When maintaining outdoor machinery, having a clear understanding of its various elements is essential. Each component plays a significant role in ensuring optimal performance and longevity of the device. This section delves into the intricate structure of your equipment, highlighting how each part interacts with one another to create a seamless operation.

Visual aids can be invaluable for both new and seasoned users, offering clarity on where each element is located and how they function together. By familiarizing yourself with these essential elements, you can make informed decisions regarding maintenance, repairs, and upgrades, ensuring your device remains in excellent condition.

In this guide, we will explore the different sections of the machinery, providing insights into their functionality and importance. Understanding these components will empower you to enhance your equipment’s performance effectively.

Overview of Stihl BG 55 Components

This section provides a comprehensive look at the essential elements of the BG 55 model, highlighting the various components that contribute to its functionality and performance. Understanding these elements can enhance maintenance efforts and ensure optimal operation.

Main Assembly Features

The primary assembly consists of several crucial parts that work together seamlessly. Each component plays a vital role in the overall performance, enabling the device to function effectively and efficiently.

Key Elements Breakdown

| Component | Function |

|---|---|

| Engine | Powers the unit for optimal air movement. |

| Fuel Tank | Holds the fuel required for operation. |

| Air Filter | Prevents debris from entering the engine. |

| Blower Tube | Directs airflow to clear debris. |

| Handle | Provides control and comfort during use. |

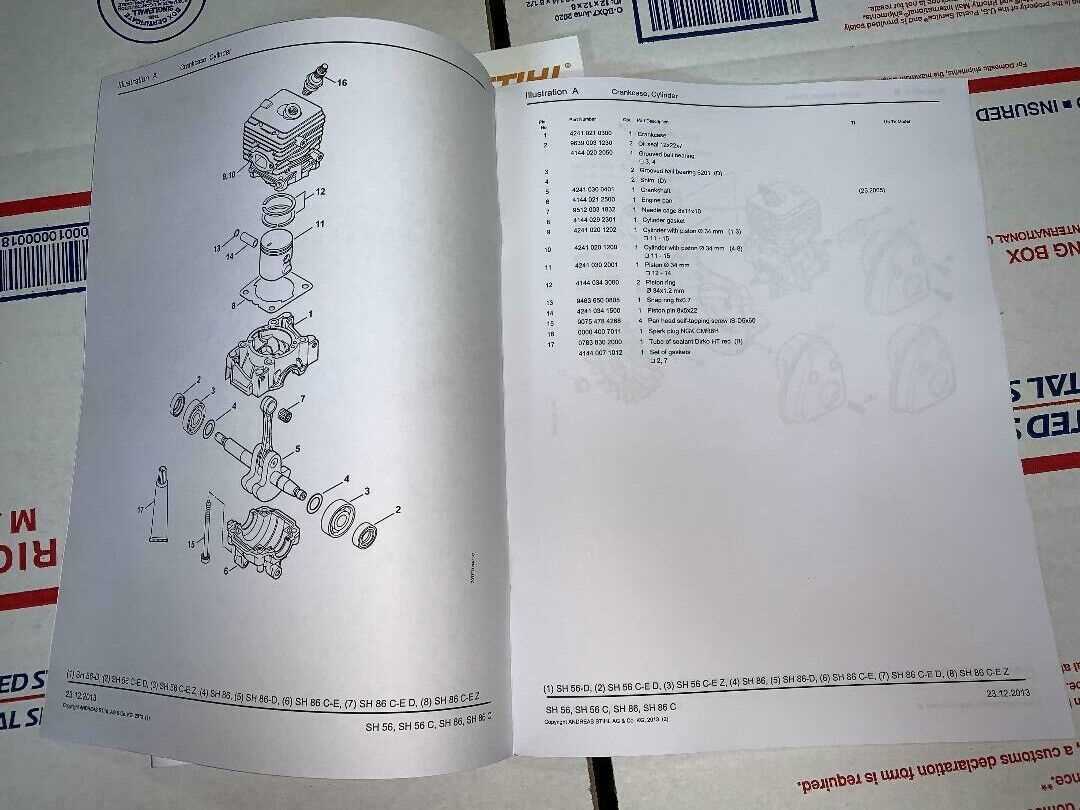

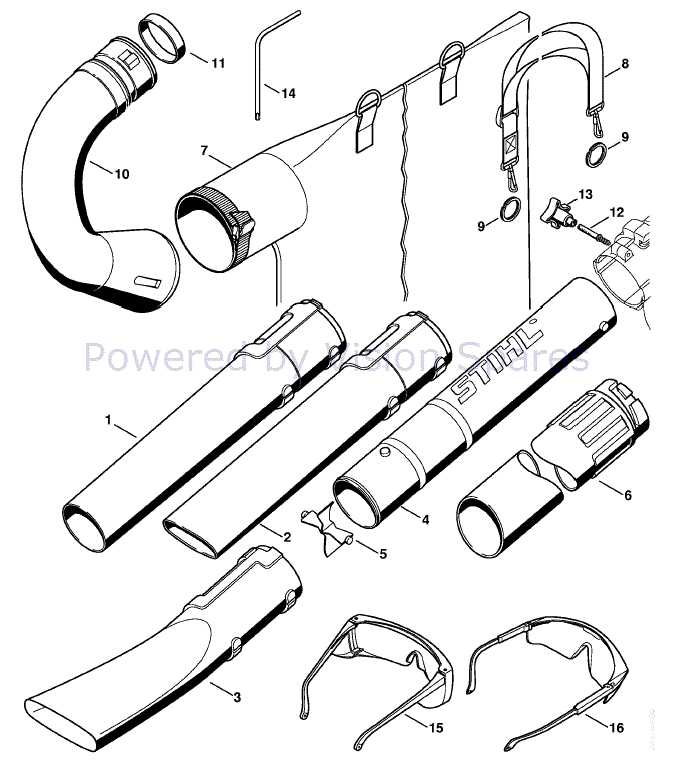

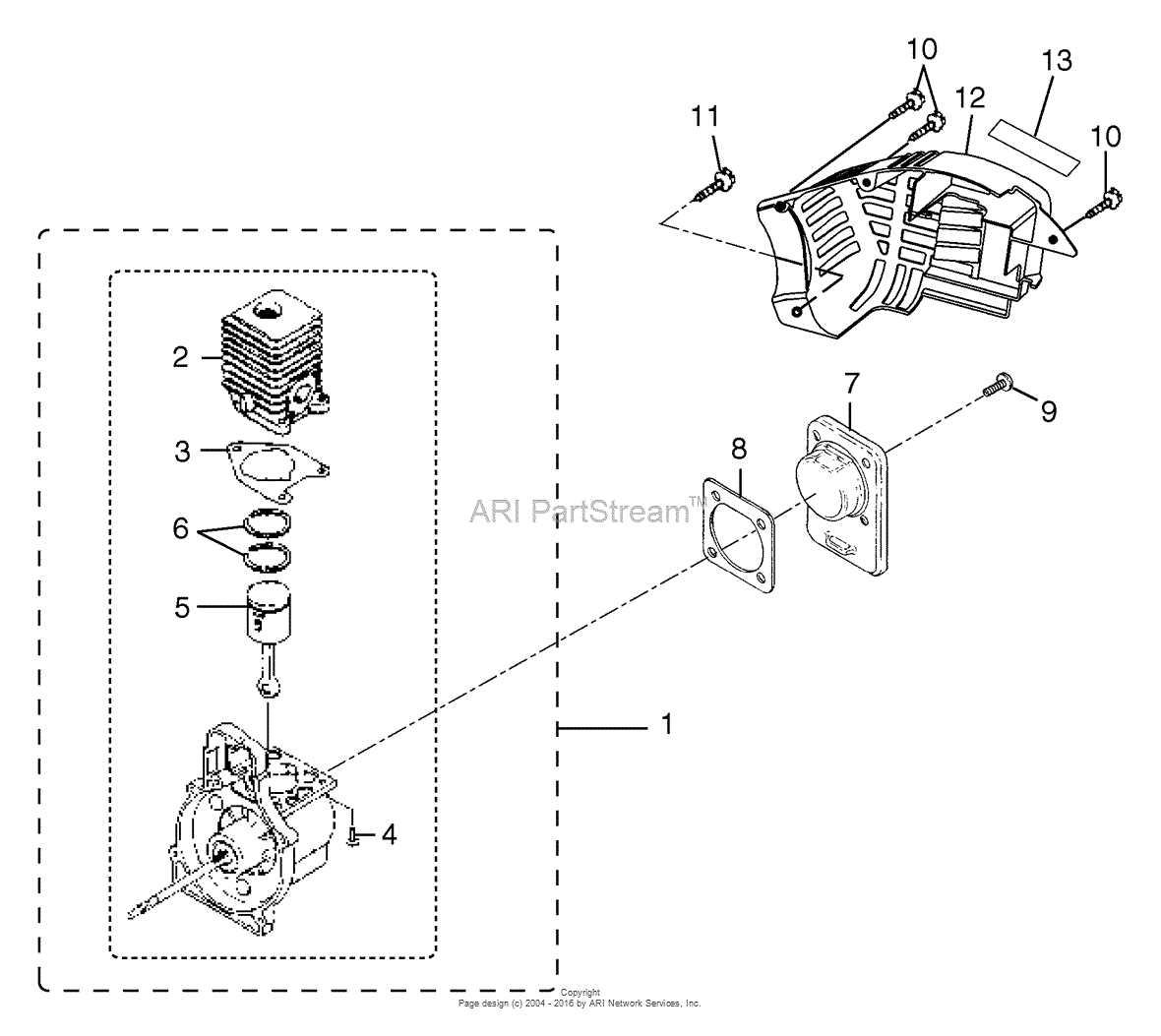

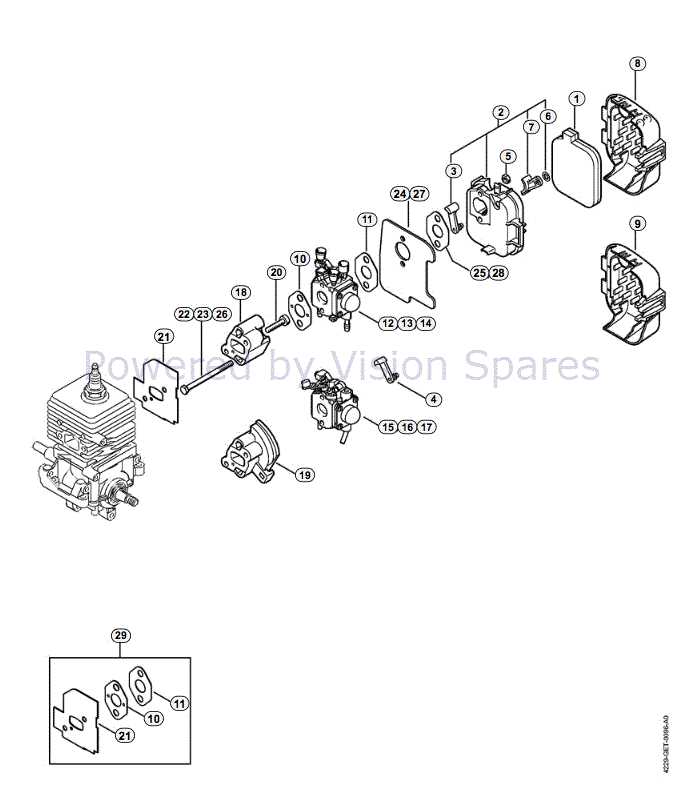

Identifying Key Parts in Diagrams

Understanding the essential components depicted in illustrations is crucial for effective maintenance and repair. Recognizing each element allows users to troubleshoot and replace specific items efficiently, ensuring optimal performance of the equipment.

Common Components and Their Functions

Illustrations often highlight various elements, each serving a distinct role. For instance, the engine assembly is vital for powering the device, while the fuel system ensures the proper mixture for combustion. Identifying these key components helps in understanding the overall operation.

Tips for Effective Identification

When examining illustrations, focus on the shape and placement of each element. Utilizing a reference guide can enhance recognition, as it provides detailed descriptions and functions of the various items. Additionally, noting the connections between components aids in grasping their interactions.

Importance of Proper Maintenance

Regular upkeep of equipment is crucial for ensuring longevity and optimal performance. Neglecting maintenance can lead to diminished efficiency and potential breakdowns, which can be costly in terms of repairs and replacements.

