Maintaining optimal functionality in lawn care machinery is essential for efficient operation. A thorough understanding of the components that facilitate movement and direction is crucial for any operator or technician. This section will delve into the intricate elements that contribute to the maneuverability of these machines.

The assembly that governs the directional control plays a vital role in ensuring precise navigation across various terrains. Familiarity with the layout and function of each element not only aids in troubleshooting but also enhances overall performance. This guide aims to provide clarity on the arrangement and interaction of these vital components.

By exploring the intricacies of these systems, operators can gain valuable insights that empower them to execute repairs and maintenance with confidence. Enhanced knowledge leads to improved reliability and longevity of the equipment, ensuring that every job is performed efficiently and effectively.

Understanding John Deere LT155 Steering System

Exploring the functionality of the maneuvering mechanism in lawn maintenance machines reveals essential components that contribute to their efficiency and ease of use. A well-designed apparatus allows for smooth navigation and precise handling, ensuring optimal performance in various terrains.

Key Components of the Maneuvering Mechanism

- Column Assembly: This crucial element connects the operator’s control to the wheels, allowing for responsive turns.

- Control Linkage: The series of rods and joints that transmit the operator’s commands to the moving parts.

- Bearings: These facilitate smooth rotation and reduce friction within the system.

- Adjustment Mechanisms: Tools that enable fine-tuning of alignment and responsiveness for better handling.

Maintenance Tips for Longevity

- Regularly inspect the connections and components for wear and tear.

- Lubricate moving parts to prevent friction and enhance performance.

- Check alignment periodically to ensure optimal handling.

- Replace any damaged or worn components promptly to avoid further issues.

Understanding the intricacies of this apparatus can greatly enhance the operational lifespan and efficiency of lawn care equipment. Proper knowledge and maintenance practices will ensure a smoother experience for the operator and improved results in the field.

Key Components of Steering Assembly

The assembly responsible for directional control consists of several essential elements that ensure smooth maneuverability and precision. Understanding these components is crucial for maintenance and troubleshooting.

Main Elements

- Control Wheel

- Linkage System

- Pivot Points

- Support Structures

Functionality Overview

Each element plays a vital role in translating the operator’s input into movement. Proper interaction among these components allows for effective navigation and responsiveness.

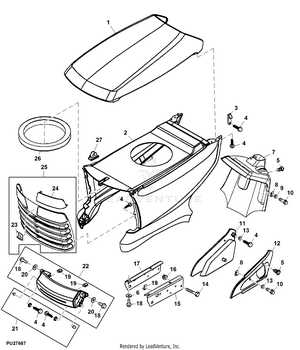

Importance of Steering Diagrams

Understanding the layout and components of control systems is crucial for effective maintenance and repair. Visual representations not only facilitate a clearer understanding but also aid in troubleshooting issues that may arise in machinery. Such illustrations serve as essential guides for both novices and experienced technicians, ensuring accuracy and efficiency in the repair process.

Enhancing Maintenance Efficiency

Detailed visuals enable users to quickly identify parts, leading to faster decision-making and reduced downtime. When technicians can easily reference a comprehensive layout, they are empowered to address issues more confidently and accurately, ultimately enhancing overall operational efficiency.

Facilitating Knowledge Transfer

Diagrams play a vital role in training and education. They provide a standardized way to convey complex information, making it easier for learners to grasp intricate concepts. This shared understanding promotes better collaboration among team members, fostering a culture of knowledge-sharing within the workplace.

How to Read Steering Parts Diagrams

Understanding technical illustrations is crucial for anyone involved in machinery maintenance or repair. These visuals provide essential information on the various components and their relationships within a system. By learning to interpret these representations, you can effectively troubleshoot issues and perform repairs with confidence.

Identifying Components

The first step in deciphering these illustrations is to familiarize yourself with the symbols used. Each part is often represented by a specific icon or label. Take note of any legends or keys included, as they provide context and explain what each symbol signifies. This understanding is vital for accurately identifying the elements you need to work on.

Understanding Connections

In addition to recognizing individual components, it is important to grasp how they interact with one another. Look for lines or arrows that indicate connections or movements. These elements can show how parts function together, which is essential for diagnosing problems. Pay attention to any notes or annotations, as they may highlight important details regarding assembly or adjustment.

With practice, interpreting these technical illustrations will become a valuable skill, enabling you to navigate repairs more efficiently and effectively.

Common Issues in LT155 Steering

When it comes to maneuvering issues in certain lawn machinery, several challenges can arise that affect performance and control. Understanding these common problems can help users maintain optimal functionality and enhance their experience.

- Loose Connections: Over time, components can become loose, leading to ineffective navigation.

- Worn Out Components: Parts such as gears and linkages may degrade, impacting the overall response.

- Hydraulic Issues: If hydraulic fluid levels are low or there are leaks, control can become sluggish.

- Misalignment: Improper alignment can cause difficulty in turning and affect maneuverability.

Regular inspection and maintenance are essential to address these challenges effectively. Keeping an eye on the machinery’s performance can ultimately lead to a smoother operation and longer lifespan.

Replacement Parts for Steering Mechanism

When maintaining the directional control system of your equipment, it is crucial to consider the various components that ensure smooth operation. Over time, wear and tear may necessitate the substitution of specific elements to restore optimal functionality. This section will explore the essential replacements that contribute to a responsive and efficient maneuvering experience.

