Exploring the intricate layout of machinery can reveal valuable insights into its operation and maintenance. Each unit consists of various elements, each playing a crucial role in the overall functionality. By delving into these components, users can gain a clearer understanding of how to optimize performance and ensure longevity.

The study of these assembly segments is essential for those who wish to troubleshoot issues or perform routine upkeep. Identifying the relationships between different parts enhances one’s ability to conduct repairs effectively. Moreover, having a visual reference can significantly streamline the maintenance process, making it easier to locate and replace worn-out pieces.

For enthusiasts and professionals alike, a comprehensive overview of the individual components offers a roadmap to successful handling. This knowledge not only fosters confidence but also empowers users to engage with their equipment more effectively. Understanding the layout and function of each element transforms the approach to care and restoration.

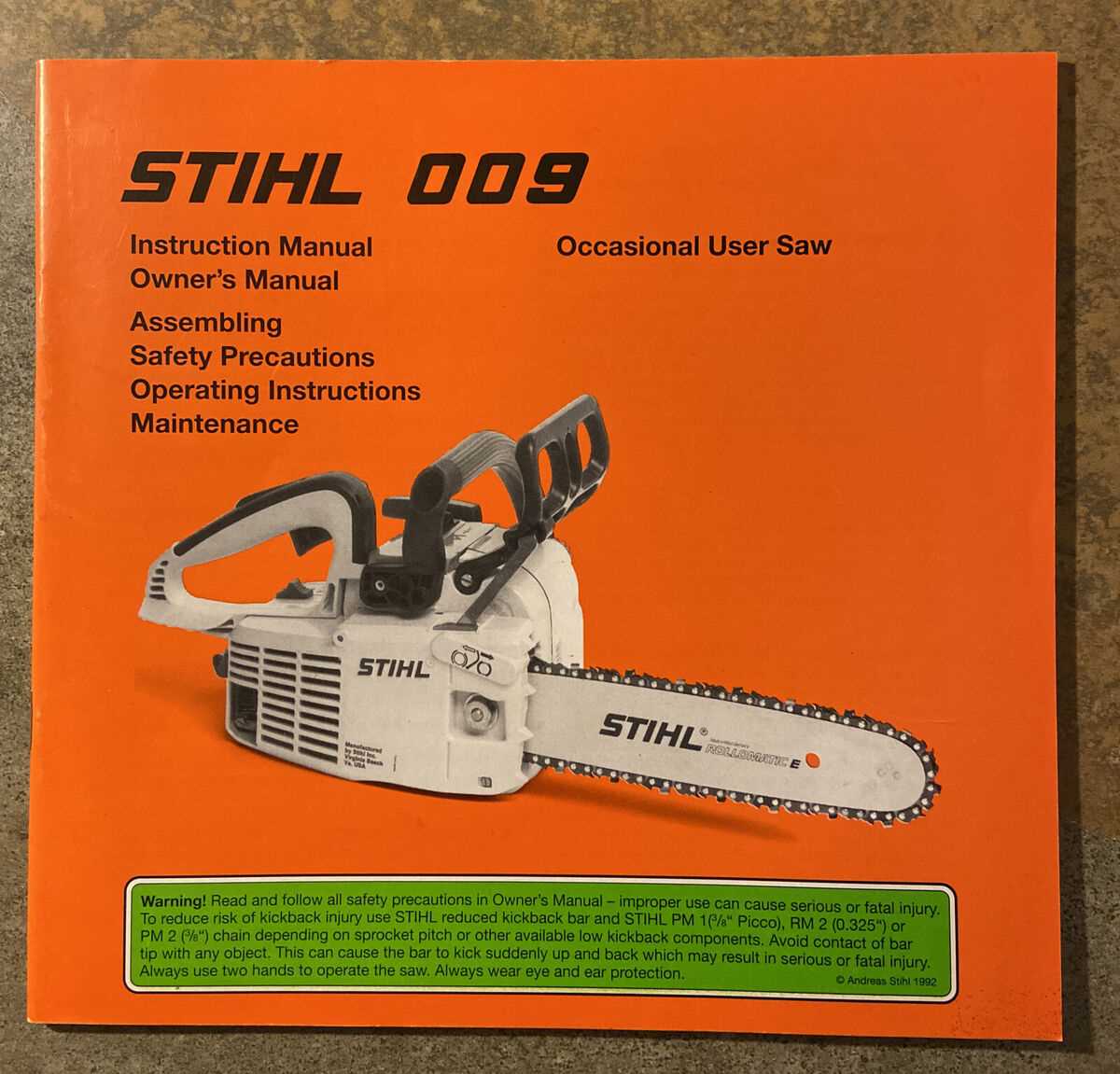

Understanding Stihl 009L Components

Exploring the intricate elements of a particular tool is essential for effective maintenance and optimal performance. Each component plays a critical role in ensuring that the device functions smoothly and efficiently. Gaining a deeper understanding of these parts can enhance troubleshooting efforts and facilitate repairs.

