For enthusiasts and operators of lawn maintenance machinery, comprehending the intricate elements that facilitate maneuverability is essential. A comprehensive exploration of these components not only enhances performance but also aids in troubleshooting common issues that may arise during operation.

The functionality of these control mechanisms is paramount for achieving precision in navigation across various terrains. Knowledge of their layout and interconnections enables users to maintain optimal efficiency and prolong the lifespan of their equipment.

This guide aims to provide a clear overview of the essential elements involved in the control system, offering insights into their arrangement and roles. With this understanding, operators can confidently address any challenges and ensure smooth operation of their machinery.

Understanding John Deere LX277

This section explores the essential features and components of a popular riding mower model. Emphasizing its design, functionality, and key attributes, we aim to provide insights that enhance user experience and maintenance practices. Knowledge of these elements ensures optimal performance and longevity of the machine.

Key Features

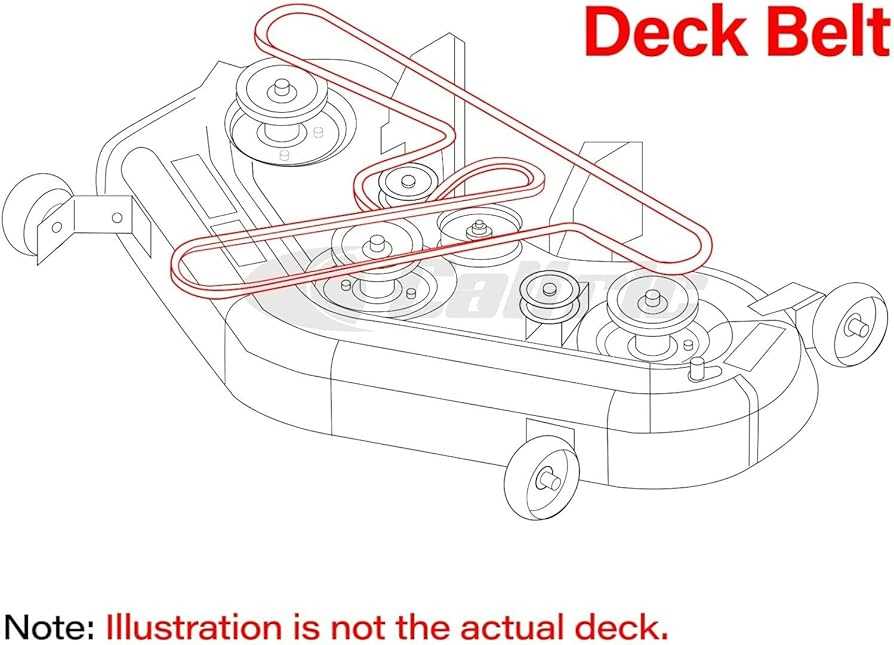

This model is recognized for its robust construction and user-friendly controls. Notable attributes include a powerful engine, reliable cutting system, and ergonomic seating, making it suitable for various lawn care tasks. The efficient operation contributes to a seamless mowing experience.

