This section delves into the intricate layout of a renowned cutting implement, known for its reliability and efficiency. Understanding the configuration and arrangement of various elements is essential for anyone seeking to maintain or repair this device. By familiarizing oneself with the structure, users can enhance their operational skills and ensure longevity in performance.

The visual representation provided here illustrates the essential components of this equipment, highlighting their specific functions and interconnections. Each element plays a crucial role in the overall functionality, contributing to the seamless operation that users have come to appreciate. Mastering the nuances of these features can significantly improve one’s handling and troubleshooting abilities.

Whether you are an experienced operator or a newcomer to the field, grasping the details presented in this section will empower you to make informed decisions regarding maintenance and repairs. An in-depth understanding of the configuration not only aids in efficient usage but also fosters a deeper appreciation for the craftsmanship behind this classic tool.

Understanding the Stihl 010 AV Chainsaw

The model in question is a classic piece of equipment, designed for efficient cutting and heavy-duty tasks. Its robust construction and user-friendly features make it a reliable choice for both professionals and enthusiasts. This article will explore the essential components, functionality, and maintenance tips to enhance the longevity of this powerful tool.

Key Features and Benefits

This device is equipped with a powerful engine that ensures optimal performance during operation. The design allows for easy handling, reducing fatigue and enhancing user comfort. Furthermore, it incorporates advanced safety mechanisms to protect the operator while working, making it a suitable choice for various cutting tasks.

Maintenance Essentials

Regular upkeep is crucial for ensuring the efficiency and longevity of this machinery. Routine checks of the essential elements, such as the air filter, fuel system, and lubrication components, can prevent potential issues. Cleaning the filters and ensuring proper fuel quality will significantly enhance performance. Familiarizing oneself with the assembly will also aid in troubleshooting and necessary repairs.

Key Features of Stihl 010 AV

This powerful cutting tool is renowned for its exceptional performance and reliability, making it a popular choice among professionals and enthusiasts alike. With its robust construction and advanced technology, it offers users a seamless experience during operation, ensuring efficiency and precision in various applications.

Among its standout characteristics are lightweight design, ergonomic grip, and innovative safety features. These elements work together to enhance user comfort and reduce fatigue, allowing for extended use without compromising performance.

| Feature | Description |

|---|---|

| Powerful Engine | Delivers high torque and cutting power, making it suitable for tough tasks. |

| Low Vibration | Minimizes operator fatigue, enhancing comfort during prolonged use. |

| Easy Start System | Facilitates quick and effortless ignition, even in cold conditions. |

| Durable Construction | Built with high-quality materials for longevity and reliability. |

| Adjustable Oil Pump | Allows for precise lubrication control based on cutting conditions. |

