The efficiency and performance of any high-powered outdoor tool depend significantly on its internal components. Familiarizing yourself with the various elements that contribute to the overall functionality can enhance both maintenance and operation. A clear visual representation of these parts can simplify troubleshooting and repairs, ensuring your equipment runs at peak performance.

By examining the intricate layout of each essential component, users can gain insights into the assembly and disassembly processes. This knowledge not only facilitates better handling but also empowers operators to make informed decisions about upgrades or replacements. Understanding these intricacies can lead to a longer lifespan for your device and improved operational effectiveness.

Moreover, having access to a detailed overview of the various sections allows for a deeper appreciation of the engineering that goes into creating such powerful machinery. Whether you’re a novice or an experienced user, this guide will provide the necessary information to enhance your understanding and boost your confidence in managing your leaf blower.

Understanding the Stihl BR 800 X Magnum

This section delves into the advanced features and functionalities of a high-performance outdoor power tool designed for professionals. The model stands out due to its impressive capabilities, making it suitable for a variety of tasks in landscaping and maintenance. Its robust design and efficient operation cater to the needs of both commercial users and serious enthusiasts.

Key Features

The machine boasts a powerful engine that enhances its performance, allowing for efficient debris clearing and maintenance tasks. With its lightweight construction, users can maneuver it easily without compromising on power. Additionally, the ergonomic design ensures comfort during extended use, reducing fatigue and enhancing productivity.

Maintenance and Care

Regular maintenance is essential to keep this tool operating at peak efficiency. Routine checks and servicing can significantly extend its lifespan and improve overall performance. Understanding the various components and their functions helps in identifying potential issues early, ensuring that the machine remains reliable in demanding conditions.

In summary, this advanced outdoor equipment exemplifies innovation in design and functionality. Whether tackling large areas or intricate details, it provides users with the reliability and performance needed to achieve professional results.

Key Features of the BR 800 X

The advanced blower model offers an impressive combination of power, efficiency, and user-friendly design, making it a top choice for both professional landscapers and homeowners. Its robust construction and innovative technology enhance performance, ensuring tasks are completed effectively and with minimal effort.

Powerful Engine

At the heart of this blower is a high-performance engine that provides remarkable air speed and volume. This powerful motor is designed to handle even the toughest debris, ensuring that users can tackle any job with ease.

- High air velocity for efficient clearing

- Durable engine components for longevity

- Optimized fuel efficiency to reduce operational costs

User Comfort and Convenience

Ergonomics play a crucial role in the design of this model. The equipment is crafted to minimize user fatigue during extended use, ensuring comfort without compromising performance.

- Adjustable harness for a custom fit

- Low vibration technology for a smoother experience

- Intuitive controls for effortless operation

With its exceptional features, this blower stands out in the market, offering both power and comfort to meet the demands of any landscaping challenge.

Importance of Replacement Parts

Maintaining the efficiency and longevity of equipment is crucial for optimal performance. When components wear out or become damaged, their timely replacement is essential to prevent further issues and ensure that machinery operates at its best. Utilizing high-quality substitutes can significantly enhance functionality and reliability.

Enhancing Performance

Replacing worn or faulty elements can restore equipment to its original capabilities. This improvement not only boosts operational efficiency but also enhances the overall user experience. Regular updates help prevent unexpected breakdowns and minimize downtime, allowing for uninterrupted productivity.

Cost-Effectiveness

Investing in quality substitutes can be more economical in the long run. While initial costs may seem high, neglecting to replace deteriorated components can lead to more extensive damage and costly repairs. By proactively addressing issues, owners can save on potential future expenses and extend the lifespan of their machinery.

Commonly Used Parts in Blowers

In the realm of outdoor power equipment, various components play crucial roles in the efficient operation of air-moving devices. Understanding these essential elements is key for maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

One of the primary components is the engine, which provides the necessary power for operation. A well-maintained engine ensures that the blower runs smoothly and effectively. The fuel system, comprising the tank, lines, and filter, is equally important, as it delivers the energy required for the engine to function.

The air intake system is vital for drawing in air, allowing for effective airflow during operation. Filters within this system help maintain air quality by preventing debris from entering the engine. Additionally, the fan or impeller is responsible for creating the airflow needed to move leaves and debris efficiently.

Another significant component is the housing, which encases the internal parts and provides structural integrity. It also aids in directing airflow to enhance performance. Lastly, control mechanisms, such as triggers and throttle controls, allow users to adjust the speed and power of the blower for various tasks.

