For enthusiasts and professionals alike, maintaining the efficiency of your outdoor power equipment is essential for achieving optimal performance. A clear understanding of the intricate elements that make up these machines can significantly enhance your repair and maintenance efforts. By familiarizing yourself with the structure and functionality of each component, you can ensure your device operates at its best.

In this section, we will delve into the various segments that constitute your device, highlighting their roles and interconnections. Whether you are troubleshooting issues or conducting routine checks, having a comprehensive view of these elements will prove invaluable. With the right knowledge, you can tackle repairs with confidence and keep your equipment running smoothly.

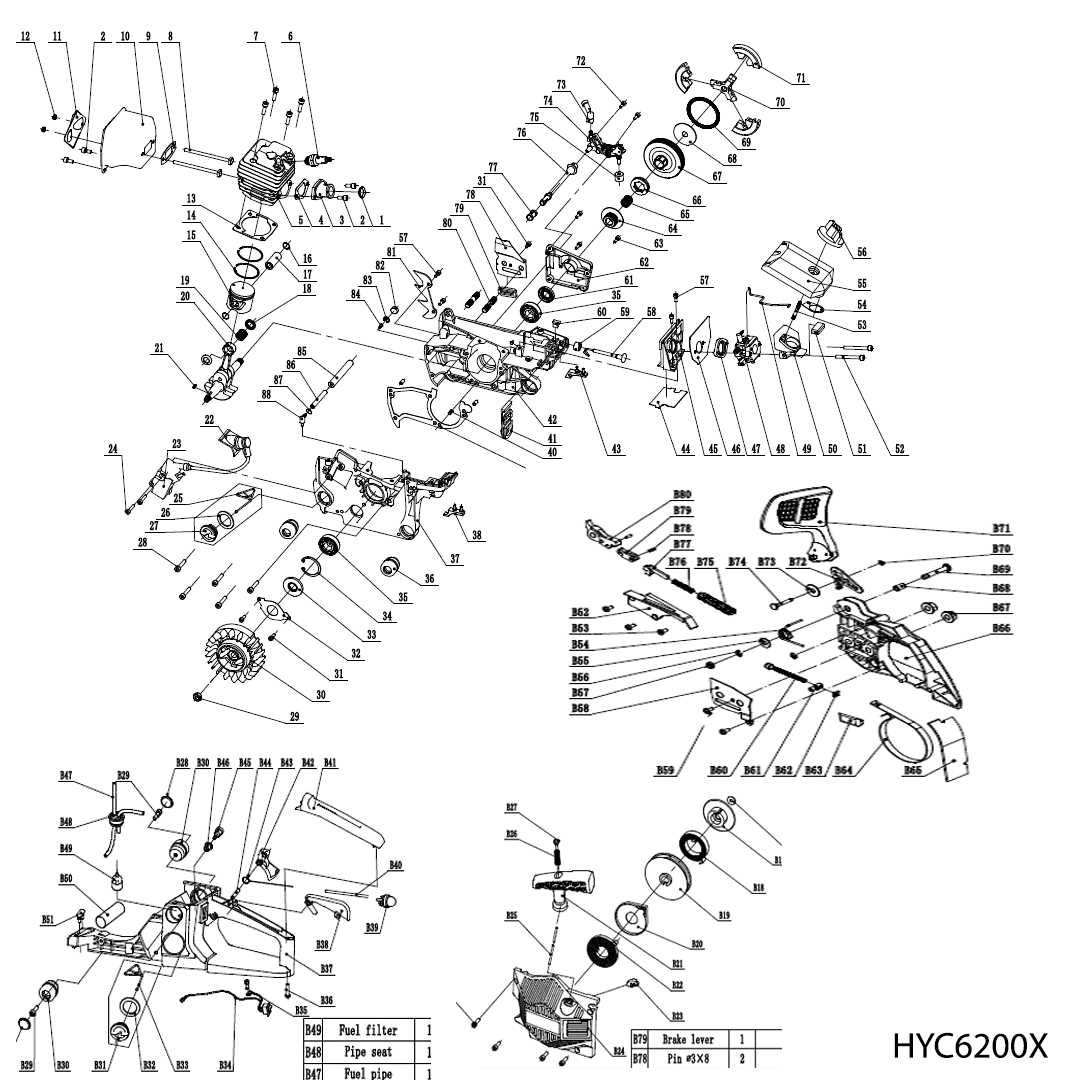

Additionally, we will provide a detailed visual reference that outlines the arrangement and specifications of each part. This resource will serve as a guide, simplifying your repair tasks and enhancing your understanding of how everything works together. Embracing this knowledge will empower you to maintain and optimize your machine effectively.

Understanding the Stihl 025 Chainsaw

This section explores the key components and functionality of a popular power tool designed for cutting and trimming. By examining its various elements, users can enhance their familiarity and ensure optimal performance.

- Engine: Powers the tool and determines cutting efficiency.

- Guide Bar: Provides the surface along which the cutting mechanism operates.

- Chain: The essential element that performs the actual cutting action.

- Handle: Offers control and stability during operation.

- Safety Features: Designed to protect the user during operation.

Understanding these components allows for better maintenance and effective use, ultimately leading to improved results in various cutting tasks.

Overview of Chainsaw Components

This section provides an insight into the essential elements that make up a cutting tool, focusing on their functions and interactions. Understanding these components is crucial for effective operation, maintenance, and troubleshooting.

Essential Elements

The primary components include the engine, bar, and cutting chain. The engine serves as the powerhouse, converting fuel into mechanical energy. The bar acts as a guide, determining the length of the cut, while the cutting chain is responsible for the actual cutting action. Each part must work harmoniously to ensure efficiency and performance.