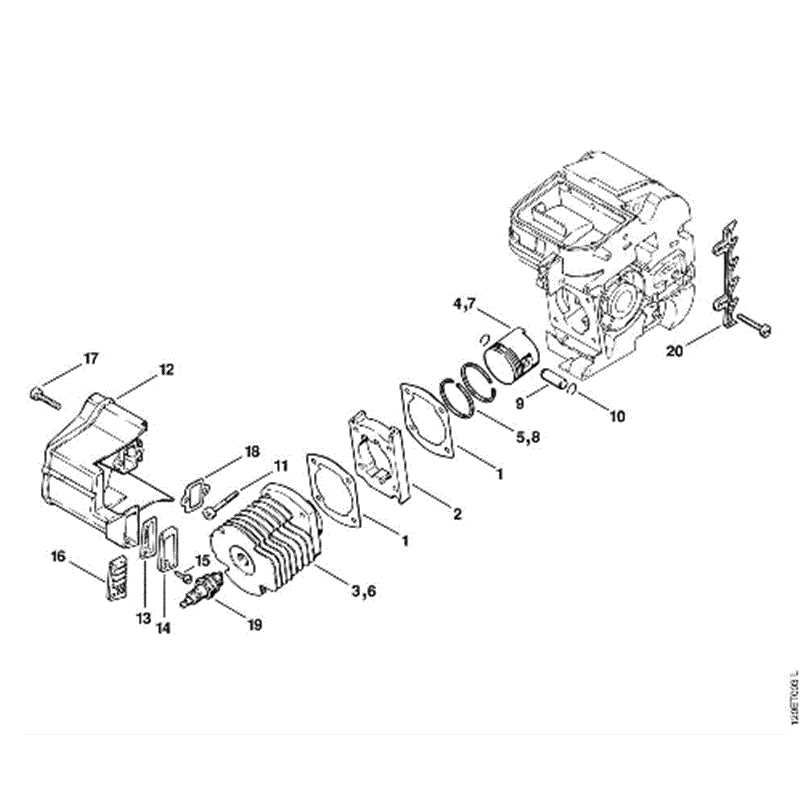

Components of the Chainsaw Engine

The functionality of a cutting tool relies heavily on its engine, which serves as the heart of the device. Each component within this assembly plays a crucial role in ensuring efficient operation, power generation, and overall performance. Understanding these elements can help in maintaining and troubleshooting the machinery effectively.

Piston and Cylinder

The piston and cylinder form the core of the combustion chamber, where fuel and air mix for ignition. The movement of the piston within the cylinder generates the power needed for operation. This dynamic interaction creates the force required to drive the cutting mechanism, making it vital for optimal performance.

Crankshaft and Ignition System

The crankshaft converts the linear motion of the piston into rotational motion, which ultimately powers the tool. Paired with this component is the ignition system, responsible for igniting the fuel-air mixture at the precise moment. This synchronization ensures that the engine runs smoothly and efficiently, providing the necessary power for cutting tasks.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of any mechanical device relies heavily on regular upkeep and care. This practice not only enhances performance but also contributes to safety and reliability. Ignoring maintenance tasks can lead to reduced functionality and unexpected failures, ultimately increasing repair costs and downtime.

Adopting a systematic approach to maintenance can yield several benefits:

- Enhanced Performance: Regular checks and servicing keep equipment running smoothly and efficiently.

- Increased Lifespan: Proper care can significantly extend the operational life of the machine.

- Safety Assurance: Well-maintained tools are less likely to malfunction, reducing the risk of accidents.

- Cost Savings: Preventative maintenance helps avoid costly repairs and replacements by addressing issues early.

Key maintenance tasks typically include:

- Cleaning: Regularly remove debris and dirt to prevent buildup.

- Lubrication: Ensure all moving parts are properly lubricated to minimize wear.

- Inspection: Routinely check for any signs of wear or damage that may need attention.

- Sharpening: Keep cutting edges sharp for optimal performance.

In conclusion, consistent maintenance is essential for the effective operation of any equipment. By prioritizing regular care, users can enjoy improved performance, safety, and overall satisfaction with their tools.

Identifying Common Replacement Parts

Understanding the components of a cutting tool is essential for effective maintenance and repairs. Recognizing which elements may require replacement can enhance performance and prolong the tool’s lifespan. Below are some of the most frequently replaced items in these machines.

- Bar: The guide element that holds the cutting chain in place. A worn or damaged bar can significantly affect cutting efficiency.

- Chain: The loop of sharp links that cuts through the material. Regular inspection is necessary to detect any wear or breakage.

- Air Filter: This component prevents dirt and debris from entering the engine, ensuring optimal performance. A clogged filter can lead to power loss.

- Fuel Filter: This part keeps impurities from contaminating the fuel system, essential for smooth operation.

- Spark Plug: Responsible for igniting the fuel-air mixture in the combustion chamber. Replacing it can restore lost power and improve starting.

Regular maintenance and timely replacement of these essential components can help maintain the efficiency and reliability of your tool. Always consult the manufacturer’s guidelines for specific recommendations regarding replacements.