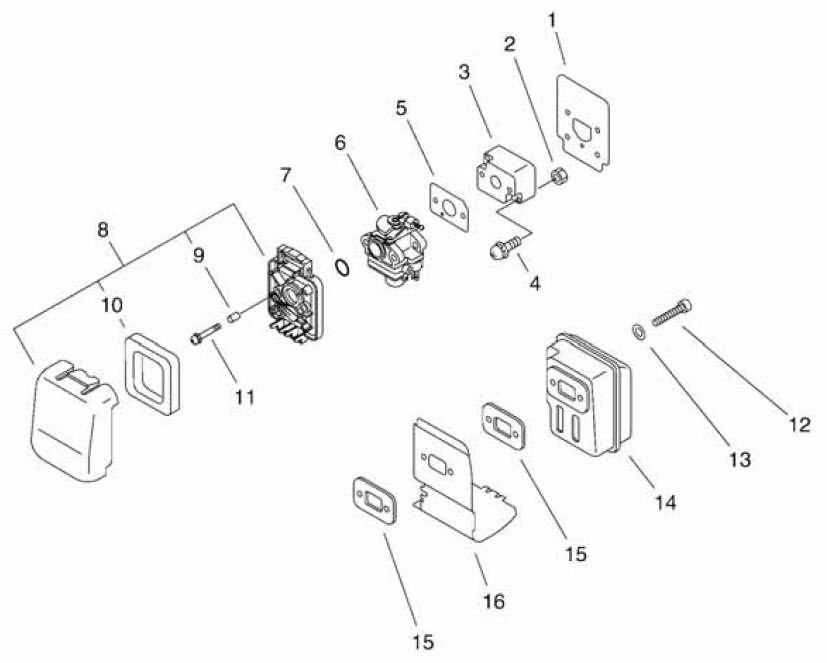

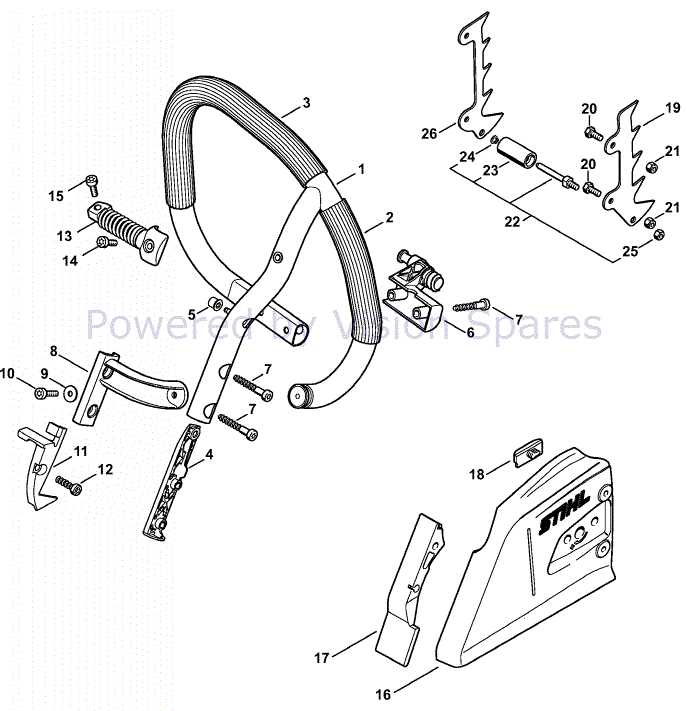

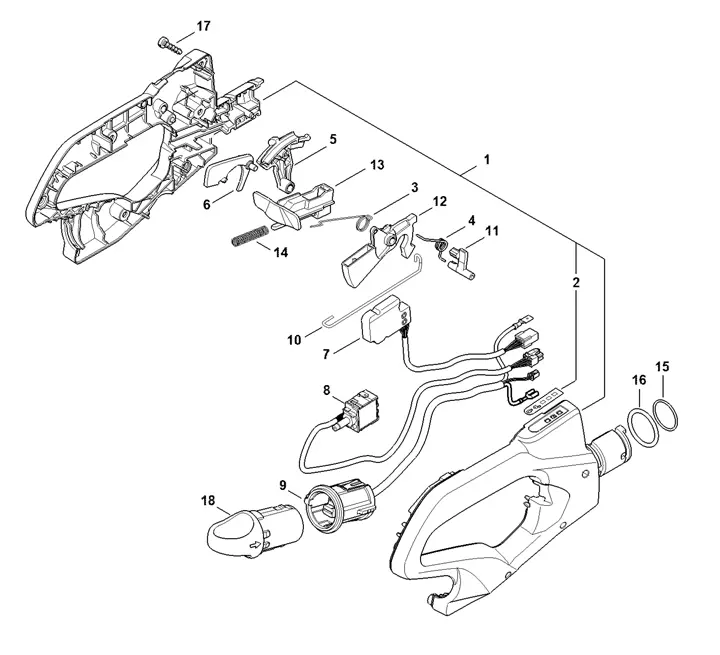

Within this specific model, the major sections include the engine assembly, fuel system, and the cutting mechanism. The engine assembly is the powerhouse, responsible for generating the necessary force to operate the tool. Understanding its structure and function can aid in diagnosing performance issues.

The fuel system is vital for delivering the correct mixture of air and fuel to the engine. Knowledge of how this system operates helps in recognizing symptoms of fuel starvation or over-saturation, which can hinder performance. Additionally, the cutting mechanism is crucial for executing tasks efficiently. Familiarity with its parts and operation allows users to maintain sharpness and effectiveness, ensuring the tool performs its intended functions with precision.

In summary, comprehending the various components of this equipment not only empowers users to manage their tools better but also promotes longevity and reliability in performance.

Key Parts of the Stihl 009L

Understanding the essential components of this powerful tool is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring the device operates smoothly and efficiently, making it vital for users to familiarize themselves with them.

Engine Assembly: The heart of the machine, responsible for generating the necessary power for cutting tasks. Its design influences performance and fuel efficiency.

Chain System: This component includes the guide bar and the chain itself. It is essential for achieving precise cuts, and regular inspection is necessary to maintain its effectiveness.

Fuel Tank: This part stores the mixture required for operation. Proper maintenance ensures a consistent supply, preventing interruptions during use.

Air Filter: Crucial for maintaining engine health, this component prevents dirt and debris from entering the engine, thereby extending its lifespan.

Starter Mechanism: This system initiates the engine’s operation. Understanding its functionality can help troubleshoot starting issues effectively.

Maintenance Tips for Longevity

Ensuring the prolonged efficiency of your outdoor power equipment requires regular care and attention. Implementing effective maintenance practices not only enhances performance but also extends the lifespan of your machine, reducing the need for costly repairs.

