When maintaining a powerful cutting tool, having a clear understanding of its individual elements is essential. This knowledge not only aids in effective upkeep but also enhances overall performance. Each component plays a crucial role in the functionality and efficiency of the equipment, making it vital to familiarize oneself with their arrangement and interaction.

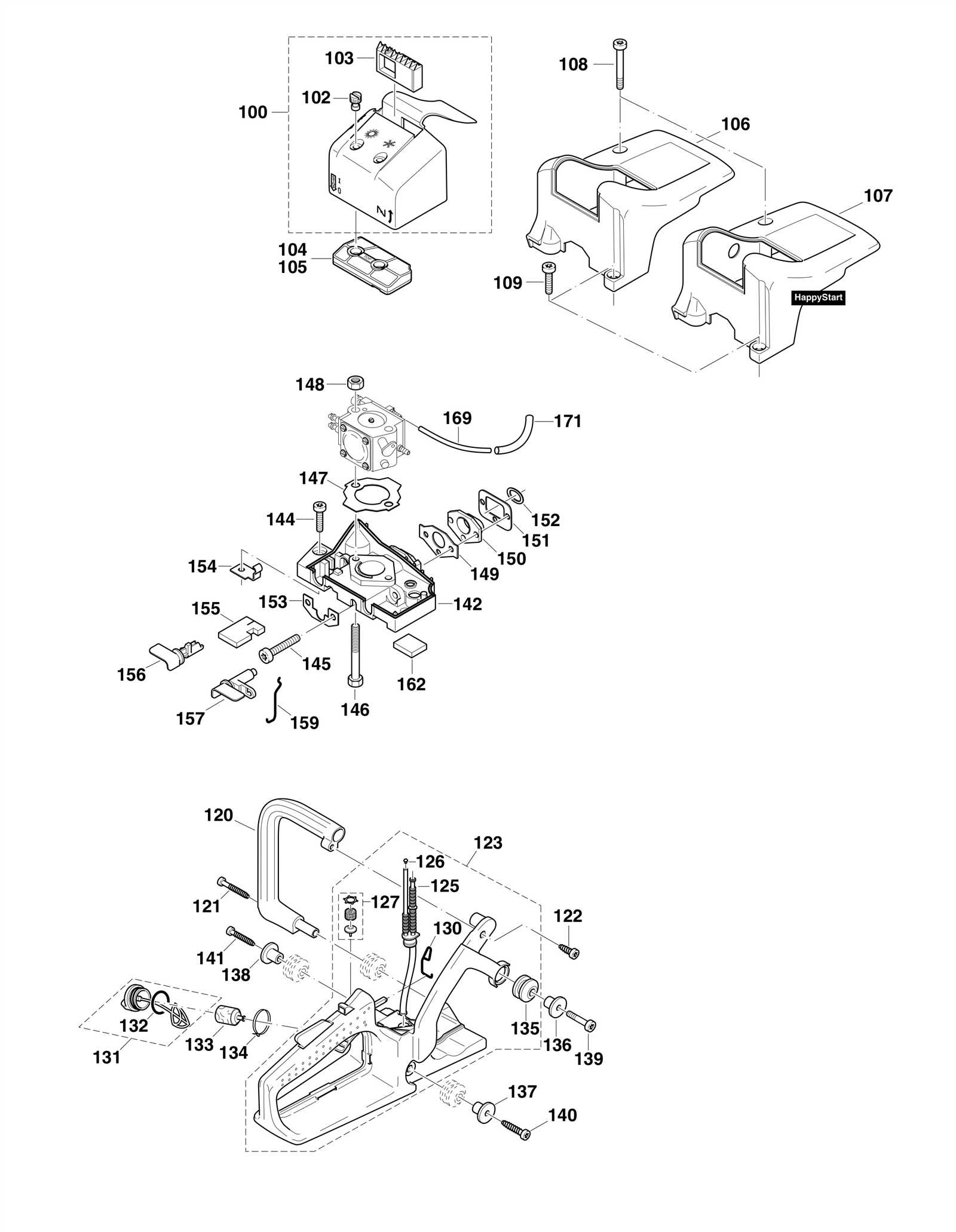

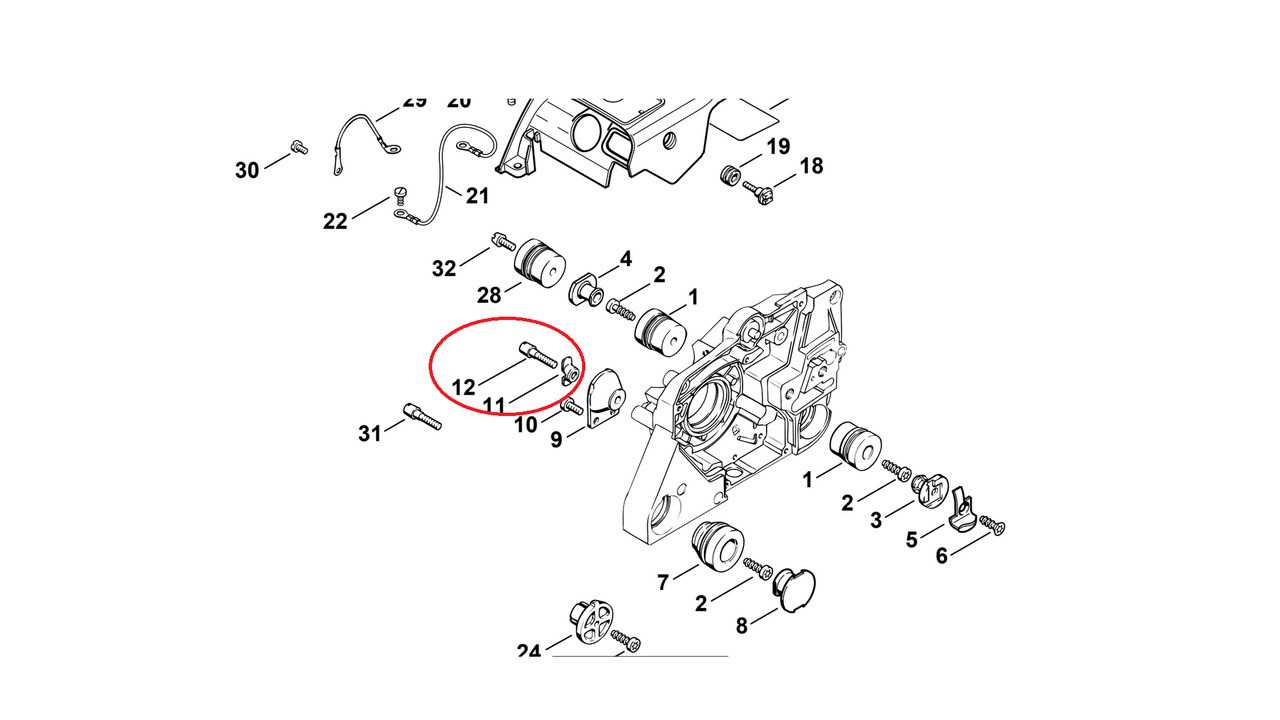

Visual references can significantly streamline the maintenance process, providing a detailed overview of how each piece fits together. By utilizing a comprehensive visual aid, users can easily identify specific parts, ensuring that any replacements or adjustments can be carried out with precision. This resource is invaluable for both seasoned professionals and those new to handling such machinery.

Moreover, grasping the structure and organization of the various elements can prevent common issues, thereby prolonging the lifespan of your equipment. Understanding the relationships between different parts can lead to informed decisions regarding repairs and upgrades, ultimately contributing to more efficient operation and enhanced longevity.

Stihl 036 Overview and Features

This segment provides a comprehensive overview of a well-known forestry tool, highlighting its capabilities and unique characteristics. Designed for efficiency, this device is tailored for both professional and amateur use, ensuring reliability and performance in various cutting tasks.

Key Characteristics

With a robust engine and advanced technology, this equipment offers powerful performance. Its lightweight design enhances maneuverability, allowing users to navigate through dense foliage with ease. Additionally, ergonomic handles contribute to user comfort during extended operation.

Performance and Applications

This tool excels in a variety of tasks, from felling trees to trimming branches. The combination of precision engineering and durable components ensures longevity, making it a preferred choice among enthusiasts and professionals alike. Whether tackling large jobs or routine maintenance, this machine stands out in its category.

Understanding the Parts Breakdown

Analyzing the assembly of a complex machine can greatly enhance your comprehension of its functionality and maintenance. By examining how individual components interact within the entire structure, you gain insights that facilitate repairs and replacements, ultimately extending the lifespan of the equipment.