Supporting Components

In addition to the main elements, there are several supporting features that enhance usability. The fuel tank stores the necessary fuel, while the oil reservoir provides lubrication to the chain, reducing wear. Safety features, such as the chain brake, are also vital, helping to prevent accidents during operation.

Importance of Replacement Parts

Maintaining optimal performance in any mechanical tool relies heavily on the quality and integrity of its components. Over time, wear and tear can lead to diminished efficiency and increased risk of failure. This makes the use of reliable substitutes essential for preserving functionality and safety.

Quality replacements play a crucial role in ensuring that equipment operates smoothly and efficiently. Using inferior alternatives can compromise the entire system, leading to subpar performance and potentially hazardous situations. Moreover, selecting appropriate components is vital for prolonging the lifespan of the equipment, ultimately saving time and resources.

Additionally, regular inspection and timely replacement of worn-out elements foster a proactive maintenance approach. This not only enhances the tool’s reliability but also instills confidence in users, knowing that their equipment is in optimal condition. Therefore, understanding the significance of quality substitutes is indispensable for anyone committed to effective and safe operation.

Common Issues with Stihl 025

Understanding the frequent problems that may arise with this particular model can significantly enhance its performance and longevity. Users often encounter various operational challenges that can be addressed with proper maintenance and troubleshooting techniques.

Engine Troubles

One of the most prevalent issues involves the engine failing to start or running inconsistently. This can be attributed to factors such as fuel blockage, spark plug malfunctions, or air filter obstructions. Regular checks and timely replacements can mitigate these issues.

Bar and Chain Problems

Another common concern includes wear and tear on the bar and chain, leading to inefficient cutting. Ensuring proper lubrication and tension adjustments is essential. Neglecting these components can result in decreased performance and potential damage to the tool.

