In the realm of outdoor machinery, comprehending the intricate elements that make up your device is essential for optimal performance and longevity. This knowledge empowers users to diagnose issues effectively and carry out maintenance with confidence.

By exploring the various components and their arrangement, one can gain valuable insights into the functionality of the equipment. This understanding not only facilitates repairs but also enhances the overall user experience, ensuring that the machine operates at its best.

Whether you are a seasoned user or a newcomer, familiarizing yourself with the essential parts can lead to a more efficient and rewarding experience. A well-informed approach to machinery care ultimately translates to improved results in your outdoor tasks.

Stihl 025c Parts Overview

This section provides an essential understanding of the various components that contribute to the functionality and efficiency of the machine. Each element plays a crucial role in ensuring optimal performance and reliability.

Main Components

- Engine assembly

- Fuel system

- Air filter

- Starter mechanism

- Chain brake

Accessories and Extras

- Guide bar

- Chain links

- Tool kit

- Safety gear

Understanding these various elements can assist users in maintenance and troubleshooting, ensuring the longevity and effectiveness of their equipment.

Essential Components of the Model

The functionality and efficiency of this tool rely on several key elements that work harmoniously together. Understanding these components is crucial for both maintenance and optimal performance.

Power System

The engine serves as the heart of the device, providing the necessary energy for operation. A reliable power source ensures that the equipment can handle various tasks without interruption. Regular checks on this system can prevent unexpected failures.

Cutting Mechanism

Central to the tool’s effectiveness is the cutting assembly, which is designed for precision and durability. The quality of this mechanism directly influences the performance and the quality of the work done. Proper alignment and maintenance are essential to achieve the best results.

In conclusion, familiarizing oneself with these essential components can significantly enhance the overall user experience and prolong the lifespan of the equipment. Regular maintenance and careful attention to each part are key to achieving optimal functionality.

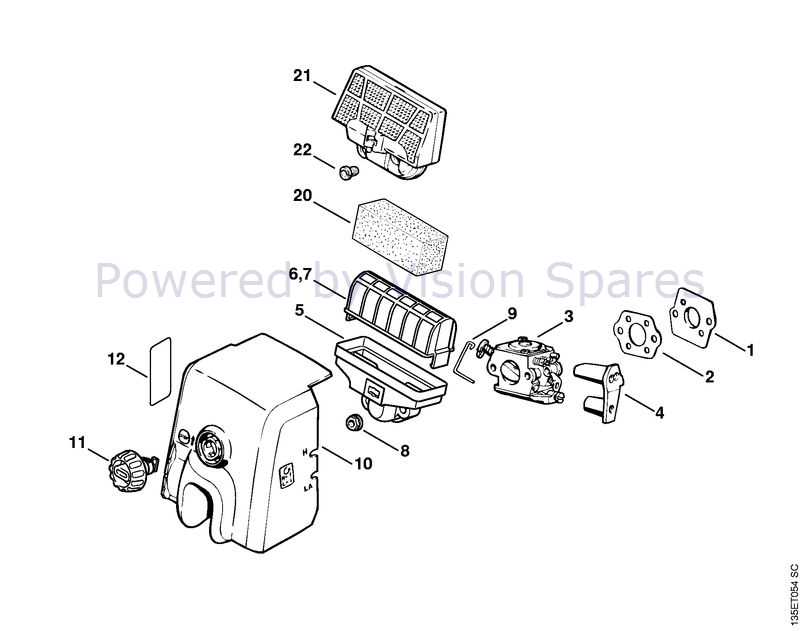

Understanding the Parts Diagram

A comprehensive overview of a machine’s components is essential for effective maintenance and repairs. By familiarizing oneself with this visual representation, users can identify each element’s role and locate specific pieces when needed. This knowledge enhances the ability to troubleshoot issues efficiently.

