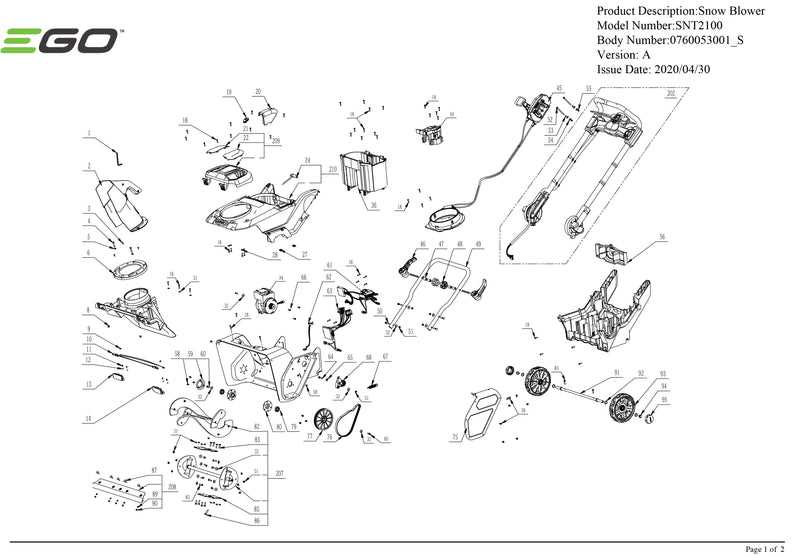

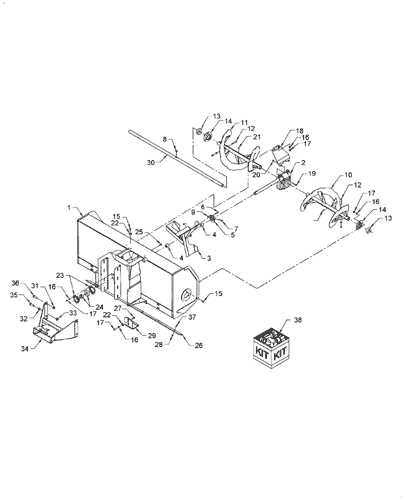

When it comes to operating a machine designed for clearing frozen precipitation, having a clear understanding of its various components is essential. Each element plays a critical role in ensuring optimal performance during challenging winter conditions. Familiarizing oneself with these components can greatly enhance the efficiency of the equipment.

In this section, we will explore a visual representation that highlights the different elements of a snow-clearing device. By examining these individual parts, users can gain insights into their functions and how they contribute to the overall operation of the machinery.

Whether you are a seasoned operator or a newcomer to using this type of equipment, recognizing each component’s place and role will facilitate better maintenance and troubleshooting. A comprehensive grasp of the inner workings will ultimately lead to a more effective snow management strategy.

