Understanding the structure and organization of mechanical assemblies is crucial for anyone involved in maintenance or repairs. Whether you’re a professional technician or an enthusiast, having access to detailed layouts can make the process of identifying and replacing individual components much easier. A clear and well-organized guide ensures efficient problem-solving and enhances the overall experience of working with complex equipment.

Detailed visual aids provide invaluable assistance by offering clear representations of how individual parts interact within a larger system. These layouts help users understand both the functional relationships between components and the correct sequence of assembly or disassembly. Such resources are especially useful for ensuring that every element is positioned accurately, preventing unnecessary errors.

For those who prefer a visual approach to troubleshooting or maintenance,

Chainsaw Overview and Specifications

This model is recognized for its durability and power, making it suitable for heavy-duty tasks. It’s designed for both professional use and demanding environments, where reliable performance is crucial. Its balanced weight distribution allows for more comfortable handling during prolonged operations, and the robust build ensures longevity even under tough working conditions.

Key Features

The engine is a high-performance unit, offering sufficient power for cutting through dense wood and large trees. It operates efficiently, delivering consistent output while maintaining fuel economy. Additionally, the cutting mechanism is optimized for precision and ease of use, with a sturdy guide bar that ensures stability during cutting operations.

Technical Specifications

With a focus on providing top-tier performance, this tool is equipped with an

Key Components of the Stihl 08s

The design of this classic chainsaw model includes several essential elements that ensure its reliable operation. Understanding these components helps in maintaining the equipment and ensuring optimal performance in various conditions. Below is an overview of the major parts that contribute to its functionality.

| Component | Description | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | The powerhouse of the saw, responsible for converting fuel into the energy needed to drive the cutting chain. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chain | A loop of metal links that rotates at high speed to cut through wood and other materials with precision. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Source Type | Description | Example Websites |

|---|---|---|

| Official Manufacturer Websites | These sites often provide comprehensive resources, including manuals and breakdowns, directly from the producer. | Manufacturer’s official site |

| Online Repair Communities | Forums and user groups can be excellent for shared knowledge and visuals contributed by experienced users. | Community forums or specialized repair blogs |

| Document Sharing Platforms | Sites that allow users to upload and share documentation can host valuable resources, but verify the credibility of the uploader. | Platforms like Scribd or Issuu |

| Online Retailers | Some retailers provide detailed visuals as part of their product listings, which can be useful for reference. | Large online marketplaces |

Utilizing these various sources can significantly enhance the likelihood of obtaining high-quality visuals necessary for effective machinery management. Always cross-reference multiple resources to ensure accuracy and comprehensiveness in your findings.

