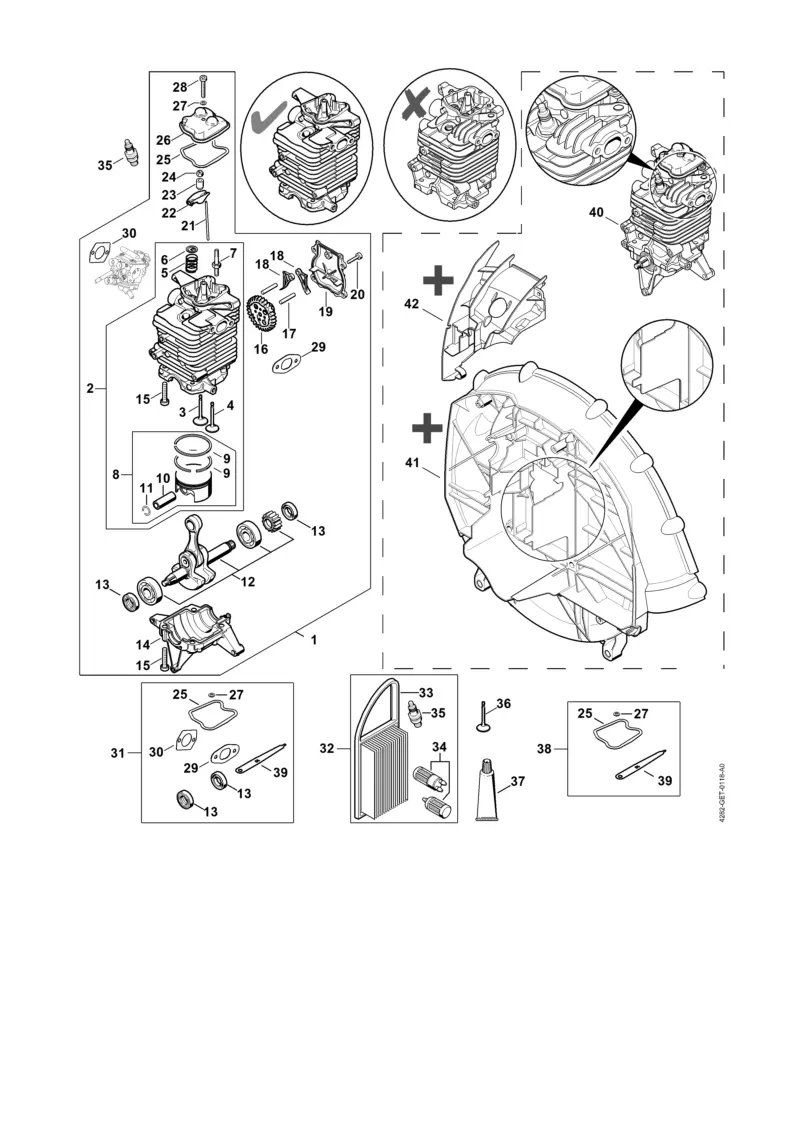

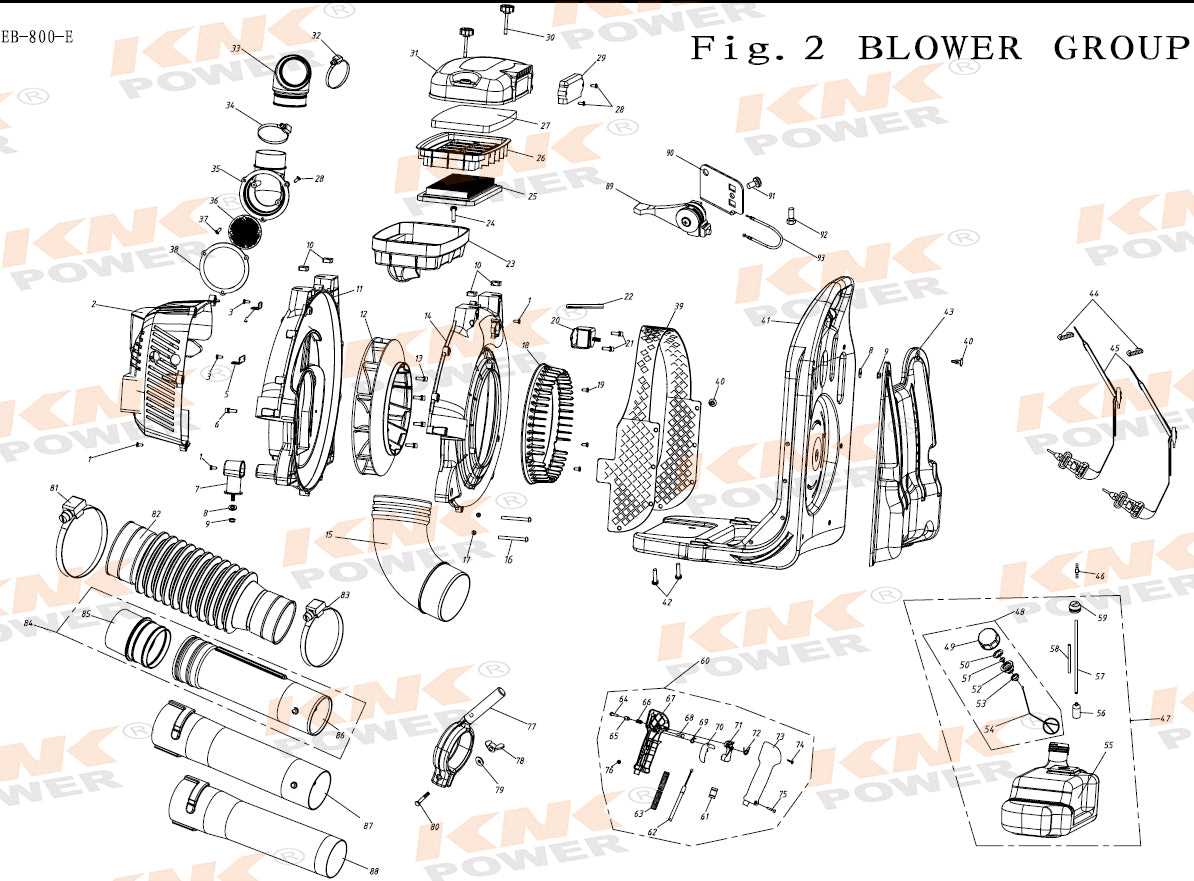

Understanding the intricate configuration of a high-performance outdoor machine is essential for efficient maintenance and troubleshooting. The arrangement of individual elements plays a crucial role in ensuring the machine operates at peak efficiency. This guide provides a detailed look into the internal structure and connections of various mechanical and electrical elements, enabling users to maintain and repair the equipment more effectively.

Whether you’re addressing routine upkeep or tackling a more complex mechanical issue, knowing how each element fits together can significantly reduce the time and effort required for repairs. This comprehensive breakdown offers clear insights into how the key components interact, ensuring that even complex issues can be handled with confidence.

By focusing on the specific roles and positioning of each element, users can gain a deeper understanding of the machine’s operation. This not only helps extend the life of the equipment but also ensures smoother performance across a range of tasks.