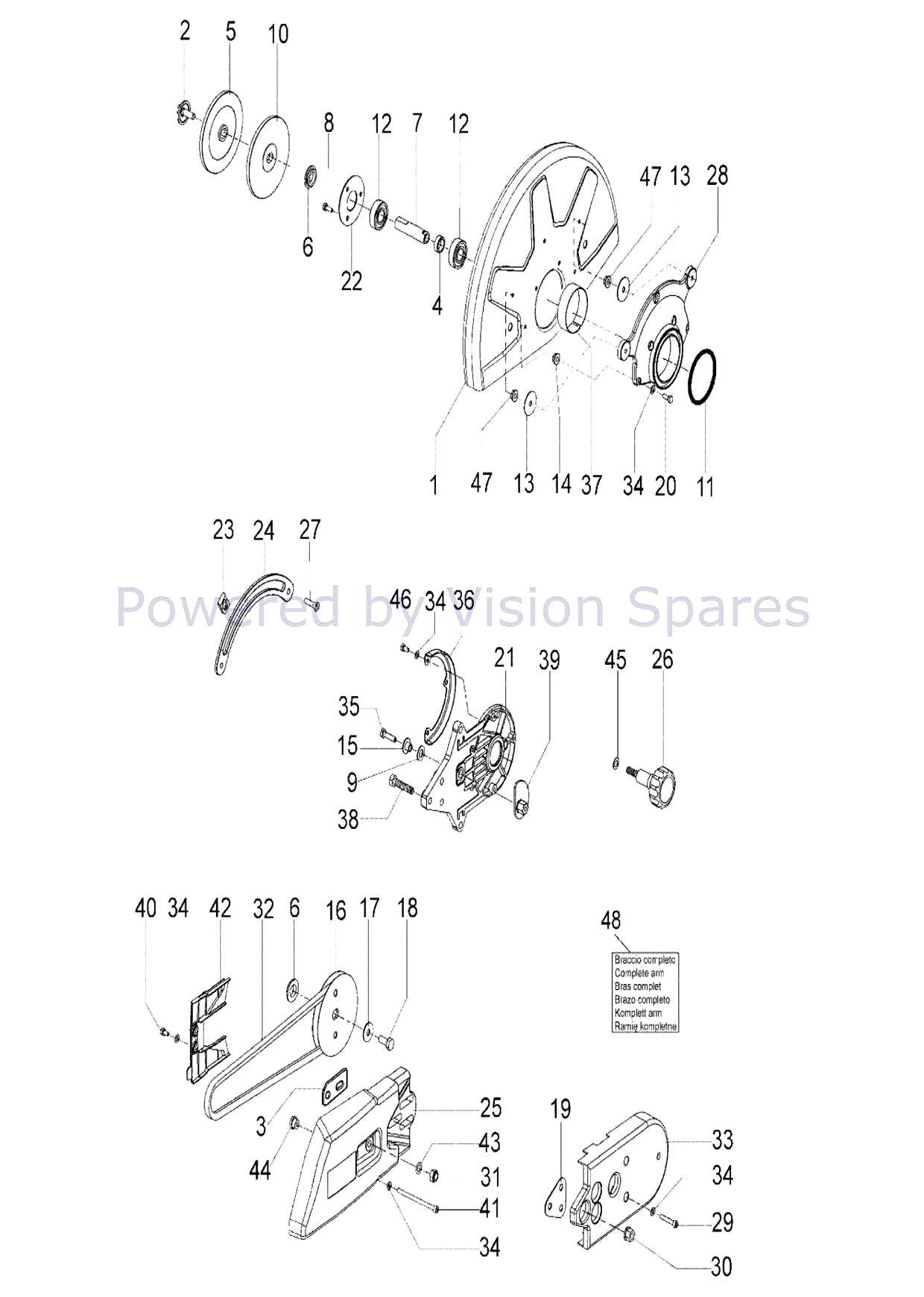

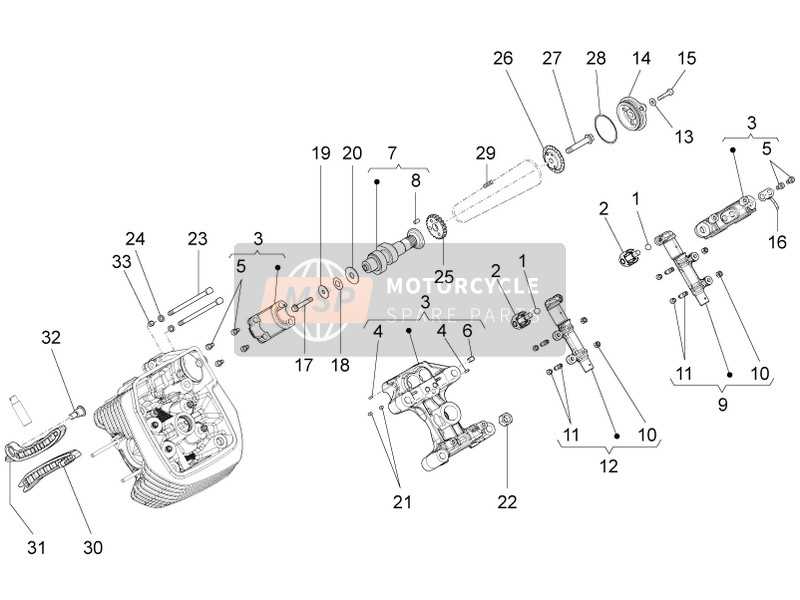

How to Interpret Parts Diagrams

Understanding the layout of an assembly illustration can greatly enhance your ability to repair or maintain equipment. These visual representations serve as guides, showcasing components and their relationships. By familiarizing yourself with their structure, you can efficiently identify the necessary elements for your task.

Begin by identifying the key sections of the illustration, which often include a legend or reference key. This will help you match component numbers with their corresponding names. Pay attention to any annotations that may indicate specific assembly instructions or maintenance tips, as these can be invaluable during your project.

Additionally, observe the arrangement of parts; this reflects the order in which they are typically assembled or disassembled. Taking note of the orientation and placement of each item can prevent errors and streamline your process. Finally, always cross-reference with the manufacturer’s documentation to ensure accuracy and completeness.

Essential Tools for Maintenance

Proper upkeep of outdoor power equipment requires a set of key implements to ensure optimal performance and longevity. These instruments not only facilitate routine checks but also assist in troubleshooting any issues that may arise during operation.

Wrenches are fundamental for adjusting and tightening various components, allowing for quick repairs and enhancements. Additionally, screwdrivers are necessary for accessing intricate areas, ensuring that all fastenings are secure. A reliable fuel mixing container is crucial for maintaining the correct fuel-to-oil ratio, which directly impacts efficiency.

Lubricants play a vital role in reducing friction and wear, extending the life of moving parts. Finally, a cleaning kit is essential for removing debris and residues that can hinder functionality, ensuring your equipment remains in peak condition.

Where to Find OEM Parts

Locating genuine components for your outdoor power equipment can significantly enhance its performance and longevity. Here are some reliable sources to consider when searching for authentic replacements.

- Authorized Dealers: Visiting a licensed distributor is often the best option. They usually carry a comprehensive selection of genuine components and can provide expert advice.

- Official Manufacturer Website: Many manufacturers offer a dedicated section on their websites where you can order genuine parts directly. This ensures you receive the correct items tailored for your equipment.

- Online Retailers: Reputable e-commerce platforms often have a variety of original components available. Always check the seller’s ratings and reviews to ensure reliability.

- Local Repair Shops: Many service centers not only repair equipment but also sell authentic components. Establishing a relationship with a local shop can be beneficial for future maintenance.

- Manufacturer Catalogs: Some brands publish detailed catalogs that list available components. These can be useful for identifying the exact parts you need.

By exploring these avenues, you can find the right components to keep your equipment operating smoothly and efficiently.

DIY Repairs for the Stihl 025

Taking on repairs for your cutting tool can be a rewarding experience that not only saves money but also enhances your understanding of the equipment. With a little knowledge and the right approach, you can address common issues effectively and efficiently.

Assessing the Issue: Begin by identifying the problem. Whether it’s difficulty starting, poor performance, or unusual noises, a thorough examination will help you determine the necessary steps for repair.

