When it comes to maintaining and operating a reliable cutting tool, having a clear understanding of its internal structure is essential. Each machine consists of various elements that work together to ensure efficiency and safety during use. Familiarity with these components not only enhances performance but also simplifies troubleshooting and repairs.

In this section, we delve into the intricate layout of a popular model, breaking down its critical elements and their functions. By examining these intricate relationships, users can gain insights into how to optimize their equipment’s operation and extend its lifespan. Knowledge of the assembly can lead to more informed decisions regarding maintenance and replacement.

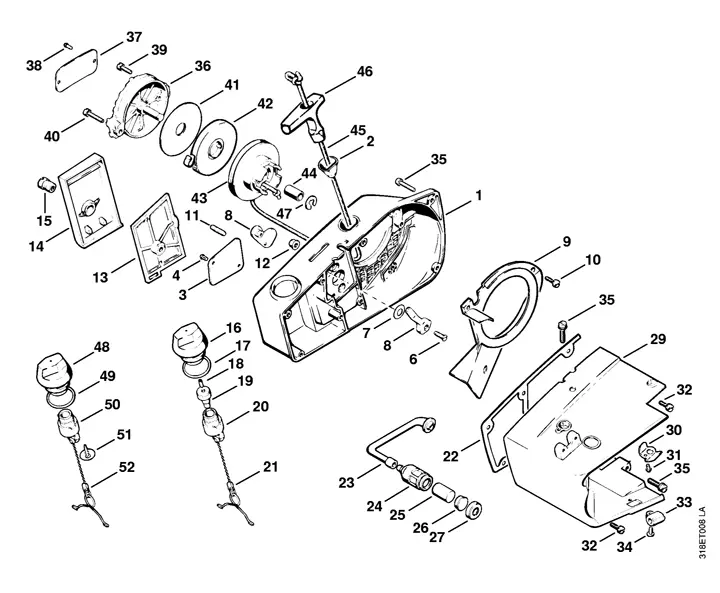

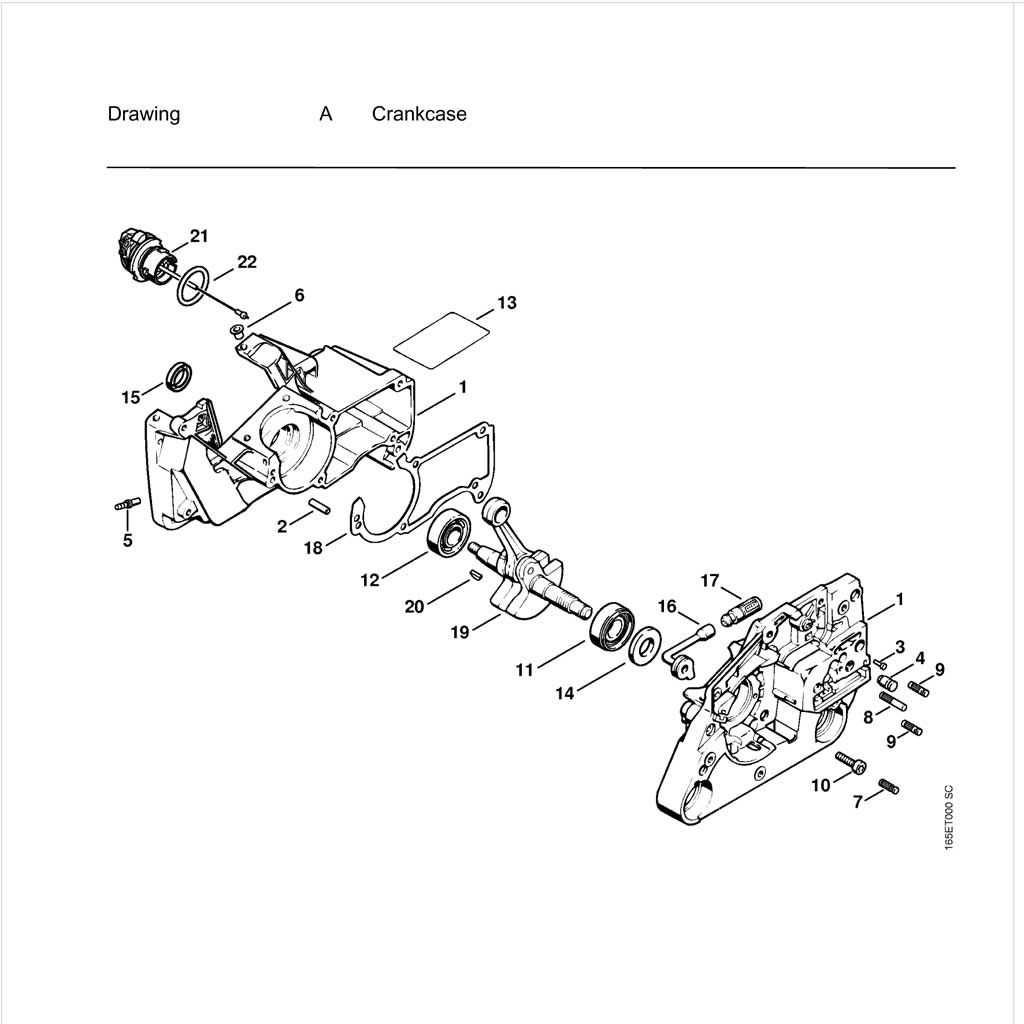

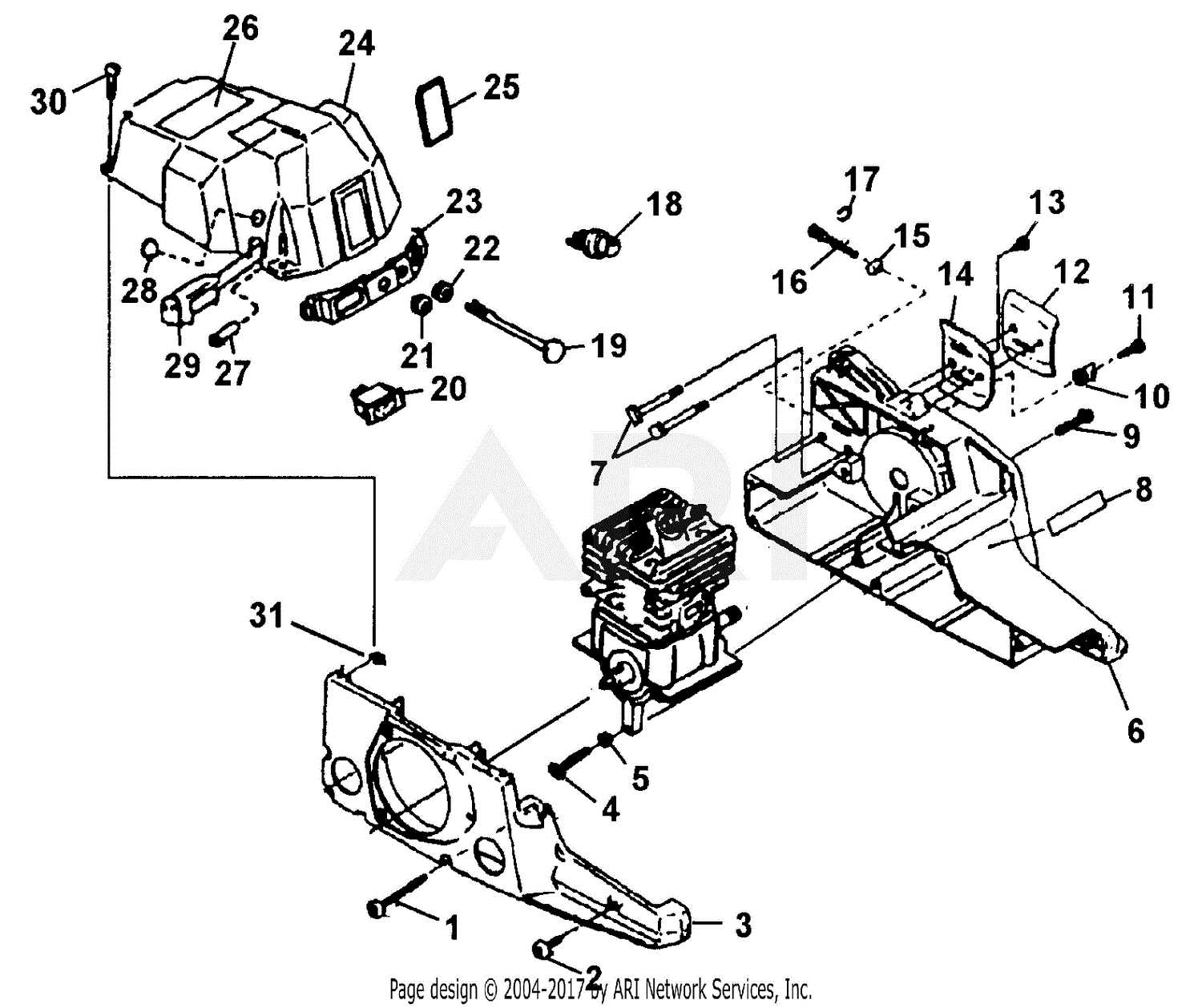

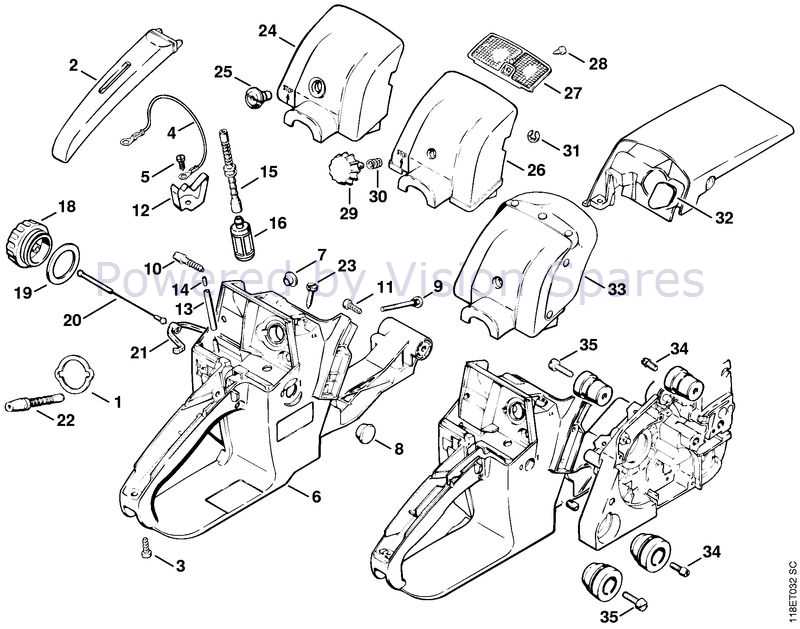

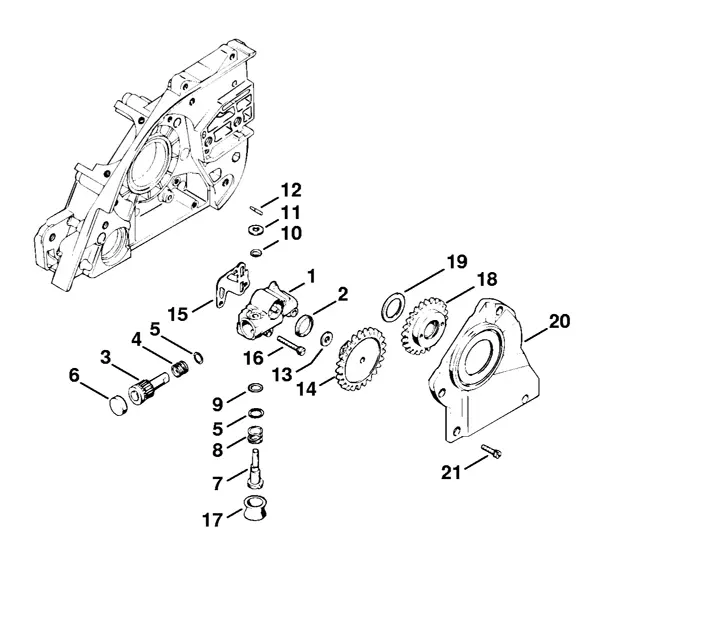