Using the Parts Diagram Effectively

Utilizing a visual representation of components can significantly enhance your understanding and maintenance of a specific tool. This guide emphasizes the importance of leveraging such illustrations to facilitate repairs and ensure optimal performance of your equipment. By familiarizing yourself with the layout and interrelations of various elements, you can streamline the process of identification and replacement.

To maximize the effectiveness of this resource, consider the following strategies:

| Strategy | Description |

|---|---|

| Familiarization | Study the illustration carefully to understand the arrangement and function of each component. |

| Identification | Use the visual aid to identify worn or damaged elements that may require attention. |

| Replacement Planning | Plan your repairs by noting the specific items that need replacing, making your shopping list more efficient. |

| Assembly Guidance | Refer to the illustration when reassembling parts to ensure everything is put back in its proper place. |

By incorporating these techniques, you can enhance your efficiency and effectiveness in maintaining your equipment, ensuring it remains in peak condition for all your tasks.

Troubleshooting Common Issues

Every mechanical tool can encounter problems that may hinder its performance. Identifying and resolving these issues promptly is essential to maintain functionality and ensure safety. This section provides guidance on recognizing and fixing frequent complications that may arise during operation.

Identifying Symptoms

Understanding the symptoms of potential malfunctions is the first step in effective troubleshooting. Here are some common indicators to watch for:

- Difficulty starting the equipment

- Inconsistent power during operation

- Unusual noises while running

- Excessive vibration

- Visible wear or damage to components

Common Solutions

Once symptoms are identified, follow these troubleshooting steps to resolve the issues:

- Check the Fuel System:

- Ensure there is adequate fuel and that it is fresh.

- Inspect for any blockages in the fuel lines.

- Inspect the Ignition System:

- Examine the spark plug for wear and replace if necessary.

- Check the ignition coil and connections for proper function.

- Examine the Air Filter:

- Clean or replace the air filter to ensure proper airflow.

- Inspect the Chain and Bar:

- Look for signs of wear or damage on the chain.

- Ensure proper tension and lubrication of the chain.

By following these guidelines, you can effectively troubleshoot and maintain your equipment, ensuring optimal performance and longevity.

Safety Precautions While Operating

Ensuring personal safety is paramount when utilizing any power equipment. Proper awareness of potential hazards and adherence to recommended guidelines can significantly reduce the risk of accidents and injuries. This section outlines essential precautions that operators should observe to maintain a secure working environment.

Protective Gear

Wearing appropriate protective clothing is vital. Operators should always don safety goggles to shield their eyes from debris, ear protection to guard against noise, and sturdy gloves for grip and protection. Additionally, wearing reinforced footwear and chainsaw chaps can offer further defense against accidental cuts and falls.

Work Environment

Before commencing work, it is crucial to assess the surrounding area. Ensure the workspace is clear of obstacles and hazards, such as loose branches or uneven ground. Maintaining a safe distance from bystanders and pets will also help to prevent potential accidents. Always keep both hands on the tool and maintain a firm footing to enhance control and stability during operation.

Choosing the Right Accessories

When it comes to enhancing the performance and efficiency of your outdoor equipment, selecting the appropriate accessories is crucial. The right tools can significantly improve functionality, safety, and ease of use, making your tasks more manageable and enjoyable. Understanding your specific needs and the features of available attachments can lead to better results and a more satisfying experience.

Consider Your Needs

Before purchasing any accessories, it’s essential to evaluate what tasks you’ll be performing. For instance, if you are focused on precision cutting, specific attachments may be necessary to achieve desired outcomes. Additionally, consider the frequency of use and the type of material you will be working with. This will guide you in selecting attachments that not only fit your equipment but also meet your operational requirements.

Quality Matters

Investing in high-quality accessories is vital for optimal performance. Durability and reliability should be at the forefront of your decision-making process. Premium attachments often come with enhanced features that can extend the lifespan of your equipment. It’s advisable to research various brands and read reviews to ensure that the accessories you choose are compatible and highly rated by other users.