Regular Cleaning

Keeping the exterior and internal components clean is crucial. After each use, remove debris and dirt to prevent buildup that could impede functionality. Pay special attention to air filters and cooling vents, as they can significantly affect performance if blocked.

Proper Lubrication

Applying appropriate lubricants to moving parts is essential for minimizing friction and wear. Regularly check and replenish lubricants as needed, ensuring that all joints and bearings are adequately serviced. This practice not only promotes smooth operation but also helps prevent premature failure.

Common Issues and Solutions

When working with outdoor power tools, users may encounter a range of typical problems that can affect performance and efficiency. Identifying these issues promptly is essential to ensure the longevity of the equipment and to minimize downtime.

1. Difficulty Starting

If the machine is hard to start, check the fuel mixture and ensure it’s fresh. Clogged air filters or spark plugs can also lead to ignition issues. Regular maintenance can prevent this problem from occurring.

2. Poor Cutting Performance

Inadequate cutting power may arise from dull blades or improper tension. Regularly sharpening cutting tools and checking their alignment can improve performance. Additionally, ensuring the right technique while using the equipment is crucial.

3. Overheating

Excessive heat can result from insufficient lubrication or blocked ventilation. Always monitor oil levels and clean any debris that may obstruct airflow. Taking breaks during operation can also help mitigate this issue.

4. Vibration Issues

Excessive vibration can indicate worn components or unbalanced parts. Regular inspections and timely replacement of faulty parts will enhance user comfort and operational stability.

By addressing these common challenges, users can enjoy a smoother experience with their outdoor tools and maintain optimal performance.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repairs. These illustrations provide a clear overview of various elements, allowing users to identify specific pieces and their arrangements within a system.

When analyzing these visuals, focus on the labels and numbers associated with each item. This information typically corresponds to a list detailing descriptions and part numbers, facilitating easy ordering and replacement. Familiarize yourself with common symbols used in these representations, as they often indicate function or relation to other components.

| Symbol | Description |

|---|---|

| ✓ | Included in assembly |

| × | Not included in assembly |

| # | Indicates quantity required |

Utilizing these guides effectively can streamline your repair processes, ensuring that you have the correct items on hand when needed. Take the time to practice interpreting these visuals to enhance your skills and confidence in handling repairs.

Tools Required for Assembly

Proper assembly of equipment requires a selection of essential instruments to ensure functionality and safety. Using the right tools not only streamlines the process but also helps prevent damage to components.

Below is a list of tools commonly needed for the assembly process:

| Tool | Purpose |

|---|---|

| Screwdriver | For fastening screws securely in place. |

| Wrench | To tighten or loosen nuts and bolts. |

| Pliers | Useful for gripping and bending components. |

| Hex Key | For assembling parts with hexagonal sockets. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

Safety Precautions During Repairs

When undertaking maintenance on any mechanical device, ensuring safety is paramount. Proper precautions not only protect the individual performing the task but also prevent potential damage to the equipment. Adhering to safety guidelines minimizes the risk of accidents and enhances the efficiency of the repair process.

Essential Safety Gear

Before beginning any repair work, it is crucial to equip yourself with appropriate protective gear. This gear includes:

- Safety goggles to shield your eyes from debris.

- Gloves to protect your hands from sharp components.

- Sturdy footwear to prevent injuries from heavy objects.

Work Environment Considerations

A well-organized and safe workspace significantly contributes to a smooth repair process. Keep the following tips in mind:

- Ensure adequate lighting to clearly see all components.

- Maintain a clutter-free area to avoid tripping hazards.

- Have all necessary tools within reach to minimize movement during repairs.

By adhering to these safety measures, you create a secure environment that facilitates effective maintenance and reduces the likelihood of mishaps.

Comparing with Other Stihl Models

When evaluating various models from a leading brand in outdoor equipment, it’s essential to analyze their features and performance. This comparison sheds light on the distinctions and similarities, helping users choose the right tool for their specific needs.