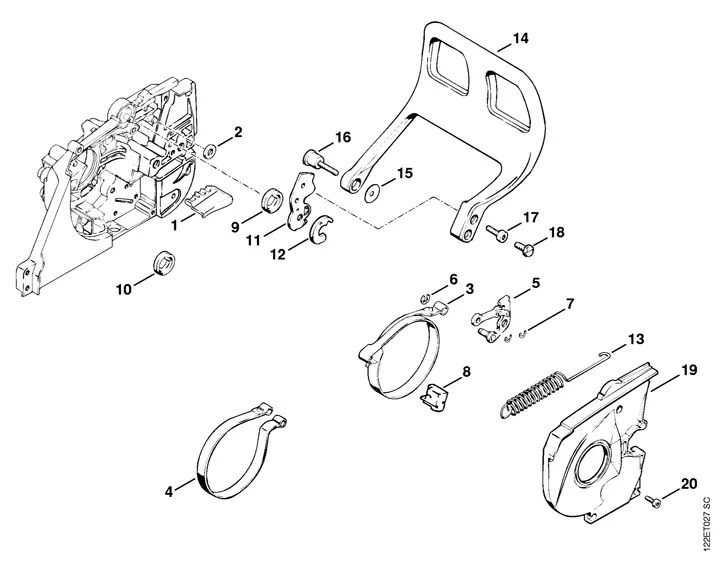

Additionally, visual representations of the machinery’s configuration serve as invaluable resources for both novice and experienced users alike. These illustrations provide a comprehensive overview, making it easier to identify parts that may require attention or replacement. Understanding this visual guide empowers users to engage confidently with their tool, ensuring they can address issues efficiently.