Maintenance and Care

| Component | Function |

|---|---|

| Engine | Powers the mower for efficient operation |

| Transmission | Controls speed and movement direction |

| Cutting Deck | Ensures precise grass cutting |

| Wheels | Provide stability and maneuverability |

| Battery | Supplies energy to start the engine |

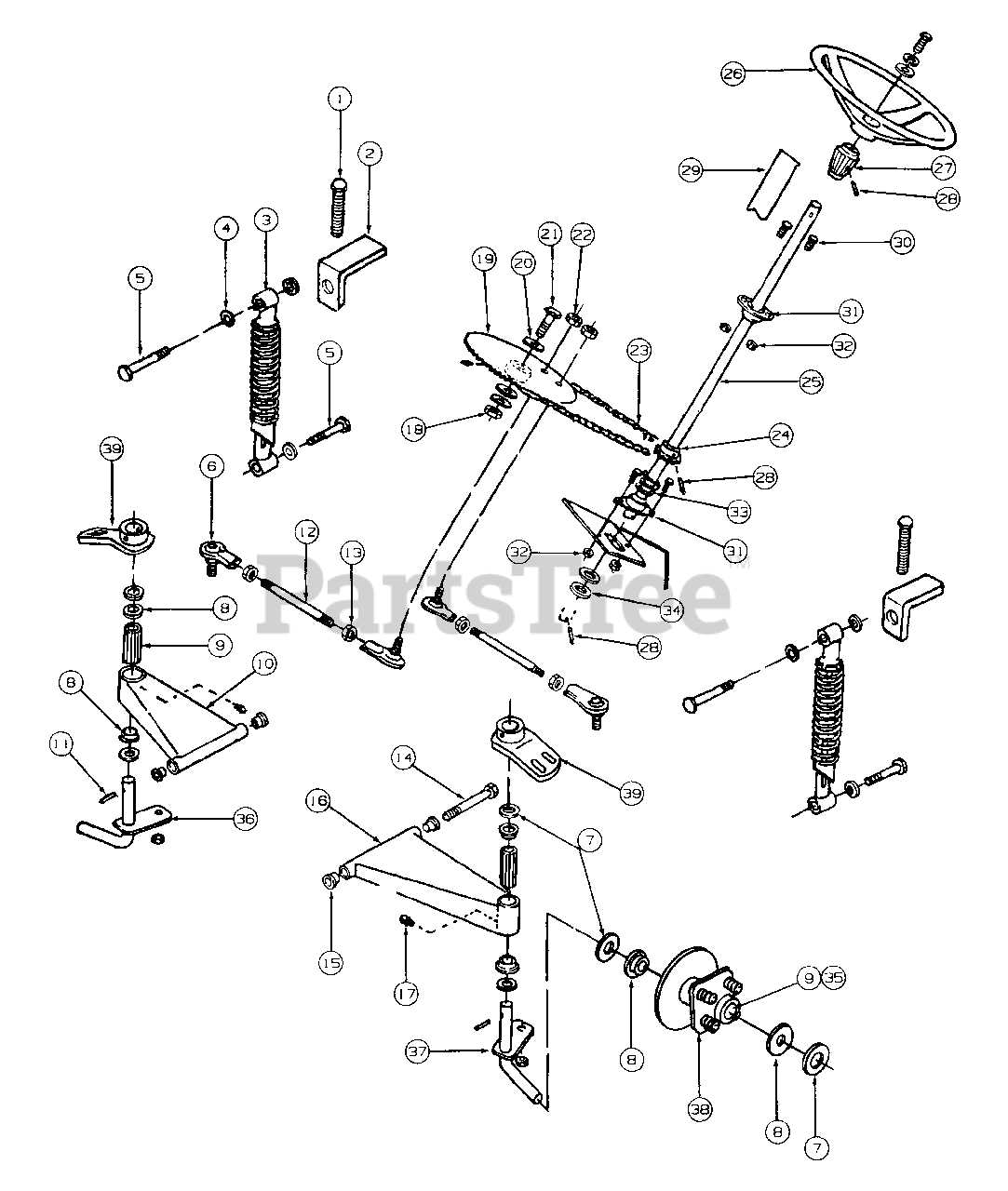

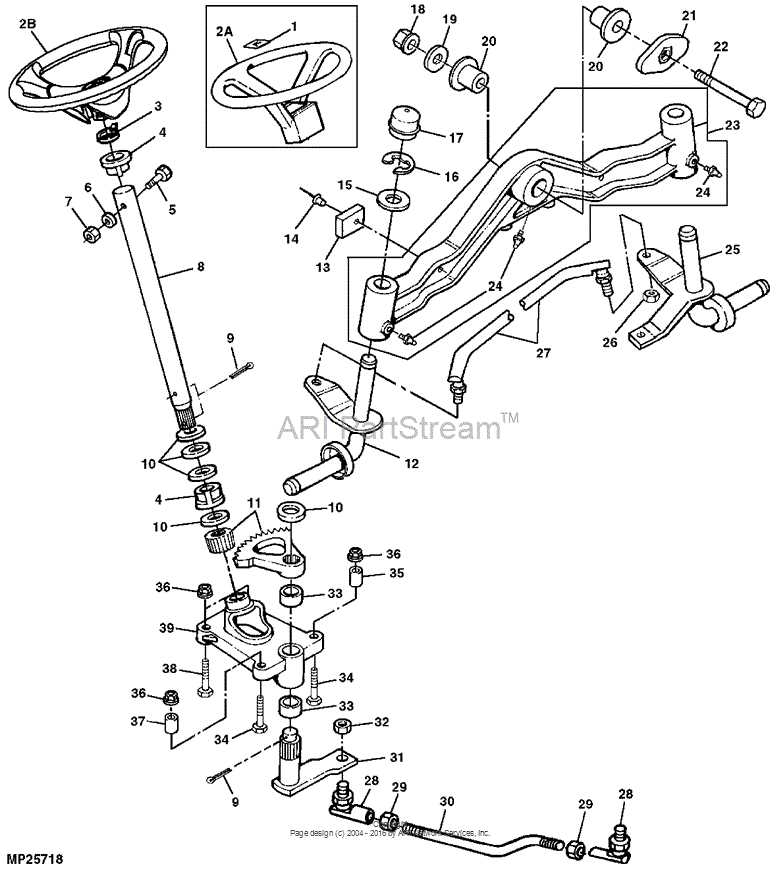

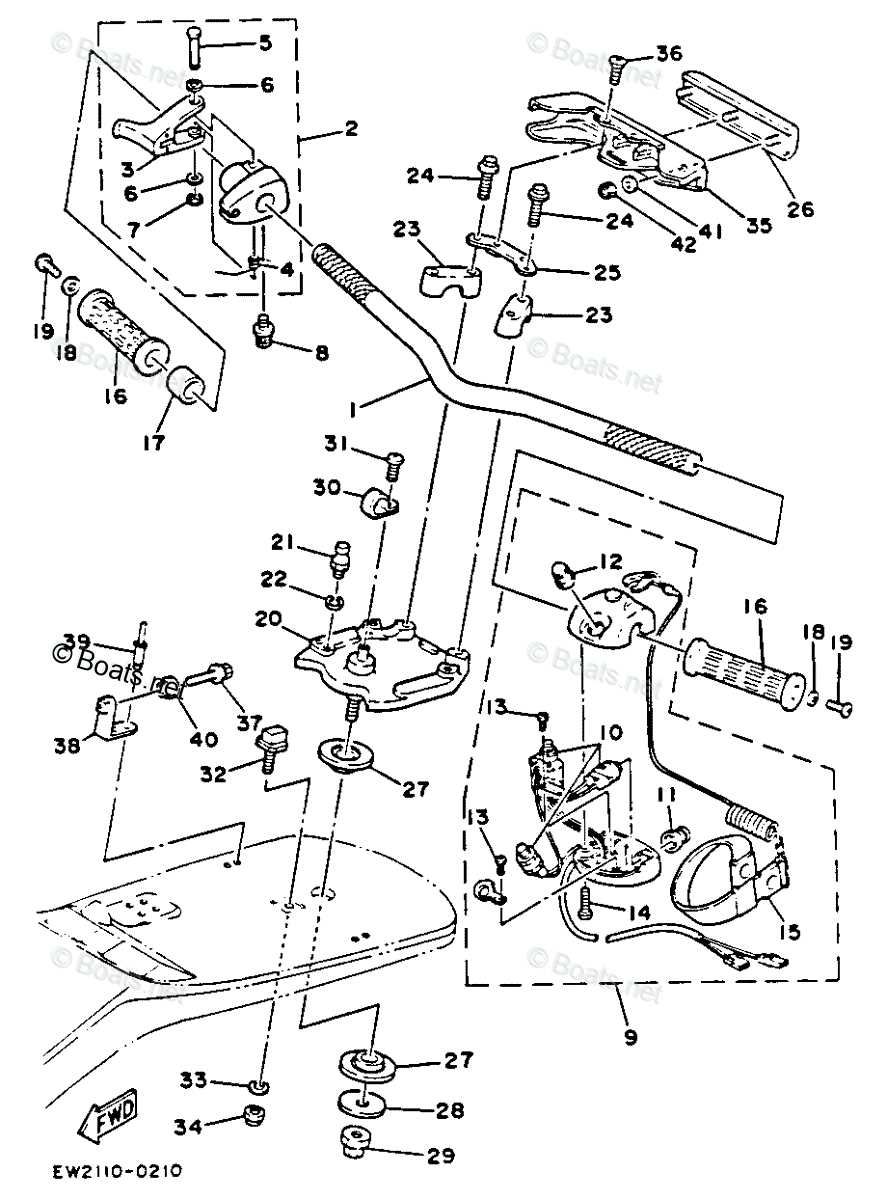

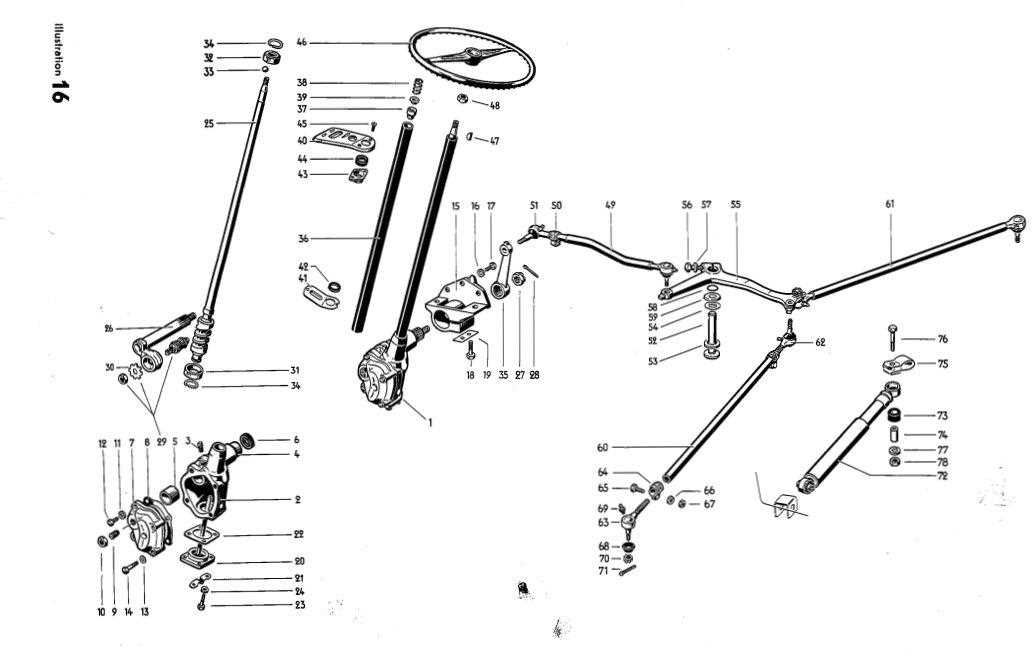

Steering System Overview

The mechanism responsible for directing the movement of a vehicle is a vital component that ensures precision and control during operation. This system consists of various elements working together to facilitate the user’s commands and maintain stability. Understanding the intricacies of this arrangement is essential for proper maintenance and functionality.

At its core, the assembly encompasses several crucial components that interact seamlessly. These elements include linkages, gears, and actuators, all designed to transmit force and allow for smooth navigation. Each part plays a significant role in enhancing responsiveness, ensuring that the operator can maneuver effectively across different terrains.