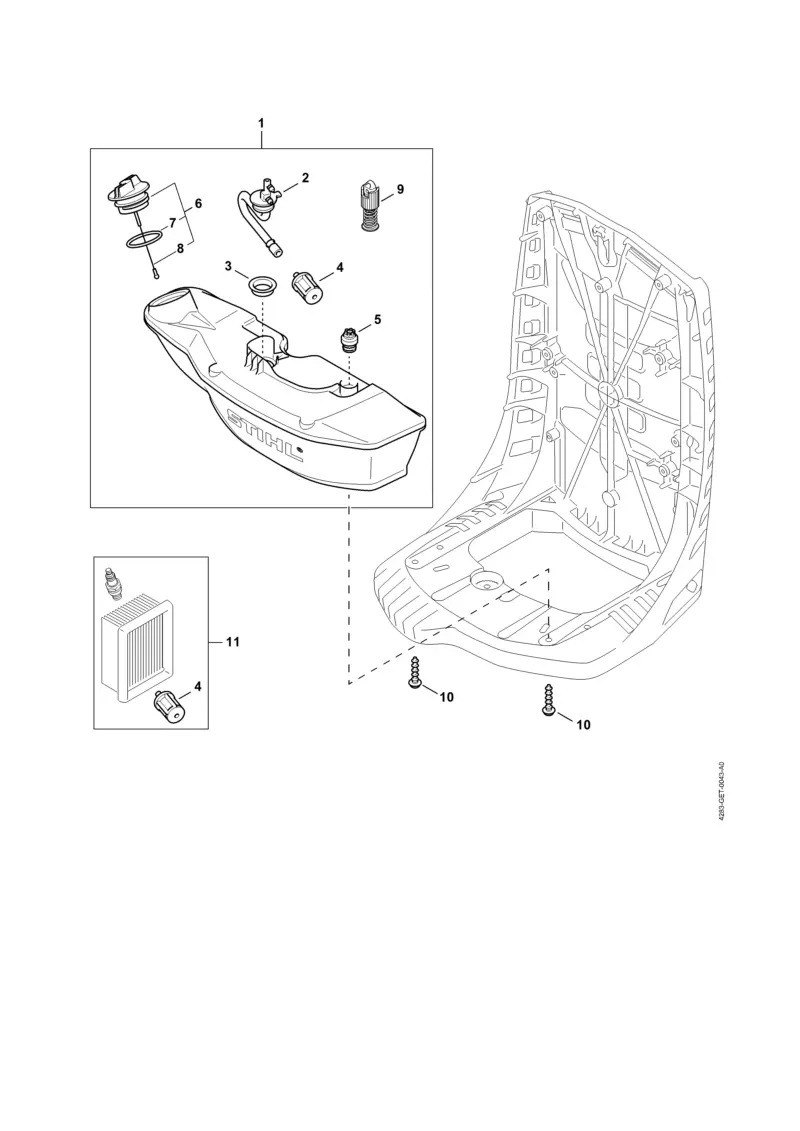

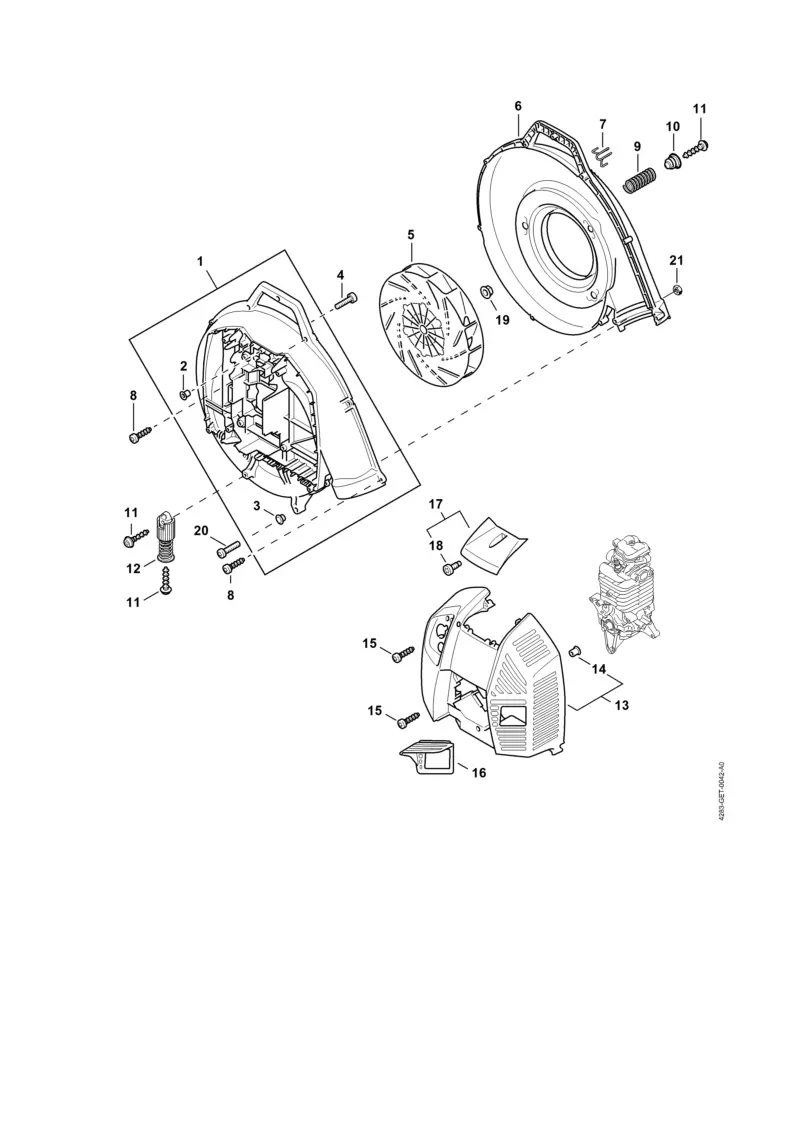

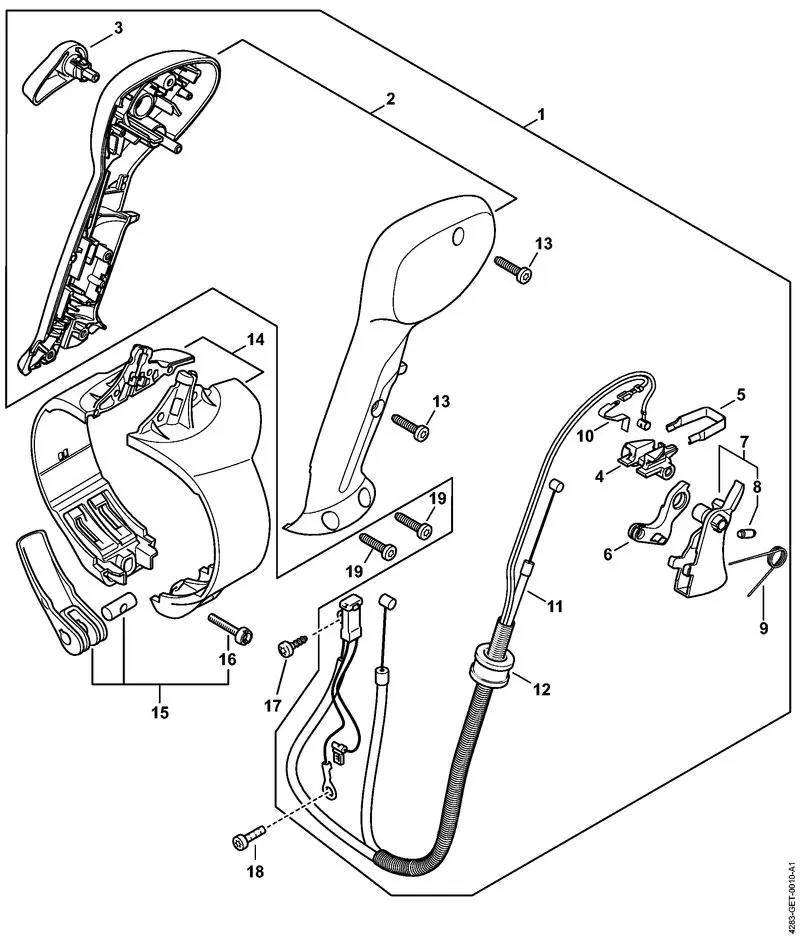

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a clear layout of various elements and their interrelations, making it easier to identify what is needed for a specific task. Familiarizing yourself with how to interpret these graphics can save time and enhance the efficiency of your work.

