The maintenance and care of lawn equipment often require a solid understanding of its key elements and how they work together. This guide is designed to help enthusiasts and professionals alike navigate the structure of a well-known trimming device, providing insight into its core elements and their functions.

Each component plays a vital role in the overall efficiency and performance of the tool. Understanding the arrangement and function of these elements can significantly improve the equipment’s lifespan and reduce the need for frequent repairs. This overview will walk you through the critical sections of the device, ensuring a thorough grasp of its assembly.

By gaining a deeper understanding of the individual components and their purpose, you’ll be better equipped to maintain and troubleshoot your equipment, enhancing its longevity and reliability. Let’s dive into the essential features and layout of this versatile garden tool.

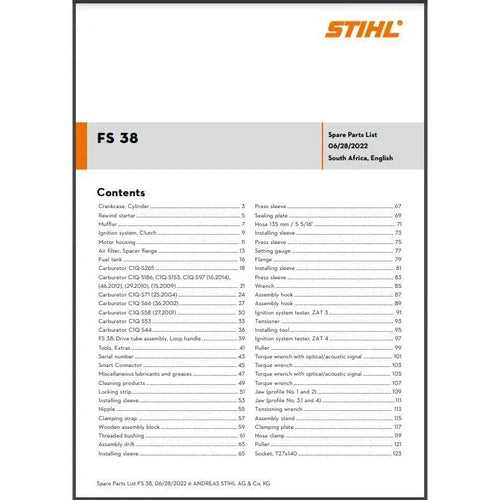

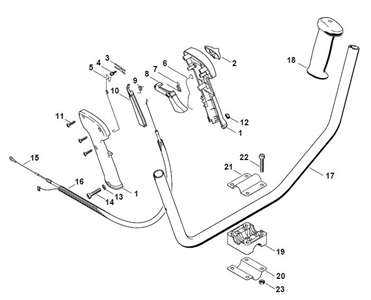

Comprehensive Overview of Stihl FS 38 Components

In this section, we will explore the various elements that make up this versatile trimmer model. Each part plays a crucial role in ensuring the machine operates efficiently and delivers the expected performance. By understanding the function and interaction of these components, users can gain a clearer perspective on how to maintain, repair, or upgrade their equipment effectively.