In this section, we will explore a structured overview of essential components and their relationships. The following table provides a clear representation of key elements, aiding in understanding their roles and interconnections.

| Component | Description |

|---|---|

| Engine Assembly | Central unit that powers the machine, consisting of various moving parts. |

| Fuel System | Components responsible for storing and delivering fuel to the engine. |

| Ignition Module | Device that generates the spark necessary for combustion. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean air intake. |

| Bar and Chain | Cutting tools that perform the primary function of the machine, facilitating precise cutting. |

Maintenance Tips for Stihl 036

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Adhering to a few simple guidelines can help maintain optimal performance and prevent potential issues over time. These practices not only enhance functionality but also contribute to safety during operation.

1. Clean the Air Filter: A clean air filter is vital for engine efficiency. Regularly inspect and clean the filter to ensure proper airflow. If it shows signs of wear or excessive dirt, consider replacing it.

2. Check the Fuel System: Inspect the fuel lines and ensure there are no leaks. Use fresh fuel and maintain the correct fuel-to-oil ratio to enhance performance and reduce emissions.

3. Sharpen the Cutting Blade: A sharp blade allows for smoother cuts and reduces strain on the engine. Regularly sharpen or replace the blade to ensure efficient operation.

4. Inspect the Spark Plug: The spark plug plays a crucial role in ignition. Regularly check its condition, clean it if necessary, and replace it if it shows signs of wear or damage.

5. Lubricate Moving Parts: Proper lubrication of moving components reduces friction and wear. Regularly apply lubricant to all necessary parts to ensure smooth operation.

6. Store Properly: After use, store the equipment in a dry and safe place. Drain fuel if the equipment will be unused for an extended period to prevent clogging.

By following these maintenance tips, you can ensure the reliable performance of your machinery and prolong its lifespan, making it a valuable asset for your tasks.

Identifying Common Replacement Components

Understanding the essential components of outdoor power equipment is crucial for effective maintenance and repair. Regularly assessing these elements helps ensure optimal performance and longevity. Below are some frequently replaced items that owners should be aware of.

- Air Filter: This component plays a vital role in maintaining engine efficiency by preventing debris from entering the combustion chamber.

- Fuel Filter: A clean fuel filter is essential for preventing contaminants from clogging fuel lines and affecting engine performance.

- Chain: Over time, the cutting chain can wear out, requiring replacement for effective cutting and safety.

- Bar: The guide bar may develop wear from frequent use, making it necessary to replace it to maintain cutting precision.

- Spark Plug: Regular replacement of this item ensures smooth ignition and optimal engine operation.

By keeping track of these components and their condition, users can enhance the reliability and efficiency of their equipment, ultimately leading to better performance during operation.

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair of machinery. These illustrations provide a comprehensive view of components and their arrangements, helping users identify and source the necessary elements for service. By following a few straightforward steps, one can navigate these resources with ease.

Here are some key tips for interpreting these visuals:

- Familiarize with Symbols: Each symbol or representation corresponds to a specific component. Knowing these can expedite your understanding.

- Check the Key: Diagrams often include a legend that explains each symbol and line type. Referencing this can clarify any confusion.

- Identify Sections: Diagrams are usually divided into sections, each detailing a part of the overall assembly. Break down the image into smaller sections for easier comprehension.

- Follow the Flow: Many schematics show how components interact. Trace the connections to understand how parts work together within the system.

- Use Reference Numbers: Items are often labeled with numbers corresponding to a list. This aids in quickly locating and ordering components.

By employing these strategies, you can effectively interpret illustrations, making maintenance tasks more efficient and manageable.

Essential Tools for Repairs

When it comes to maintaining and fixing equipment, having the right instruments at your disposal is crucial. Proper tools not only enhance efficiency but also ensure that tasks are completed safely and accurately. Understanding which implements are necessary can greatly simplify the repair process, making it smoother and more effective.

Basic Hand Tools

Every repair kit should start with fundamental hand tools. A reliable set of screwdrivers, wrenches, and pliers is indispensable. These tools allow for the removal and installation of various components, enabling you to tackle most standard repairs with ease. Additionally, incorporating a durable hammer and a measuring tape can help in ensuring precision during adjustments.