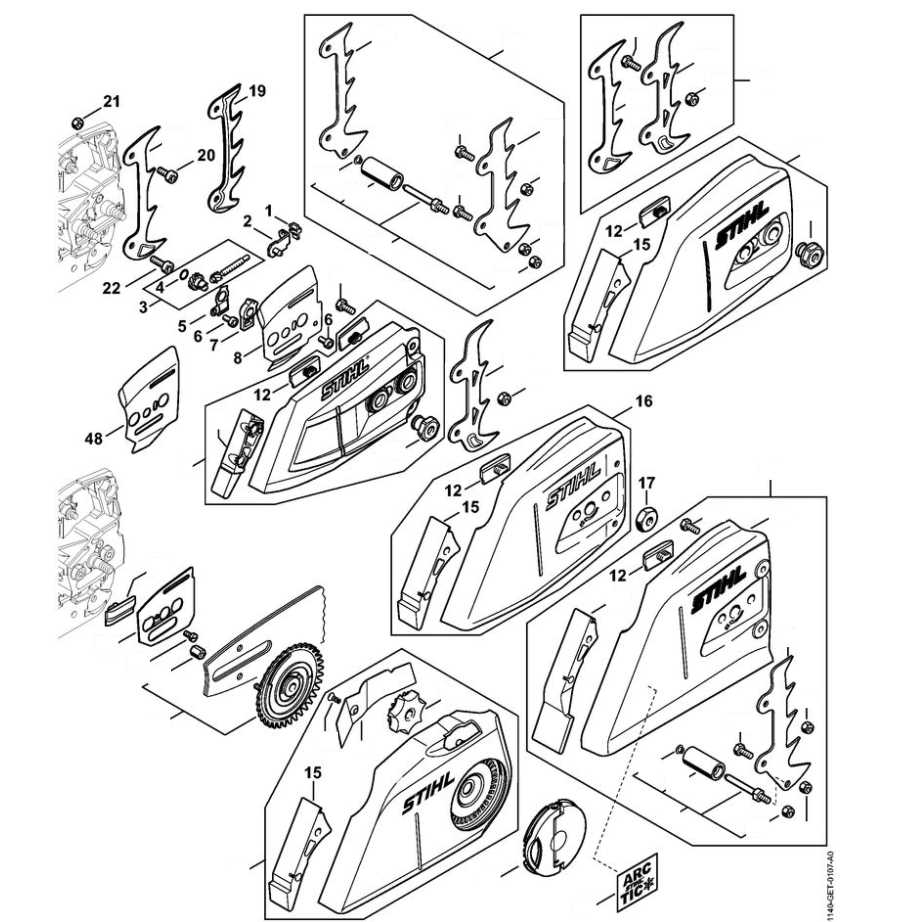

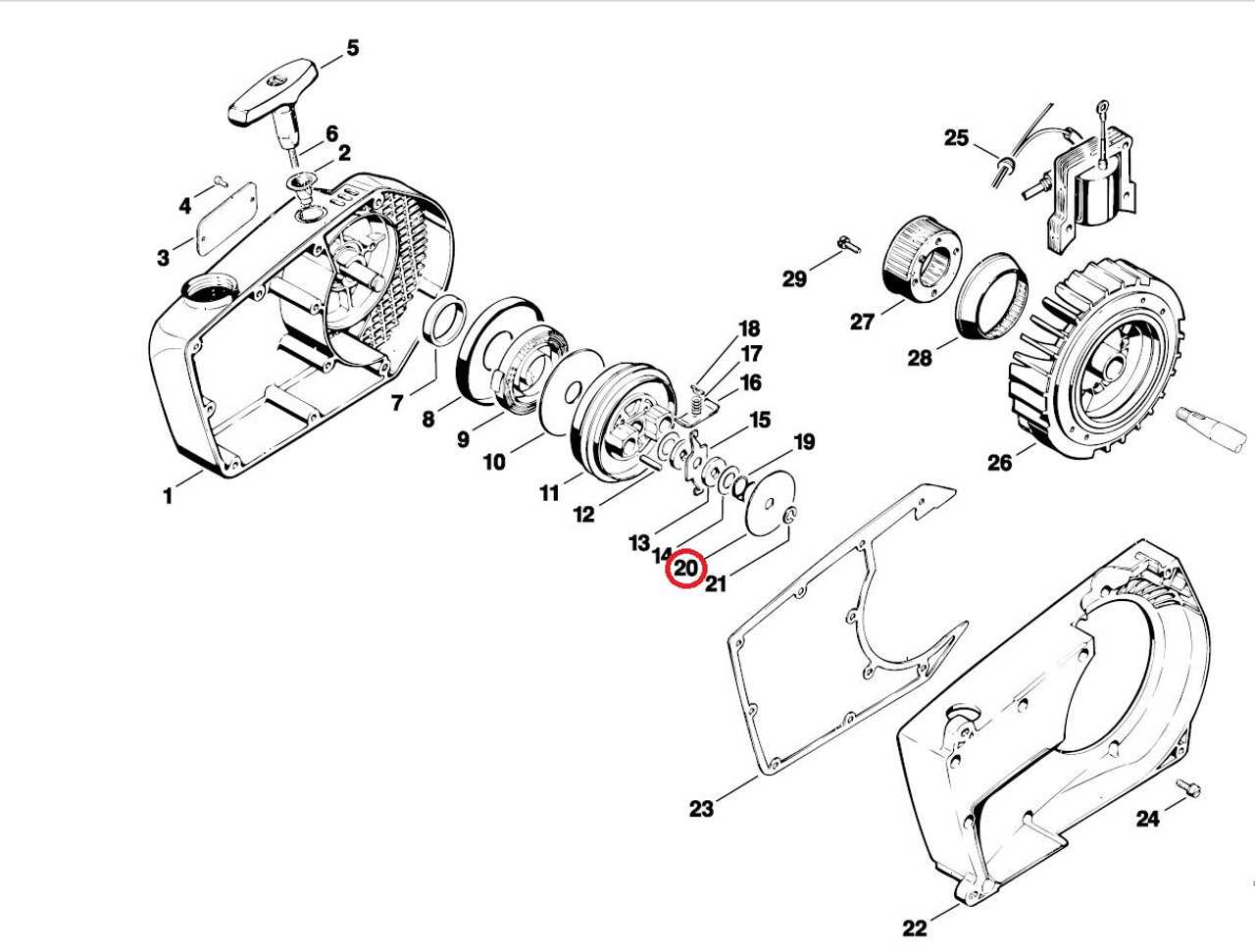

How to Read a Stihl 08s Parts Diagram

Understanding the layout of an equipment component illustration can greatly enhance your ability to perform maintenance and repairs. These visual guides provide a clear representation of individual elements, helping you identify and locate each piece necessary for optimal functioning.

To begin, familiarize yourself with the overall structure of the illustration. Look for a legend or key, often found in a corner, which explains the symbols and notations used throughout. This reference will help you decipher various parts, ensuring you can locate the correct items quickly.

Next, pay attention to the organization of the components. Typically, items are grouped by function or location, making it easier to find related parts. For instance, you’ll notice assemblies linked by lines or numbers, indicating how they interact with one another.

Additionally, note any exploded views present in the illustration. These views display components separated from their assembly, providing a clearer understanding of how everything fits together. This approach allows you to visualize the assembly sequence, which is especially helpful during reassembly after servicing.

Lastly, consider keeping a checklist of the components you need. As you reference the visual guide, marking off parts as you acquire them can help streamline your repair process, ensuring that no critical element is overlooked.