Common Components Needing Replacement

Key components that often require replacement include the pivot arms, linkages, and control rods. These elements are subject to stress and can degrade over time, leading to diminished performance. Regular inspections can help identify issues early, preventing more extensive repairs.

Benefits of Using Quality Replacements

Utilizing high-quality replacements enhances durability and improves handling. Investing in reliable components not only ensures better performance but also extends the lifespan of the entire mechanism. By prioritizing quality, users can enjoy a smoother operation and reduce the likelihood of future malfunctions.

Tools Needed for Steering Repairs

When addressing issues with the maneuverability or control of a vehicle, the right equipment is crucial to ensure both efficiency and safety. In this section, we will outline the essential tools required for making adjustments, replacements, and general fixes to the mechanism responsible for turning and direction control.

Basic Hand Tools

For most repairs, standard hand tools will cover the majority of tasks. These include various wrenches, screwdrivers, and pliers. Having a range of socket sizes and types of drivers will be important to handle different components, ensuring that bolts and nuts of different sizes can be properly secured or removed.

Specialty Tools

Certain repairs may require specialized tools that are designed for precision work. These could include pullers to remove tightly fitted parts,

Step-by-Step Steering Repair Process

Ensuring the smooth operation of your equipment’s navigation system is crucial for its overall performance. Over time, components responsible for directional control can wear out, leading to difficulty in maneuvering. This guide will walk you through the process of restoring full functionality to your machine, focusing on the key steps for repair and maintenance.

Tools and Materials Required

- Wrenches of various sizes

- Socket set

- Grease or lubrication oil

- Replacement bushings, gears, or rods

- Jack or lift system

Step-by-Step Procedure

- Preparation: Park the machine on a fl

Preventive Maintenance for Steering Systems

Ensuring the longevity and smooth operation of your equipment’s maneuvering mechanisms requires regular and thorough care. Proper upkeep reduces the likelihood of unexpected breakdowns and ensures consistent performance over time. Proactive maintenance not only extends the life of components but also enhances the overall safety and reliability of the machine during operation.

Inspection and Lubrication

Regularly inspecting all moving elements is key to avoiding excessive wear. It’s essential to look for signs of corrosion, dirt accumulation, or physical damage that could hinder movement. Proper lubrication of these components reduces friction and helps maintain smooth operation. Always use the appropriate type of lubricant specified for the system, as it prevents premature wear and enhances longevity.

Alignment and Adjustment

Frequent checks for misalignment or improper movement play a critical role in maintaining accuracy and control. Small adjustments made early can prevent bigger, costlier issues

Upgrades for Enhanced Steering Performance

Improving control and maneuverability of a lawn tractor can greatly enhance both efficiency and ease of use. Implementing key modifications can reduce effort required for handling and improve overall precision, making tasks smoother and more enjoyable. The following upgrades focus on increasing responsiveness and stability, offering a more refined experience when navigating challenging terrain.

Optimized Linkage Components

Upgrading linkage mechanisms with reinforced materials and improved design ensures smoother motion and reduces friction. This leads to more precise movements, offering greater accuracy in navigation. High-quality materials also enhance durability, ensuring that these parts withstand the rigors of regular use, especially in tough working conditions.

Improved Bearing Systems

Installing advanced bearing systems can significantly reduce wear and tear, allowing for better fluidity in motion. Bearings with low-resistance properties help minimize drag,

Finding Original Replacement Components

When it comes to ensuring the longevity and performance of your machinery, sourcing authentic replacement components is essential. These high-quality elements not only fit perfectly but also meet the original equipment standards. Opting for genuine parts guarantees smooth operation and avoids potential complications that can arise from using aftermarket alternatives.

To identify and order the right component, you should follow a few straightforward steps. Understanding model specifications and using official resources will greatly simplify this process. Below is a useful table with tips for locating the appropriate elements for your equipment.

Step Description 1 Check the official manual or online catalog for the component number. 2 Visit an authorized dealer or use certified online platforms for purchases. 3 Confirm compatibility by cross-referencing th DIY vs. Professional Steering Repairs

When it comes to addressing mechanical issues in your lawn equipment, a common question arises: should you handle the repairs yourself or hire a professional? This choice depends on several factors, including the complexity of the problem, your technical skills, and the cost of repair. Both approaches offer distinct advantages and potential drawbacks.

Advantages of DIY Repairs

For those with basic mechanical knowledge, tackling a repair job on your own can be a cost-effective solution. DIY repairs allow you to learn more about your equipment, save on labor fees, and have greater control over the repair process. Many guides and online tutorials can provide step-by-step instructions, making it easier to manage minor issues.

Benefits of Professional Assistance

Hiring an expert ensures that the job is done accurately and efficiently. Trained technicians have the experience to quickly diagnose problems and access specialized tools. This minimizes the risk of further damage and ensures that the

FAQs About LT155 Steering Parts

In this section, we will answer the most common questions regarding the components responsible for controlling the direction and handling of the vehicle. These elements are crucial for smooth maneuverability, and understanding them can help maintain and repair the equipment efficiently.

What are the signs of worn directional components?

When certain elements responsible for navigation wear out, users might notice increased difficulty when turning, looseness in the controls, or uneven response during operation. It’s important to inspect these issues early to avoid more significant problems.

How often should these components be inspected?

Regular check-ups are recommended, especially if the equipment is used frequently or in tough conditions. Annual main