Understanding the intricate components of a robust cutting tool is essential for optimal performance and longevity. Each element plays a critical role in the functionality and efficiency of the device, ensuring it operates smoothly and effectively. A thorough examination of these essential components can greatly enhance the user’s experience and facilitate maintenance tasks.

By familiarizing oneself with the various sections and functionalities, operators can diagnose issues more effectively and undertake repairs with confidence. This knowledge empowers users to keep their equipment in peak condition, maximizing both safety and efficiency during use. Furthermore, recognizing how each part interacts within the system is vital for informed decision-making regarding replacements and upgrades.

Key Features of the 311y

The subject in focus showcases a range of remarkable characteristics that enhance its performance and usability. Designed with precision and care, this tool stands out due to its reliability and efficiency in various applications.

Performance and Efficiency

One of the most notable aspects of this model is its powerful engine, which provides robust performance for a variety of tasks. The innovative engineering ensures optimal fuel consumption, allowing users to maximize productivity without frequent refueling.

User-Friendly Design

The ergonomic design features contribute to a comfortable grip, reducing fatigue during extended use. Additionally, the lightweight construction facilitates easy maneuverability, making it accessible for both novice and experienced users. Durability is a key element, with materials selected to withstand harsh conditions, ensuring longevity and reliability.

Common Parts and Their Functions

This section explores essential components commonly found in mechanical devices, detailing their respective roles in overall functionality. Understanding these elements can enhance the user’s ability to maintain and troubleshoot the equipment effectively.

- Engine: The primary source of power, converting fuel into energy to drive the entire mechanism.

- Guide Bar: A crucial part that directs the movement of the cutting chain, ensuring precision during operation.

- Chain: The element responsible for cutting, made of linked segments designed to slice through materials efficiently.

- Throttle Trigger: Allows the user to control the speed of the engine, providing flexibility based on task requirements.

- Fuel Tank: Holds the fuel necessary for operation, designed to deliver a steady supply to the engine.

- Air Filter: Protects the engine by filtering out debris and contaminants from the air intake.

- Oil Reservoir: Stores lubrication fluid essential for reducing friction between moving parts.

- Starter Mechanism: Facilitates the initial ignition of the engine, enabling the user to begin operation smoothly.

Familiarity with these components and their functions can greatly assist users in performing maintenance and identifying any issues that may arise during use.

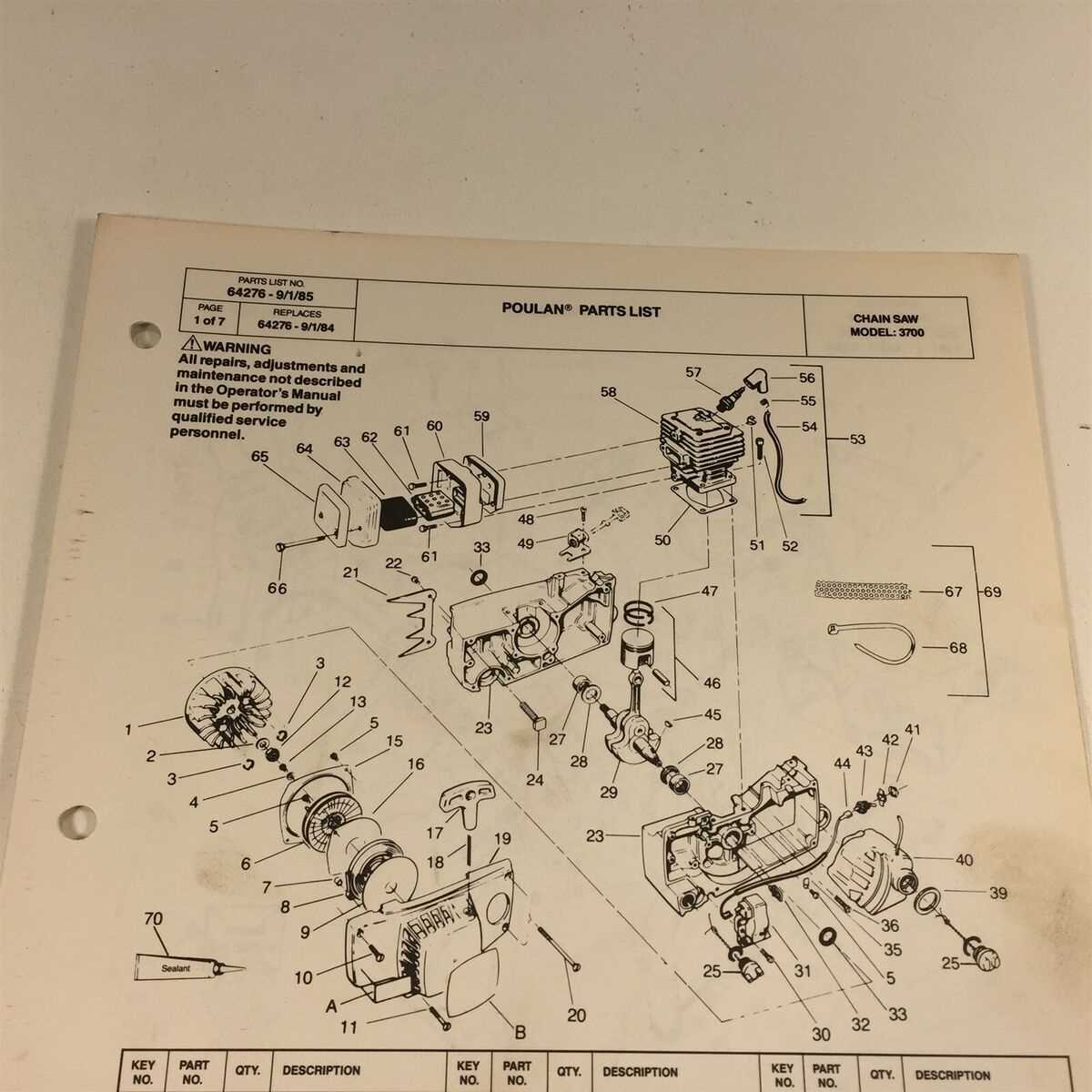

Understanding the Parts Diagram

Comprehending the visual representation of components is crucial for effective maintenance and repair. Such illustrations offer a clear overview of individual elements, their arrangement, and interconnections. By grasping this layout, users can enhance their understanding of the assembly, troubleshoot issues, and facilitate smoother operations.

Importance of Visual Representation

A well-crafted illustration serves several purposes:

- It simplifies the identification of specific elements.

- It aids in understanding how different pieces interact.

- It provides a reference for reassembly after servicing.

Utilizing the Visual Guide

When engaging with this guide, consider the following tips:

- Familiarize yourself with the overall layout before diving into specifics.

- Pay attention to any labels or annotations that clarify functions.

- Cross-reference the illustration with your equipment to locate components effectively.

Maintenance Tips for Chainsaw Components

Proper upkeep of essential tools ensures their longevity and optimal performance. By regularly checking and caring for various elements, users can prevent issues that may hinder efficiency or lead to costly repairs. Adopting a systematic approach to maintenance is key to keeping these devices in peak condition.

Regular Cleaning: Keeping all components clean is vital. Dirt and debris can accumulate and cause wear or blockages. Regularly inspect and clean the exterior surfaces, air filters, and any accessible internal parts to maintain smooth operation.

Lubrication: Ensuring that moving parts are adequately lubricated is crucial for reducing friction and preventing damage. Apply the appropriate lubricant to gears, bearings, and other critical areas to enhance performance and extend lifespan.

Inspection of Wear and Tear: Routine inspections can identify signs of wear before they escalate into major problems. Look for cracks, bends, or other irregularities in components, and replace any damaged pieces promptly to ensure safe and efficient functioning.

Proper Storage: When not in use, store tools in a dry, protected area to prevent rust and deterioration. Utilize covers or cases to shield them from dust and environmental factors that could lead to damage over time.

Adherence to Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance practices. Following these guidelines will provide specific instructions tailored to the model, ensuring proper care and functionality.

Identifying Replacement Parts Easily

Finding suitable components for maintenance and repairs can significantly enhance the longevity and performance of your equipment. A clear understanding of the various elements and their functions aids in selecting the correct replacements, ensuring optimal operation.

Understanding Component Functionality

Familiarizing yourself with the role of each element is crucial. Components work in harmony, and knowing how they interact helps in identifying which ones may need replacement. Consider the following:

- Identify any signs of wear or damage.

- Determine the specific function of each element.

- Note any unusual sounds or performance issues.

Resources for Accurate Identification

Utilizing various resources can facilitate the process of identifying suitable components:

- Consult user manuals for detailed information.

- Visit reputable websites that offer comprehensive guides.

- Engage with online communities for insights and recommendations.

By employing these strategies, you can ensure you select the appropriate replacements, ultimately contributing to the efficient operation of your equipment.

Assembly and Disassembly Guide

This section aims to provide clear instructions on the process of putting together and taking apart various components of a power tool. Understanding how to correctly assemble and disassemble these parts ensures optimal functionality and can aid in maintenance tasks. Following these guidelines will help users avoid potential damage and extend the lifespan of the equipment.

To begin, it’s crucial to have the right tools and workspace prepared. Ensure that you have access to all necessary instruments before starting the process. Below is a simplified table outlining essential components and their corresponding functions, aiding in identification during assembly and disassembly.

| Component | Function |

|---|---|

| Housing | Encases internal mechanisms and provides structural integrity. |

| Engine | Powers the device and performs the main cutting functions. |

| Guide Bar | Directs the cutting chain and determines cutting width. |

| Chain | Interacts with the guide bar to perform cutting tasks. |

| Oil Tank | Supplies lubrication to ensure smooth operation of the chain. |

Always refer to the manufacturer’s manual for specific instructions on how to safely dismantle and reassemble each component. This ensures a thorough understanding of each part’s role, enhancing overall efficiency and safety during operation.

Safety Precautions During Repairs

Engaging in maintenance tasks requires a thorough understanding of safety measures to prevent accidents and injuries. Adhering to protective guidelines not only ensures personal safety but also promotes the longevity of the equipment being serviced. By implementing appropriate precautions, individuals can work confidently and effectively, minimizing the risk of mishaps during the repair process.

Essential Protective Gear

Wearing the right protective equipment is fundamental when undertaking any repair work. This includes items such as gloves, which shield hands from sharp edges and potential hazards, and safety glasses to protect the eyes from debris. Additionally, using ear protection is advisable to prevent hearing damage from loud machinery. Ensuring that all necessary safety gear is in place before beginning repairs significantly reduces the likelihood of injuries.

Work Environment Considerations

Creating a safe workspace is crucial for effective maintenance activities. A clean and organized area minimizes the chances of tripping or losing tools. Proper lighting is essential, as it allows for better visibility of small components and intricate details. Furthermore, keeping flammable materials away from the work zone enhances safety, reducing the risk of fire hazards during repair tasks.

Upgrades and Accessories for Efficiency

Enhancing performance and productivity is essential for achieving optimal results in outdoor tasks. Implementing various enhancements and additional tools can significantly improve functionality and user experience, making operations smoother and more effective.

Powerful Enhancements can include upgraded engines or advanced cutting mechanisms designed for improved efficiency. These modifications often lead to faster cutting speeds and reduced fatigue, allowing users to accomplish more in less time.

Additionally, supportive tools such as high-quality lubricants and protective gear contribute to maintaining performance and ensuring safety. Accessories like ergonomic handles or lightweight components can greatly enhance comfort during prolonged usage, further maximizing effectiveness.

Lastly, investing in maintenance products such as cleaning kits and sharpening tools ensures longevity and optimal performance of the equipment. These upgrades and accessories are vital for anyone looking to elevate their operational efficiency in their outdoor endeavors.

Troubleshooting Common Issues

Understanding and resolving frequent problems with cutting equipment is essential for maintaining optimal performance and longevity. This section provides insights into common malfunctions and effective solutions that can enhance the user experience.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Engine won’t start | Fuel problems, ignition failure, or clogged air filter | Check fuel levels, replace spark plug, clean or replace the air filter |

| Excessive vibration | Worn parts, unbalanced chain, or loose components | Inspect for wear, balance the chain, tighten loose screws |

| Poor cutting performance | Dull blade, incorrect tension, or improper angle | Sharpen the blade, adjust tension, verify cutting angle |

| Overheating | Insufficient lubrication, clogged exhaust, or extended use | Check oil levels, clear exhaust pathways, take breaks during use |

Where to Find Quality Parts

Finding reliable components for your equipment can significantly enhance its performance and longevity. It is essential to seek sources that ensure both authenticity and durability in their offerings. This section will guide you through various avenues where you can discover high-quality replacements and accessories.

One of the most trusted methods is to explore authorized retailers and official websites. These platforms typically provide a comprehensive selection of genuine items, ensuring compatibility with your device. Additionally, they often feature customer support to assist with any inquiries.

Another valuable option is to check local hardware stores. Many of these establishments stock a variety of essential components and can offer personalized advice based on your needs. Furthermore, connecting with fellow enthusiasts or local mechanics can lead to recommendations for dependable suppliers.

Online marketplaces also present a wide array of options. However, it is crucial to research seller ratings and reviews to ensure the quality of the components. Look for vendors that specialize in your equipment type to improve the chances of receiving authentic products.

| Source Type | Benefits |

|---|---|

| Authorized Retailers | Genuine products, customer support |

| Local Hardware Stores | Personalized advice, immediate availability |

| Online Marketplaces | Diverse options, competitive pricing |

Comparing the 311y to Other Models

When evaluating various models within a particular category of outdoor power equipment, it’s essential to consider their distinct features and performance capabilities. Each model serves specific needs, catering to a range of tasks from light maintenance to heavy-duty operations.

Performance and Power: The examined model is designed for efficiency, delivering impressive output compared to its counterparts. Its robust engine ensures that users can tackle demanding projects without sacrificing speed or effectiveness.

Weight and Maneuverability: One of the notable aspects of this unit is its weight, which strikes a balance between stability and ease of use. This feature allows for greater maneuverability, making it suitable for both novice and experienced users. In contrast, other models may offer different weight distributions that affect handling.

Durability and Maintenance: The longevity of outdoor equipment is crucial for users who rely on it regularly. This model is built with high-quality materials that enhance its durability, requiring less frequent maintenance than many alternatives. Understanding the maintenance needs of competing units is vital for long-term satisfaction.

Overall Value: Assessing the cost-to-performance ratio is important when choosing equipment. This particular model provides excellent value, often outperforming others in its price range. A thorough comparison reveals that while some alternatives may have lower upfront costs, they may lack the same level of efficiency and durability over time.