Understanding the inner workings of off-road machines is essential for enthusiasts and owners alike. By examining their components and how they interconnect, one can ensure optimal performance and longevity. This exploration unveils the complexity and engineering marvels behind these rugged vehicles.

In this section, we will delve into the various elements that contribute to the functionality of these powerful machines. Recognizing each component’s role allows for informed maintenance and effective upgrades, ensuring the ultimate riding experience.

Whether you are a seasoned rider or a newcomer, familiarizing yourself with these crucial aspects will enhance your appreciation of off-road adventures. Knowledge of these elements fosters a deeper connection with the vehicle and enhances your ability to tackle any terrain.

Understanding Polaris Sportsman 550

This section provides an overview of a popular all-terrain vehicle, focusing on its components and functionality. Whether you are a seasoned rider or a newcomer, grasping the intricate workings of this machine enhances your riding experience.

Key aspects include the engine performance, suspension design, and the various systems that ensure a smooth ride. Familiarity with these elements allows for better maintenance and informed upgrades.

Delving into the specifics, you’ll discover how each part interacts and contributes to the overall operation, making it essential for enthusiasts to understand their vehicle thoroughly.

Key Components of the ATV

Understanding the essential elements of an all-terrain vehicle is crucial for both enthusiasts and operators. Each component plays a significant role in ensuring optimal performance and reliability during rides. Familiarity with these parts allows for better maintenance and enhances overall driving experience.

Engine: The heart of the vehicle, responsible for generating power and torque. A robust engine ensures efficient operation across various terrains.

Transmission: This system transmits power from the engine to the wheels, allowing for smooth acceleration and deceleration. Proper transmission function is vital for effective handling.

Suspension: A critical feature that absorbs shocks and impacts, ensuring a comfortable ride on uneven surfaces. Good suspension contributes to stability and control.