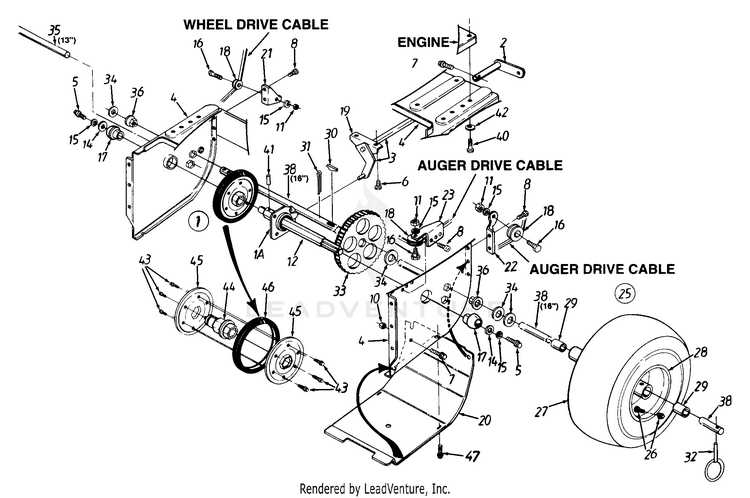

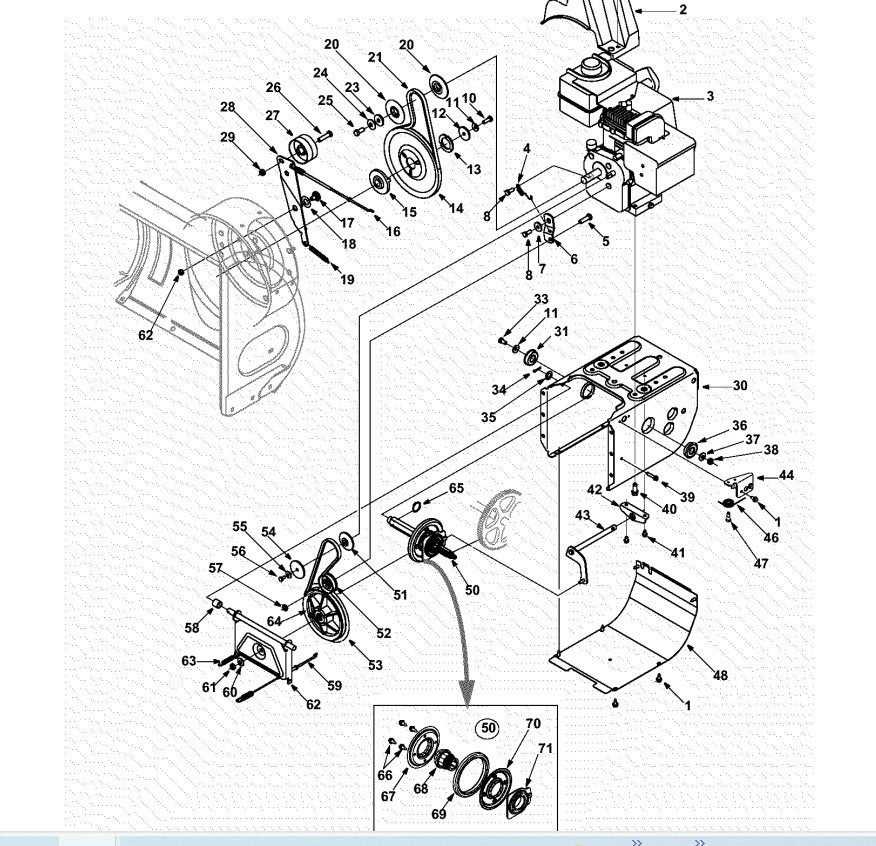

The drive mechanism is a crucial component in any snow-clearing machine, playing a vital role in its overall functionality and efficiency. This system ensures that the equipment operates smoothly, allowing it to maneuver effectively across various surfaces and conditions.

A well-functioning drive assembly contributes significantly to the performance of the equipment, impacting its ability to handle heavy snowfall and challenging terrain. Understanding the key elements of this system can aid in maintaining optimal operation and extending the lifespan of the machine.