Gathering Tools: Equip yourself with essential tools, such as screwdrivers, wrenches, and a manual. Having the right equipment will streamline the process and ensure safety.

Common Fixes: Basic repairs often include replacing the spark plug, cleaning the air filter, or adjusting the chain tension. Each task can significantly improve functionality and longevity.

Safety First: Always prioritize safety by wearing protective gear and following proper procedures. This will help prevent accidents while working on your equipment.

With patience and diligence, you can successfully navigate repairs and keep your tool in peak condition for all your cutting needs.

Safety Tips When Repairing

Ensuring safety during repairs is crucial to prevent accidents and injuries. Following specific guidelines can help maintain a secure environment while working on machinery. Here are essential tips to keep in mind.

Preparation and Environment

- Work in a well-lit area to enhance visibility.

- Clear the workspace of any clutter or distractions.

- Wear appropriate personal protective equipment, including gloves and goggles.

Handling Tools and Components

- Use tools designed for the specific task to avoid mishandling.

- Disconnect power sources before starting any repairs.

- Inspect all components for wear and damage before reassembly.

Regular Maintenance Schedule

Maintaining equipment is essential for optimal performance and longevity. A consistent schedule ensures that all components function efficiently, reducing the risk of failure and enhancing safety. Regular checks and servicing can prevent minor issues from escalating into major problems.

Weekly Checks

- Inspect the air filter for dirt and debris.

- Check the oil level and top up if necessary.

- Examine the cutting mechanism for wear and damage.

Monthly Maintenance

- Sharpen the cutting blade to maintain effectiveness.

- Clean the exterior to remove any buildup.

- Inspect all bolts and screws for tightness.

Upgrades for Enhanced Performance

Improving the efficiency and power of your cutting tool can significantly enhance your overall experience. By selecting the right modifications and enhancements, you can boost performance, increase durability, and optimize functionality for various tasks. This section explores some effective upgrades that can lead to noticeable improvements in performance.

Engine Modifications

One of the most impactful areas for enhancement is the engine. Upgrading to a higher-performance carburetor can improve fuel flow and combustion efficiency, resulting in better power output. Additionally, tuning the ignition system can lead to improved starting and smoother operation. Consider installing a high-performance air filter to ensure optimal airflow, which contributes to increased horsepower.

Cutting Accessories

Switching to premium cutting accessories can drastically affect cutting speed and precision. Opt for chains designed for specific materials, such as hardwoods or softwoods, to maximize efficiency. Using a bar with a longer length may also enhance your reach and cutting capabilities. Regular maintenance of these components, including sharpening and lubrication, is essential for sustained performance improvement.

Comparing Stihl Models and Parts

When exploring different models within a well-known brand, it’s essential to examine the unique features and components that distinguish each variant. Each version offers a range of specifications, designed to cater to diverse needs and preferences of users. By understanding the similarities and differences among these models, enthusiasts and professionals alike can make informed choices.

Key characteristics often include engine size, weight, and intended use, which can vary significantly across models. For instance, some versions are tailored for heavy-duty tasks, while others are better suited for lighter, more occasional use. These variations not only affect performance but also influence maintenance requirements and part compatibility.

Additionally, examining the available components for each model can reveal insights into repairability and customization options. Understanding which parts are interchangeable between models may also benefit users seeking to enhance their equipment’s efficiency or longevity.

Ultimately, a thorough comparison of the different offerings within this brand allows potential buyers to select the best model for their specific tasks, ensuring optimal performance and satisfaction.

Resources for Further Learning

Expanding your knowledge about maintenance and repairs can significantly enhance your skills and confidence. Various resources offer insights and detailed information that can guide you through understanding the components and their functions in power tools.

Books and Manuals

- Maintenance guides specific to power tools.

- Repair manuals that cover troubleshooting techniques.

- Comprehensive handbooks on tool mechanics and design.

Online Platforms

- Video tutorials on platforms like YouTube.

- Forums and communities for exchanging tips and experiences.

- Websites dedicated to tool reviews and comparisons.