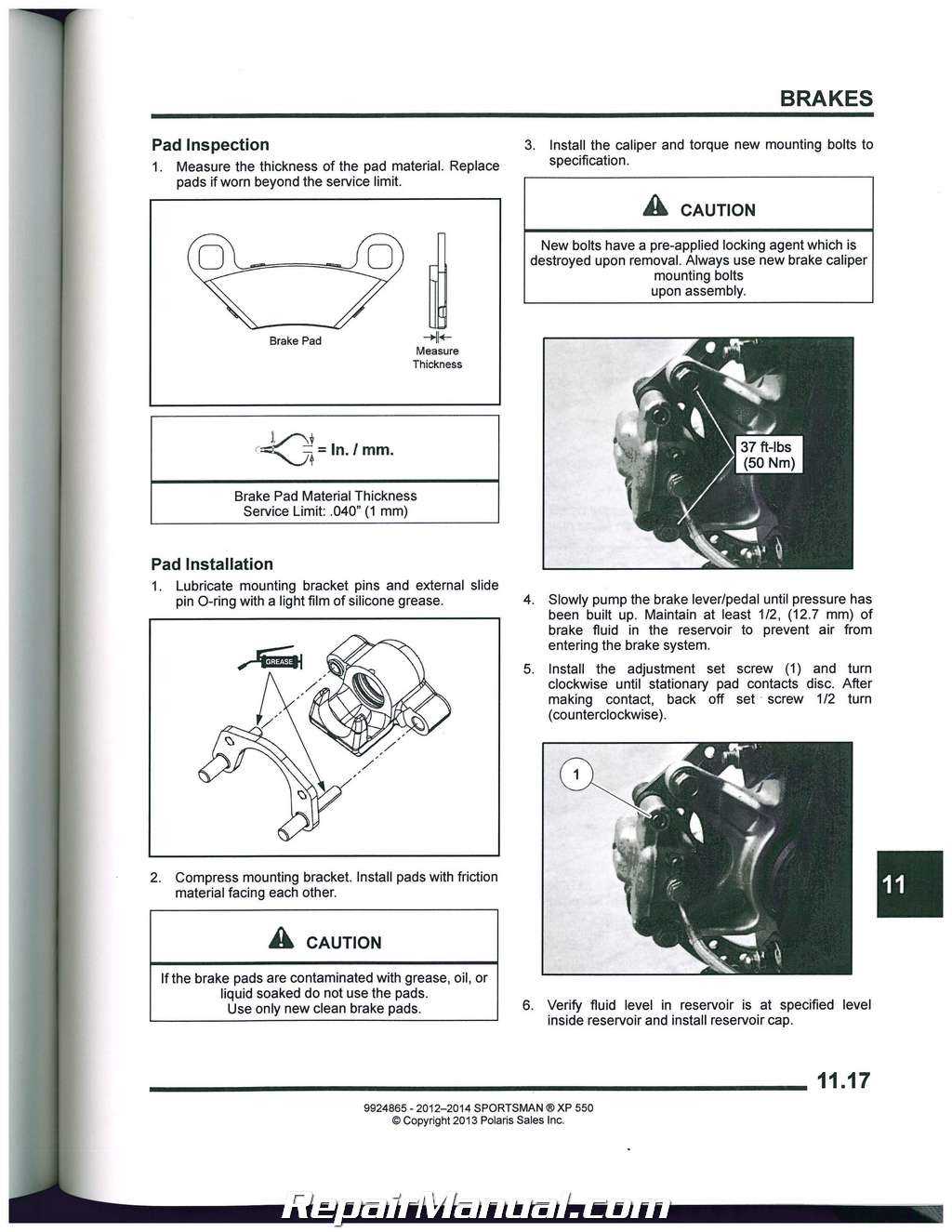

Brakes: Essential for safety, the braking system enables the rider to stop the vehicle effectively. Regular checks are necessary to ensure optimal performance.

Chassis: The frame that supports all other components, providing structure and durability. A well-designed chassis enhances overall strength and stability.

Wheels and Tires: These components directly affect traction and handling. Selecting the right type of tires can significantly improve performance in different environments.

Each part, from the engine to the tires, contributes to the ultimate experience of riding an ATV, making understanding their functions essential for any rider.

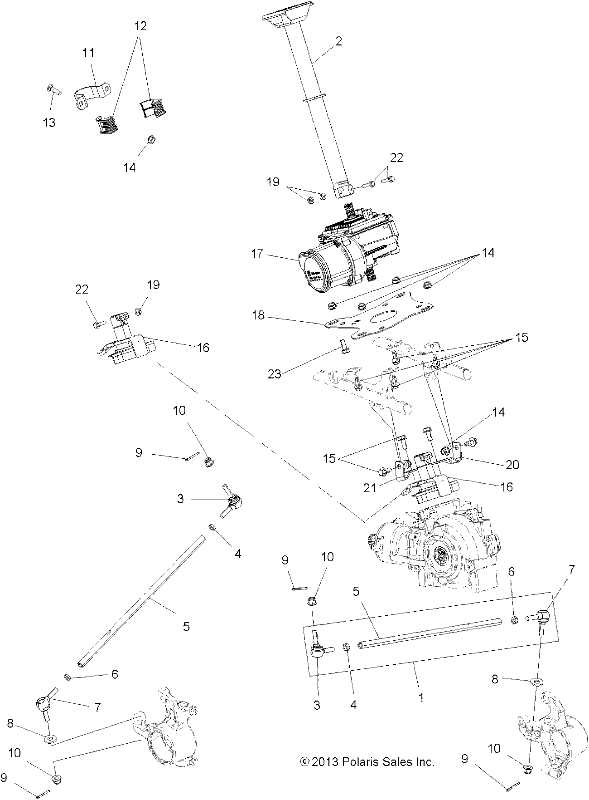

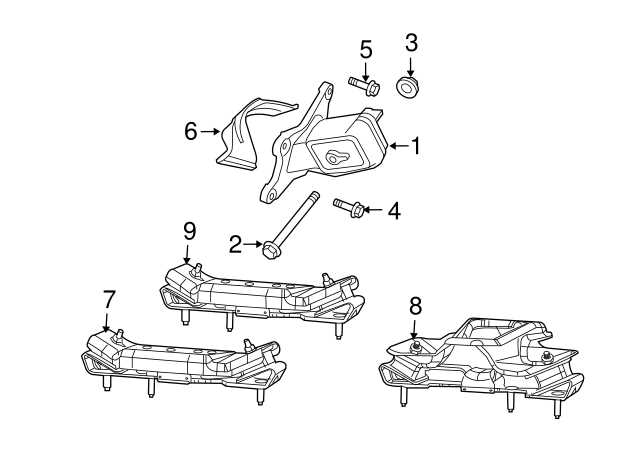

Importance of Parts Diagrams

Understanding the layout and functionality of mechanical components is crucial for efficient maintenance and repairs. Visual representations not only simplify the identification of each element but also enhance the overall comprehension of the assembly process.

Benefits of Visual Representations

- Facilitates easy identification of components

- Enhances understanding of assembly and disassembly

- Helps in pinpointing issues quickly

- Guides proper reassembly after repairs

Streamlining Maintenance Processes

Utilizing these visual guides streamlines the maintenance workflow, allowing technicians to work more efficiently. This ultimately leads to reduced downtime and improved performance.