Key Elements to Look For

- Labels: Look for annotations that indicate specific parts and their functions. These often provide crucial information.

- Numbering: Many diagrams use a numerical system to correlate components with a list, making identification straightforward.

- Sections: Components are typically grouped by function or location, which aids in understanding how they work together.

- Arrows and Lines: These visual aids illustrate connections and pathways between parts, showing how they interact within the assembly.

Steps to Interpret the Illustration

- Start by examining the overall layout to get a sense of the arrangement of components.

- Identify labeled sections and correlate them with the accompanying list for detailed descriptions.

- Pay attention to the numbering system to ensure you locate the correct parts.

- Review the connections indicated by arrows and lines to understand the relationships between elements.

By following these guidelines, you can effectively navigate a components illustration, ensuring you have a clear understanding of what you need for your project.

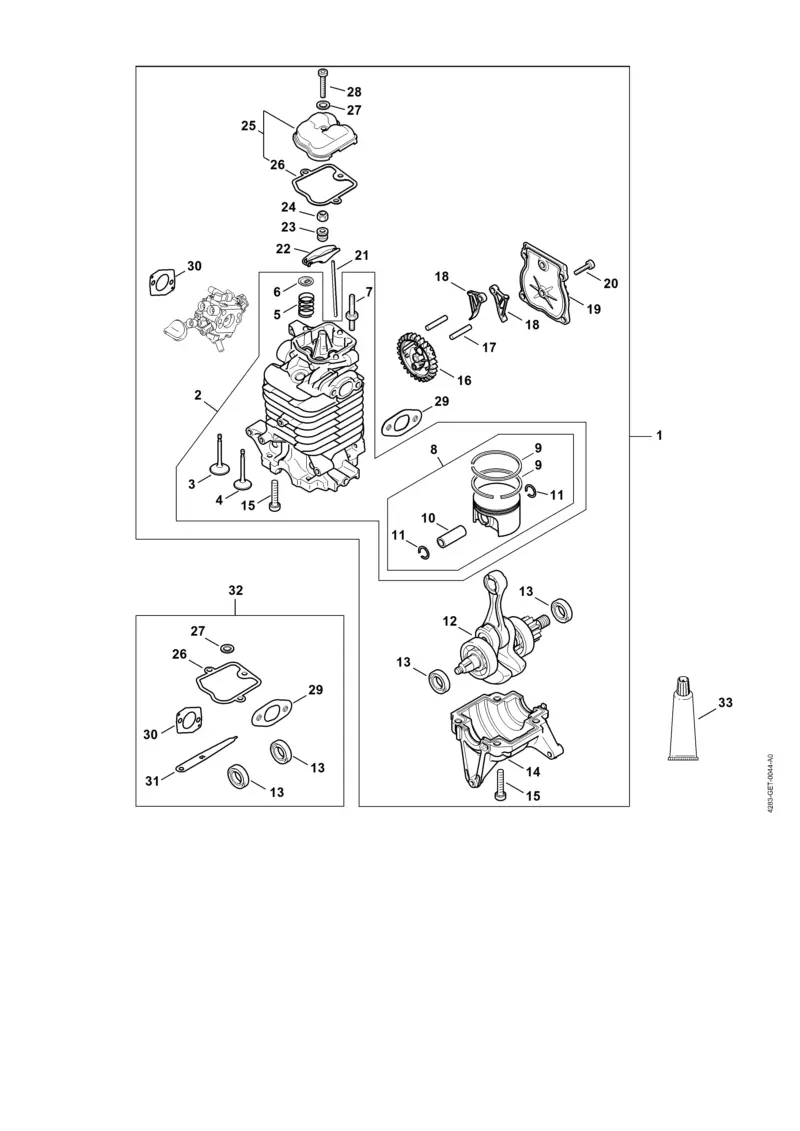

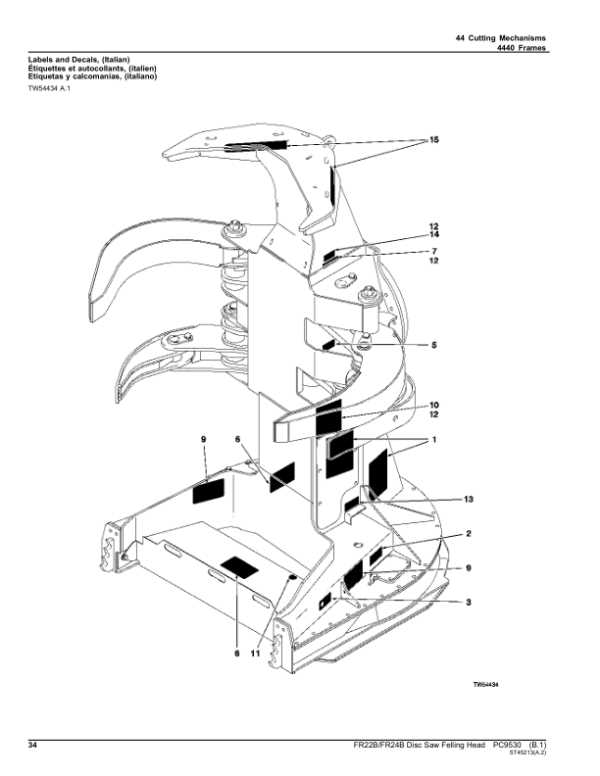

Identifying Each Component

Understanding the various elements of a high-performance tool is essential for effective maintenance and operation. Each part plays a crucial role in the overall functionality, contributing to both efficiency and durability. By familiarizing yourself with these components, you can ensure optimal performance and longevity of your equipment.

1. Engine Assembly: The heart of the machinery, responsible for power generation. Recognizing its components, such as the carburetor and spark plug, is vital for troubleshooting and repairs.

2. Air Intake System: This system filters and delivers air to the engine. Key parts include the air filter and intake manifold. Ensuring these are clean and functional is crucial for engine performance.

3. Fuel System: Comprised of the fuel tank, lines, and pump, this assembly is critical for supplying energy. Regular checks can prevent clogging and enhance efficiency.

4. Exhaust Components: These elements expel combustion gases, including the muffler and exhaust pipe. Proper maintenance ensures compliance with noise regulations and optimal engine function.

5. Handle and Controls: This section includes grips, triggers, and switches that allow for user interaction. Familiarity with these controls enhances safety and ease of use.

6. Housing and Frame: The structural foundation that supports all components. Checking for wear and damage can prevent larger issues and ensure stability during operation.