Regular inspection and upkeep of this system are critical. Wear and tear can lead to diminished performance and, in some cases, safety hazards. Therefore, identifying potential issues early and addressing them through replacement or repair is vital for sustaining optimal operation and prolonging the lifespan of the entire vehicle.

Moreover, advancements in technology have introduced innovative designs that enhance efficiency and ease of use. Understanding these developments can empower users to make informed decisions when it comes to upgrades or modifications, ultimately improving their overall experience.

Common Issues with Steering Parts

Various challenges can arise with the control mechanisms of machinery, impacting their performance and maneuverability. Recognizing these problems is crucial for effective maintenance and ensuring operational efficiency.

| Issue | Description |

|---|---|

| Worn Components | Over time, frequent use can lead to the deterioration of essential elements, affecting responsiveness. |

| Misalignment | Improper adjustments can cause elements to be out of sync, leading to difficulty in handling. |

| Fluid Leaks | Leaks can result in inadequate lubrication, leading to increased friction and wear. |

| Loose Connections | Connections that become loose may result in instability and reduced control, impacting overall functionality. |

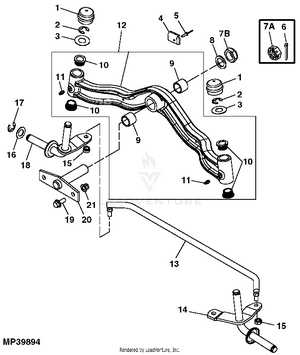

Identifying Key Components

Understanding the essential elements of a maneuvering system is crucial for effective maintenance and operation. Each component plays a specific role in ensuring smooth navigation and control. Familiarity with these parts can greatly enhance troubleshooting and repair processes.

- Control Mechanism: The primary interface for directing movement, allowing the operator to navigate with precision.

- Linkages: These connectors transmit force from the control mechanism to the wheels, ensuring responsiveness.

- Pivot Points: Critical for enabling rotation and flexibility, allowing for sharp turns and agile movements.

- Support Framework: The structural base that houses and secures the components, providing stability during operation.

Recognizing and understanding these key elements will not only aid in efficient repairs but also enhance overall performance. Regular inspection and maintenance of these components can prevent potential issues and extend the life of the equipment.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of your equipment. By implementing a few straightforward practices, you can enhance performance, reduce wear, and avoid costly repairs. This section highlights key strategies to maintain optimal functionality and durability.

Regular Inspections

Conducting routine checks is crucial for identifying potential issues before they escalate. Examine all components, paying close attention to wear and tear. Look for signs of damage or loose fittings. Addressing minor problems early can save significant time and money in the long run.

Lubrication and Cleaning

Keeping all moving elements well-lubricated is vital for smooth operation. Regularly apply appropriate lubricants to reduce friction and prevent corrosion. Additionally, clean the machine frequently to remove dirt and debris that can cause blockages or damage over time. Maintaining a clean and lubricated system is key to achieving longevity.

Tools Needed for Repairs

When tackling maintenance tasks on machinery, having the right instruments is essential for efficient and effective work. Proper tools not only enhance the repair process but also ensure safety and accuracy.

- Wrenches: Various sizes to fit different bolts and nuts.

- Screwdrivers: Both flathead and Phillips for removing screws.

- Pliers: Useful for gripping and twisting components.

- Socket set: For easy access to hard-to-reach fasteners.

- Torque wrench: To ensure bolts are tightened to the correct specifications.

Gathering these essentials will prepare you to delve into repairs with confidence, leading to the ultimate restoration of your equipment.