| Component | Function |

|---|---|

| Drive Belt | Transfers power from the engine to the wheels |

| Gearbox | Regulates speed and torque |

| Wheels | Facilitates movement across different terrains |

| Clutch | Engages and disengages the drive system |

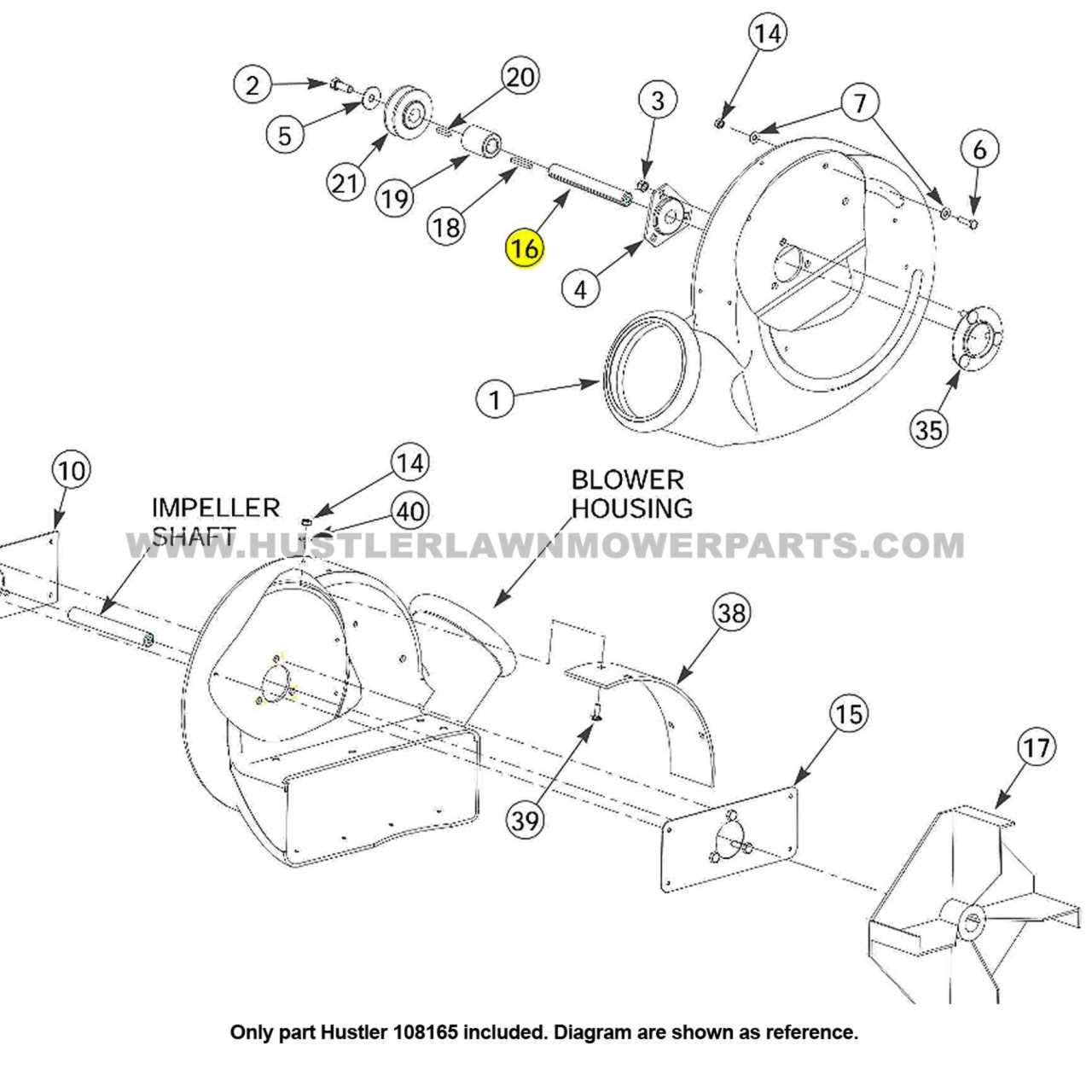

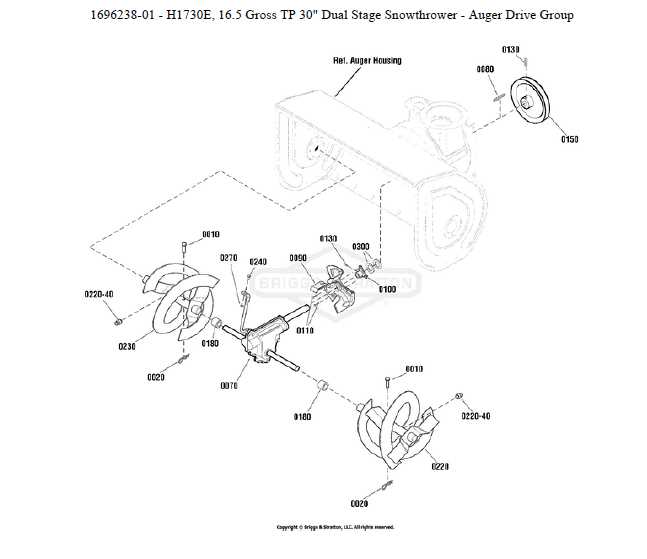

Snow Discharge Mechanism Explained

The mechanism responsible for the expulsion of frozen precipitation is a critical component of any winter clearing equipment. Understanding how this system operates can enhance the effectiveness and efficiency of the machinery, ensuring optimal performance during harsh weather conditions.

Functionality of the Discharge System

The discharge system is designed to efficiently direct the removed ice and snow away from the clearing path. This is achieved through a combination of rotating blades and a chute that can be adjusted to control the angle of discharge. Proper operation of this mechanism is essential for preventing clogging and ensuring smooth operation.

Components Involved

Several key elements work in harmony to facilitate the discharge process:

| Component | Function |

|---|---|

| Auger | Collects and moves the material towards the discharge area. |

| Impeller | Propels the material out of the discharge chute. |

| Chute | Guides the expelled material to the desired location. |

Electrical Components in Snowblowers

The efficient operation of winter equipment relies heavily on its electrical systems. These components play a crucial role in ensuring that the machinery functions smoothly and effectively in harsh weather conditions. Understanding these elements can aid in troubleshooting and maintenance, ultimately enhancing the performance of the device.

Key Electrical Elements

- Motor: The primary driving force, responsible for powering various functions.

- Switches: Control the activation and deactivation of the equipment.

- Wiring Harness: Connects all electrical components, facilitating communication between them.

- Fuses: Protect the electrical system from overloads and shorts.

- Battery: Supplies power to start the motor and run auxiliary features.

Maintenance Tips

- Regularly check connections for corrosion or wear.

- Replace any blown fuses immediately to prevent damage.

- Keep the battery terminals clean and securely connected.

- Test switches periodically to ensure proper functionality.

Maintaining the Control Panel

Regular upkeep of the control interface is essential for optimal performance and reliability. This section outlines key practices to ensure the longevity and effectiveness of the operational system.