By identifying and understanding each element, users can maintain their tools effectively, leading to improved performance and reliability in various tasks.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for maintaining optimal performance and ensuring longevity. Using original replacements not only guarantees compatibility but also supports the manufacturer’s standards of quality. Below are some reliable sources where you can obtain these essential items.

Authorized Dealers

One of the most dependable places to acquire genuine components is through authorized dealers. These establishments often provide:

- Expert advice on selecting the right parts

- Access to the latest inventory

- Manufacturer warranties for peace of mind

Online Retailers

Many reputable online retailers specialize in high-quality equipment components. When shopping online, consider the following:

- Check for customer reviews to gauge reliability.

- Verify that the retailer is an authorized distributor.

- Look for clear return policies in case of issues.

By utilizing these sources, you can ensure that you are purchasing genuine components that will enhance the performance and durability of your equipment.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers several advantages that can enhance the performance and longevity of your equipment. These elements are specifically designed to meet the precise standards of the machinery, ensuring optimal functionality and reliability. Below are some key benefits of choosing these authentic replacements over generic alternatives.

Quality Assurance

One of the primary benefits of OEM components is their superior quality. These items are crafted with the following in mind:

- Strict manufacturing standards

- High-grade materials

- Comprehensive testing procedures

As a result, using these parts often leads to improved performance and reduced risk of malfunction.

Compatibility and Performance

Another significant advantage is the assurance of compatibility. OEM components are designed to fit perfectly within your machinery. This ensures:

- Seamless installation

- Consistent performance

- Minimized wear and tear on other components

In the long run, this compatibility can save time and money on repairs and replacements, providing a more efficient and hassle-free experience.

Maintenance Tips for Your Blower

Regular upkeep is essential for ensuring the longevity and efficiency of your blower. Proper maintenance not only enhances performance but also prevents potential issues down the line. Here are some effective strategies to keep your equipment in top shape.

Routine Cleaning

Keeping your blower clean is crucial for optimal performance. Dust and debris can affect airflow and efficiency. Follow these steps:

- Wipe down the exterior regularly to remove dirt and grime.

- Check the air intake and exhaust for blockages.

- Use compressed air to clear out any stubborn debris from the fan and housing.