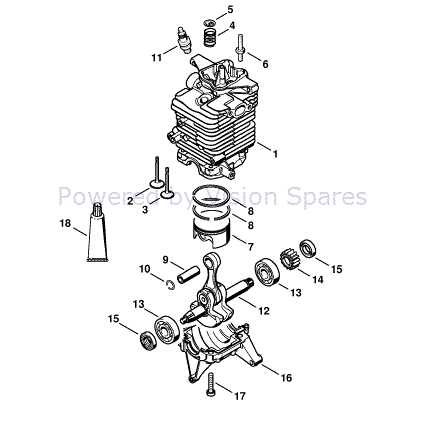

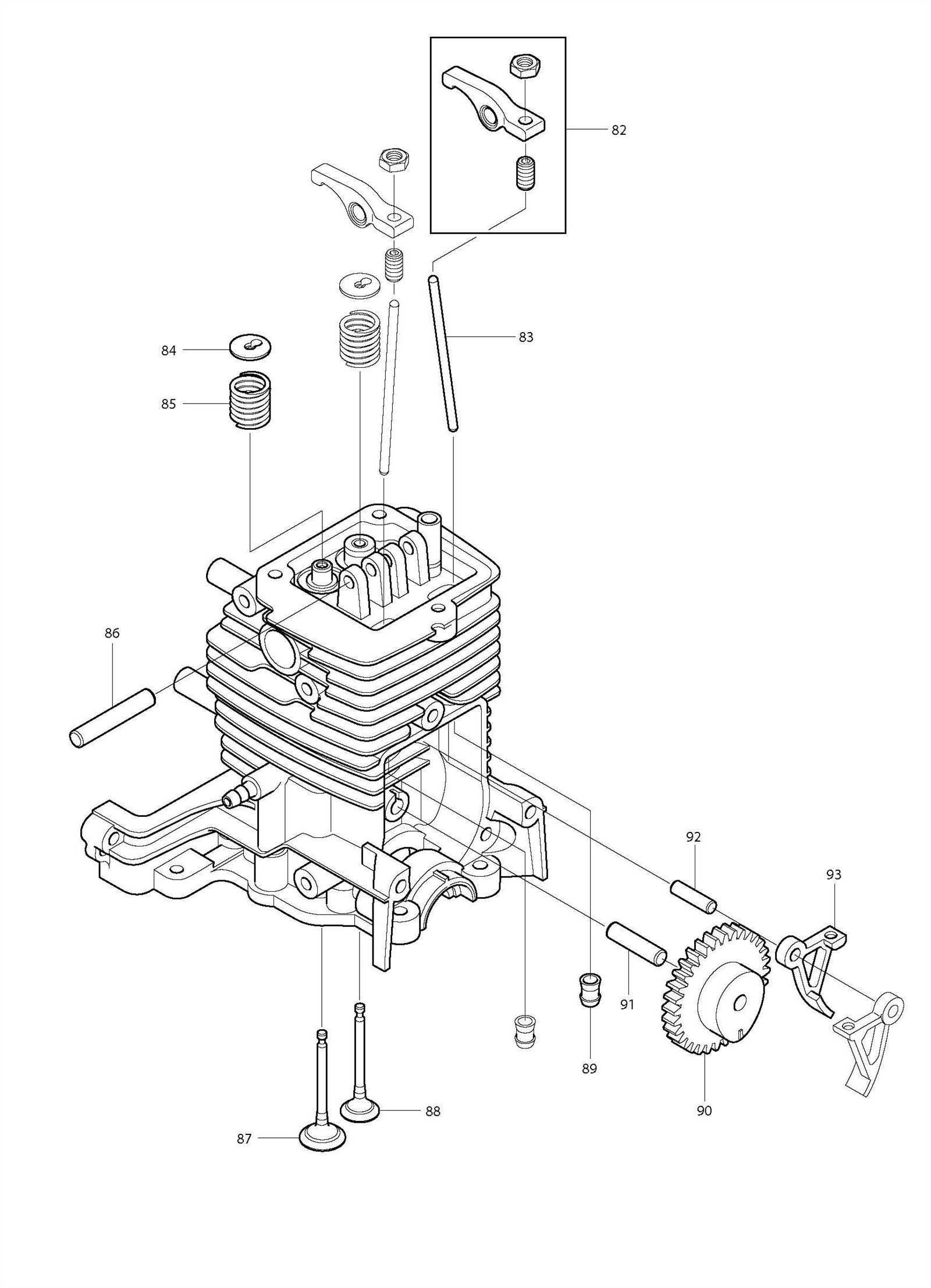

Understanding the Key Components of the Stihl BR600

Mastering the use of any power equipment requires a thorough understanding of its essential elements. By familiarizing yourself with the primary sections and mechanisms, you ensure smooth operation and easier troubleshooting when necessary. This overview focuses on the main elements that make up the overall structure and functionality of this powerful tool, providing insights into what makes it an efficient machine for various tasks.