Proper maintenance encompasses various tasks that contribute to the overall functionality of the machinery. These tasks include:

- Regular cleaning to prevent debris buildup.

- Routine inspections to identify wear and tear.

- Timely replacement of worn components to ensure safe operation.

- Lubrication of moving parts to minimize friction and wear.

By adhering to a maintenance schedule, users can experience numerous benefits:

- Increased efficiency and performance.

- Prolonged lifespan of the equipment.

- Reduced risk of unexpected failures.

- Enhanced safety during operation.

Ultimately, a commitment to regular upkeep not only safeguards the investment but also promotes a safer and more effective working environment.

Common Issues and Solutions

When utilizing handheld outdoor equipment, encountering various challenges is not uncommon. Understanding these frequent problems and their corresponding solutions can enhance performance and prolong the lifespan of the device.

Starting Difficulties: One prevalent issue is trouble starting the engine. This can often be attributed to factors such as stale fuel or a clogged air filter. To resolve this, ensure fresh fuel is used and clean or replace the air filter as needed.

Loss of Power: If the equipment is struggling to maintain power, it may indicate an obstruction in the exhaust or a dirty spark plug. Cleaning the spark plug and checking for blockages in the exhaust can help restore optimal functionality.

Vibration Issues: Excessive vibrations can lead to discomfort and decreased efficiency. This might result from loose components or worn-out grommets. Inspect all connections and replace any damaged parts to minimize vibration.

Fuel Leaks: Observing fuel leaks can be alarming and may suggest a damaged fuel line or connections. Examine these areas closely and replace any compromised sections to prevent further issues.

By addressing these common challenges with the appropriate solutions, users can ensure smoother operation and greater reliability of their outdoor equipment.

Replacement Parts Availability

Access to essential components is crucial for maintaining the efficiency and longevity of your equipment. Ensuring that you have the right substitutes on hand can significantly enhance performance and reduce downtime during operation. Various outlets offer a range of options for sourcing these vital elements, allowing for seamless replacements when needed.

Where to Find Components

Numerous retailers specialize in offering high-quality substitutes, both online and in physical stores. Authorized dealers and specialized websites provide a comprehensive selection, ensuring compatibility with your model. Additionally, local hardware shops may carry commonly needed replacements, making it convenient for immediate repairs.

Considerations for Quality

When selecting components, it’s important to prioritize quality and compatibility. Opting for reputable manufacturers can prevent issues and ensure optimal functionality. Researching customer reviews and ratings can also guide you in making informed decisions, helping you choose reliable options for your needs.

How to Read Parts Diagrams

Understanding visual schematics can enhance your ability to identify components in various equipment. These illustrations provide a clear representation of each element and its relationship to others, aiding in maintenance and repairs.

Key Components to Look For

- Labels: Each section typically features labels that indicate the function or type of item.

- Numbers: Numerical identifiers often correspond to a list that details specifications or replacement options.

- Sections: Different areas of the illustration might focus on distinct assemblies or functions.

Steps to Interpret the Illustration

- Start by identifying the main assembly depicted.

- Follow the connections to see how individual elements interact.

- Cross-reference any numbers with the accompanying list for more information.

- Note any special notations or symbols that indicate specific instructions or warnings.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the repairs but also ensure that the equipment remains in optimal condition. Following guidelines helps mitigate risks associated with handling tools and machinery.

Essential Safety Measures

Before beginning any repair work, it’s important to follow certain essential safety measures:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate PPE, including gloves, goggles, and ear protection to safeguard against potential hazards. |

| Work Area Setup | Ensure the work area is clean and well-lit. Remove any unnecessary items that may cause distractions or accidents. |

| Tool Inspection | Inspect all tools for damage or wear before use. Replace or repair any defective tools to avoid malfunctions. |

| Read Instructions | Familiarize yourself with the manufacturer’s guidelines and safety instructions before starting the repair. |

Emergency Preparedness

Being prepared for emergencies is also vital. Keep a first aid kit accessible and know how to use it. Familiarize yourself with emergency contact numbers and procedures in case of an accident during repairs.

Tools Needed for Assembly

When preparing for the assembly process of your equipment, having the right tools is essential for ensuring a smooth and efficient experience. Each component requires specific instruments to secure and align parts accurately, enhancing both performance and longevity.

