When it comes to maintaining outdoor machinery, having a comprehensive understanding of its components is essential. Familiarity with the various elements that make up your device not only enhances its performance but also aids in troubleshooting and repairs. Each segment plays a vital role in the overall functionality, ensuring that your equipment operates smoothly and efficiently.

Identifying the various sections of your machinery can significantly simplify the maintenance process. Whether you’re looking to replace a worn-out piece or simply wish to learn more about the operational aspects, a clear illustration of the components provides valuable insights. This knowledge empowers users to make informed decisions, thus prolonging the lifespan of the equipment.

Equipped with this information, users can approach maintenance tasks with confidence. Understanding how each part interacts within the whole allows for better management and care of the machinery, ultimately leading to enhanced performance and reliability.

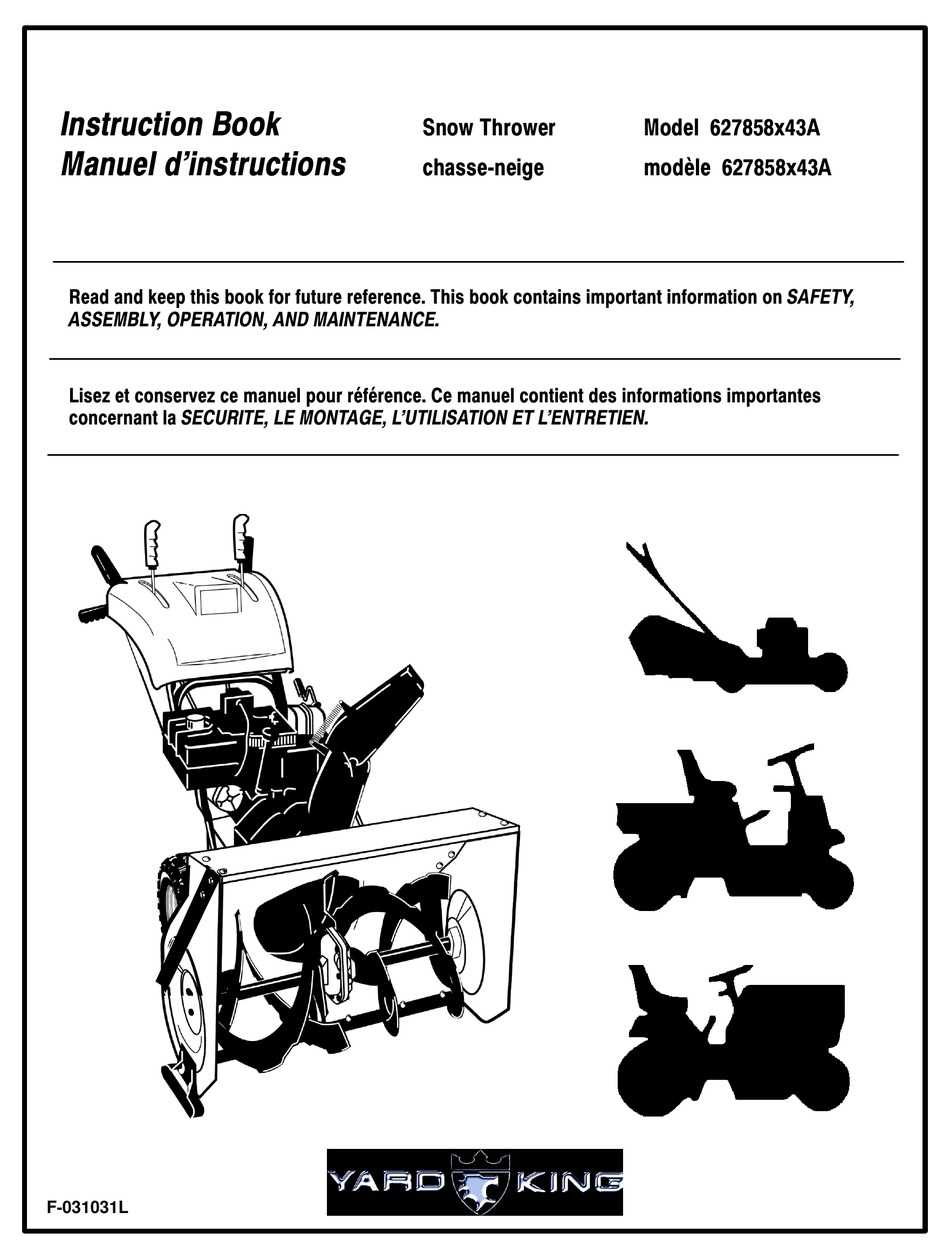

Understanding the various elements of a winter maintenance machine is essential for effective operation and maintenance. This section provides an overview of the key components that make up this type of equipment, ensuring users can identify and comprehend each part’s function and significance.

- Introduction to Key Components

This section will highlight the main components that contribute to the machine’s performance.

- Engine Overview

Discussion on the power unit and its role in driving the entire mechanism.

- Chassis Structure

Explanation of the frame and its importance in providing stability and support.

- Auger Functionality

Details about the component responsible for gathering and processing snow.

- Impeller Insights

A look at the part that helps discharge snow away from the machine.

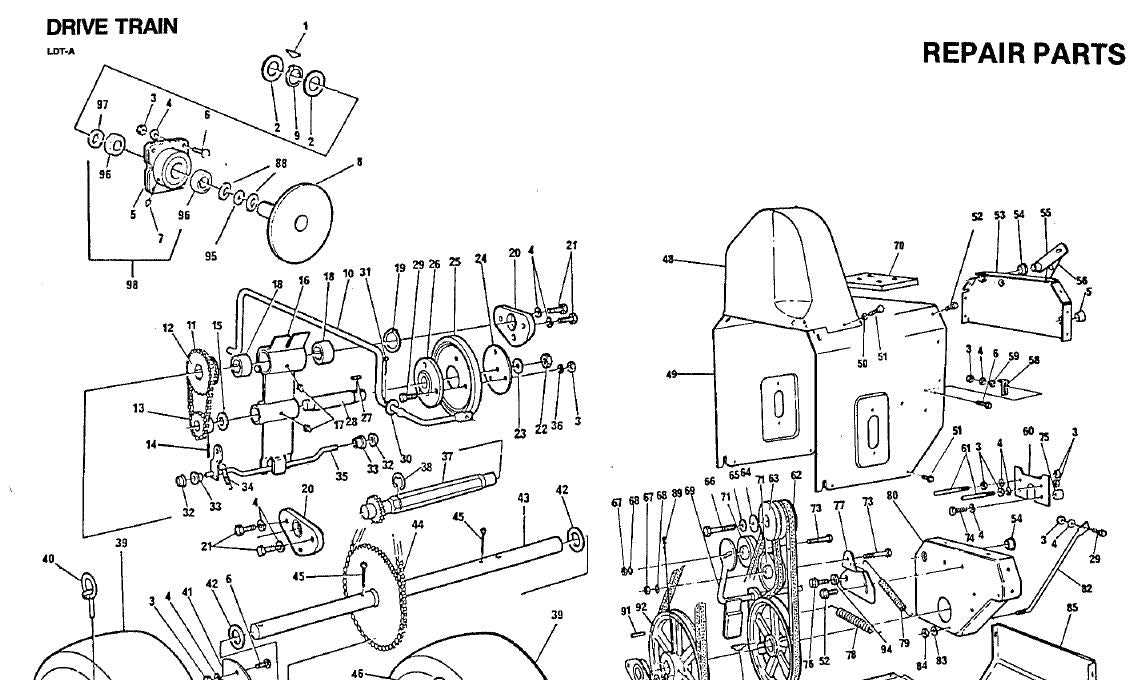

- Transmission Mechanism

Insights into the system that transfers power from the engine to the wheels and other components.

- Control Panel Features

An overview of the interface used to operate various functions.

- Wheels and Traction

Discussion on the types of wheels and how they contribute to mobility on snowy surfaces.

- Fuel System Basics

Information on how fuel is stored and delivered to the engine.

- Maintenance Tips

Guidelines for keeping each component in optimal condition.

- Common Issues and Solutions

Addressing frequent problems and how to troubleshoot them effectively.

Overview of Snow Removal Machine Functionality

This section delves into the essential operations and mechanisms behind machines designed for clearing snow. Understanding how these devices function is crucial for effective usage and maintenance. They are engineered to efficiently handle winter challenges, transforming heavy snowfall into manageable piles that can be easily removed.

| Component | Function |

|---|---|

| Auger | Collects and chops the snow, preparing it for expulsion. |

| Impeller | Propels the snow away from the unit, ensuring effective discharge. |

| Chassis | Supports and houses all components, providing stability and durability. |

| Engine | Powers the machine, driving the auger and impeller. |

| Controls | Allow the operator to adjust speed, direction, and discharge angle. |

Key Parts of the Yard King Model

This section delves into the essential components of a specific model, highlighting their significance and functionality. Understanding these elements is crucial for effective operation and maintenance.

Essential Components

Each unit comprises various vital elements that work harmoniously to ensure optimal performance. Familiarity with these components aids in troubleshooting and enhancing overall efficiency.

| Component | Description |

|---|---|

| Engine | The power source driving the entire system. |

| Auger | Responsible for gathering and moving snow into the discharge chute. |

| Chassis | The main frame that supports all other components. |

| Discharge Chute | Directs the expelled snow away from the machine. |

| Controls | Enables the operator to adjust settings and navigate the unit. |

Importance of Regular Maintenance

Ensuring these crucial components are well-maintained is essential for longevity and peak performance. Regular inspections and timely replacements can prevent breakdowns and enhance functionality.

Importance of Regular Maintenance

Routine care is essential for the longevity and efficiency of any machinery. Neglecting maintenance can lead to reduced performance and potential failures, which can be both inconvenient and costly. By committing to regular upkeep, operators can ensure that their equipment functions optimally and remains reliable throughout its use.

Regular inspections and timely servicing can identify potential issues before they escalate. This proactive approach not only enhances operational efficiency but also extends the lifespan of the machine. Moreover, well-maintained equipment tends to operate more safely, minimizing the risk of accidents caused by mechanical failures.

Additionally, adhering to a consistent maintenance schedule can save money in the long run. Preventative measures are often more affordable than extensive repairs, and they help maintain the value of the machinery. By investing time and resources into care practices, users can enjoy uninterrupted performance and peace of mind.

Common Issues with Snow Removal Equipment

When operating snow removal machines, users often encounter various challenges that can hinder performance. Understanding these common issues can aid in maintaining functionality and prolonging the life of the equipment. Below are some frequent problems and their potential solutions.

Mechanical Failures

Mechanical failures can arise due to wear and tear over time. Here are a few typical concerns:

- Engine Troubles: Difficulties starting the engine may stem from fuel issues or battery malfunctions.

- Drive System Issues: Slips in the drive system can result from damaged belts or improper tension.

- Shear Pin Breakage: These pins are designed to protect the machine from damage but can break under excessive strain.

Operational Hiccups

Operational hiccups can significantly affect performance during use. Common occurrences include:

- Ineffective Clearing: This may be due to dull blades or improper speed settings.

- Blockages: Snow accumulation in the chute can lead to stoppages and requires regular clearing.

- Fuel Issues: Using stale fuel can lead to poor engine performance; fresh fuel is essential.

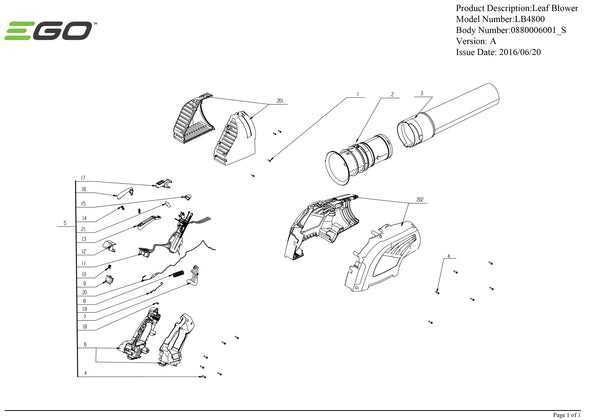

Identifying Replacement Parts Needed

When maintaining outdoor machinery, understanding the components that may require attention is essential for optimal performance. Recognizing which elements need replacement can enhance the lifespan of your equipment and ensure smooth operation during use.

Common Components to Check

- Blades

- Belts

- Filters

- Fuel lines

- Wheels

Steps to Identify Necessary Replacements

- Examine the equipment for any visible wear or damage.

- Refer to the user manual for specific maintenance guidelines.

- Check online resources or forums for common issues related to your model.

- Consult with a professional if uncertain about any components.

By following these steps, you can effectively determine which components need to be replaced, ensuring your machinery operates efficiently and reliably.

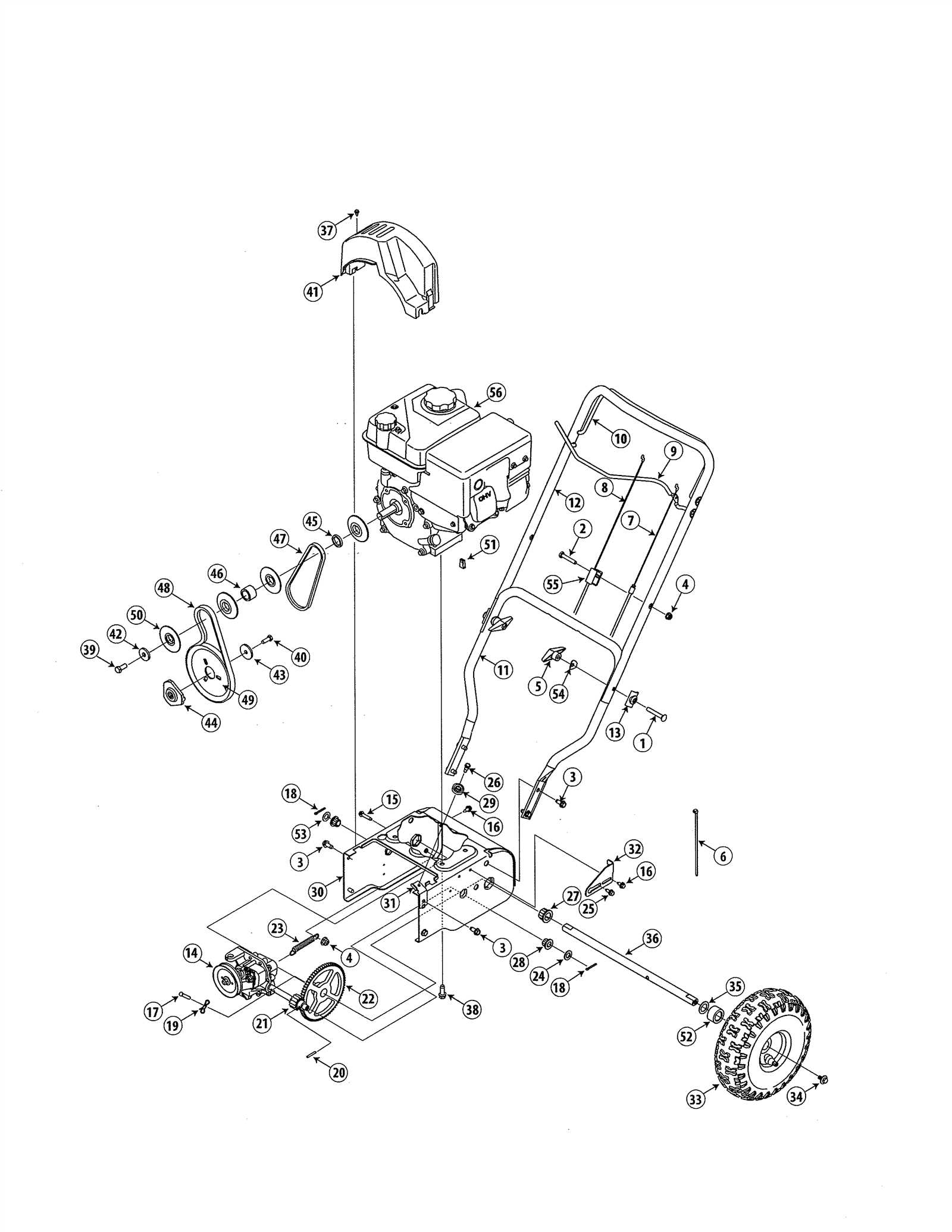

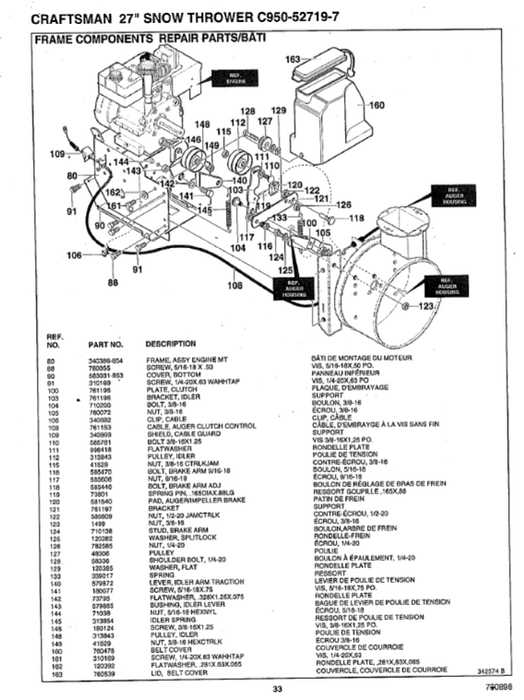

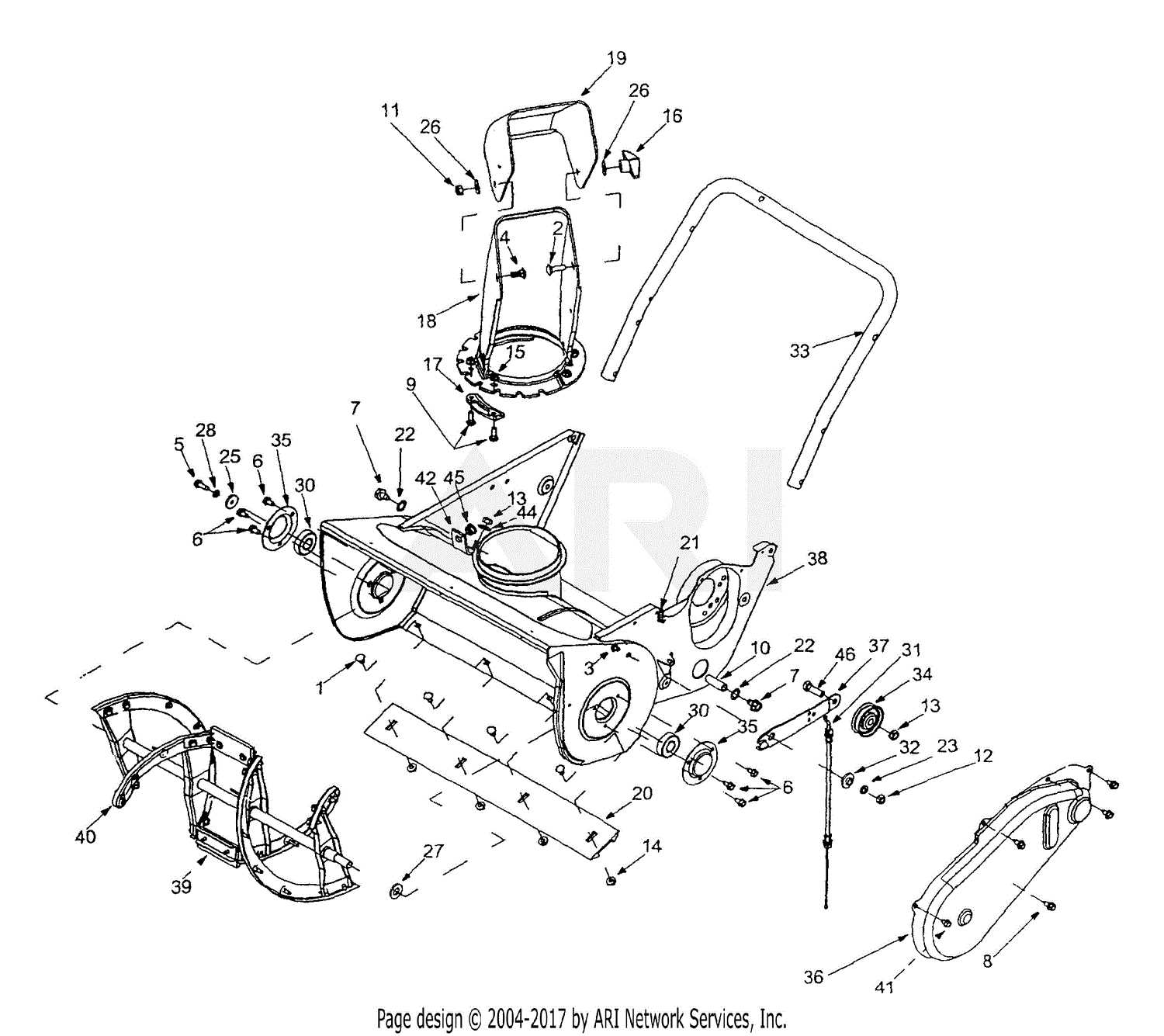

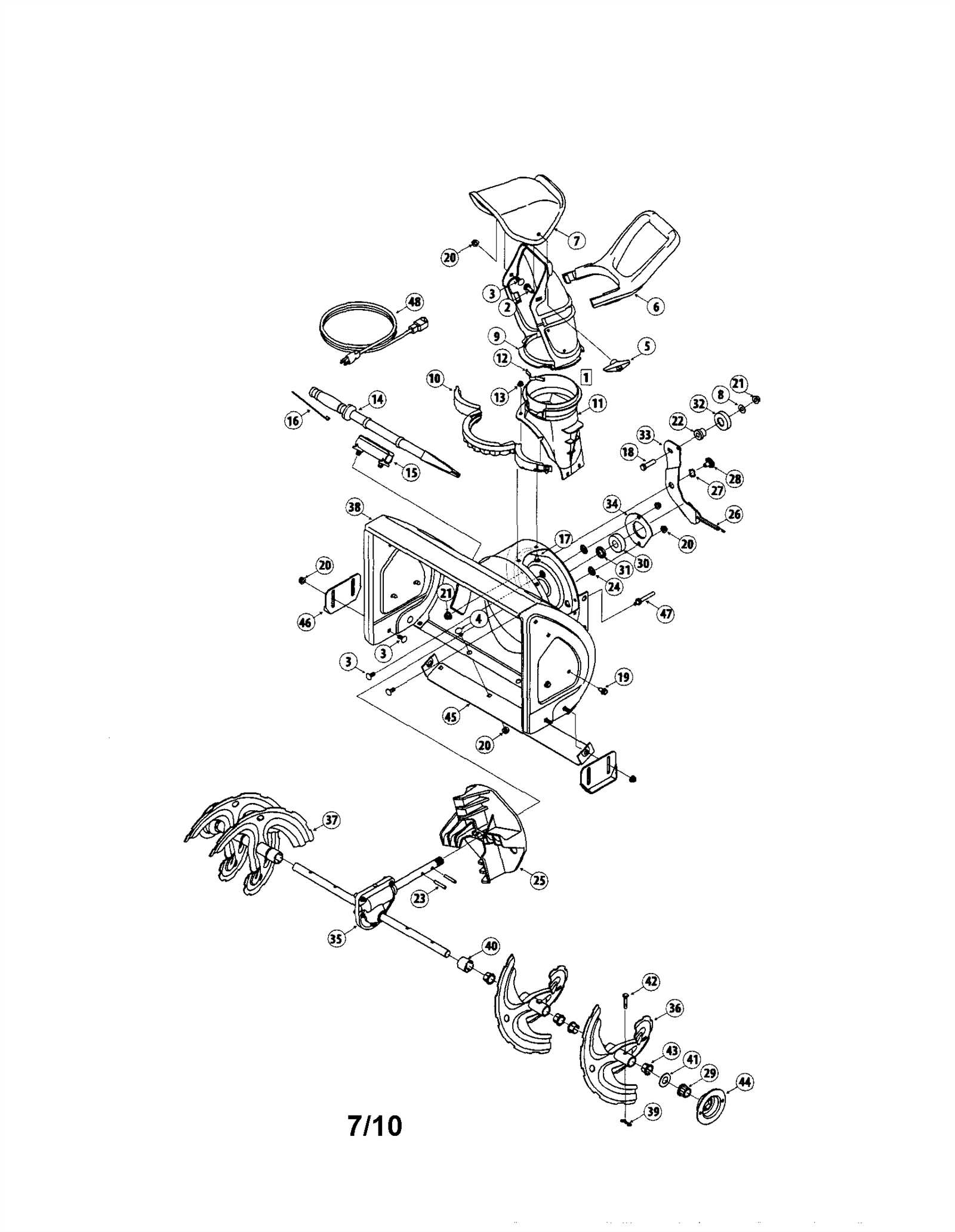

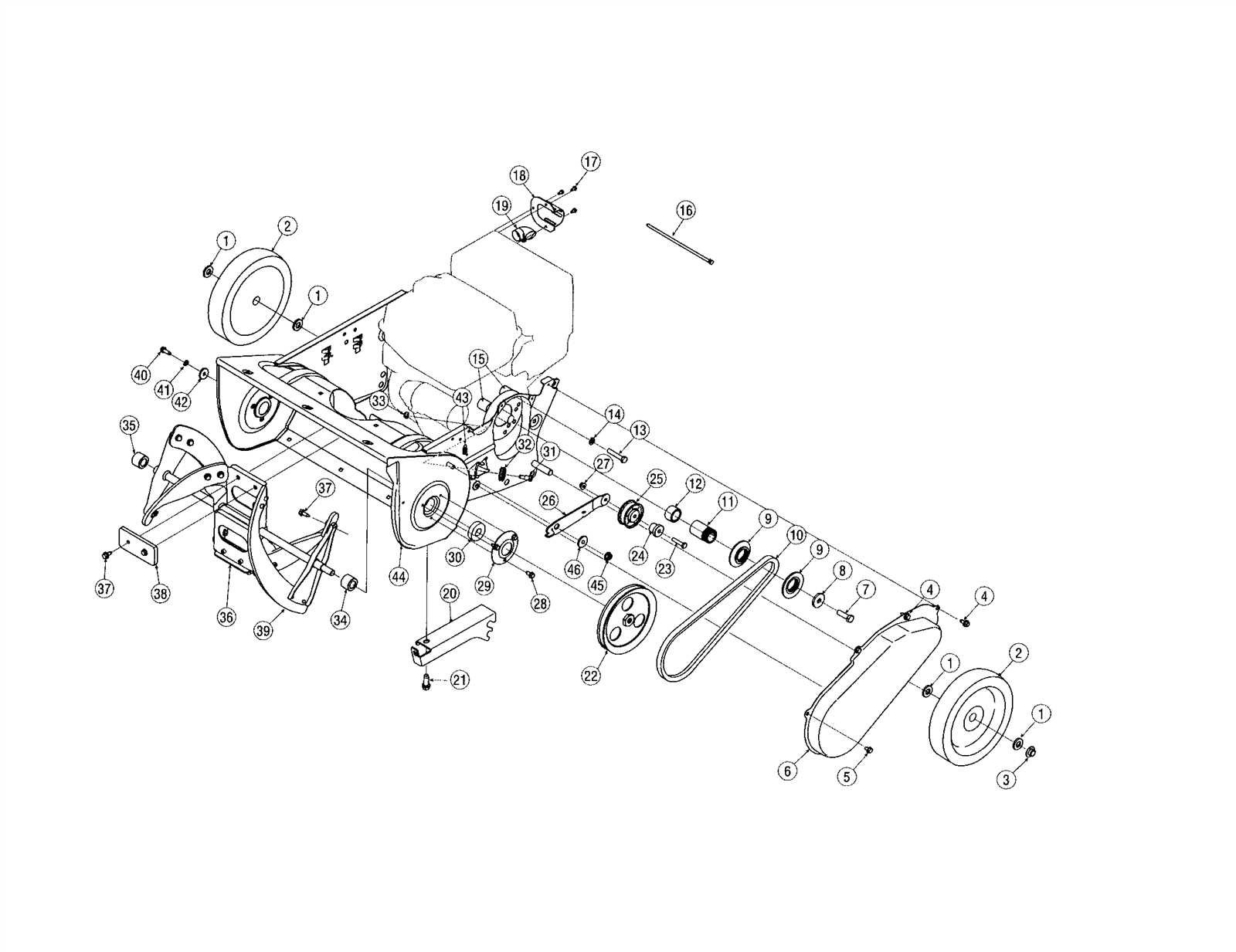

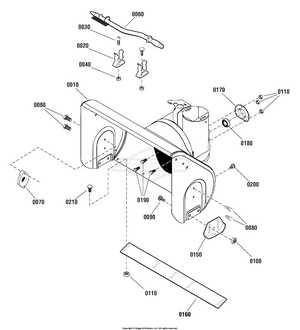

Visual Parts Diagram Explanation

This section aims to provide a comprehensive overview of a graphical representation illustrating various components of a specific machine. Understanding the layout and relationships among these elements is essential for effective maintenance and repairs.

Such a visual representation typically highlights each segment’s function and placement, making it easier to identify essential elements when troubleshooting or performing upgrades. By breaking down the overall structure into manageable segments, users can gain insights into the operation and assembly of the equipment.

Moreover, this illustration serves as a valuable resource for both novice and experienced users alike, enhancing their ability to engage with the machine. Familiarity with this guide can significantly streamline the repair process, ultimately improving efficiency and longevity.

Where to Find Quality Replacement Parts

Finding reliable components for your outdoor equipment is essential to ensure optimal performance and longevity. Whether you are a DIY enthusiast or a professional, sourcing high-quality replacements can significantly impact the functionality of your machinery.

Local retailers often carry a variety of options, providing the advantage of immediate availability. Visiting these stores allows you to physically inspect the items, ensuring they meet your specifications.

Online marketplaces present a vast selection, making it easy to compare prices and reviews. Look for reputable websites that specialize in outdoor equipment, as they usually offer detailed descriptions and customer feedback to aid in your decision-making.

Additionally, consider checking with manufacturer-approved dealers for authentic replacements. This ensures compatibility and quality assurance, which is crucial for maintaining your equipment’s efficiency.

Tools Required for Repairs

When undertaking maintenance or fixing machinery, having the right equipment is crucial for a smooth process. Proper tools not only ensure efficiency but also contribute to safety and effectiveness during the repair tasks.

Essential Hand Tools

Basic hand tools are indispensable for any repair job. These typically include screwdrivers, wrenches, and pliers. Each tool serves a unique function, from loosening or tightening fasteners to handling intricate components. Ensuring that these items are readily available can significantly streamline the repair process.

Power Tools and Accessories

In addition to hand tools, power tools can enhance efficiency and precision. Drills and impact drivers can help in fastening or removing stubborn parts quickly. It’s essential to use the appropriate accessories, such as drill bits and sockets, to match the specifications of the task at hand.

Step-by-Step Repair Instructions

Maintaining your equipment is essential for optimal performance and longevity. This section provides detailed guidance on the repair process, ensuring that you can effectively address common issues and keep your machinery running smoothly.

Gathering Necessary Tools

Before starting the repair, it’s crucial to assemble all the required tools. Having the right instruments on hand will streamline the process and prevent unnecessary interruptions. Common tools needed include: wrenches, screwdrivers, and pliers.

Follow the Repair Steps

Begin by identifying the specific issue affecting your machine. Once you’ve pinpointed the problem, refer to the repair instructions:

- Disconnect the power source to ensure safety while working.

- Inspect and replace any damaged components.

- Reassemble the unit carefully, ensuring all parts are securely fastened.

- Test the functionality to confirm the repair was successful.

By following these steps diligently, you can restore your equipment to its optimal condition.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, adhering to specific safety measures is crucial to ensure a secure and effective repair process. These precautions help prevent accidents and injuries, allowing for a smoother workflow while working on equipment.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Disconnect the power source before starting any repair work to avoid accidental activation.

- Ensure that the workspace is clean and free of hazards to reduce the risk of slips and falls.

- Use tools that are in good condition and suitable for the task to prevent malfunctions.

Handling Components Safely

- Inspect all parts for wear and damage before reassembly.

- Keep hands dry and free from oils to maintain a secure grip on components.

- Store small parts in labeled containers to prevent loss and confusion during repairs.

Best Practices for Seasonal Storage

Proper storage techniques during off-seasons are essential for maintaining the longevity and functionality of your equipment. By following a few simple guidelines, you can ensure that your machinery remains in peak condition, ready for use when needed. This section outlines key strategies to consider when preparing your equipment for seasonal downtime.

Thorough Cleaning: Before storing, clean the machinery thoroughly to remove any dirt, debris, or residues. This practice prevents corrosion and prepares the surface for protective treatments.

Drain Fluids: It is advisable to drain any fuel and oil from the system. Stale fuel can lead to clogs and operational issues, while old oil may cause engine damage over time.

Lubricate Moving Parts: Apply a suitable lubricant to all moving components to prevent rust and ensure smooth operation upon reactivation. This step is crucial for maintaining the integrity of the equipment.

Store in a Controlled Environment: If possible, keep the machinery in a dry, temperature-controlled space. Extreme temperatures and humidity can adversely affect the performance and lifespan of various components.

Cover the Equipment: Using a protective cover can shield the machinery from dust and environmental elements, further preserving its condition. Make sure the cover allows for ventilation to avoid moisture buildup.

By implementing these best practices, you can safeguard your equipment against wear and tear, ensuring its reliability for future use.