In any vehicle, the mechanism that facilitates directional navigation is essential for ensuring smooth operation and safety. This intricate system comprises various elements that work in harmony, allowing drivers to maneuver with precision. Each component plays a vital role, contributing to the overall functionality and responsiveness of the control system.

Recognizing the individual elements within this mechanism can enhance one’s appreciation for its complexity. From the main support structure to the various linkages and controls, each segment has its unique function that aids in the driver’s command of the vehicle. A thorough understanding of these components can lead to better maintenance practices and informed decisions during repairs.

By exploring the intricacies of this system, enthusiasts and professionals alike can gain valuable insights into automotive engineering. This knowledge not only fosters a deeper connection with the mechanics of driving but also empowers individuals to address potential issues effectively. Understanding these components is crucial for anyone looking to enhance their automotive expertise.

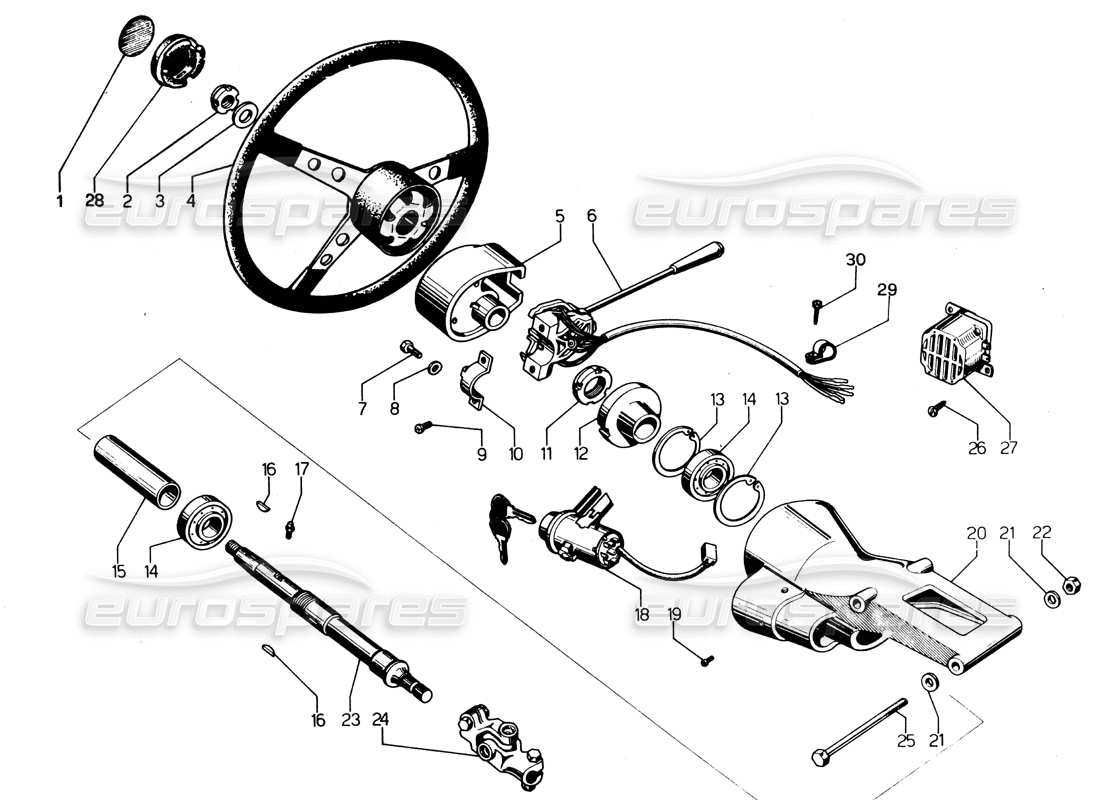

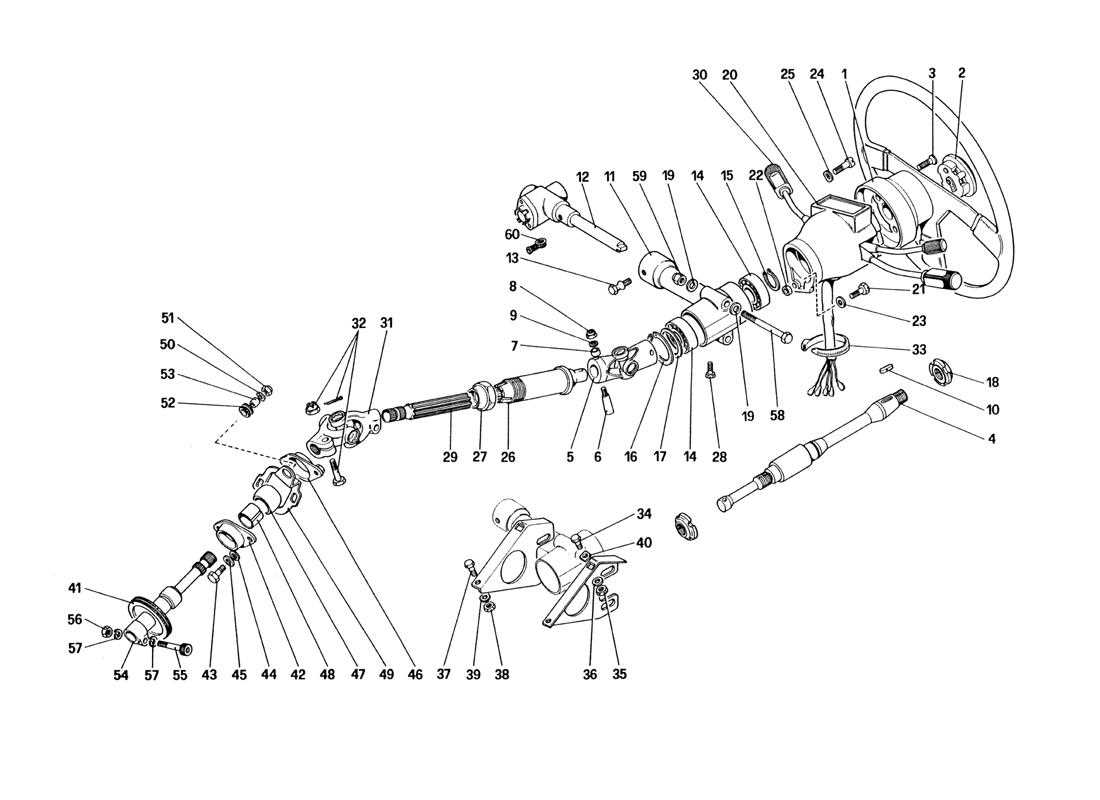

Overview of Steering Column Assembly

The assembly responsible for controlling the direction of a vehicle is a critical component in ensuring safe and effective navigation. This system consists of various interconnected elements that work in harmony to provide drivers with the necessary control over their vehicle’s trajectory. Understanding the intricacies of this assembly is essential for maintenance and troubleshooting.

Key Components and Their Functions

