When it comes to maintaining the smooth operation of handling mechanisms, it is crucial to understand the intricate assembly of various elements involved. These systems, designed for controlling and maneuvering, rely on precise alignment and quality components. Ensuring their proper maintenance not only extends the lifespan of the equipment but also enhances overall functionality.

Understanding the importance of these systems requires a closer look at their structure and how each element interacts with one another. Whether it’s for routine checks or comprehensive overhauls, knowing where each component fits is essential for optimal performance. Properly maintaining these elements can prevent unexpected issues and improve efficiency.

In this guide, we will explore the key assemblies that contribute to smooth and responsive handling, providing a clear understanding of their layout and purpose. With this knowledge, you can ensure that your equipment continues to perform at its best.

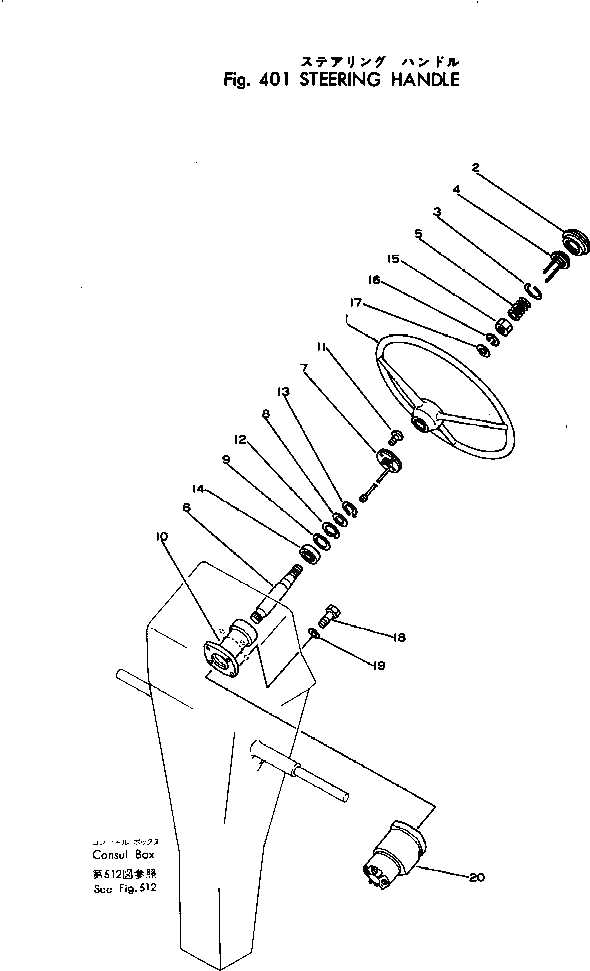

Understanding the Steering System of STX38

The control mechanism responsible for guiding this equipment is a complex assembly that ensures smooth and responsive maneuverability. It’s built with precision to allow accurate control, especially during tight turns or on uneven terrain. In this section, we’ll explore the key components and how they contribute to the machine’s navigation capabilities.

Key Components Involved in the Control Mechanism

- Control Wheel Assembly: This essential part transfers input from the operator to the system, ensuring accurate movement.

- Linkage Rods: These metal rods connect the control wheel to the guiding mechanism, converting manual input into physical motion.

- Rotation Axis: Allows the equipment to turn smoothly by pivoting the system around a central point.

Maintenance Tips for Optimal Performance

- Regularly inspect and lubricate all moving joints to prevent wear and ensure smooth operation.

- Ensure you have all necessary tools ready, such as wrenches, sockets, and any specific equipment for the task.

- Refer to the manual for details on the parts and their assembly, as accuracy in installation is crucial.

- Inspect surrounding areas for signs of wear or damage that might affect the overall system once the new components are installed.

- Begin by safely securing the machine to prevent movement while you work on the mechanism.

- Carefully remove the old components, noting the order in which they are dis

Overview of STX38 Steering Assembly

The guiding system in this model is designed with precision to ensure smooth maneuverability and reliability. It consists of interconnected elements that work in harmony to provide control and stability during operation. Understanding how these components function together can help in maintaining efficient performance.

Key components of the assembly include the primary linkage and various control mechanisms. These are essential for translating the user’s input into directional movement, allowing for accurate navigation and ease of use.

By examining each part of the guiding system, one can identify areas that may require attention, ensuring long-term functionality. Proper maintenance and understanding of this mechanism are crucial for optimal operation in various conditions.

Maintenance Guide for Steering Mechanism

Regular upkeep of the control system is essential for ensuring smooth and precise operation. Addressing issues before they escalate can extend the lifespan of the system and prevent costly repairs. This guide covers key practices to maintain optimal performance and avoid common problems.

Lubrication of Moving Components

One of the most important steps in maintaining the control mechanism is proper lubrication. All joints, bearings, and movable elements should be inspected and greased regularly to reduce friction and wear. A high-quality lubricant can protect these parts from rust and corrosion, ensuring longevity.