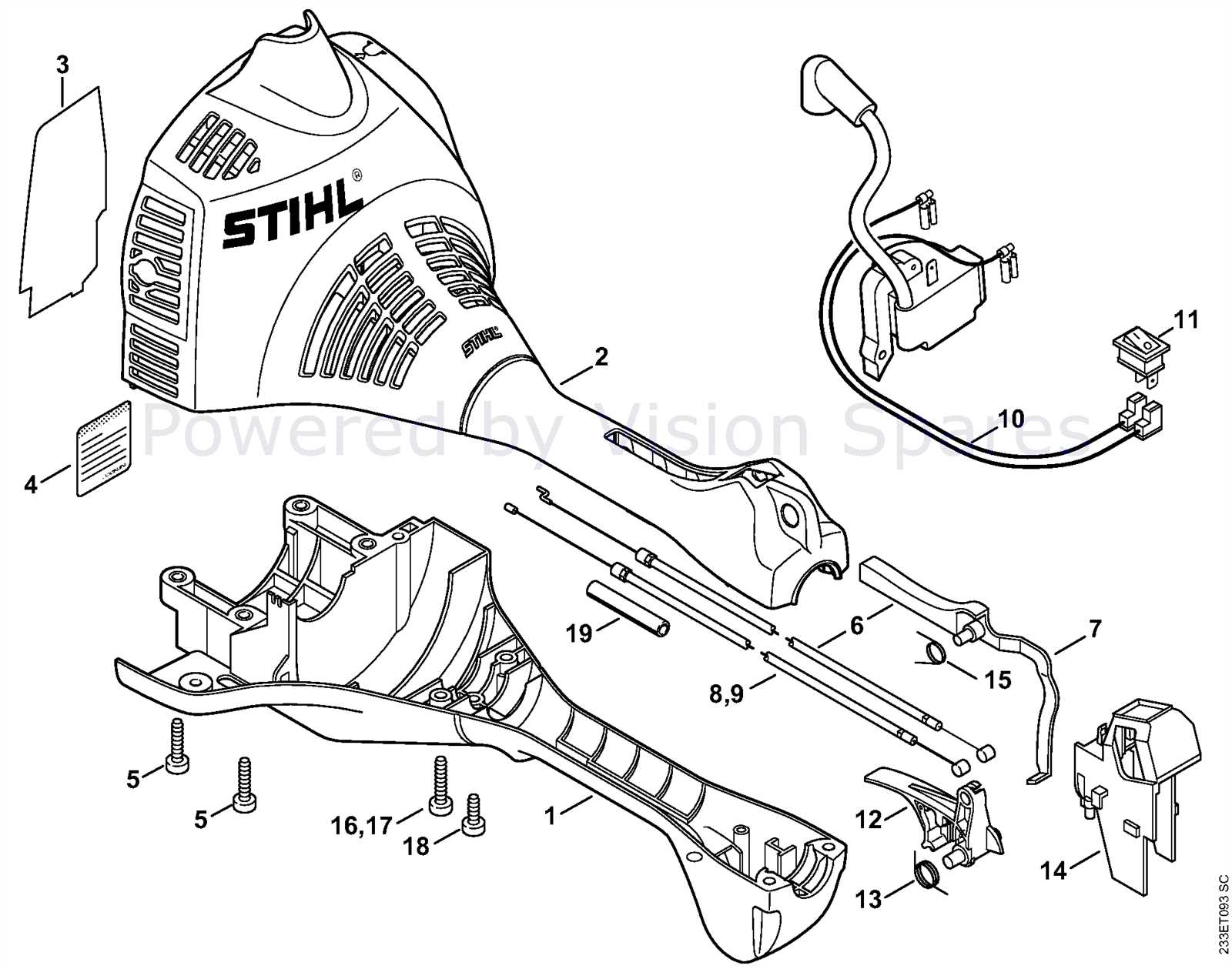

The main framework consists of several key elements, including the power unit, cutting head, and drive mechanisms. These components are engineered to work together seamlessly, offering reliability and ease of use. Additionally, the construction incorporates both mechanical and protective features, contributing to its durability and user safety during operation.

Another essential aspect is the fuel and air management system, which ensures optimal engine performance. The fuel delivery, air filtration, and exhaust systems are designed to maximize power output while minimizing emissions, keeping the machine compliant with environmental standards.

Finally, the ergonomic design, including the handle and harness attachments, provides user comfort and control, making it easier to maneuver the machine for extended periods. Regular maintenance and proper handling of these elements can significantly

Key Features of Stihl FS 38 Trimmer

This trimmer model offers a variety of important functionalities that make it ideal for home gardening and lawn maintenance. Its lightweight build, combined with efficient performance, ensures that users can easily handle different trimming tasks with minimal effort.

- Lightweight Design: One of the standout qualities is its manageable weight, which makes it comfortable to use for extended periods without causing fatigue.

- Ergonomic Handle: The well-designed grip ensures optimal control, allowing for precise movements and reducing strain on the hands and arms.

- Fuel Efficiency: This trimmer operates with excellent fuel consumption, helping users save on operational costs over time while maintaining performance.

- Easy Start System: Starting the engine is simple and reliable, with a quick pull system that reduces the effort required to begin trimming.

- Durability: Built with high-quality materials, this model is designed to withstand regular use,

Understanding the Function of Major Parts

In any mechanical system, each component plays a vital role in ensuring smooth operation and efficiency. The key to maintaining such equipment lies in understanding how each element contributes to the overall functionality. This knowledge not only aids in troubleshooting but also in extending the lifespan of the device through proper maintenance.

Engine Mechanism

The engine is the core of the system, converting fuel into the necessary power to drive other components. Its combustion process is carefully regulated, ensuring consistent energy output. Without this mechanism, no other section would be able to function effectively.

