Understanding the structure and layout of essential equipment elements is crucial for efficient maintenance and repair. By familiarizing yourself with how each section is interconnected, you can ensure smooth functionality and address any issues that arise more effectively.

In this guide, we’ll explore the various components that make up outdoor machinery. Each section will highlight the most critical elements, helping you to navigate and identify specific areas that require attention. With this knowledge, maintaining the equipment will become a more manageable task.

Accurate identification of these elements is vital to ensure proper care and smooth performance. Whether you’re handling regular upkeep or more complex repairs, a clear understanding of the system’s layout will save both time and effort. Get ready to delve into the details of these integral parts and streamline your maintenance process.

Understanding Key Components of Leaf Blowers

Leaf blowers consist of several crucial elements that work together to provide efficient air movement and debris removal. These components are essential for ensuring the machine operates effectively and reliably. Understanding the basic structure helps users maintain and troubleshoot their equipment, ensuring optimal performance in a variety of outdoor tasks.

- Engine: The power source of the machine, responsible for generating the force that drives air through the blower.

- Fan Housing: Encloses the fan mechanism, which directs airflow and increases the velocity of the air output.

- Throttle Control: Allows the user to regulate the engine speed and airflow intensity, providing more or less power as needed.

- Nozzle: A specially designed attachment that focuses the air, making it easier to target specific areas for efficient cleaning.

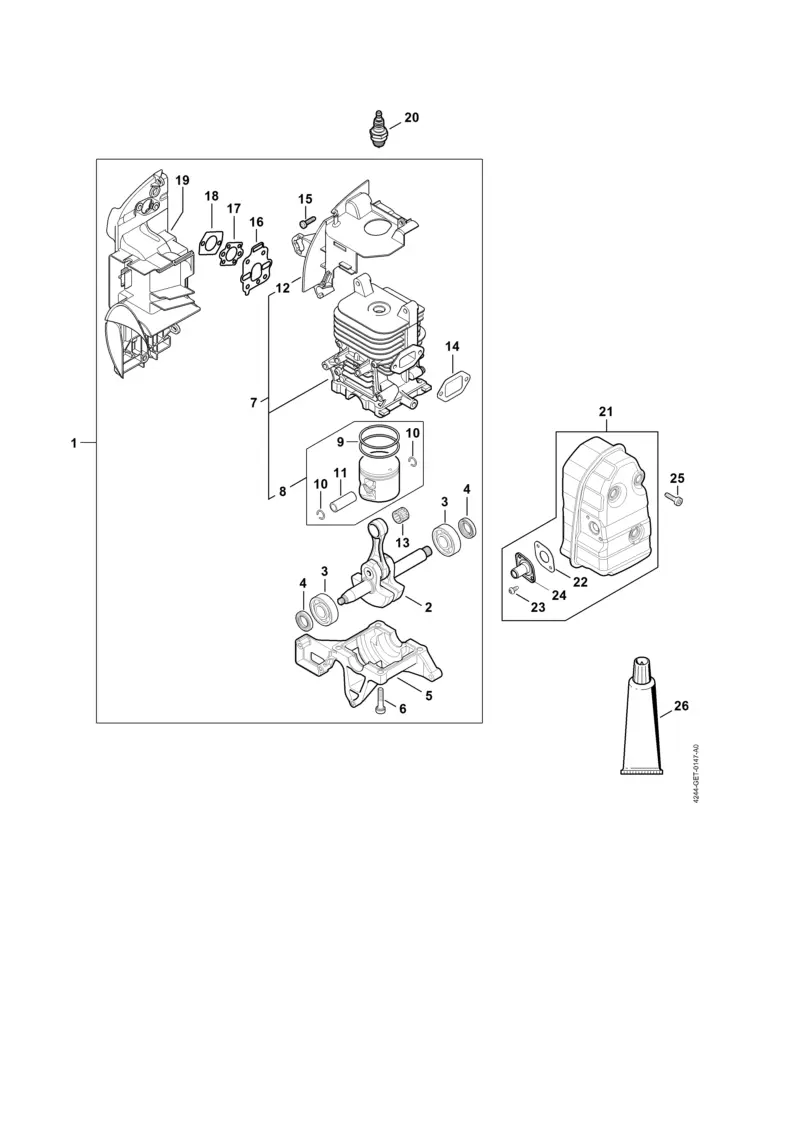

Exploring the BR700 Blower Mechanism

The internal structure of this powerful blower is designed to provide efficient air movement and high performance. Understanding its key components and how they interact can help in maintaining optimal functionality over time. Below, we delve into the essential elements that work together to create the strong airflow and durability this tool is known for.