At the core of this assembly lies a central shaft, which transmits the driver’s input to the vehicle’s front wheels. Additionally, various linkages and couplings are integrated into the system to facilitate smooth operation. Moreover, the integration of electronic modules enhances functionality, offering features such as tilt adjustments and built-in safety mechanisms.

Maintenance Considerations

Regular maintenance of this assembly is crucial for optimal performance. Inspecting for wear and tear, ensuring proper lubrication, and checking for alignment issues can prevent potential problems. Staying proactive in these areas can significantly extend the lifespan of the components involved and ensure a safer driving experience.

Components of the Steering Mechanism

The system responsible for guiding the direction of a vehicle consists of various interconnected elements that work together to ensure smooth maneuverability. Understanding these components is crucial for comprehending how the entire mechanism functions efficiently.

Essential Elements

- Wheel Assembly: The interface that allows the driver to control the direction of travel.

- Linkages: These are mechanical connections that transmit the driver’s inputs to the wheels.

- Gear Mechanism: This component multiplies the input force from the driver, allowing for precise adjustments.

- Universal Joints: Flexible connectors that accommodate angular misalignment between the various parts.

Auxiliary Components

- Power Assist: Enhances the driver’s effort, making it easier to turn the wheels.

- Bearings: Provide smooth rotation and reduce friction within the system.

- Adjustment Mechanisms: Allow for tuning and aligning the system for optimal performance.

Each of these components plays a vital role in ensuring that the entire assembly operates smoothly, providing the driver with control and stability while navigating various terrains.