Inspection of Wear and Tear

It’s crucial to routinely check for signs of wear, such as cracks, loose connections, or misalignment. Any damaged components should be replaced immediately to maintain precise functionality. Tightening any loosened fasteners will also contribute to a more

Choosing the Right Replacement Parts

When selecting suitable components for repair or maintenance, it’s essential to focus on quality and compatibility. Opting for reliable alternatives ensures that your equipment functions smoothly and safely. Considering the specific needs of your machinery can lead to better performance and longevity.

Durability should be a top priority when evaluating replacement options. High-quality materials often translate to fewer issues over time, reducing the need for frequent repairs.

Additionally, compatibility plays a key role in ensuring the new elements integrate well with the existing system. Carefully matching specifications guarantees a seamless fit and avoids complications during installation.

Common Issues with STX38 Steering

Maintaining the proper functioning of a vehicle’s control system is essential for its overall performance. Over time, several challenges can arise that may impact the smoothness and precision of handling.

- Loose control linkage: With regular use, the connections within the control mechanism can loosen, leading to less responsive movement.

- Wear on key components: Certain parts within the system are prone to wear, especially after extensive operation. This can result in decreased control efficiency.

- Alignment issues: Misalignment can develop gradually, causing uneven movement or difficulty when turning.

- Lubrication problems: Inadequate lubrication of key points within the control system can lead to stiffness, making operation more difficult.

- Component fatigue: Continuous use can cause certain elements to weaken, which may lead to unexpected malfunctions.

Steps to Improve Steering Performance

Enhancing the maneuverability and responsiveness of your machinery involves several essential actions. By addressing various components and implementing regular maintenance practices, you can significantly boost performance and ensure a smoother operation.

- Regular Inspection: Frequently check all relevant components for wear and tear. Look for signs of damage or excessive play that may hinder performance.

- Lubrication: Ensure all moving parts are adequately lubricated to minimize friction. Use appropriate lubricants to enhance longevity and functionality.

- Alignment Adjustment: Verify that all components are properly aligned. Misalignment can lead to uneven wear and diminished control.

- Tightening Connections: Periodically inspect and tighten all bolts and connections. Loose components can cause instability and reduced effectiveness.

- Replacement of Worn Components: Identify and replace any worn or damaged parts immediately. This step is crucial for maintaining optimal performance.

Implementing these steps will help maintain and improve the overall handling of your equipment, leading to enhanced efficiency and safety during operation.

Importance of Regular Steering Inspections

Routine evaluations of directional control mechanisms are crucial for ensuring safe and efficient operation of any vehicle or machinery. Regular assessments help identify potential issues before they escalate, promoting longevity and reliability.

Benefits of Routine Evaluations

- Safety: Frequent checks help detect wear and tear that could lead to accidents or loss of control.

- Performance: Keeping the directional system in optimal condition ensures smooth maneuverability.

- Cost-Effectiveness: Early identification of problems can prevent costly repairs and part replacements.

Key Components to Inspect

- Alignment of control mechanisms

- Condition of connecting elements

- Lubrication levels of moving parts

Adhering to a regular inspection schedule not only enhances operational efficiency but also significantly contributes to the overall safety of equipment and its operators.