One of the most important areas to focus on is the motor, which is the driving force behind the entire system. It’s designed for maximum efficiency, ensuring consistent performance across various conditions. Supporting the motor, several parts work together to manage airflow and control, enabling users to adjust settings based on their needs. Additionally, ergonomic features are incorporated into the design

How the Air Filter Affects Performance

The air filter plays a crucial role in ensuring the efficiency of engine-driven equipment. Its main function is to prevent dust, dirt, and other particles from entering the engine. A clean and well-maintained filter helps the engine perform optimally, while a clogged one can lead to significant issues.

When the filter is blocked, airflow to the engine is restricted, which directly impacts its power and fuel consumption. Regular maintenance of this component is essential to maintain peak performance and avoid costly repairs.

- Ensures clean airflow into the engine

- Prevents debris from causing internal damage

- Maintains fuel efficiency by regulating air intake

Neglecting to clean or replace the filter can result in reduced power output and increased wear on the internal com

Examining the Role of the Carburetor

The carburetor plays a crucial role in ensuring the efficiency of various engine types by carefully regulating the mixture of fuel and air. Its proper functioning directly impacts how smoothly an engine runs, affecting both performance and longevity. Understanding how this component operates can help in identifying potential issues that may arise during use.

Functions of the Carburetor

- Maintaining the right fuel-to-air ratio

- Adjusting the mixture depending on engine speed and conditions

- Facilitating the combustion process through optimal fuel delivery

Common Issues with Carburetors

- Clogged jets causing poor fuel flow

- Improper adjustments leading to rough idling

Proper Maintenance for the Spark Plug

The spark plug is a crucial component in ensuring the efficient operation of any gas-powered tool. Regular care and attention to this small but essential part can significantly improve performance and longevity. By following some simple guidelines, you can maintain the spark plug in optimal condition and avoid potential issues.

Steps to Inspect and Clean

- Remove the spark plug gently to avoid damaging the threads.

- Check for any carbon deposits or debris on the plug’s surface.

- Use a soft brush or spark plug cleaner to remove buildup.

- Inspect the gap between the electrodes and adjust it if necessary.

When to Replace

Throttle Cable Functions and Troubleshooting

The throttle cable plays a crucial role in regulating the flow of power to the engine, allowing users to control speed and performance. It is essential for smooth operation and responsiveness, ensuring the engine reacts to the user’s input. Proper functioning of this component is necessary for optimal efficiency, and any issues with it can lead to performance loss or malfunctions.

To address common problems with the throttle cable, it’s important to recognize the signs and apply basic troubleshooting methods. The following table highlights typical issues, their symptoms, and potential solutions.

| Problem | Symptoms | Solution | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sticking cable | Slow or unresponsive throttle | Lubricate or replace cable |

| Component | Function |

|---|---|

| Handle | Gripped by the user to pull and activate the mechanism. |

| Cord | Connects the handle to the internal spring-loaded pulley, transferring force to the engine. |

| Pulley | Rotate

Understanding the Role of the Cooling SystemThe cooling mechanism in machinery plays a crucial part in maintaining optimal performance. It helps regulate the temperature of the engine, preventing overheating and ensuring that all components operate within safe limits. Without proper heat dissipation, machines could suffer from increased wear and tear, which may lead to costly repairs. Below are key functions of the cooling system:

Efficient cooling Best Practices for Inspecting the Ignition CoilEnsuring the proper functioning of the ignition system is critical for maintaining optimal performance. One of the key components to monitor is the ignition coil, which plays a central role in generating the necessary energy for engine ignition. Regular inspections help prevent potential issues and ensure smooth operation. Step 1: Visual InspectionStart by examining the ignition coil for any visible signs of wear or damage. Look for cracks, corrosion, or discoloration on the surface, which could indicate electrical problems. It is also important to check the connectors and wires for loose or broken connections. A thorough visual assessment helps identify immediate concerns before they become major issues. Step 2: Testing for Continuity

After the visual check, perform a continuity test using a multimeter to verify the coil’s electrical integrity. This test helps determine if there are any internal breaks in the coil’s windings. Set the multimeter to the appropriate setting and connect the probes |