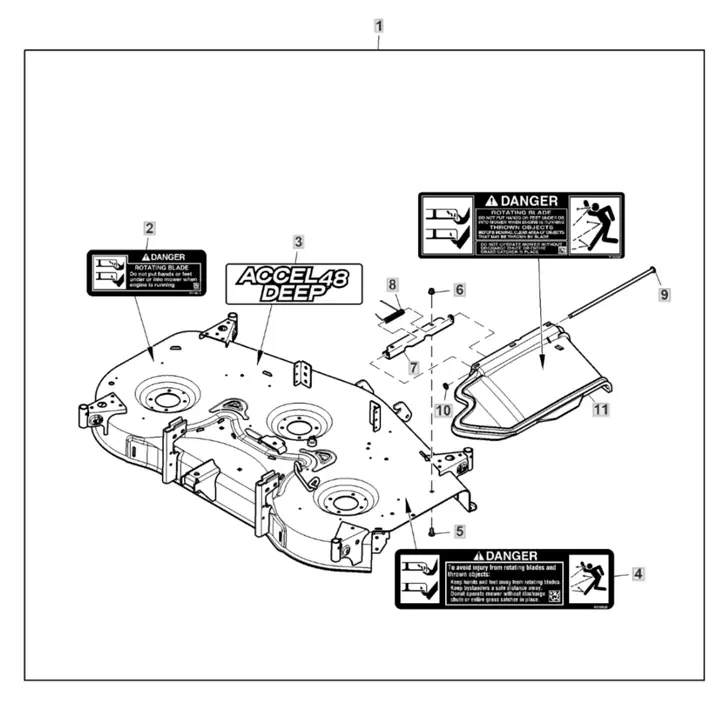

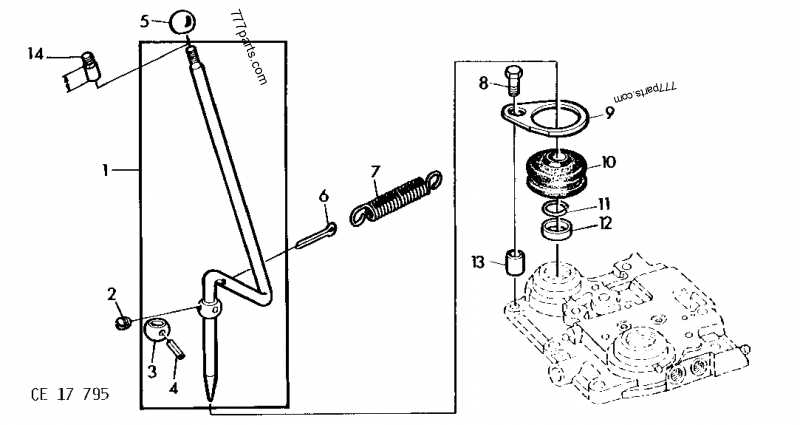

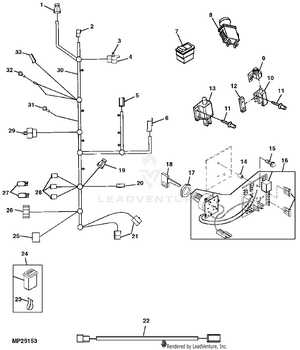

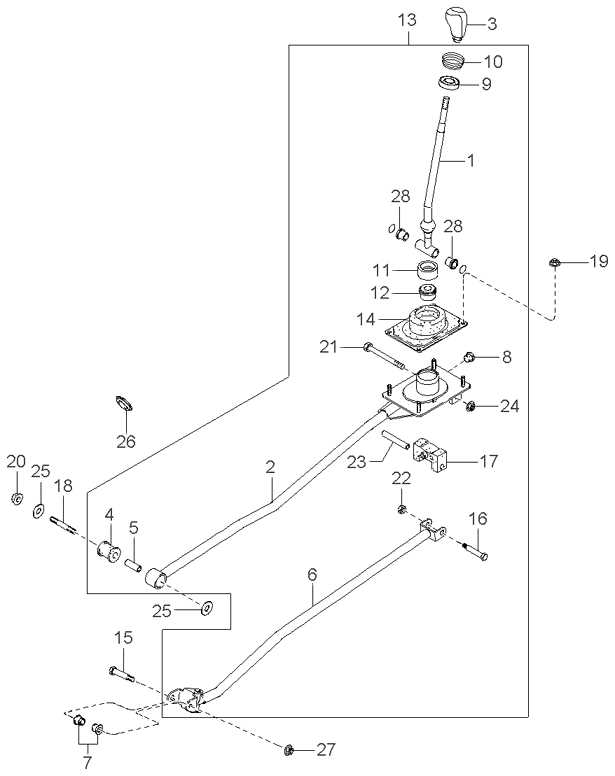

How to Read a Parts Diagram

Understanding a technical illustration can be crucial for effective maintenance and repairs. These visual representations provide essential insights into the components of machinery, allowing users to identify, locate, and replace specific elements as needed. By familiarizing yourself with the layout and symbols used in these graphics, you can streamline your repair process and ensure accuracy in your work.

Step 1: Familiarize Yourself with the Layout

Begin by examining the overall structure of the illustration. Typically, components are arranged in a logical manner, reflecting their physical assembly. Pay attention to how parts are grouped together, as this can indicate their relationships and functionality within the system.

Step 2: Identify Symbols and Labels

Many illustrations include various symbols or notations to represent different components. These might include letters, numbers, or specific icons. Refer to the accompanying legend or key to decipher what each symbol means, ensuring you correctly identify each part.

Step 3: Follow the Connections

Look for lines or arrows that indicate how parts connect or interact with one another. Understanding these relationships can provide clarity on how to disassemble or reassemble the equipment properly. This step is particularly important for complex systems where components may overlap or influence one another.

Step 4: Take Notes

As you analyze the illustration, consider jotting down notes or marking key components. This practice can be beneficial during the repair process, allowing you to track which items you need to purchase or replace. Clear documentation can also help prevent confusion when multiple components are involved.

Step 5: Consult Additional Resources

If certain elements remain unclear, don’t hesitate to seek out additional documentation or online resources. Forums, tutorials, and manufacturer guides can provide further explanations and examples, enriching your understanding and enabling you to tackle repairs with confidence.