Performance Overview

Different models showcase unique capabilities in terms of power output and efficiency. While some are designed for heavy-duty tasks, others excel in lightweight applications. Understanding these differences is crucial for users to select the best fit for their workload.

Maintenance and Parts Availability

Another vital aspect to consider is the ease of maintenance and the availability of components. Some models may require more frequent servicing, while others are engineered for durability and low upkeep. Users should assess how these factors impact long-term usage.

Where to Find Replacement Parts

Locating suitable components for your equipment can be crucial for maintaining optimal performance. Various avenues exist to acquire these essential items, ensuring that you can continue using your device without interruption.

Online retailers often provide a vast selection of quality replacements. Websites specializing in outdoor machinery typically feature an extensive inventory, making it easy to browse and order what you need from the comfort of your home. Additionally, you can explore forums and community groups where enthusiasts share recommendations and personal experiences regarding reliable suppliers.

Local dealers also play a significant role in sourcing necessary elements. Visiting a nearby shop allows you to consult with knowledgeable staff who can assist you in finding the correct items. They may even offer guidance on installation, ensuring you get the best performance from your equipment.

Lastly, consider checking out second-hand marketplaces. These platforms can be treasure troves for finding used but functional components at a fraction of the cost. However, it’s important to verify the condition and compatibility before making a purchase.

Ordering from Authorized Dealers

Acquiring components from certified retailers ensures that you receive high-quality and reliable items for your equipment. These authorized vendors are equipped with the knowledge and expertise to assist you in finding the right solutions tailored to your specific needs.

When placing an order, it is essential to verify that you are purchasing from a reputable source. Authorized dealers provide genuine merchandise, which enhances performance and longevity. Furthermore, they often offer warranties and customer support, providing peace of mind with your purchase.

To facilitate the ordering process, consider reaching out to your local dealer or visiting their website. Most authorized retailers have comprehensive catalogs that outline available options, making it easier to select the necessary components. Additionally, many dealers offer online ordering systems, allowing for convenient transactions from the comfort of your home.

Remember to provide the model and specifications of your equipment when making inquiries. This information aids the dealer in ensuring that you receive the correct items for optimal functionality.

In summary, utilizing authorized dealers for your component needs not only guarantees the quality of products but also supports your equipment’s efficiency and reliability. Always prioritize purchasing from certified sources to ensure the best outcomes for your investments.

Using Diagrams for Troubleshooting

Visual representations can significantly enhance the troubleshooting process by providing clear insights into the components and their relationships within a device. These illustrations serve as valuable references, allowing users to identify issues more efficiently and implement effective solutions.

Benefits of Visual Aids

Utilizing graphic aids streamlines the identification of malfunctioning elements, facilitating quicker resolutions. Users can easily compare the actual setup with the reference material, minimizing confusion and reducing the likelihood of mistakes during repairs.

Effective Troubleshooting Steps

To maximize the utility of these visual aids, follow a systematic approach:

| Step | Action |

|---|---|

| 1 | Identify the issue by observing the performance of the equipment. |

| 2 | Refer to the visual representation to locate the relevant components. |

| 3 | Cross-check the physical parts with the illustration to pinpoint discrepancies. |

| 4 | Implement repairs or replacements based on the findings. |

FAQs About Stihl 009L Parts

This section addresses common inquiries regarding components for a specific model of chainsaw. Understanding these elements can help users maintain and operate their equipment effectively, ensuring optimal performance and longevity.

What are the most frequently replaced components?

Users often find that the fuel filter, air filter, and spark plug require regular replacement. These items play a crucial role in maintaining the efficiency of the machinery and preventing operational issues.

Where can I find replacement components?

Replacement items can typically be sourced from authorized dealers, online retailers, or local hardware stores. It’s important to verify compatibility with the specific model to ensure seamless functionality.