Main Components Overview

- Engine System: The heart of the blower, responsible for generating the necessary power to drive the fan and produce high-speed air output.

- Fan Assembly: This part ensures a steady, concentrated stream of air, essential for effective debris removal.

- Air Intake and Filtration: A vital component that helps prevent de

How the Engine Powers Your Equipment

The heart of your outdoor machine is its engine, which transforms fuel into the energy required to operate. This intricate process involves several key components working together to ensure that the necessary power is generated for smooth operation. By understanding how energy flows through the system, you can better appreciate the efficiency and performance of your tool.

Fuel Combustion and Power Generation

The engine begins by burning fuel in a controlled combustion process. As the fuel ignites, it creates a rapid expansion of gases that push internal components, such as pistons, to convert the chemical energy of the fuel into mechanical force. This force then moves other critical parts, leading to the activation of the equipment’s primary functions.

Energy Transfer to the Main Mechanism

Once mechanical energy is generated, it must be transferred effectively to the rest of

Importance of a Quality Air Filter

A well-functioning air filter plays a critical role in maintaining the efficiency and longevity of various equipment. By preventing harmful particles such as dust and debris from entering the engine, a reliable filter ensures that the internal components remain clean and functional. This simple yet essential part helps improve overall performance, reducing the need for frequent maintenance and repairs.

There are several reasons why a high-quality air filter is crucial:

- Engine Protection: A good filter prevents contaminants from causing internal damage, preserving the integrity of the engine.

- Fuel Efficiency: A clean filter allows for better air circulation, which leads to more efficient fuel consumption.

- Reduced Wear: By keeping the engine clean, it minimizes unnecessary wear on parts, prolonging the life of

Fan Housing: Design and Functionality

The fan housing plays a crucial role in directing airflow efficiently, ensuring optimal performance and reducing the overall noise level of the equipment. Its structure is engineered to enclose the fan securely while promoting the smooth movement of air, which is essential for maintaining the effectiveness of the cooling system. Understanding its design helps users appreciate how each component works together to provide a balanced and effective air flow mechanism.

Streamlined Design for Efficiency

The streamlined shape of the housing is crafted to reduce air resistance, allowing for a more focused and controlled airflow. This design not only enhances performance but also helps to minimize vibrations and wear over time. The careful placement of air vents ensures proper ventilation without compromising the structural integrity of the system.

Durability and Material Considerations

The materials

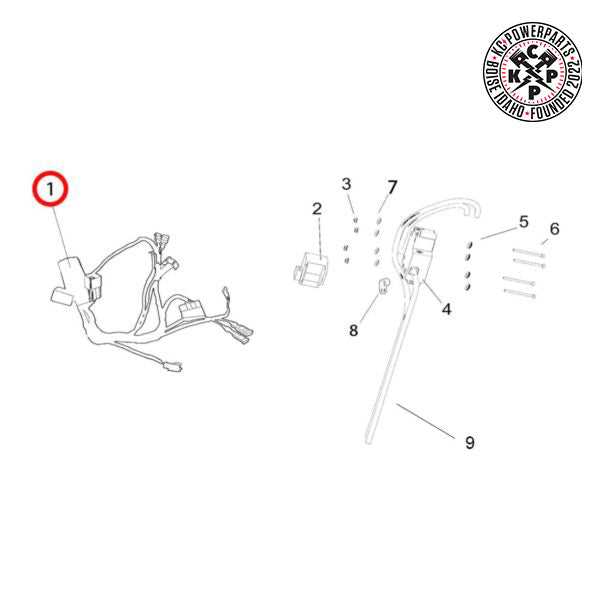

Throttle System Overview and Maintenance

The throttle system is a crucial component that controls the engine’s power output by regulating airflow. Understanding its functionality is essential for ensuring optimal performance and longevity of the equipment. Regular maintenance of this system can prevent issues that may lead to decreased efficiency or operational failures.

Inspection: Periodically check the throttle linkage and springs for wear and damage. Ensure that the throttle operates smoothly without any sticking or binding. Any signs of corrosion or deterioration should be addressed immediately to maintain proper functionality.

Cleaning: Keep the throttle components clean by removing dirt and debris that can affect performance. Use a suitable cleaning solution to gently clean the throttle body and linkage. Avoid using harsh chemicals that could damage the components.

Adjustment: Proper adjustment of the throttle system is vital for maintaining correct engine speed. Refer to the manufacturer’s guidelines for specific adjustment procedures. Ensuring the throttle is calibrated correctly can enhance responsiveness and prevent engine stalling.

Lubrication: Apply a light lubricant to moving parts of the throttle system to ensure smooth operation. Use a lubricant that is compatible with the materials of the components to avoid any adverse reactions.

By following these maintenance practices, you can ensure the throttle system operates efficiently, contributing to the overall performance and reliability of your equipment.

Fuel Tank Assembly for Optimal Performance

The fuel tank assembly plays a crucial role in ensuring efficient operation of outdoor power equipment. A well-designed fuel reservoir not only stores the necessary fuel but also contributes to the overall performance and longevity of the machine. Proper maintenance and attention to this component can significantly enhance the functionality of the equipment.

To achieve optimal performance, it is essential to regularly inspect the fuel tank for any signs of wear or damage. Leakage can lead to fuel wastage and reduced efficiency, making it imperative to replace any faulty seals or components. Additionally, keeping the tank clean and free from debris helps in maintaining a steady fuel flow, preventing potential blockages that could hinder performance.

Furthermore, using the correct type of fuel is vital for the smooth operation of the equipment. High-quality fuel not only ensures better combustion but also reduces the risk of carbon buildup, which can adversely affect performance. Regularly checking fuel levels and replacing old fuel can lead to improved starting and overall functionality.

Vibration Dampening for User Comfort

Effective vibration dampening systems are crucial for enhancing user comfort during prolonged usage of handheld equipment. These systems are designed to minimize the transmission of vibrations from the tool to the operator, ensuring a more pleasant working experience.

Key benefits of implementing vibration dampening technology include:

- Reduction of fatigue: Prolonged exposure to vibrations can lead to physical strain and fatigue. Advanced dampening mechanisms help alleviate these effects.

- Enhanced control: Improved stability allows for greater precision and control while operating the equipment, contributing to overall efficiency.

- Decreased risk of injury: By reducing the impact of vibrations, the likelihood of developing musculoskeletal disorders or other related injuries is significantly lowered.

Incorporating quality vibration dampening components not only improves user comfort but also increases productivity by allowing operators to work longer with less discomfort.

Benefits of a Well-Maintained Muffler

A properly maintained exhaust component is essential for optimal performance in various machinery. Its primary function is to control noise and emissions, ensuring a smoother operation while reducing environmental impact.

Enhanced Efficiency: Regular upkeep of the exhaust system can lead to improved fuel efficiency. A clean and functional muffler allows for better airflow, which can result in more effective combustion and reduced fuel consumption.

Noise Reduction: An effective muffler significantly diminishes operational noise, contributing to a quieter work environment. This is particularly important in residential or urban areas where noise regulations may be in place.

Prolonged Equipment Lifespan: Neglecting the maintenance of the exhaust system can lead to increased wear and tear on engine components. By ensuring the muffler is in good condition, operators can help extend the overall life of their equipment.

Compliance with Regulations: Many regions have strict guidelines regarding emissions and noise levels. A well-maintained exhaust system can help ensure compliance, avoiding potential fines and promoting a responsible approach to machinery operation.

In conclusion, the benefits of keeping the exhaust component in prime condition extend beyond mere performance; they encompass efficiency, noise control, longevity, and regulatory compliance, all contributing to a more effective and environmentally conscious operation.

Spark Plug Role in Ignition Efficiency

The spark plug is a crucial component in the ignition system, significantly influencing the overall performance and efficiency of an engine. Its primary function is to generate a spark that ignites the air-fuel mixture, ensuring smooth and reliable engine operation. A well-functioning spark plug can lead to improved fuel efficiency and reduced emissions, highlighting its importance in modern engine design.

Impact on Engine Performance

The efficiency of the ignition process directly affects how effectively the engine converts fuel into energy. When a spark plug is in optimal condition, it ensures complete combustion, maximizing power output and minimizing fuel wastage. Conversely, a worn or faulty spark plug can lead to incomplete combustion, resulting in decreased performance and increased exhaust emissions.

Maintenance and Replacement

Regular maintenance and timely replacement of spark plugs are essential for sustaining ignition efficiency. Over time, deposits can accumulate on the electrode, diminishing the spark’s effectiveness. By routinely checking and replacing spark plugs as needed, engine owners can maintain optimal performance and extend the lifespan of their equipment.

Understanding the Carburetor’s Function

The carburetor plays a crucial role in the operation of small engines, managing the blend of fuel and air that is essential for combustion. This component ensures that the engine receives the correct mixture to perform efficiently, impacting overall performance and reliability.

Essentially, the device draws in air and combines it with fuel to create a vaporized mixture. This process involves several mechanisms, including the use of jets and valves, which help regulate the flow based on the engine’s demands. A well-functioning carburetor is vital for smooth operation, as it influences power output and fuel efficiency.

Moreover, the effectiveness of the carburetor can significantly affect the engine’s responsiveness. If the mixture is too rich or too lean, it can lead to issues such as stalling or reduced power. Regular maintenance and proper adjustment of the carburetor are therefore necessary to ensure optimal performance and longevity of the engine.

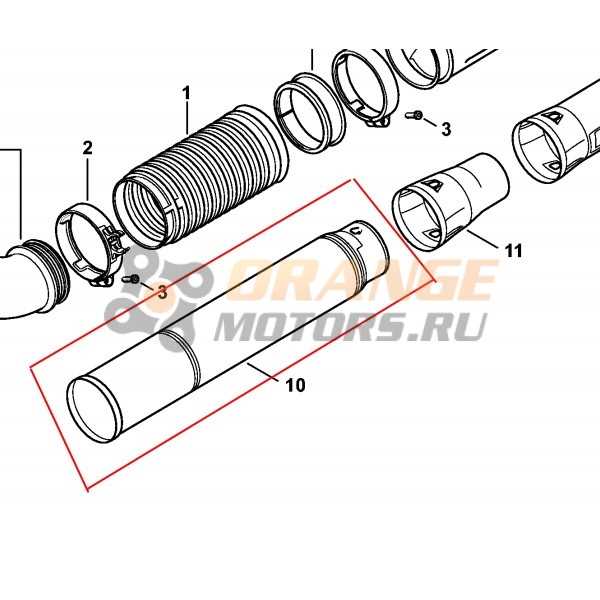

Blower Tube Variations and Installation

The choice of blower tube can significantly impact the efficiency and effectiveness of outdoor tasks. Various designs and lengths are available, each suited for specific applications and environments. Understanding these variations can help users select the most appropriate option for their needs.

When it comes to installation, it is crucial to ensure that the tube is securely attached to the device. Begin by aligning the attachment points and gently pushing the tube into place until you hear a click or feel a snug fit. Always check for any gaps or misalignments, as these can lead to decreased performance.

In addition, consider the length and shape of the tube you select. A longer tube may provide greater reach for large areas, while a narrower design can enhance maneuverability in tight spaces. Proper installation and selection will ensure optimal performance and ease of use during your outdoor tasks.

Safety Considerations for Leaf Blower Parts

When using a device designed for clearing leaves and debris, safety should always be a top priority. Understanding the components and how they function can help prevent accidents and ensure a safe working environment. Here are some key safety considerations to keep in mind.

- Always wear appropriate personal protective equipment, including gloves, goggles, and ear protection, to safeguard against potential hazards.

- Regularly inspect the equipment for any signs of wear or damage. Replace any compromised components immediately to maintain safety standards.

- Ensure that all attachments are securely fastened before operation to prevent them from becoming loose or detached during use.

- Be aware of your surroundings. Keep bystanders and pets at a safe distance when operating the machine to avoid injuries.

- Follow the manufacturer’s recommendations for maintenance and operation to promote longevity and safe usage of the equipment.

By adhering to these safety practices, users can enhance their protection while effectively using their leaf-clearing equipment.