How to Assemble the Chainsaw

Putting together a cutting tool requires careful attention to detail and a clear understanding of its components. This process ensures optimal performance and safety during use. Following a systematic approach can help you effectively assemble the equipment while minimizing the risk of errors.

Step-by-Step Assembly Process

Begin by gathering all necessary components and tools. Refer to your assembly guide to identify each piece. Start with the frame, attaching the motor securely. Next, install the guiding mechanism and ensure it is aligned correctly. Follow this by fixing the blade and any other attachments, making sure everything is tightened properly to avoid any accidents during operation.

Final Checks and Maintenance

After assembly, perform a thorough inspection to confirm that all elements are securely fitted and functioning as intended. Check for any signs of wear or misalignment. Regular maintenance, including lubrication and cleaning, will prolong the lifespan of your equipment and ensure its reliability in demanding tasks.

Adjusting Tension and Chain Features

Proper adjustment of tension and understanding chain characteristics are essential for optimal performance and longevity of cutting tools. Achieving the right balance ensures efficient operation, preventing unnecessary wear and potential damage during use. Regular maintenance, including tension adjustments, enhances safety and improves the overall effectiveness of the equipment.

Importance of Chain Tension

Maintaining the correct tension on the cutting element is vital for several reasons:

- Prevents the chain from slipping off during operation.

- Reduces the risk of binding, which can lead to stalling.

- Enhances cutting efficiency, allowing for smoother operations.

- Extends the lifespan of both the chain and the guide bar.

Adjusting Chain Tension

To adjust the tension correctly, follow these steps:

- Ensure the tool is turned off and the guide bar is free from debris.

- Locate the tensioning mechanism, typically found at the rear or side of the bar.

- Using the appropriate tool, turn the tensioning screw clockwise to tighten or counterclockwise to loosen.

- Check the tension by pulling the chain slightly away from the guide bar; it should snap back into place without excessive force.

- Once satisfied, secure all components and check for proper operation before use.

Regularly checking and adjusting the tension not only improves performance but also enhances safety, ensuring that the equipment operates smoothly and effectively.

Resources for Further Assistance

For those seeking additional help and information, numerous avenues are available to enhance your understanding and support your needs. Whether you’re looking for detailed manuals, online forums, or customer service contacts, a wealth of resources exists to assist you in your endeavors.

User Manuals and Documentation

Accessing comprehensive guides can significantly enhance your knowledge. Manuals provide essential insights into operation, maintenance, and troubleshooting. Here are some sources to consider:

| Resource | Description |

|---|---|

| Manufacturer’s Website | Visit the official site for downloadable manuals and product information. |

| Online Retailers | Many e-commerce platforms offer PDF versions of product guides. |

| Community Forums | Participate in discussion boards where users share tips and advice. |

Customer Support Services

When issues arise, reaching out to dedicated support services can provide direct assistance. Consider the following options:

| Service Type | Details |

|---|---|

| Helplines | Contact customer support via phone for immediate assistance. |

| Email Support | Use email to submit inquiries for detailed responses. |

| Live Chat | Engage with representatives in real-time through chat features. |

Comparing with Other Models

This section focuses on evaluating the features and specifications of a specific model against its counterparts in the market. Understanding these differences can assist users in making informed decisions based on their specific needs and preferences.

Key Features to Consider

- Power Output: Compare engine capabilities to determine which model delivers superior performance.

- Weight: Analyze the weight of each unit for ease of handling and maneuverability during operation.

- Fuel Efficiency: Examine how various models perform in terms of fuel consumption for prolonged usage.

- Durability: Assess the materials used in construction and their impact on longevity under different conditions.

- Maintenance Requirements: Review the frequency and complexity of required upkeep across different models.

Popular Alternatives

- Model A: Known for its lightweight design and user-friendly features, making it ideal for homeowners.

- Model B: Offers robust power output suitable for professional-grade tasks.

- Model C: Features advanced safety mechanisms, appealing to first-time users.

In conclusion, when selecting the right tool, it’s essential to weigh these aspects against personal requirements and preferences to find the most suitable option.