Using certified pieces often maintains warranty coverage, safeguarding your investment.

- Optimal Performance: Authentic components ensure your machine operates at its best, maximizing efficiency.

In summary, opting for genuine items leads to enhanced reliability and performance, ultimately contributing to a more efficient operation.

Maintenance Tips for Toro Snowblowers

Proper upkeep is essential for ensuring optimal performance and longevity of your outdoor equipment. Regular attention not only enhances efficiency but also prevents potential breakdowns during critical times. Following a structured maintenance routine can make all the difference.

Check the Fuel System: Always use fresh fuel to avoid issues. Periodically inspect the fuel lines and filters for any signs of wear or blockage. Replacing old fuel is crucial for smooth operation.

Inspect the Blades: Keeping the blades sharp ensures effective clearing. Regularly examine them for damage and sharpen as needed to maintain performance.

Clean After Use: After each use, remove any snow and ice buildup. This prevents corrosion and ensures that all components remain functional and in good condition.

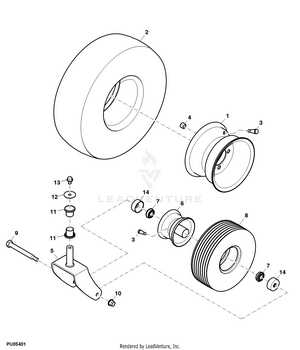

Check the Belts: Inspect the drive belts for cracks or fraying. Replacing worn belts in a timely manner can prevent more significant issues down the line.

Store Properly: During off-seasons, store your equipment in a dry place. Consider using a cover to protect it from dust and moisture, which can cause long-term damage.

Where to Find Parts Online

When it comes to maintaining your outdoor equipment, sourcing the right components is essential. The internet provides a vast array of options for finding what you need, whether you’re looking for replacements or upgrades. Understanding where to look can save you time and ensure you get quality items at competitive prices.

Online Retailers

Major online retailers often stock a wide selection of components for various brands and models. Websites like Amazone and eBay feature both new and used options, allowing you to compare prices and conditions easily. Make sure to read reviews and check seller ratings for a reliable shopping experience.

Specialized Websites

There are also dedicated websites that focus specifically on outdoor equipment maintenance. These platforms typically offer detailed catalogs, including specifications and compatibility information. Utilizing search filters can help narrow down your options quickly. Additionally, consider subscribing to newsletters for updates on promotions and new arrivals.

Cost Comparison: OEM vs. Aftermarket

When considering replacement components for machinery, the choice between original equipment manufacturer (OEM) and alternative options can significantly impact both budget and performance. OEM products typically promise reliability and compatibility, while aftermarket alternatives often present a more economical solution. This section will explore the financial implications of each option, helping consumers make informed decisions based on their needs.

OEM components usually come with a higher price tag, reflecting their assurance of quality and a warranty that provides peace of mind. Conversely, aftermarket items are generally less expensive, appealing to those seeking to save on immediate costs. However, the trade-off might include variations in durability and performance, which can ultimately affect long-term value.

It is essential to evaluate not just the upfront expense, but also the potential for future costs related to maintenance and replacement. Investing in OEM parts might be advantageous in terms of longevity, while choosing aftermarket solutions could lead to savings in the short term. Balancing these factors is crucial for achieving the best outcome based on individual circumstances.

Upgrading Your Snowblower’s Performance

Enhancing the efficiency of your winter clearing equipment can significantly improve its functionality and longevity. By making strategic upgrades, you can ensure optimal operation in even the harshest conditions.

1. Improve the Engine: Consider tuning or upgrading the engine for increased power. A more robust engine can handle heavier snowfall and rough terrain more effectively.

2. Optimize the Auger: Upgrading the auger blades to a more durable material can enhance cutting efficiency. This change allows for smoother operation and better snow removal.

3. Enhance the Chassis: Reinforcing the frame with quality materials can improve stability and reduce wear over time. A sturdy chassis will withstand the rigors of frequent use.

4. Upgrade Tires: Installing all-terrain tires can provide better traction and control, making it easier to navigate slippery surfaces.

By focusing on these key areas, you can delve deeper into performance improvements and achieve the ultimate efficiency for your winter maintenance tasks.