The illustration typically includes various sections, each highlighting different groups of components. Below is a simplified representation of some common elements:

| Component | Description |

|---|---|

| Engine | Power source that drives the machine. |

| Fuel Tank | Holds the fuel necessary for operation. |

| Bar | The part that guides the cutting chain. |

| Chain | Rotates around the bar for cutting purposes. |

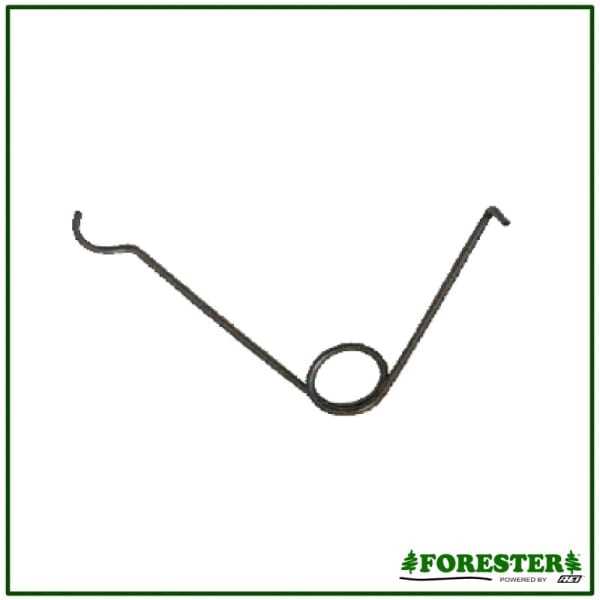

Common Replacement Parts List

This section outlines frequently replaced components for efficient maintenance of your equipment. Regularly inspecting and updating these elements can enhance performance and extend the lifespan of the machine.

- Air Filter: Ensures proper airflow and engine efficiency.

- Fuel Filter: Prevents contaminants from entering the fuel system.

- Spark Plug: Essential for ignition and optimal combustion.

- Chain: Critical for cutting performance and should be sharpened or replaced as needed.

- Sprocket: Works with the chain to facilitate smooth operation.

- Oil Pump: Delivers lubrication to maintain chain and bar health.

- Bar: The guiding structure for the cutting chain, subject to wear over time.

Regularly checking and replacing these components can lead to improved functionality and reduced downtime.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its durability and efficient performance over time. By following a few simple maintenance practices, you can significantly extend the lifespan of your tools and keep them running smoothly.

Regular Cleaning

Keeping your equipment clean is crucial. After each use, wipe down surfaces to remove dirt and debris. Regularly check for any build-up that could affect performance. Clean filters and air intakes to promote optimal airflow and prevent overheating.

Routine Inspections

Conduct regular inspections to identify potential issues before they escalate. Look for signs of wear on components and ensure that all moving parts are well-lubricated. Replace any damaged parts promptly to maintain overall functionality. Following these steps will help ensure your tools remain in peak condition for years to come.

Identifying Wear and Tear Signs

Understanding the indicators of deterioration is crucial for maintaining the longevity and efficiency of equipment. Regular inspections can help spot issues before they escalate, ensuring optimal performance and safety during use.

Common Signs of Wear

- Cracks and Fractures: Look for visible cracks on components, as these can compromise structural integrity.

- Surface Damage: Scratches or gouges on the surface may indicate excessive friction or contact with other parts.

- Rust and Corrosion: Any signs of rust suggest exposure to moisture, which can weaken metal components over time.

Performance Indicators

- Decreased Efficiency: If the machine struggles to operate at its usual capacity, it may signal worn parts.

- Unusual Noises: Grinding or rattling sounds often indicate loose or damaged components.

- Vibration Changes: Increased vibrations during operation can be a sign of imbalance or wear in rotating parts.

How to Order Genuine Parts

Acquiring authentic components for your equipment ensures optimal performance and longevity. When seeking these essential items, following the right steps can simplify the process and guarantee quality.

Steps to Follow

Begin by identifying the specific component needed. Use your device’s model number to ensure you are searching for the correct item. This will help avoid any potential issues with compatibility.

Where to Purchase

There are several reliable sources for acquiring original components. You can explore authorized dealers, reputable online retailers, or even the manufacturer’s website for direct purchases.

| Source | Description |

|---|---|

| Authorized Dealers | Local shops certified to sell genuine components. |

| Online Retailers | Websites that specialize in selling high-quality equipment parts. |

| Manufacturer’s Website | Direct purchasing option from the brand’s official online store. |

Tools Needed for Disassembly

Proper disassembly of equipment requires specific tools to ensure efficiency and safety. Having the right instruments on hand not only facilitates the process but also prevents potential damage to components.

Here is a list of essential tools for effective disassembly:

- Wrenches: A set of various sizes is necessary for loosening bolts and nuts.