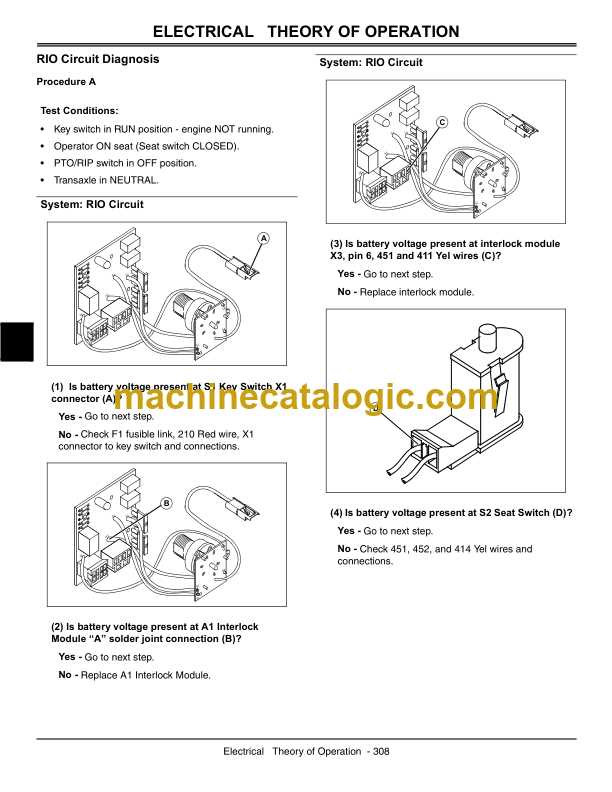

Step-by-Step Repair Guide

This guide offers a comprehensive approach to addressing issues related to the directional control system of your equipment. By following these detailed instructions, you can effectively troubleshoot and rectify common problems, ensuring optimal performance and longevity of the machinery.

1. Gather Necessary Tools

Before starting the repair process, collect all required tools, including wrenches, screwdrivers, and replacement components. Having everything at hand will streamline your efforts and reduce downtime.

2. Safety First

Ensure that the machine is turned off and disconnected from any power source. Wear appropriate safety gear, such as gloves and goggles, to protect yourself during the repair.

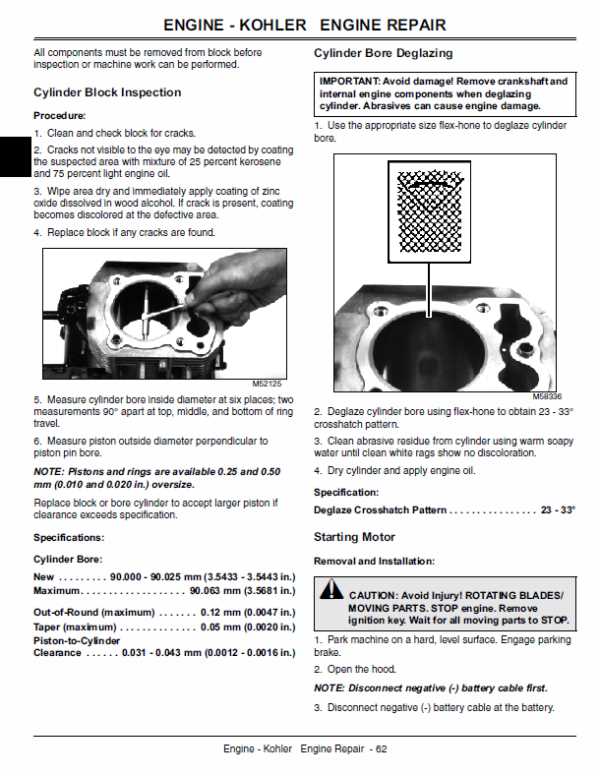

3. Identify the Issue

Begin by diagnosing the problem. Look for signs of wear, loose connections, or any visible damage. Document your findings to help guide the repair process.

4. Disassemble the Assembly

Carefully remove the necessary components to access the affected area. Keep track of all screws and small parts to facilitate reassembly later. Use a systematic approach to avoid confusion.

5. Inspect and Replace Components

Examine all parts thoroughly. Replace any damaged or worn components with new ones. Ensure that all replacements match the specifications required for your model.

6. Reassemble and Test

Once replacements are made, reassemble the unit carefully, ensuring everything is tightened and secure. Conduct a test run to verify that the directional system is functioning correctly and efficiently.

7. Final Checks

After testing, perform a final inspection to ensure that no tools or loose parts are left behind. Monitor the system during initial use to confirm that repairs were successful.

Where to Buy Replacement Parts

Finding quality components for your machinery can greatly enhance its performance and longevity. It’s essential to choose reliable sources to ensure you receive durable and compatible items. Below are some effective options for acquiring these necessary components.

Online Retailers

- Specialty websites that focus on agricultural and outdoor equipment often carry a wide range of options.

- Marketplaces such as Amazon or eBay may have both new and refurbished items.

- Manufacturer’s official websites usually provide original components with specifications that match your model.

Local Dealers and Distributors

- Authorized dealerships can offer expertise and genuine components tailored for your machinery.

- Local repair shops often have a network of suppliers and may assist in sourcing specific items.

- Check hardware and equipment stores for a selection of common components that may meet your needs.

Choosing the right vendor can make all the difference in maintaining the efficiency of your equipment. Consider factors such as customer service, return policies, and product warranties when making your decision.

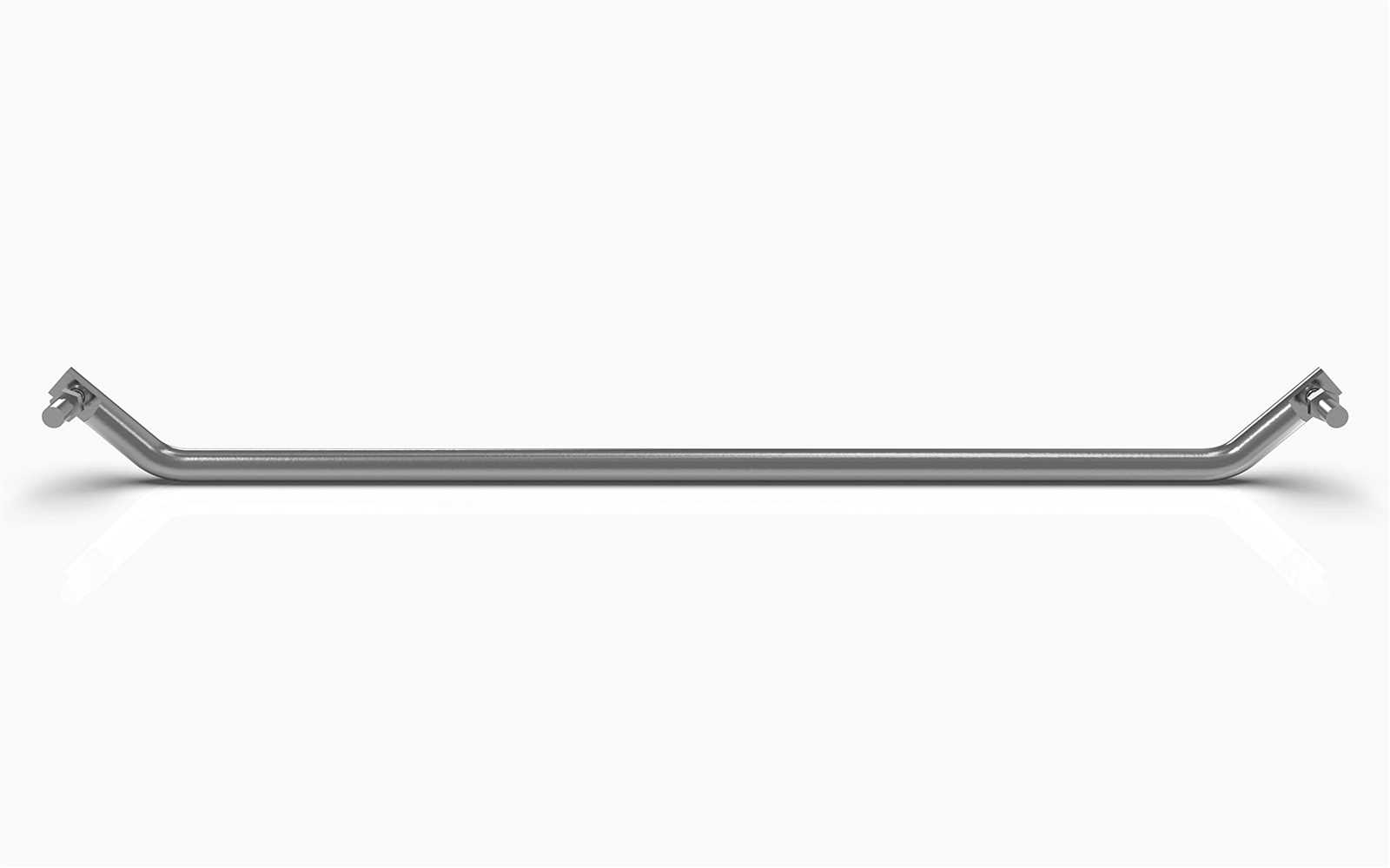

Upgrading Steering Components

Enhancing the maneuverability of your machinery can significantly improve overall performance and user experience. By investing in advanced mechanisms, operators can achieve smoother control and greater responsiveness.

- Evaluate current functionality to identify areas for improvement.

- Research modern alternatives that offer better durability and precision.

- Consider ergonomic designs to reduce operator fatigue.

Upgrading may involve:

- Replacing outdated mechanisms with newer, more efficient models.

- Incorporating adjustable features for personalized control.

- Utilizing high-quality materials for longevity and reliability.

Ultimately, these enhancements not only boost performance but also contribute to safer and more enjoyable operation.

Importance of Proper Alignment

Maintaining accurate alignment within machinery is crucial for optimal performance and longevity. Misalignment can lead to excessive wear and tear on components, resulting in costly repairs and decreased efficiency. Ensuring that all elements are correctly positioned minimizes friction and allows for smoother operation, which ultimately enhances productivity.

Moreover, proper alignment plays a significant role in safety. When machinery functions as intended, the risk of accidents or malfunctions decreases significantly. Regular checks and adjustments can prevent potential hazards, ensuring a safer working environment for operators.

Additionally, well-aligned systems contribute to better fuel efficiency and reduced energy consumption. When components operate harmoniously, the strain on the engine and other mechanisms is lessened, leading to overall cost savings over time. Investing in alignment not only protects the equipment but also promotes sustainable practices.

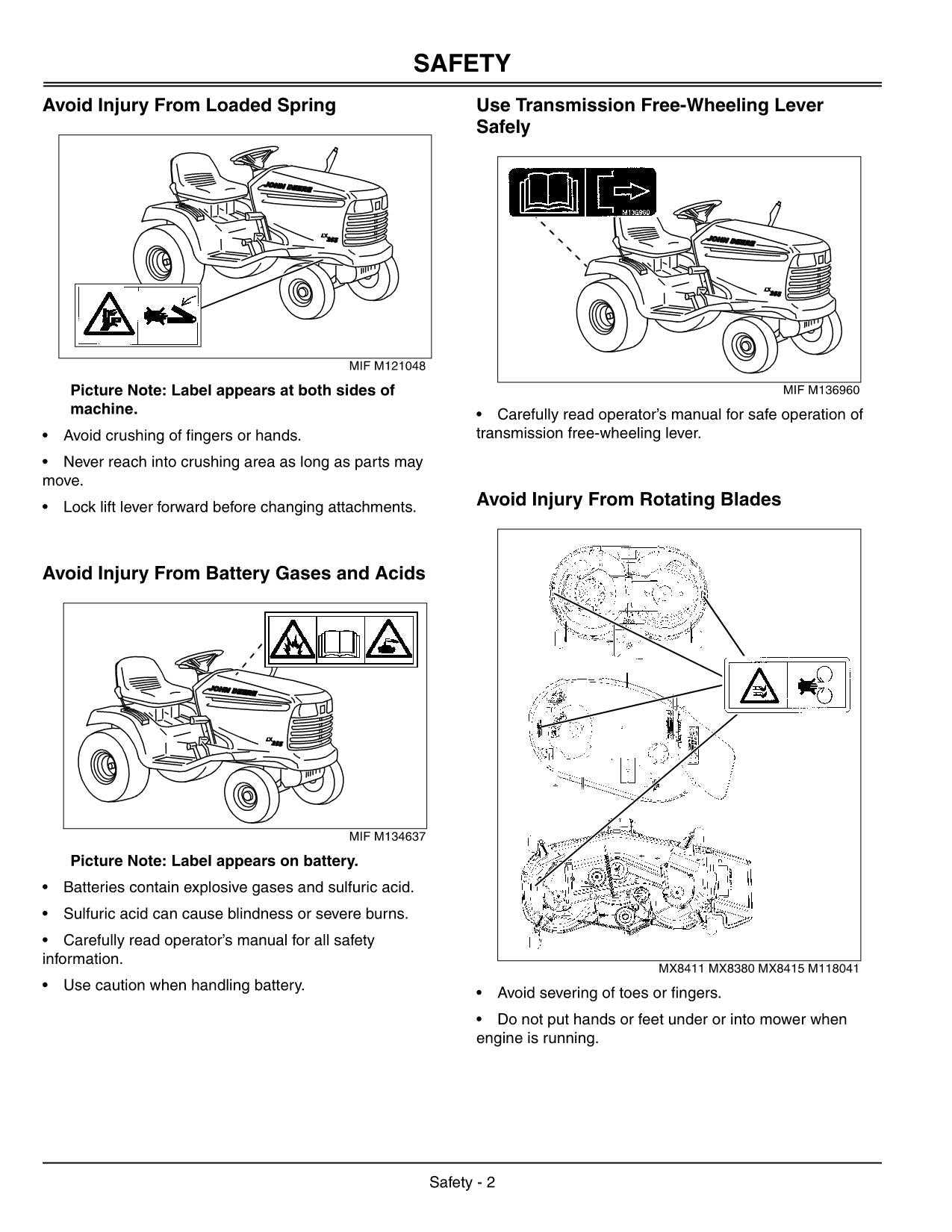

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both personal well-being and the longevity of equipment. Proper precautions help prevent accidents and injuries, enabling a smoother and more efficient repair process.

Before starting any repair work, consider the following essential guidelines:

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the work area is clean and well-lit to minimize hazards.

- Disconnect the power source to prevent accidental startups during repairs.

- Keep tools organized and within reach to avoid unnecessary movements.

Additionally, follow these steps for a safer repair experience:

- Read the manufacturer’s instructions thoroughly before beginning any work.

- Use the correct tools for each task to avoid damage and ensure efficiency.

- Inspect all equipment and components for wear and tear before reassembly.

- Work in pairs when handling heavy or cumbersome parts to reduce strain and risk of injury.

By adhering to these safety measures, individuals can conduct repairs with greater confidence, reducing the likelihood of accidents and ensuring a successful maintenance operation.

Customer Reviews and Feedback

This section highlights the experiences and opinions of users regarding their machinery, focusing on various components and their performance. Understanding customer insights can provide valuable information for potential buyers and help improve future designs and functionalities.

| Customer Name | Review Summary | Rating (Out of 5) |

|---|---|---|

| Mike T. | Excellent durability and performance in tough conditions. | 5 |

| Susan R. | Great value for money, but installation was tricky. | 4 |

| Tom W. | Overall satisfied, though I’ve experienced minor issues. | 3 |

| Linda J. | Impressive responsiveness, made operation smoother. | 5 |

| Kevin B. | Had to replace some components sooner than expected. | 2 |