Inspect and Replace Parts

Regular inspections can help identify wear and tear before they become serious issues. Focus on these key components:

- Check the spark plug for signs of wear or damage.

- Examine the fuel filter and replace it if it appears clogged.

- Inspect the ignition system to ensure proper operation.

Troubleshooting Common Issues

When operating outdoor power equipment, users may encounter various challenges that hinder performance. Addressing these issues promptly can restore functionality and extend the lifespan of the machine. This section will guide you through common problems and their solutions, enabling efficient operation.

Engine Won’t Start

If the engine fails to ignite, check the fuel supply first. Ensure that fresh, clean fuel is being used and that the tank is filled. Additionally, inspect the ignition system and spark plug for wear or damage. A faulty spark plug can prevent the engine from starting effectively. Lastly, verify that the air filter is clean, as a clogged filter can restrict airflow and hinder ignition.

Reduced Performance

Should you notice a decline in efficiency or power, several factors could be at play. Begin by examining the fuel mixture; using an improper ratio can lead to subpar performance. Also, assess the condition of the air filter and spark arrestor, as these components can become obstructed over time. Regular maintenance, including cleaning and replacing worn parts, will ensure optimal operation.

Understanding Warranty Coverage

Warranty coverage is a crucial aspect of product ownership, providing consumers with protection against defects and malfunctions. It assures buyers that the manufacturer stands behind their product, offering peace of mind in the event of unforeseen issues. Understanding the specifics of this coverage is essential for maximizing the value of your purchase and ensuring that you can make informed decisions regarding maintenance and repairs.

Key Elements of Warranty Coverage

When examining warranty coverage, several key components should be considered. These elements can vary significantly between manufacturers, and knowing what to expect can prevent misunderstandings down the line.

| Element | Description |

|---|---|

| Duration | The time period during which the warranty is valid, typically starting from the date of purchase. |

| Scope | Details what is covered under the warranty, including specific components or conditions. |

| Exclusions | List of circumstances or damages not covered by the warranty, such as wear and tear or misuse. |

| Claim Process | The steps required to file a warranty claim, including necessary documentation and contact information. |

Importance of Reading the Fine Print

Reading the terms and conditions of warranty coverage is essential. Often, the details are outlined in fine print, which can significantly impact the level of protection you receive. Being aware of your rights and responsibilities can empower you to navigate any potential issues effectively.

How to Assemble and Disassemble

Understanding the process of putting together and taking apart equipment is essential for effective maintenance and repair. Proper assembly ensures optimal performance, while disassembly allows for thorough inspection and cleaning. This guide will provide clear steps for both procedures, ensuring that you can handle your equipment confidently.

Assembling the Equipment

Begin by laying out all components in a clean workspace. Familiarize yourself with each part, referring to a reference guide if necessary. Start with the base unit, ensuring it is stable. Next, attach the necessary components in the correct sequence, securing them tightly but avoiding over-tightening to prevent damage. Always double-check your work, making sure all connections are secure and properly aligned.

Disassembling the Equipment

When it’s time to take apart the unit, ensure it is powered off and disconnected from any power source. Use appropriate tools to carefully remove each part, starting from the last component added during assembly. Keep track of screws and small pieces by organizing them in a container. Handle all components gently to avoid any unintentional damage. After disassembly, inspect each part for wear and tear before cleaning or replacing them as needed.

By following these steps, you will maintain the longevity and efficiency of your equipment while ensuring safe handling during both assembly and disassembly.

Upgrading Your Stihl Equipment

Enhancing the performance and efficiency of your outdoor tools can lead to a significant improvement in productivity. By investing in quality components and accessories, you can ensure that your equipment operates at its best, providing reliable service for years to come. This process involves selecting the right upgrades that not only boost functionality but also enhance user experience.

Choosing the Right Enhancements

When considering upgrades, it is essential to identify areas where improvements can be made. This may include components such as engines, blades, and filters. Upgrading these elements can result in better fuel efficiency and increased power output. Additionally, opting for aftermarket accessories can expand the versatility of your tools, allowing you to tackle a wider range of tasks.

Maintenance and Compatibility

Before making any modifications, always ensure that the new components are compatible with your existing equipment. Regular maintenance plays a crucial role in prolonging the lifespan of your tools. Keeping everything clean and well-lubricated will help in maintaining optimal performance. Always refer to the manufacturer’s guidelines when selecting new parts to avoid potential issues.