Cutting System

Essential Maintenance Tips for Stihl FS 38

Regular upkeep of your garden equipment is crucial for ensuring longevity and optimal performance. By following simple guidelines and maintaining your tool properly, you can avoid unnecessary wear and tear, keeping it in top working condition for years to come.

- Clean the air filter frequently to prevent clogging, which can affect the efficiency of the engine.

- Inspect the fuel system regularly to ensure there are no leaks or blockages that could hinder operation.

- Sharpen the cutting blades or string to maintain precise and smooth cutting action.

- Check the spark plug for any signs of corrosion or build-up that could reduce ignition performance.

- Lubricate moving parts periodically to prevent friction and prolong the life of the components.

- Store your tool

How to Replace Trimmer Line Efficiently

Maintaining a trimmer is essential for ensuring optimal performance and durability. Replacing the cutting line regularly is a straightforward task that significantly impacts the efficiency of the equipment. In this section, we will cover how to replace the cutting cord quickly and without unnecessary complications, providing simple steps for smooth operation.

Step-by-Step Guide

Follow these instructions to change the cutting string without hassle:

Step Description 1 Turn off the device and ensure it is disconnected from any power source. 2 Remove the spool cover by pressing the release tabs or unscrewing it, depending on the model. 3 Take out any remaining string from Identifying Common Issues in FS 38

Regular maintenance and awareness of typical problems can significantly enhance the lifespan and performance of your outdoor equipment. Recognizing these issues early on allows for timely interventions, ensuring smooth operation and reducing the risk of costly repairs. This section outlines frequent concerns users may encounter, along with their potential causes and solutions.

Issue Possible Causes Recommended Solutions Engine won’t start Fuel issues, clogged air filter, spark plug malfunction Check fuel levels and quality, clean or replace air filter, inspect and replace spark plug if necessary Overheating Poor ventilation, dirty cooling fins, low oil levels Ensure proper airflow, clean cooling fins, check and top up oil levels Excessive vibrations Loose components, unbalanced cutting head Tighten all screws and bolts, balance the cutting head or replace it if damaged Reduced cutting efficiency Dull blades, improper line length Sharpen or replace blades, adjust line length according to manufacturer specifications Exploring Stihl FS 38 Engine Assembly