Functionality of the Steering Shaft

The component in question plays a crucial role in the overall operation of a vehicle’s directional control system. Its primary responsibility is to transmit motion from the input mechanism to the mechanism that pivots the front wheels. This essential link ensures that the driver’s intentions are accurately reflected in the vehicle’s movements, providing an optimal driving experience.

Role in Directional Control

The element serves as a critical conduit, allowing the driver’s inputs to be transformed into corresponding movement. By effectively converting rotational motion into linear motion, it enables precise adjustments to the vehicle’s trajectory. The integrity of this connection is vital, as any disruption can lead to a loss of control, highlighting its importance in maintaining road safety.

Construction and Material

Typically constructed from robust materials, the component is designed to withstand the stresses of regular use. Its design often includes features that reduce friction and enhance durability, ensuring a smooth transmission of forces. The attention to material selection not only contributes to performance but also to the longevity of the system.

In conclusion, this vital element plays an indispensable role in the functionality of a vehicle, directly influencing the ease and safety of driving. Understanding its mechanisms can provide valuable insights into vehicle operation and maintenance.

Importance of Steering Column Design

The design of the assembly that houses the control mechanisms for direction and navigation is crucial for ensuring safety, comfort, and functionality in vehicles. A well-thought-out configuration enhances the driving experience and minimizes risks during operation.

Key aspects of this design include:

- Safety: The arrangement must protect occupants during impacts, reducing injury risk.

- Ergonomics: Proper positioning enhances driver comfort and reduces fatigue during long journeys.

- Functionality: An efficient layout allows for easy access to controls, improving overall usability.

- Durability: The materials and structure should withstand wear and tear, ensuring long-term reliability.

- Aesthetics: Visual appeal plays a role in consumer preferences, impacting vehicle sales.

In summary, thoughtful engineering of this essential component significantly influences vehicle performance and user satisfaction, making it a vital focus for manufacturers and designers alike.

Common Issues with Steering Parts

When it comes to vehicle control, various components play crucial roles in ensuring smooth operation and safety. However, certain complications may arise that can compromise performance and lead to discomfort or hazards while driving. Understanding these issues is essential for maintaining an optimal driving experience.

Wear and Tear

Over time, regular use can cause components to degrade, resulting in decreased responsiveness and precision. Factors such as exposure to the elements and the quality of materials can contribute to this wear. Regular inspections are vital to identify and address these issues before they escalate.

Alignment Problems

Misalignment is another common concern that can lead to uneven tire wear and handling difficulties. This can stem from various sources, including impacts from potholes or curbs, which affect the overall stability of the vehicle. Timely adjustments can help restore proper alignment and enhance control.

How to Maintain Steering Components

Proper upkeep of the control mechanism is essential for ensuring vehicle safety and performance. Regular checks and maintenance can prevent wear and tear, which can lead to serious issues. By focusing on a few key areas, you can prolong the life of these crucial components and enhance your driving experience.

Regular Inspection

Conducting frequent examinations is vital. Look for any signs of damage, corrosion, or wear. Pay attention to any unusual noises during operation, as these may indicate underlying problems that need immediate attention.

Lubrication and Cleaning

Keeping the components clean and well-lubricated will help in reducing friction and prolonging their lifespan. Use appropriate lubricants recommended by the manufacturer and ensure that any dirt or debris is cleared away during routine maintenance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Check for damage or wear |

| Lubrication | Every 6 months | Use manufacturer-recommended products |

| Professional Check | Annually | Schedule a thorough evaluation by a technician |

Upgrading Your Steering System

Enhancing the control and precision of your vehicle’s navigation can significantly improve your overall driving experience. By focusing on key components that influence maneuverability, you can achieve a more responsive and enjoyable ride. Whether you’re looking for improved feedback, reduced effort, or increased safety, upgrading specific elements can lead to a more satisfying connection between you and your vehicle.

Identifying Key Components for Improvement

Begin by assessing the essential elements that contribute to your vehicle’s maneuverability. Upgrading the mechanism that transmits force can lead to noticeable changes in handling and responsiveness. Additionally, enhancing the fluid dynamics or exploring electronic alternatives may provide further benefits, offering a modern twist on traditional designs.

Installation and Maintenance Considerations

Once you’ve selected the components for enhancement, proper installation is crucial. Consult with professionals to ensure compatibility and optimal performance. Regular maintenance and inspection will help maintain the upgrades and prolong the lifespan of your vehicle’s handling system, ensuring consistent performance on the road.

Tools Required for Steering Repairs

Maintaining and fixing the components responsible for vehicle navigation is crucial for safe operation. The correct tools can significantly streamline the process, ensuring both efficiency and precision. Familiarity with the necessary equipment not only saves time but also reduces the risk of damaging sensitive parts during repairs.

Essential Tools

When embarking on repair work, it is vital to have a well-organized set of tools at your disposal. The following table outlines the essential instruments commonly used in these tasks:

| Tool | Purpose |

|---|---|

| Socket Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For adjusting and removing screws from various components. |

| Pliers | For gripping and manipulating various parts. |

| Torque Wrench | To ensure fasteners are tightened to manufacturer specifications. |

| Ball Joint Separator | For disconnecting ball joints safely. |

Safety Equipment

In addition to standard tools, protective gear is crucial when working on a vehicle’s navigation system. This includes gloves, safety glasses, and sturdy footwear to prevent injuries during the repair process.

Understanding Steering Column Safety Features

Modern vehicle designs prioritize occupant protection, focusing on various mechanisms that enhance safety during collisions. These systems are integral in mitigating the impact forces experienced during an accident, ensuring that passengers remain secure within the cabin.

Key Mechanisms for Enhanced Safety

- Crumple Zones: Engineered areas that deform upon impact, absorbing energy and reducing the force transmitted to occupants.

- Energy Absorption Systems: Components designed to dissipate kinetic energy, minimizing injury risk during a collision.

- Collapsible Structures: Features that collapse in a controlled manner, helping to lessen the likelihood of harm to passengers.

Additional Safety Considerations

- Airbag Deployment: Strategically placed inflatable devices that deploy during impacts to cushion occupants.

- Safety Belt Systems: Restraint systems that secure passengers, preventing excessive movement during a crash.

- Advanced Sensor Technology: Systems that detect collision risks and trigger necessary safety features proactively.

Incorporating these innovative safety enhancements not only protects individuals in the event of an accident but also reinforces the overall integrity of the vehicle’s design, making transportation safer for everyone on the road.

Diagnosing Steering Column Malfunctions

Identifying issues within the directional control system is essential for ensuring safe and effective vehicle operation. Various symptoms can indicate potential failures, and recognizing these signs early can help prevent further complications. This section outlines the common indicators and diagnostic approaches to troubleshoot such complications effectively.

Common Symptoms of Failure

- Unusual noises during operation

- Difficulty in turning the control mechanism

- Unexpected vibrations or looseness

- Warning lights on the dashboard

Diagnostic Steps

- Start by conducting a visual inspection for any visible damage or loose components.

- Test the functionality of the control mechanism by turning it from side to side.

- Listen for abnormal sounds, such as grinding or clunking, which could indicate wear.

- Check for any warning signals on the vehicle’s interface that may point to underlying issues.

- If problems persist, consult a professional for a comprehensive examination.

Future Innovations in Steering Technology

The evolution of vehicle control mechanisms is poised for significant advancements, driven by emerging technologies and changing consumer demands. As the automotive industry embraces automation and connectivity, the focus is shifting towards enhancing user experience and safety through innovative solutions. This section explores potential breakthroughs that could redefine how drivers interact with their vehicles.

One promising area of development is the integration of advanced sensor systems that provide real-time feedback and assistance to the driver. These systems could enable more precise handling and improved maneuverability, allowing for greater control under various driving conditions. Furthermore, the incorporation of artificial intelligence may lead to adaptive systems that learn and adjust to individual driving styles, enhancing overall performance.

Additionally, the rise of electric vehicles has opened the door to novel approaches in control design. The implementation of electronic controls can eliminate traditional mechanical components, leading to a reduction in weight and complexity. This shift not only promises improved responsiveness but also paves the way for innovative user interfaces, including touch-sensitive controls and gesture recognition.

Another exciting prospect is the development of haptic feedback technology. By providing tactile sensations in response to driving conditions, this technology can offer drivers a more immersive experience, enhancing their connection with the vehicle. This feedback could also serve as a safety feature, alerting drivers to potential hazards or changes in road conditions.

In conclusion, the future of vehicle control mechanisms is set to transform significantly. As technology continues to advance, innovations in design, functionality, and user experience will play a crucial role in shaping the next generation of automotive systems, ensuring they meet the demands of modern drivers while enhancing safety and performance.