Understanding the 028 Stihl Model

This section explores a well-known tool designed for cutting and trimming, highlighting its features and operational nuances. Understanding its mechanics and components can greatly enhance its performance and longevity, making it an essential subject for enthusiasts and professionals alike.

Key Features

This model is celebrated for its durability and efficiency. Key characteristics include a powerful engine, ergonomic design, and user-friendly controls that facilitate a smooth operation.

Maintenance Essentials

| Component | Function |

|---|---|

| Engine | Provides power for cutting |

| Chain | Executes the cutting action |

| Guide Bar | Supports the chain during operation |

Key Features of the 028 Stihl

This section explores the essential characteristics that define a particular model in the chainsaw category. These attributes contribute to its performance, efficiency, and overall user experience, making it a preferred choice among outdoor equipment enthusiasts.

| Feature | Description |

|---|---|

| Powerful Engine | Designed for high torque and efficiency, ensuring reliable operation even under tough conditions. |

| Lightweight Design | Facilitates easy handling and maneuverability, reducing user fatigue during prolonged use. |

| Durable Build | Constructed with robust materials to withstand harsh environments and extend the lifespan. |

| Advanced Safety Features | Equipped with mechanisms that enhance user safety while operating the equipment. |

| Easy Maintenance | Designed for straightforward upkeep, allowing users to keep it in optimal condition with minimal effort. |

Importance of Parts Diagrams

Understanding the intricate assembly of machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, offering clarity on the various components involved. These illustrations not only simplify complex structures but also enhance the user’s ability to identify and replace parts accurately.

Moreover, having a detailed visual reference minimizes the risk of errors during reassembly, ultimately ensuring optimal performance. This resource becomes invaluable for both professionals and hobbyists, enabling them to delve deeper into the mechanics and function of their equipment. Knowledge of individual elements fosters a greater appreciation for the entire system.

Common Issues with the 028 Stihl

Understanding frequent challenges with this model can enhance maintenance and performance. Operators often encounter various problems that may affect efficiency and longevity.

- Fuel delivery issues: Clogged filters or improper mixtures can lead to inadequate performance.

- Inefficient ignition: Worn spark plugs or faulty coils may cause starting difficulties.

- Chain tension problems: Incorrect adjustments can lead to poor cutting performance or chain derailment.

- Overheating: Lack of proper lubrication or airflow may result in engine overheating.

Addressing these common concerns can ultimately extend the life of your equipment and improve overall functionality.

Where to Find Parts Diagrams

Locating detailed visual guides for machinery components can greatly enhance your understanding and maintenance capabilities. These resources are essential for identifying the specific elements required for repairs or upgrades.

Official Manufacturer Websites

One of the most reliable sources is the official website of the manufacturer. Here, you can typically access comprehensive resources, including manuals and visual guides that showcase the arrangement of components.

Online Retailers and Forums

Many online retailers also provide visual references alongside their product listings. Additionally, specialized forums often feature user-shared resources, allowing enthusiasts to delve into discussions about repairs and maintenance.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear view of how various elements interact within a device, enabling users to identify specific items and their functions.

Here are some key steps to help you interpret these illustrations:

- Familiarize Yourself with the Legend: Most diagrams include a legend that explains symbols and numbering.

- Identify Main Sections: Break down the illustration into its primary areas to focus on one part at a time.

- Trace Connections: Follow lines and arrows that indicate how components are linked.

- Check for Numbers: Look for numerical references that correspond to a list of items or descriptions.

- Consult Documentation: Always have the accompanying manual handy for detailed explanations and part specifications.

By following these steps, you will gain a clearer understanding of the assembly, making it easier to locate and replace specific items when necessary.

Essential Parts for Maintenance

Proper upkeep of your equipment is crucial for optimal performance and longevity. Regular attention to key components ensures that your tool operates efficiently and safely. Understanding these vital elements can help prevent issues and extend the life of your machinery.

Key components to focus on include the air filter, which prevents dust and debris from entering the engine, and the fuel system parts that ensure proper combustion. Additionally, keeping the spark plug in top condition is essential for reliable ignition. Regular checks on the lubrication system are equally important to reduce friction and wear.