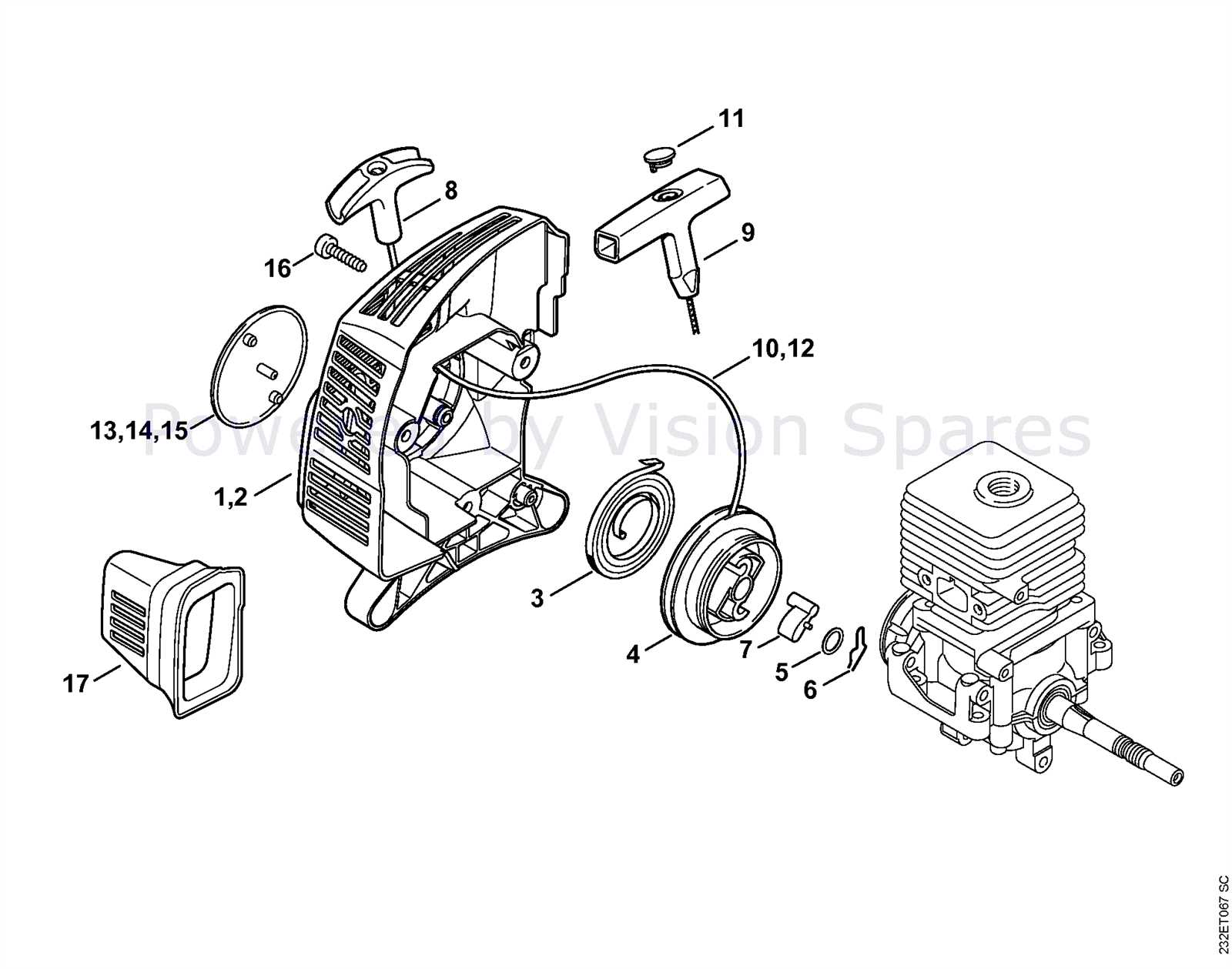

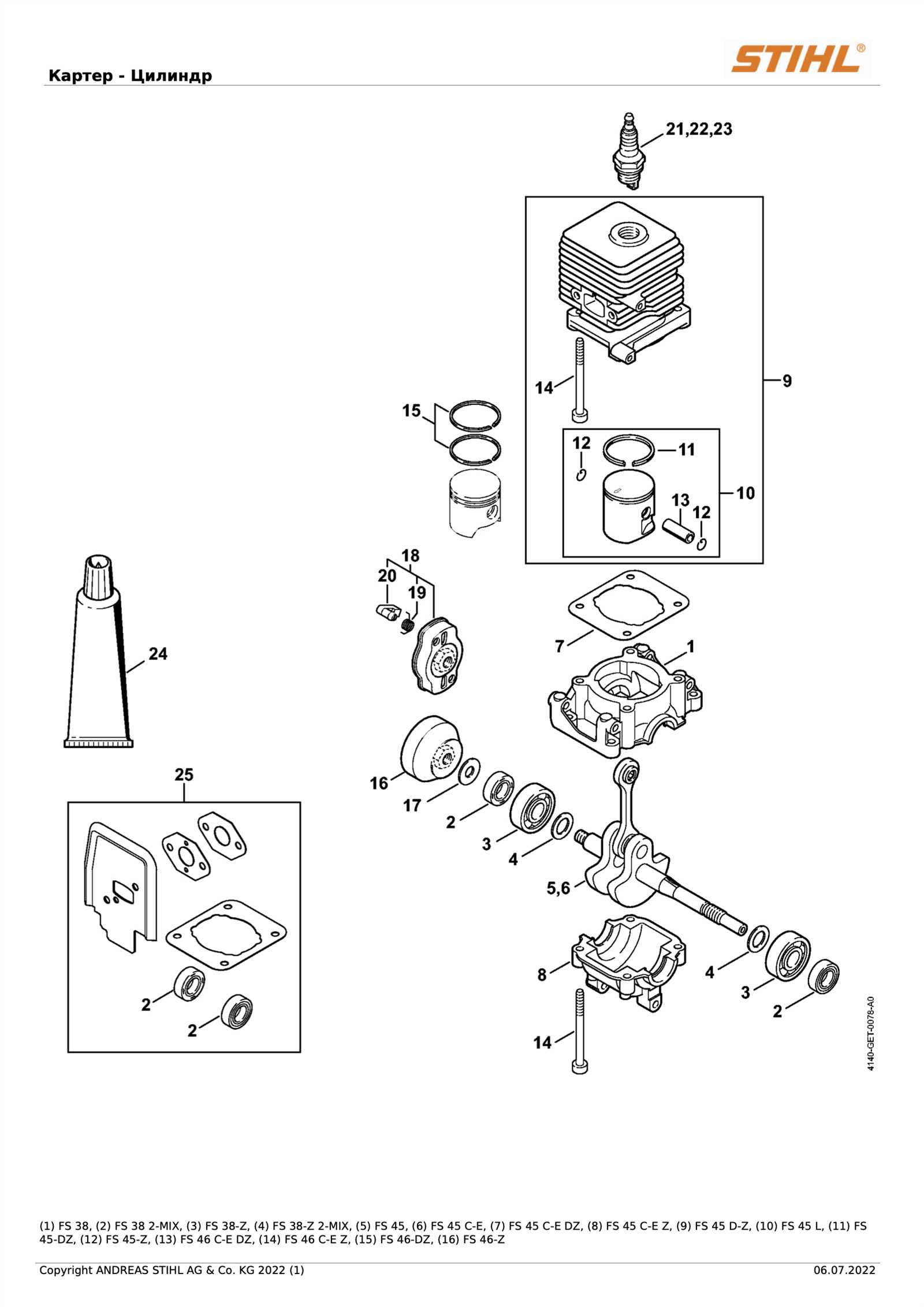

The engine assembly of a two-stroke handheld machine is a crucial component that significantly influences its performance and reliability. Understanding the layout and functionality of the engine parts can help users maintain their equipment effectively. This section will delve into the intricacies of the engine structure, highlighting key components and their roles in the overall operation.

Key Components of the Engine Assembly

The assembly consists of several essential elements, each designed to perform a specific function. The cylinder serves as the heart of the engine, where the combustion process takes place. The piston, moving within the cylinder, compresses the fuel-air mixture, enabling efficient combustion. Additionally, the crankshaft converts the linear motion of the piston into rotational energy, which powers the machine.

Importance of Proper Assembly

Ensuring that all components are correctly assembled is vital for optimal performance. Misalignment or improper installation can lead to decreased efficiency and potential damage. Regular inspection and maintenance of the engine assembly not only prolong the life of the machine but also enhance its overall functionality, making it a worthwhile investment for users.

Guide to Proper Air Filter Installation

Ensuring optimal performance of your equipment involves careful attention to the air filtration system. A properly installed air filter plays a crucial role in maintaining engine efficiency and longevity. This guide will provide you with essential steps to effectively install and maintain the air filter, ensuring that your machinery operates smoothly.

Follow these steps for proper installation:

- Gather Necessary Tools:

- Clean cloth

- Screwdriver (if required)

- Replacement air filter

- Locate the Air Filter Compartment:

Consult your user manual to find the exact location of the air filtration unit. This is typically found near the engine housing.

- Remove the Cover:

Carefully unscrew or unclip the cover of the air filter compartment. Place it in a safe location to prevent loss.

- Take Out the Old Filter:

Gently pull out the old filter. Inspect it for any debris or damage that may indicate a need for more frequent replacements.

- Clean the Compartment:

Use a clean cloth to wipe away any dust or dirt from the compartment. This helps ensure that no contaminants enter the engine.