Where to Find Official Diagrams

Locating authentic schematics for your vehicle can significantly enhance your maintenance and repair efforts. These visual aids are crucial for understanding the intricate assembly of components and ensuring that every part is correctly fitted. Whether you’re a professional technician or a DIY enthusiast, having access to reliable illustrations can make all the difference in your projects.

There are several reputable sources where you can obtain these essential visuals:

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides downloadable resources, including comprehensive schematics for various models. |

| Authorized Dealers | Local or online dealers may offer access to official manuals and diagrams, often included with purchase or available for a fee. |

| Repair Shops | Many established repair facilities have access to technical resources and may share diagrams for educational purposes. |

| Online Forums | Community-driven platforms may have members who share scanned versions or links to official schematics. |

| Service Manuals | Printed or digital service manuals usually include detailed diagrams and can be purchased through various retailers. |

Utilizing these resources will ensure you have the most accurate and helpful illustrations for your vehicle’s components, facilitating a smoother maintenance process.

Common Replacement Parts Explained

Understanding the essential components of an off-road vehicle can significantly enhance maintenance and performance. Certain items tend to require replacement more frequently due to wear and tear, usage conditions, and overall vehicle age. This section highlights the key elements that users should be aware of, ensuring that they can keep their machines running smoothly.

| Component | Description | Signs of Wear |

|---|---|---|

| Brake Pads | Essential for effective stopping power, these components wear down over time. | Squeaking noises, decreased braking efficiency. |

| Air Filter | Maintains engine performance by filtering out dirt and debris from the air intake. | Reduced engine power, increased fuel consumption. |

| Battery | Supplies electrical power to start the engine and run accessories. | Difficulties starting, dim lights, electrical issues. |

| Spark Plugs | Ignite the air-fuel mixture in the engine, crucial for optimal performance. | Inefficient acceleration, engine misfires. |

| Tires | Provide traction and support for off-road activities. | Uneven wear, low tread depth, loss of traction. |

How to Interpret Diagrams Effectively

Understanding visual representations of mechanical assemblies can significantly enhance your maintenance and repair skills. These illustrations often serve as a guide, depicting the relationship between various components and providing insights into their functions. By mastering the art of interpreting these visuals, you can streamline your workflow and avoid common pitfalls during assembly or disassembly processes.

Focus on the Legend and Symbols

Every illustration typically includes a legend or key that explains the symbols used throughout. Familiarizing yourself with these icons is crucial, as they often denote specific parts, connection types, or assembly sequences. Take the time to study this section thoroughly, as it will serve as a roadmap for navigating the visual information presented.

Follow the Flow of Assembly

Diagrams usually depict a logical sequence for assembling components. By following the arrows or lines that indicate connections, you can grasp the intended order of installation or removal. Pay close attention to any notes or annotations that provide additional context, as these can highlight important tips or cautionary advice to ensure successful assembly.

Tools Needed for Repairs

When embarking on maintenance or repair tasks, having the right tools is essential for efficiency and effectiveness. Proper equipment not only simplifies the process but also ensures safety and precision in handling various components. Investing in quality tools can greatly enhance the overall experience and outcome of any mechanical work.

Key instruments include wrenches for loosening and tightening bolts, screwdrivers for securing panels, and pliers for gripping and manipulating parts. Additionally, a socket set can provide versatility for various fasteners, while a torque wrench ensures that specifications are met accurately. Having a reliable tool kit on hand streamlines the repair process significantly.

Moreover, safety gear such as gloves and goggles is vital to protect against potential hazards during repairs. Depending on the complexity of the task, specialized tools like jacks or lifts may also be necessary to access hard-to-reach areas. By preparing a comprehensive set of tools, the repair journey can become more manageable and effective.

Step-by-Step Repair Process

Understanding the repair process for your all-terrain vehicle is essential for maintaining its performance and longevity. By following a systematic approach, you can effectively troubleshoot issues, replace worn components, and ensure everything operates smoothly. This section outlines a comprehensive method for executing repairs with clarity and precision.

Preparation and Assessment

Begin by gathering all necessary tools and replacement components. Conduct a thorough inspection of the vehicle to identify specific problems. Document any visible damage or irregularities, as this will guide your repair efforts. Always consult the manufacturer’s guidelines for reference, ensuring you have the correct information at hand before proceeding.

Execution of Repairs

Once you have assessed the situation, carefully disassemble the affected parts, taking care to keep track of screws and small components. Replace any damaged elements with new ones, ensuring they fit correctly. After reassembly, perform a functional test to verify that the issue has been resolved. Regular maintenance checks following repairs will help prevent future problems and enhance overall performance.

Maintenance Tips for Longevity

Ensuring the durability of your all-terrain vehicle requires regular upkeep and attention to detail. By following a few essential practices, you can significantly extend its lifespan and enhance performance.

Regular Inspections

- Check fluid levels frequently, including oil, coolant, and brake fluid.

- Inspect tires for wear and proper inflation.

- Examine the battery for corrosion and secure connections.

Routine Cleaning

- Wash the exterior regularly to prevent dirt buildup.

- Clean the air filter to ensure optimal airflow.

- Remove debris from the undercarriage to avoid rust and damage.

By incorporating these practices into your maintenance routine, you will ultimately enhance the performance and longevity of your vehicle.

Identifying Aftermarket Options

Exploring alternative components can significantly enhance the performance and customization of your all-terrain vehicle. Aftermarket offerings often provide a range of enhancements that may not be available through original equipment manufacturers. Understanding the available choices can lead to better performance, increased durability, and personalized modifications tailored to your specific riding style.

Benefits of Aftermarket Components

Opting for non-original replacements can present various advantages. These options frequently come at competitive prices while offering superior materials and advanced technology. Additionally, many aftermarket suppliers specialize in performance upgrades that can boost speed, handling, and overall efficiency.

Choosing the Right Supplier

When selecting aftermarket items, it’s essential to identify reputable suppliers. Look for those with positive customer reviews and a proven track record in the industry. Research their offerings thoroughly to ensure compatibility with your machine. Engaging with community forums can also provide valuable insights and recommendations from experienced riders.

Common Issues and Solutions

In the realm of off-road vehicles, various challenges can arise that impact performance and reliability. Understanding these common complications and their corresponding remedies is crucial for maintaining optimal functionality and enhancing the overall riding experience.

1. Engine Starting Difficulties

If the engine fails to start, it could be due to a drained battery or faulty connections. Ensure the battery is fully charged and check the terminals for corrosion. If the issue persists, inspect the ignition system and starter motor.

2. Overheating

Overheating can stem from inadequate coolant levels or a malfunctioning radiator. Regularly monitor coolant levels and inspect the radiator for blockages. If necessary, replace the coolant or repair any leaks in the cooling system.

3. Steering Problems

Issues with steering responsiveness may indicate low fluid levels in the steering system or worn-out components. Check the fluid and inspect the steering mechanism for wear. Replacing damaged parts can restore proper handling.

4. Brake Failure

Brake issues can arise from worn brake pads or low brake fluid levels. Regularly inspect the brake system and replace pads as needed. Always ensure that fluid levels are adequate for safe operation.

5. Electrical Failures

Electrical problems may manifest as flickering lights or malfunctioning accessories. Begin troubleshooting by checking fuses and wiring connections. If issues continue, consider consulting a professional for further diagnostics.

By being aware of these common problems and implementing appropriate solutions, riders can enhance the longevity and performance of their vehicles, ensuring a safer and more enjoyable experience on the trails.

Safety Precautions During Repairs

When engaging in maintenance or repair tasks, ensuring personal safety and the integrity of the equipment is paramount. Taking appropriate precautions can prevent accidents and injuries, creating a secure working environment.

Wear Protective Gear

Always equip yourself with the necessary protective gear, including gloves, goggles, and sturdy footwear. This attire helps shield against sharp objects, flying debris, and potential spills, minimizing the risk of injury during repairs.

Work in a Well-Ventilated Area

Conducting repairs in a properly ventilated space is crucial, especially when using chemicals or fuels. Adequate airflow reduces the accumulation of harmful fumes, promoting a safer atmosphere for working on machinery.

FAQs About Polaris Sportsman 550

This section addresses common inquiries regarding the all-terrain vehicle, providing essential insights for owners and enthusiasts alike. Understanding the intricacies of maintenance and operation can enhance the riding experience.

- What is the recommended maintenance schedule? Regular check-ups every 50 hours or annually are advised.

- How do I troubleshoot starting issues? Check the battery, ignition switch, and fuses before seeking professional help.

- What types of accessories can be added? Options include winches, plows, and storage solutions tailored for versatility.

- How do I improve handling in rough terrain? Consider upgrading tires and suspension components for better performance.

- Where can I find replacement components? Authorized dealers and online retailers offer a wide selection of items.