Furthermore, inspecting the cutting mechanism is necessary for effective operation. Sharp blades enhance efficiency, while worn parts can lead to unnecessary strain on the engine. Ensuring all components are in good shape is the ultimate way to maintain functionality and performance.

In summary, a proactive approach to monitoring and servicing these critical parts will result in a smoother, more reliable operation and help you achieve the best results every time you use your equipment.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for a successful outcome. The right tools not only streamline the repair process but also ensure that you work safely and efficiently. Whether you’re a seasoned technician or a DIY enthusiast, being prepared can save time and reduce frustration.

Basic Hand Tools: A set of reliable hand tools is fundamental. Wrenches, screwdrivers, and pliers should be on hand to manage various fasteners. Additionally, a hammer may come in handy for adjusting parts without causing damage.

Measuring Instruments: Accurate measurements are crucial in any repair task. Tools such as calipers and tape measures help ensure that components fit together perfectly, avoiding potential issues later on.

Power Tools: For more demanding repairs, power tools like drills and saws can expedite the process. They provide the necessary force to handle tougher materials, making complex tasks more manageable.

Safety Gear: Don’t overlook safety equipment. Gloves, goggles, and ear protection should be utilized to prevent injuries while working. Being mindful of safety is as important as the repairs themselves.

Cleaning Supplies: Keeping your workspace tidy is key to effective repairs. Brushes, rags, and cleaning agents help maintain tools and equipment in top condition, ensuring longevity and optimal performance.

By gathering these essential tools and materials, you can approach your repair tasks with confidence, knowing you’re well-equipped to handle any challenge that arises.

Aftermarket vs. OEM Parts

The choice between alternative and original components can significantly impact performance and longevity. Understanding the differences helps users make informed decisions that align with their needs and budget.

Quality and Performance

Original components are typically manufactured to meet strict specifications, ensuring reliability and optimal functionality. In contrast, alternative options may vary widely in quality, with some providing excellent value and others falling short.

Cost Considerations

While original parts often come with a higher price tag, they can offer peace of mind through consistent performance. On the other hand, aftermarket alternatives can be more budget-friendly, but users should carefully evaluate their quality to avoid potential issues.

Replacing Chainsaw Components Safely

Ensuring the longevity and efficiency of your cutting tool requires careful attention during the replacement of various components. Safety should always be a priority, as improper handling can lead to accidents or damage. Understanding proper techniques can greatly enhance your maintenance experience.

Preparation Before Replacement

- Disconnect the power source to avoid accidental starts.

- Gather necessary tools and replacement items beforehand.

- Wear appropriate personal protective equipment (PPE).

Steps for Safe Replacement

- Consult the manufacturer’s guidelines for specific instructions.

- Carefully remove the old component, ensuring no parts are lost.

- Inspect surrounding areas for any signs of wear or damage.

- Install the new component securely, following the recommended procedures.

- Double-check all connections and ensure everything is properly aligned.

Tips for Extended Lifespan

Maintaining equipment properly is crucial for ensuring its durability and optimal performance over time. By following a few essential practices, users can significantly enhance the longevity of their tools and machinery.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and residues after each use to prevent corrosion and blockages. |

| Routine Inspections | Check components regularly for wear and tear, addressing issues before they escalate. |

| Proper Lubrication | Apply appropriate lubricants to moving parts to reduce friction and wear. |

| Correct Storage | Store tools in a dry, protected environment to shield them from moisture and temperature extremes. |

| Use Quality Fuel | Opt for high-grade fuel to minimize deposits and enhance engine efficiency. |

Resources for Further Learning

Expanding your knowledge about machinery and their components can greatly enhance your maintenance skills and overall understanding. There are numerous resources available to help you dive deeper into this subject, from manuals to online forums. Here are some valuable options to consider:

- Manufacturer Manuals: Always refer to the official manuals for in-depth information regarding assembly, disassembly, and troubleshooting.

- Online Tutorials: Websites and video platforms offer step-by-step guides and visual demonstrations to assist with various tasks.

- Community Forums: Joining forums allows you to connect with fellow enthusiasts who can share experiences, tips, and solutions to common issues.

- Workshops and Classes: Look for local workshops or classes that focus on machinery maintenance and repair to gain hands-on experience.

- Books and eBooks: Consider reading comprehensive texts that cover the theoretical aspects of machine mechanics and repair techniques.

Utilizing these resources can empower you to enhance your skills and ensure efficient upkeep of your equipment.