Essential Instruments

Start with a set of wrenches and screwdrivers, as these are fundamental for tightening and loosening fasteners. Additionally, a torque wrench may be necessary to apply the correct tension, preventing damage to components.

Additional Equipment

Consider including a pair of pliers and a utility knife for various tasks that may arise. Having a workbench or a sturdy surface is also advisable to provide a stable working environment throughout the assembly process.

Understanding Engine Specifications

When delving into the mechanics of small engines, it is crucial to comprehend the key specifications that define their performance and efficiency. These characteristics provide insights into how well an engine operates and its suitability for various tasks.

- Displacement: This measurement indicates the engine’s capacity, affecting power output and fuel consumption.

- Power Rating: Often expressed in horsepower or watts, this figure signifies the engine’s ability to perform work over time.

- Fuel Type: Different engines require specific fuel types, influencing performance and maintenance needs.

- Compression Ratio: This ratio impacts the engine’s efficiency and power, determining how well it converts fuel into energy.

- Weight: The overall mass of the engine can affect the balance and maneuverability of the equipment it powers.

Understanding these elements not only aids in selecting the right engine for your needs but also enhances maintenance practices and operational efficiency.

Fuel System Components Explained

The efficiency of any outdoor power equipment largely depends on its fuel system, which is crucial for optimal performance. Understanding its various elements can help users maintain and troubleshoot their devices more effectively.

- Fuel Tank: The reservoir that holds the fuel before it is drawn into the engine.

- Fuel Line: A tube that transports the fuel from the tank to the carburetor.

- Filter: A component that removes impurities from the fuel to ensure clean delivery to the engine.

- Carburetor: A device that mixes air and fuel in the correct proportions for combustion.

- Primer Bulb: A pump that helps draw fuel into the carburetor, making starting easier.

- Gaskets and Seals: Essential for preventing leaks and maintaining pressure within the system.

Each of these components plays a vital role in the overall functionality, making their proper maintenance essential for reliable operation.

Tips for Efficient Performance

To achieve optimal functioning of your outdoor equipment, it’s essential to implement a few key practices. Maintaining a clean and well-organized workspace can significantly enhance your workflow, ensuring that tools and supplies are easily accessible when needed.

Regular maintenance is crucial. This includes checking and replacing worn components promptly, as neglect can lead to decreased efficiency and potential damage. Additionally, ensuring that all moving parts are adequately lubricated will minimize friction and wear, allowing the machine to operate smoothly.

Using high-quality fuel and oil is another important factor. Choosing the right fuel mixture can prevent engine problems and improve performance. Furthermore, familiarize yourself with the operation guidelines to maximize the effectiveness of your equipment while minimizing the risk of accidents.

Finally, practice proper storage techniques. Keeping your equipment in a dry and sheltered area will protect it from environmental damage, extending its lifespan and maintaining its performance over time.

Warranty Information for Parts

This section provides essential details regarding the guarantee coverage for components associated with your equipment. Understanding the warranty terms can help ensure that you receive support in case of defects or issues arising from normal usage.

Typically, warranty protection includes specific conditions and timeframes during which the manufacturer commits to repairing or replacing defective items. It is crucial to retain your purchase documentation to facilitate any claims.

| Coverage Type | Duration | Conditions |

|---|---|---|

| Manufacturer Defects | 2 Years | Normal use; excludes wear and tear |

| Replacement Components | 90 Days | Must be installed by authorized service |

| Accessories | 1 Year | Limited to original purchase |

Always consult the warranty documentation specific to your equipment for comprehensive information on coverage and claim procedures.

Contacting Customer Support for Help

When facing challenges with your equipment, reaching out to customer assistance can provide the guidance you need. Whether you have questions about functionality or require technical support, professionals are available to help resolve your concerns efficiently.

Ways to Get in Touch

There are several methods to connect with support services. You can utilize phone support for immediate assistance or explore online resources, including FAQs and chat options, for quick answers. Additionally, email communication may be effective for detailed inquiries.

What to Prepare

Before contacting support, gather relevant information such as your equipment model and any specific issues you are experiencing. This preparation allows the support team to assist you more effectively and expedites the resolution process.