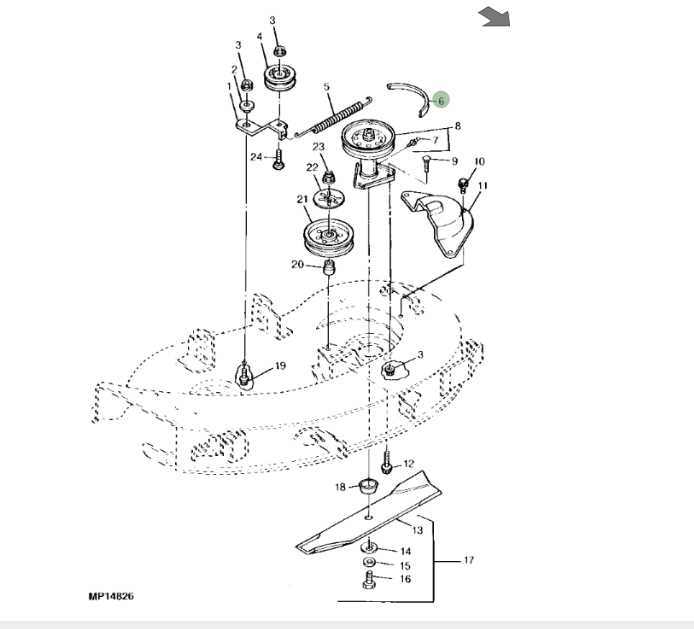

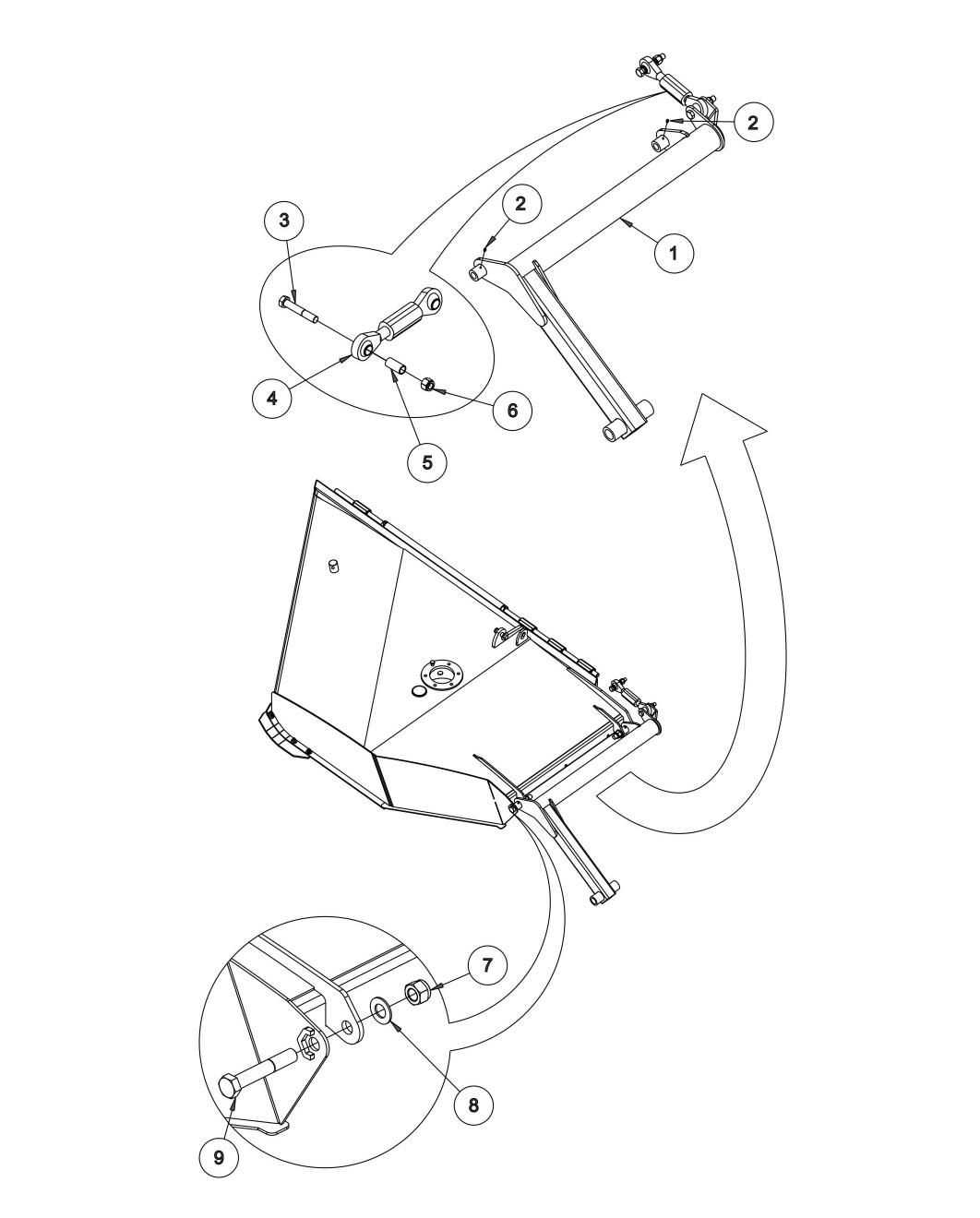

Detailed Diagram of STX38 Steering

This section provides an in-depth visual representation of the components involved in the directional control mechanism of the mower. Understanding these elements is crucial for effective maintenance and repair, ensuring optimal performance and longevity of the equipment.

Key Components: The layout includes essential elements such as the control column, linkage, and pivot points. Each part plays a significant role in the functionality of the directional system, allowing for precise maneuverability.

Maintenance Insights: Regular inspection of these components is vital. Identifying wear and tear early can prevent more significant issues, enhancing the overall efficiency of the mower. Familiarity with the arrangement of these parts facilitates easier troubleshooting and replacement when necessary.

Key Components of John Deere STX38

The machinery in question incorporates several essential mechanical elements that ensure its smooth operation and reliability over time. Each of these components contributes to the overall performance, making it crucial to understand their functions and interactions within the system.

| Component | Description | |||||||

|---|---|---|---|---|---|---|---|---|

| Chassis | The main structural framework that provides support and houses other crucial elements of the equipment. | |||||||

| Engine | The power unit responsible for driving the entire system, delivering the necessary force to perform various tasks efficiently. | |||||||

| Transmission | A system of gears that transmits power from the engine to the wheels, enabling smooth movement and speed control. | |||||||

| Wheels and Tires |

| Symptom | Description |

|---|---|

| Loose or Unresponsive Handling | If the vehicle feels unsteady or responds poorly to direction changes, it may point to issues within the control system. |

| Vibrations While Turning | Unusual shaking or vibrations when turning can indicate worn-out components or alignment issues. |

| Strange Noises | Tips for Replacing Steering Parts

When working on the mechanism that controls your vehicle’s direction, it’s important to approach the task with care and precision. Over time, various components can wear out or become misaligned, requiring attention to restore smooth handling and proper function. By following a few key steps, you can ensure a successful replacement process and prolong the lifespan of your machine’s system. Preparation Before ReplacementStep-by-Step Process

|