Start by routinely inspecting the panel for any signs of wear or damage. Pay attention to buttons and switches, as these components are frequently used and may require special care.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Weekly | Check for cracks, loose connections, and debris accumulation. |

| Cleaning | Monthly | Wipe down surfaces with a damp cloth to remove dirt and grime. |

| Functional Testing | Before Use | Ensure all buttons and indicators respond correctly during operation. |

By following these maintenance steps, you can help maintain the functionality of the control panel and enhance the overall performance of the equipment.

Common Accessories for Snow Removal

Effective clearing of winter precipitation often requires a range of supplementary tools that enhance efficiency and ease of use. These accessories can help users manage varying conditions and improve overall performance during snow clearing tasks.

- Chute Extensions: These attachments allow for better direction and distance of snow discharge, making it easier to avoid obstacles and reach desired areas.

- Heated Hand Grips: Essential for comfort, heated grips provide warmth during prolonged use, helping to maintain dexterity and control.

- Skid Shoes: These components help protect surfaces by adjusting the height of the machine, ensuring effective clearance without damaging driveways or sidewalks.

- Headlight Kits: Visibility is crucial during early morning or evening operations; additional lighting ensures safe and efficient working conditions.

- Drift Cutters: Designed to assist in cutting through heavy accumulations, these tools make tackling compacted snow much more manageable.

- Snow Chains: Enhancing traction on slippery surfaces, these accessories improve stability and control during operation.

Repairing the Fuel System

The fuel mechanism is crucial for the efficient operation of outdoor machinery. Addressing issues within this system is essential to ensure proper functionality and longevity. This section outlines key steps to diagnose and fix common problems that may arise.

Initial Inspection: Begin by examining the fuel lines for any signs of leaks, cracks, or blockages. Inspect the fuel filter to ensure it is not clogged, as this can restrict fuel flow and cause performance issues.

Cleaning Components: If debris is found, clean or replace the affected components. Use a suitable solvent to clean the fuel lines and filter, ensuring that all residues are removed for optimal performance.

Testing Fuel Flow: After cleaning, check the fuel pump’s operation. You can do this by disconnecting the fuel line and observing if fuel is being pumped adequately when the machinery is turned on. If there is insufficient flow, the pump may require replacement.

Sealing and Reassembly: Once repairs are completed, reassemble all components securely. Ensure that all connections are tight to prevent any future leaks, and fill the system with fresh fuel before testing the equipment.

Wear Parts and Their Replacement

Understanding the components that experience wear and tear is essential for maintaining optimal performance of your equipment. Regularly checking and replacing these items can prevent larger issues and ensure longevity.

Commonly affected items include:

- Blades: Over time, blades can become dull or chipped, affecting efficiency.

- Belts: These can fray or break, leading to loss of power.

- Bearings: Worn bearings can cause excessive noise and vibrations.

- Seals: Damaged seals can lead to fluid leaks, impacting overall functionality.

Replacement steps generally include:

- Identify the component needing replacement.

- Gather the necessary tools for removal.

- Carefully detach the old component.

- Install the new item, ensuring it is secured properly.

- Test the equipment to confirm functionality.

Regular inspections and timely replacements of these critical items contribute to smoother operation and prevent unexpected breakdowns.

Seasonal Maintenance Checklist

Regular upkeep of your outdoor equipment is essential for ensuring optimal performance and longevity. A well-structured maintenance routine helps identify potential issues before they escalate, ensuring reliable operation throughout the seasons.

Key Maintenance Tasks:

- Inspect the engine oil: Change oil and replace the filter as necessary.

- Check the fuel system: Ensure fuel lines are clear and fuel is fresh.

- Examine belts and cables: Look for signs of wear and adjust tension if needed.

- Clean air filters: Replace or clean filters to maintain airflow.

- Test the electrical system: Check battery health and connections.

- Lubricate moving parts: Apply appropriate lubricant to enhance mobility.

- Inspect the overall structure: Look for cracks or damages that may require attention.

Following this checklist will help ensure that your machinery is ready for the challenges of the upcoming seasons.

Finding Replacement Parts Online

Locating suitable components for your equipment can often seem daunting, yet the internet offers a wealth of resources to streamline this process. Various platforms provide extensive inventories, allowing users to browse and select the necessary items from the comfort of their homes.

Start by visiting specialized websites that focus on outdoor machinery, as they typically feature detailed catalogs of available components. Utilize search functions to narrow down your options based on model specifications, ensuring compatibility with your device.

Additionally, consider exploring forums and community groups dedicated to maintenance and repair discussions. Members often share valuable insights and recommendations for reliable suppliers, enhancing your ability to find quality replacements.

Don’t overlook the potential of local retailers that maintain an online presence. They may offer a combination of online ordering and in-store pickup, providing flexibility and convenience.

Lastly, always compare prices and shipping options before finalizing a purchase. This diligence not only helps secure the best deal but also contributes to a more satisfying buying experience.