Specialized Equipment

In certain cases, specialized tools may be required to address specific issues effectively. For instance, a torque wrench ensures that bolts are tightened to the correct specifications, preventing damage caused by over-tightening. Likewise, a multi-meter is essential for diagnosing electrical problems. Having access to these specialized instruments can significantly enhance your repair capabilities.

Common Issues and Solutions

When working with outdoor power equipment, users often encounter a range of challenges that can affect performance and efficiency. Understanding these common problems and their resolutions can significantly enhance the user experience and prolong the lifespan of the machinery.

Engine Performance Problems

One frequent issue is related to engine performance. Symptoms may include difficulty starting, stalling, or inconsistent power output. These problems can often be traced back to fuel quality or a clogged air filter. Regular maintenance, such as replacing the air filter and ensuring the use of fresh, high-quality fuel, can mitigate these issues. Cleaning the fuel system and checking spark plugs are also recommended steps to restore optimal function.

Chain and Bar Issues

Another area where users may face difficulties is with the cutting chain and guide bar. Common signs of trouble include excessive wear, poor cutting performance, or the chain coming off during use. To address these concerns, regular sharpening of the chain and proper lubrication are essential. Ensuring that the tension is correctly adjusted can prevent the chain from disengaging and enhance overall cutting efficiency. Regular inspections for damage and wear can also help in identifying potential issues before they escalate.

Where to Find Replacement Parts

When seeking components for your equipment, it’s essential to know the best sources for quality replacements. Numerous avenues are available, from authorized retailers to online marketplaces, ensuring you can find what you need efficiently.

Authorized Dealers: Visiting an official dealer is one of the most reliable ways to obtain genuine components. These locations typically carry a full range of products and can provide expert advice on compatibility and installation.

Online Retailers: Many websites specialize in selling equipment components. They often offer detailed catalogs, allowing you to browse through various options and compare prices. Look for customer reviews to gauge the reliability of the seller.

Local Repair Shops: Local technicians can be invaluable resources. They may have spare components on hand or can order them for you. Additionally, they can offer insights on the best products for your specific needs.

Manufacturer’s Website: The official website of the manufacturer often features a section for ordering components directly. This option ensures you receive authentic items that meet the required specifications.

By exploring these resources, you can find high-quality replacements that will help maintain your equipment’s performance and longevity.

Advantages of Using Original Parts

Utilizing genuine components in equipment maintenance offers numerous benefits that enhance performance and longevity. Authentic items are designed to fit perfectly and work seamlessly with your machinery, ensuring optimal functionality and reliability over time.

Quality Assurance

Original items undergo rigorous testing and quality control processes, guaranteeing that they meet the manufacturer’s specifications. This commitment to excellence minimizes the risk of breakdowns and ensures consistent performance.

Long-Term Cost Efficiency

While the initial investment may be higher, using authentic components can lead to significant savings in the long run. Genuine items often last longer and require fewer replacements, reducing overall maintenance costs.

| Benefits | Description |

|---|---|

| Reliability | Designed for optimal compatibility, reducing the likelihood of failures. |

| Performance | Maintains the efficiency and effectiveness of your equipment. |

| Warranty Protection | Using original components often helps preserve warranty coverage. |

Comparing Aftermarket Parts Options

When seeking alternatives to original components for your outdoor equipment, it’s essential to evaluate the variety of aftermarket offerings available. These options can provide cost-effective solutions while maintaining performance. However, understanding the differences in quality, compatibility, and longevity is crucial to making an informed choice.

Aftermarket components can vary significantly in terms of material quality, design accuracy, and manufacturing standards. It’s important to consider the reputation of the manufacturer and the feedback from users who have previously opted for these alternatives.

| Criteria | OEM Parts | Aftermarket Parts |

|---|---|---|

| Quality | Generally higher, often with stringent quality control | Varies widely; some high-quality options available |

| Cost | Typically more expensive | Usually more affordable, providing budget-friendly alternatives |

| Compatibility | Perfect fit for specific models | May fit multiple models, but compatibility can vary |

| Warranty | Often comes with a manufacturer warranty | Warranty policies can vary; check details before purchasing |

Ultimately, weighing the benefits and drawbacks of each option can help ensure that your choice aligns with your performance expectations and budget constraints. Researching user reviews and seeking recommendations can further assist in identifying the best alternatives for your needs.