Interpreting Symbols and Labels

Understanding the various symbols and labels found in technical illustrations is essential for effective maintenance and repair. These graphical representations convey vital information about component functions, assembly instructions, and safety precautions, enabling users to navigate complex systems with confidence.

Each symbol is carefully designed to represent specific actions or components, often utilizing universally recognized imagery. Familiarity with these symbols enhances the user’s ability to identify parts and comprehend their relationships within the assembly. Additionally, labels provide crucial details, such as part numbers, specifications, and torque settings, ensuring that the correct procedures are followed during repairs.

When interpreting these elements, it is important to approach them methodically. Begin by familiarizing yourself with the key legends or keys accompanying the illustrations, as they often provide explanations for the symbols used. Take note of color coding, as it can indicate different functions or statuses, such as operational versus non-operational components. By mastering these interpretations, you can streamline maintenance tasks and reduce the risk of errors.

Identifying Genuine Stihl 08s Spare Parts

Ensuring the authenticity of replacement components is crucial for optimal performance and longevity of your equipment. Recognizing genuine items involves understanding specific features and markings that distinguish them from counterfeits. This section aims to guide you through the key aspects to consider when evaluating replacement components.

Here are some essential tips for identifying authentic replacements:

| Feature | Description |

|---|---|

| Brand Markings | Check for clearly printed logos and trademarks. Authentic items typically have precise branding. |

| Quality of Materials | Genuine components are manufactured with high-grade materials, ensuring durability and reliability. |

| Packaging | Original products usually come in well-designed packaging with proper labeling and information. |

| Serial Numbers | Look for serial numbers that can be verified with the manufacturer for authenticity. |

| Seller Reputation | Purchase from authorized dealers or well-known retailers to reduce the risk of acquiring counterfeit items. |

By following these guidelines, you can ensure that the components you choose are genuine, ultimately contributing to the effective operation of your machinery.

Distinguishing Between OEM and Aftermarket Parts

When it comes to sourcing components for equipment, understanding the differences between original manufacturer offerings and third-party alternatives is crucial for maintaining optimal performance and reliability. Each category of components has its own characteristics, advantages, and potential drawbacks that can impact the longevity and efficiency of your machinery.

Original Equipment Manufacturer (OEM) Components

OEM components are designed and produced by the same manufacturer that created the original equipment. These parts are often considered the gold standard for replacement, as they typically guarantee compatibility and adherence to the manufacturer’s specifications. Users can expect the same quality, durability, and performance as the original components, which can be particularly important for maintaining warranties and ensuring safety standards.

Aftermarket Alternatives

Aftermarket alternatives are produced by companies other than the original manufacturer. While these options can offer cost savings and a wider selection, quality can vary significantly. Some aftermarket components are engineered to meet or exceed OEM standards, while others may fall short, potentially leading to performance issues or even equipment damage. Therefore, it is essential to research and select reputable aftermarket brands to ensure reliability.

| Feature | OEM Components | Aftermarket Alternatives |

|---|---|---|

| Quality Assurance | High, meets original specs | Varies, not always guaranteed |

| Cost | Generally higher | Often lower |

| Compatibility | Designed for perfect fit | May require verification |

| Warranty | Usually retains equipment warranty | May void warranty |

Commonly Replaced Parts in Stihl 08s

In any machinery, certain components are more prone to wear and tear over time, necessitating their replacement to maintain optimal functionality. This section discusses the frequently swapped elements that users should consider for enhanced performance and longevity of their equipment. Understanding which components are often replaced can aid in proactive maintenance and minimize downtime.

Fuel System Components

The fuel system is crucial for the efficient operation of any engine. Key components, such as the fuel filter and lines, are often replaced to ensure proper fuel flow and prevent clogs. Over time, these parts can degrade due to exposure to fuel additives and environmental factors, leading to performance issues.

Ignition System Elements

The ignition system is essential for starting and running the engine. Commonly replaced items include spark plugs and ignition coils, which can wear out and affect starting efficiency. Regular inspection and timely replacement of these components are vital to prevent starting difficulties and ensure reliable operation.

Guide to Frequently Worn Components

In any mechanical device, certain elements tend to experience more wear over time due to repeated use and environmental factors. Understanding these components is crucial for maintaining optimal performance and ensuring longevity. This section outlines the common parts that may require regular inspection or replacement to prevent operational issues.

Commonly Affected Parts

The following table highlights frequently worn components, their functions, and signs indicating they may need attention:

| Component | Function | Signs of Wear |

|---|---|---|

| Sprocket | Transmits power to the chain | Excessive play, missing teeth |

| Chain | Cutting through materials | Stretched links, rough movement |

| Guide Bar | Holds the chain in place | Uneven wear, bending |

| Air Filter | Prevents debris from entering the engine | Clogging, reduced airflow |

Maintenance Tips

Regular maintenance is key to extending the life of these components. Here are some helpful practices:

- Inspect components frequently for signs of wear.

- Clean and replace filters as needed to ensure efficient operation.

- Lubricate moving parts regularly to reduce friction and prevent damage.