- Screwdrivers: Both flathead and Phillips types will cover most screw heads.

- Hex Keys: Also known as Allen wrenches, useful for hexagonal screws.

- Pliers: For gripping and twisting smaller components.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Utility Knife: Handy for cutting through any adhesive or securing materials.

Ensure that all tools are in good condition and readily accessible before beginning the disassembly process. This preparation will help in avoiding interruptions and facilitate a smoother operation.

Step-by-Step Assembly Instructions

This section provides a comprehensive guide for assembling your equipment effectively. Following these instructions will ensure proper functionality and longevity of the device.

- Gather All Components:

Before starting, ensure all parts are collected and organized for easy access.

- Start with the Base:

Begin by placing the main base on a flat surface. Secure any essential components as per the specifications.

- Attach the Handle:

Carefully connect the handle to the main structure. Ensure it fits snugly and securely.

- Install the Motor:

Align the motor with the designated mounts. Use the provided screws to fasten it firmly.

- Connect the Power Supply:

Attach the power supply to the motor. Ensure the connections are tight and secure.

- Final Assembly:

Double-check all connections and parts. Make any necessary adjustments to ensure everything is aligned correctly.

Once all steps are completed, perform a thorough inspection to verify that everything is securely in place before use.

Troubleshooting Common Issues

When operating a power tool, encountering challenges is not uncommon. Understanding the common problems and their potential solutions can enhance the tool’s performance and prolong its lifespan. Below are some frequent issues faced by users and how to address them effectively.

- Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for signs of wear or damage.

- Examine the air filter for blockages that may restrict airflow.

- Unusual Noises:

- Listen for rattling sounds, which may indicate loose components.

- Identify any grinding noises, possibly suggesting worn-out parts.

- Inconsistent Performance:

- Ensure that the cutting mechanism is sharp and properly adjusted.

- Check for any fuel delivery issues that could affect operation.

By regularly maintaining your equipment and being aware of these common challenges, you can ensure smoother operation and mitigate potential setbacks.

Recommended Upgrades for Performance

Enhancing the efficiency and effectiveness of your equipment can significantly improve its overall functionality. By implementing certain modifications and improvements, users can achieve better results and extended service life.

Essential Upgrades

- High-Performance Air Filter: Upgrading to a more efficient air filtration system can enhance airflow and boost engine performance.

- Aftermarket Spark Plug: A premium spark plug can improve ignition efficiency, leading to better fuel combustion and power output.

- Improved Fuel System: Consider installing a performance carburetor or tuning the existing one for optimal fuel delivery.

Maintenance Enhancements

- Regular Lubrication: Ensure all moving parts are well-lubricated to reduce friction and wear.

- Periodic Cleaning: Keep all components clean to prevent buildup that could hinder performance.

- Upgrade to Synthetic Oils: Using high-quality synthetic lubricants can lead to better engine protection and efficiency.

Where to Find Replacement Diagrams

Locating accurate visual guides for various equipment can significantly streamline the maintenance and repair processes. These illustrations often provide essential information about the components and their arrangement, making it easier to identify and source the necessary replacements.

Official Manufacturer Resources

One of the most reliable sources for finding detailed visuals is the official website of the manufacturer. Here, you can often access downloadable manuals or online resources that include comprehensive illustrations of each model’s configuration. It’s advisable to search using the specific model number to ensure the information is relevant.

Online Retailers and Forums

Numerous online retailers specialize in equipment supplies and may offer visual references alongside their product listings. Additionally, community forums and discussion boards related to equipment maintenance can be invaluable. Enthusiasts and experts frequently share diagrams and insights that can help locate specific components or provide tips on where to find them.

Customer Reviews and Feedback

This section aims to provide insights into user experiences and opinions regarding the product’s performance and reliability. Customers often share their thoughts on various aspects, including usability, maintenance, and overall satisfaction.

Many users appreciate the tool’s efficiency and effectiveness in various tasks, highlighting the following points:

- Durability and build quality

- Ease of operation and handling

- Accessibility of replacement components

- Affordability of maintenance

However, some feedback includes constructive criticism, with users mentioning:

- Occasional difficulty in sourcing specific components

- Initial learning curve for new users

- Weight considerations during extended use

Overall, the feedback from the customer community reflects a balanced view, offering valuable insights for potential buyers and existing users.