- Insert the New Filter:

Position the new air filter in the compartment. Make sure it fits snugly and is oriented correctly, following any directional arrows if provided.

- Replace the Cover:

Once the new filter is securely in place, reattach the cover. Ensure it is fastened tightly to prevent any dirt from entering the filter.

- Test the Equipment:

Start the engine to check for any unusual noises or performance issues. A properly installed air filter should contribute to smoother operation.

Regular maintenance of the air filtration system is essential for the longevity and efficiency of your machinery. Following these steps will help you ensure that your air filter is installed correctly and functioning optimally.

Safety Mechanisms of Stihl FS 38 Explained

When operating a powerful outdoor tool, understanding the safety features is crucial for ensuring user protection and preventing accidents. This device incorporates several mechanisms designed to minimize risks while maximizing performance. By adhering to these built-in safety elements, users can enhance their experience and maintain a secure working environment.

Cutting Safety Features

The cutting equipment is equipped with protective shields that prevent accidental contact with the rotating blades. These barriers are essential in safeguarding users from debris and potential injuries during operation. Additionally, the tool’s throttle control is engineered to ensure that the engine responds smoothly, allowing for better handling and reducing the chance of unintended activation.

Operational Controls and Ergonomics

Ergonomically designed handles not only improve comfort but also enhance grip security. The presence of a lock-off switch ensures that the motor does not start inadvertently, further reinforcing safe usage. Regular maintenance checks and adherence to operational guidelines amplify the effectiveness of these safety features, allowing users to operate the device confidently and efficiently.

Optimizing Fuel System for Better Performance

Enhancing the efficiency of the fuel delivery mechanism is essential for achieving optimal performance in any engine. A well-tuned fuel system ensures that the engine receives the right mixture of air and fuel, which maximizes power output while minimizing emissions. By focusing on key components and maintenance practices, users can significantly improve overall functionality and reliability.

Key Components for Efficiency

Critical elements such as the fuel filter, pump, and injectors play vital roles in maintaining the system’s performance. Regularly checking and replacing the fuel filter prevents debris from clogging the lines, allowing for smoother fuel flow. Moreover, ensuring that the pump operates efficiently guarantees consistent fuel delivery under varying conditions. The injectors, responsible for atomizing the fuel, should be cleaned periodically to prevent buildup that can disrupt the spray pattern.

Regular Maintenance Practices

Adopting routine maintenance practices, including using high-quality fuel and checking for leaks, can enhance the fuel system’s longevity. It is advisable to inspect hoses and connections for signs of wear or damage, as these issues can lead to inefficient operation. Additionally, periodically reviewing the tuning of the engine ensures that it operates within its optimal range, further contributing to performance improvements.

Best Practices for Blade and Spool Care

Maintaining the sharpness and efficiency of cutting tools is essential for optimal performance. Proper care for blades and spools not only extends their lifespan but also ensures safety during use. Here are key practices to enhance the longevity and effectiveness of these components.

Blade Maintenance

- Regular Cleaning: After each use, remove debris and grass clippings from the blade to prevent corrosion and maintain its sharpness.

- Sharpness Check: Regularly inspect the blade for dullness. A sharp blade cuts more efficiently, reducing strain on the equipment.

- Sharpening: Use a suitable sharpening tool or file to restore the edge. Follow the manufacturer’s guidelines for the correct angle and technique.

- Storage: Store blades in a dry place, preferably in a protective sheath or covered to avoid accidental damage or rust.

Spool Care

- Line Replacement: Regularly check the line for wear. Replace it when it becomes frayed or too short to maintain effective cutting.

- Proper Loading: Ensure the line is loaded correctly in the spool to prevent tangling or snapping during operation.

- Cleaning: Clean the spool regularly to remove dirt and grass. This prevents the line from sticking and ensures smooth operation.

- Inspection: Periodically inspect the spool for cracks or wear. Replace it if any damage is observed to avoid malfunction.

By following these best practices, users can enhance the performance and longevity of their cutting tools, ensuring a smoother and more efficient operation.

- Gather Necessary Tools: